Pivotal stairway systems and method

a stairway and pivoting technology, applied in the field of pivoting stairway systems and methods, can solve the problems of not allowing users to straight access on and off the unit, difficult and dangerous to climb, and difficulty in folding/unfolding and pulling up/down from the ceiling level, so as to maintain operational control and safety, and increase assembly flexibility. the effect of cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034]Although the disclosure hereof is detailed and exact to enable those skilled in the art to practice the invention, the physical embodiments herein disclosed merely exemplify the invention which may be embodied in other specific structures. While the preferred embodiment has been described, the details may be changed without departing from the invention, which is defined by the claims.

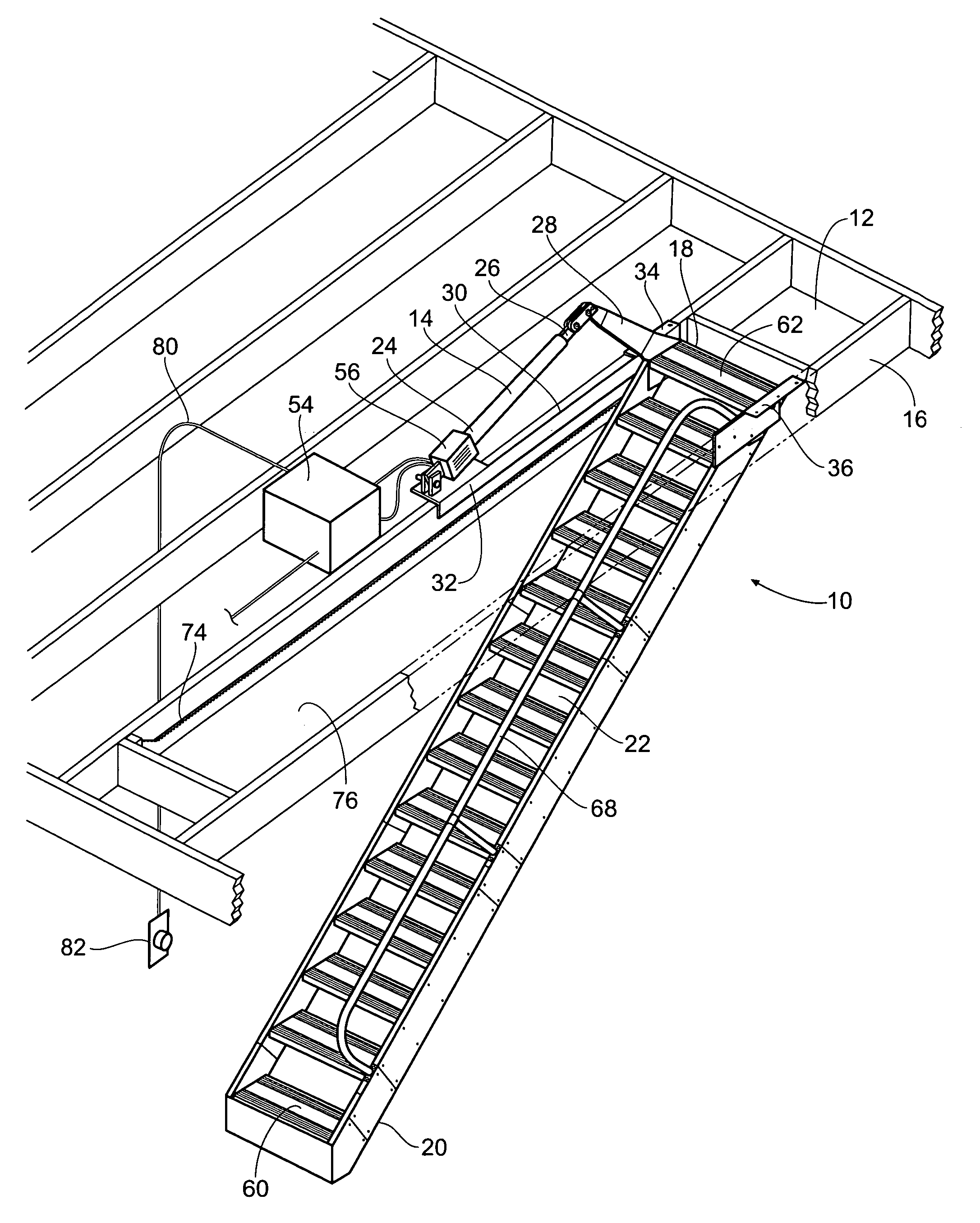

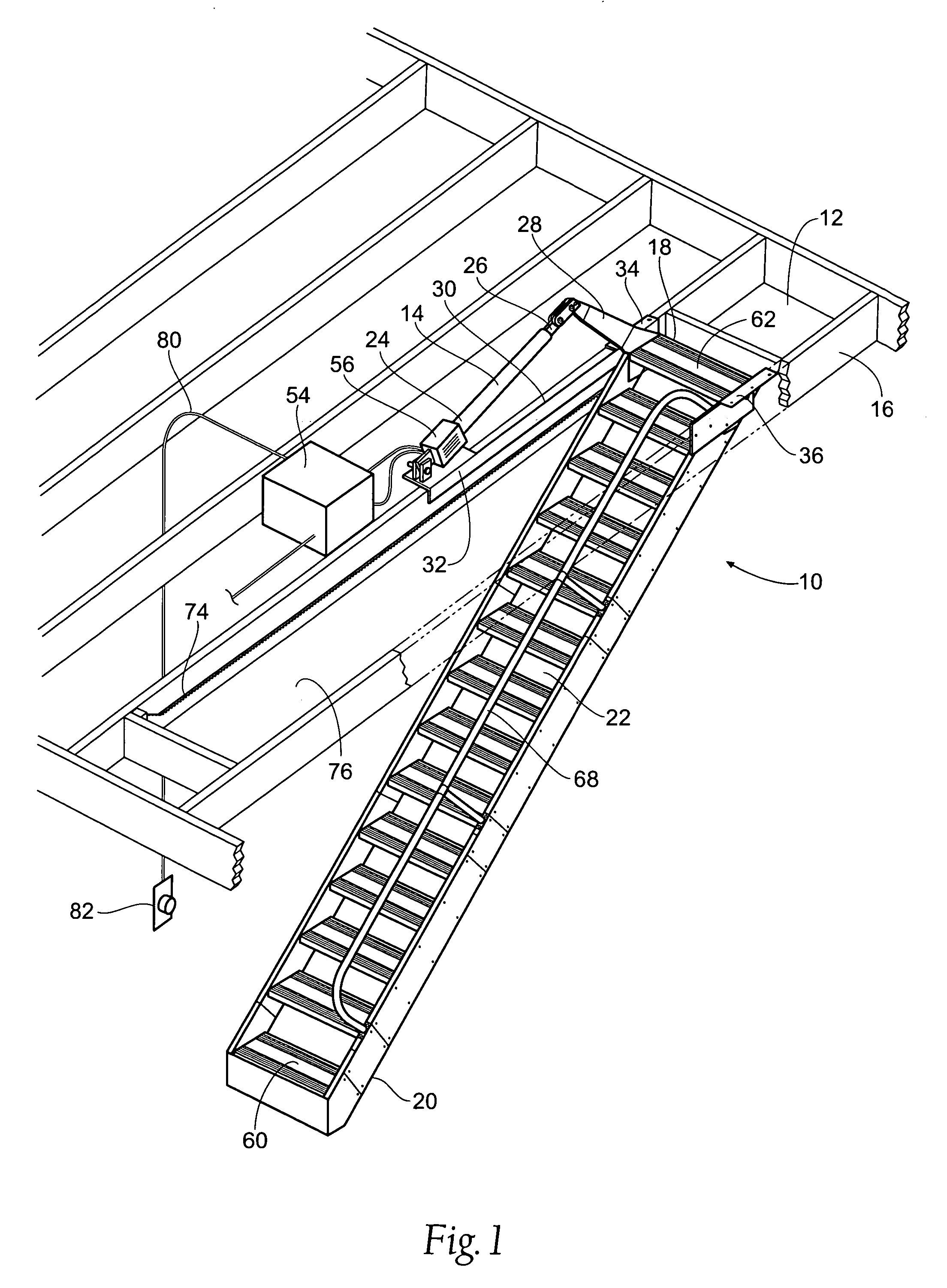

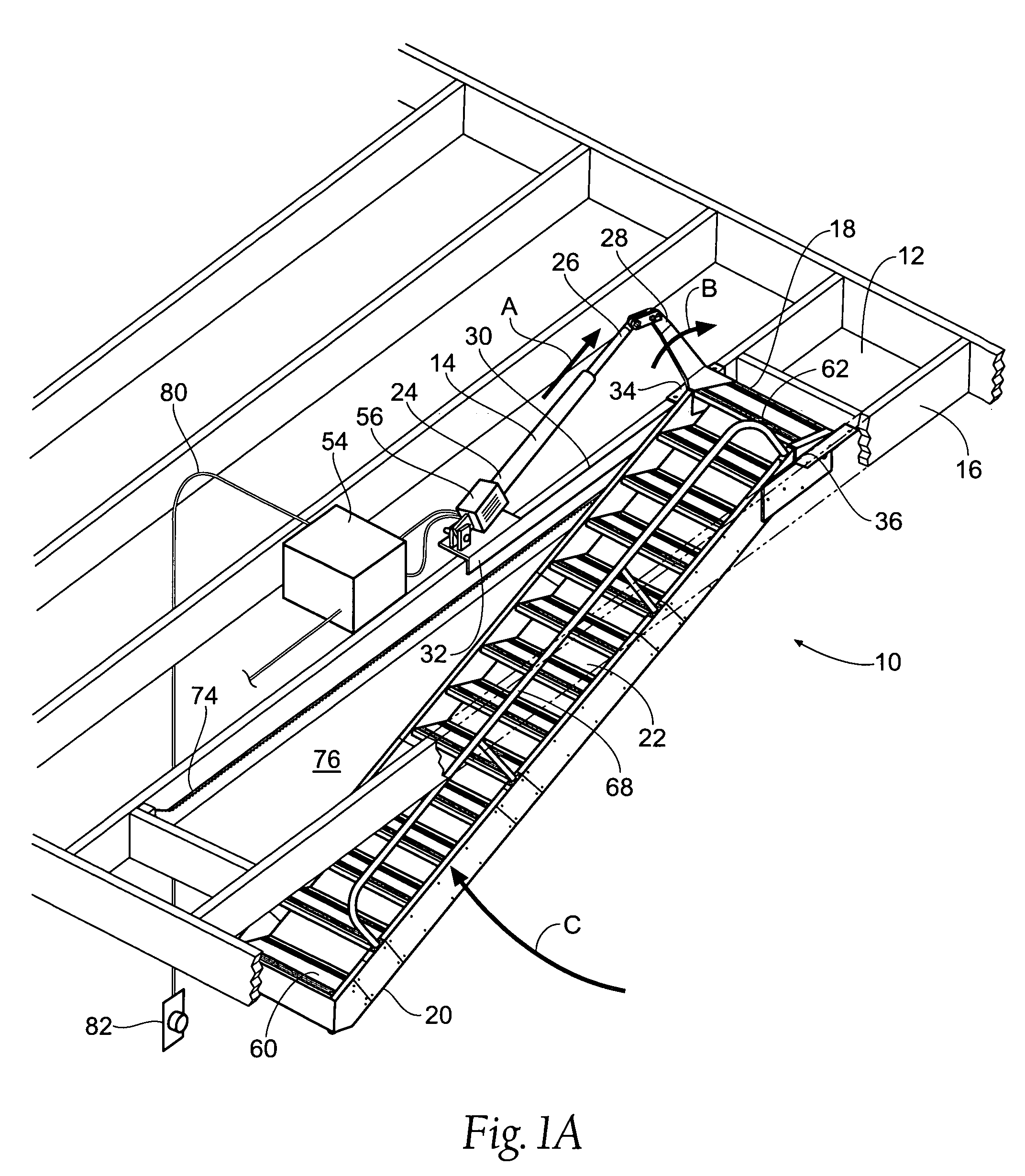

I. Stowable Stairway System

[0035]The present invention may be generally described as a stairway system 10 to provide access between spaces on two or more different levels of a building or other multi-level structure. Specifically, the invention is directed to a stairway system 10 having means for retracting into the ceiling or floor 12 of a level. Means may include use of an actuator 14 as part of the system 10 (See FIGS. 1 through 15).

[0036]As will be apparent, the systems and methods of the present invention allow installation of the stairway system 10 without drilling of pivot holes in the exis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com