Electric Compressor and Air Conditioning System for vehicle, Using the Electric Compressor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

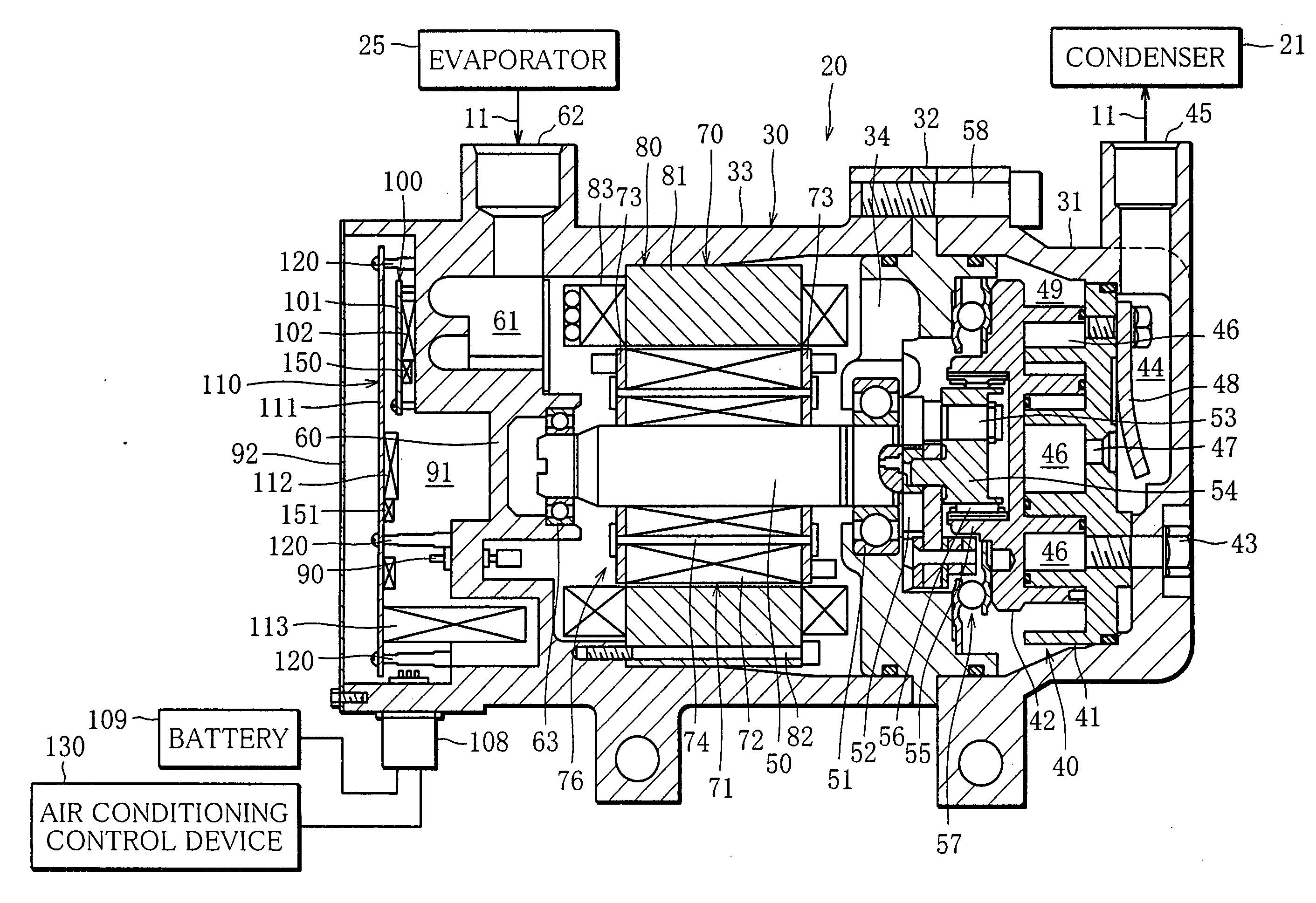

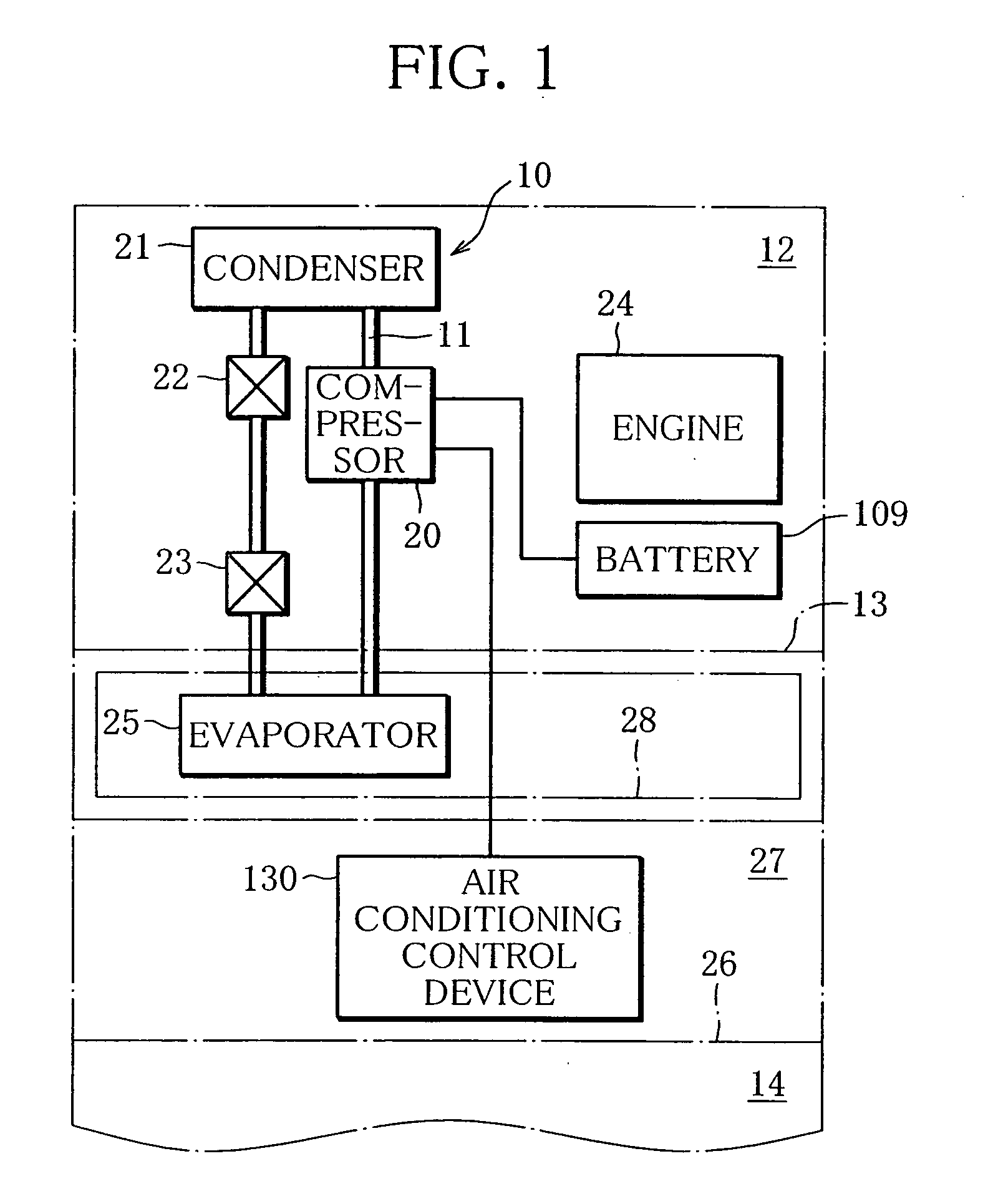

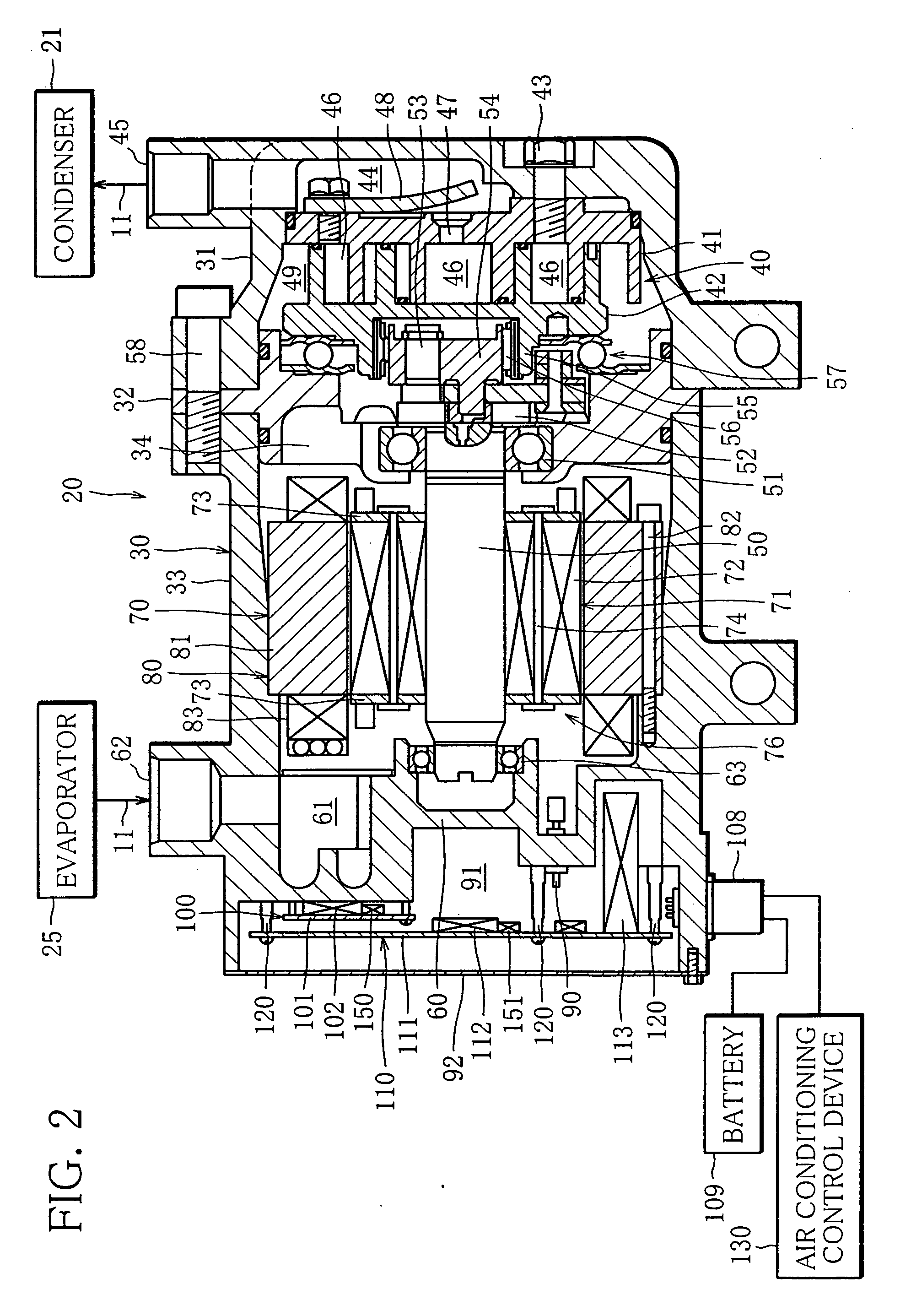

[0025]FIG. 1 shows a schematic configuration of an embodiment of an automotive air conditioning system.

[0026]The system includes a refrigeration circuit 10, and a refrigerant circulation passage 11 of the refrigeration circuit 10 extends from a vehicle engine room 12 into a vehicle interior 14 through a partition wall 13. Within the engine room 12, an electric compressor 20, a condenser 21, a receiver 22 and an expansion valve 23 are disposed in the refrigerant circulation passage 11 in this order as viewed in the direction of the refrigerant circulation. The electric compressor 20 is arranged near the engine 24, and the condenser 21 is arranged near a vehicle radiator grill, together with a fan (not shown).

[0027]Within the vehicle interior 14, an evaporator 25 is disposed in the refrigerant circulation passage 11. The evaporator 25 is located downstream of the expansion valve 23. A front part of the vehicle interior 14 is defined as an instrument room 27 by an instrument panel 26, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com