Closure for silica glass crucible, silica glass crucible and method of handling the same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

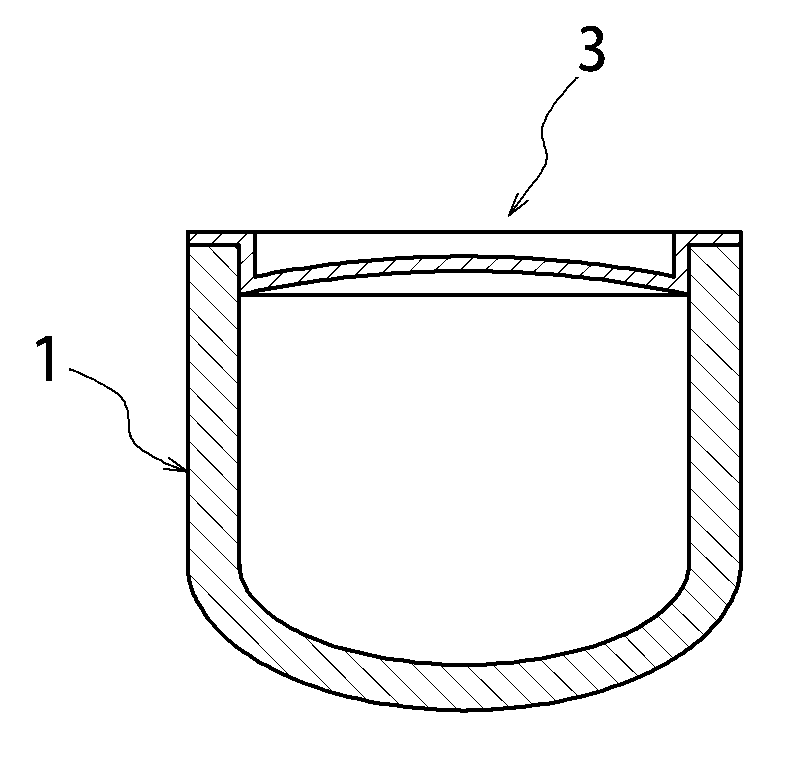

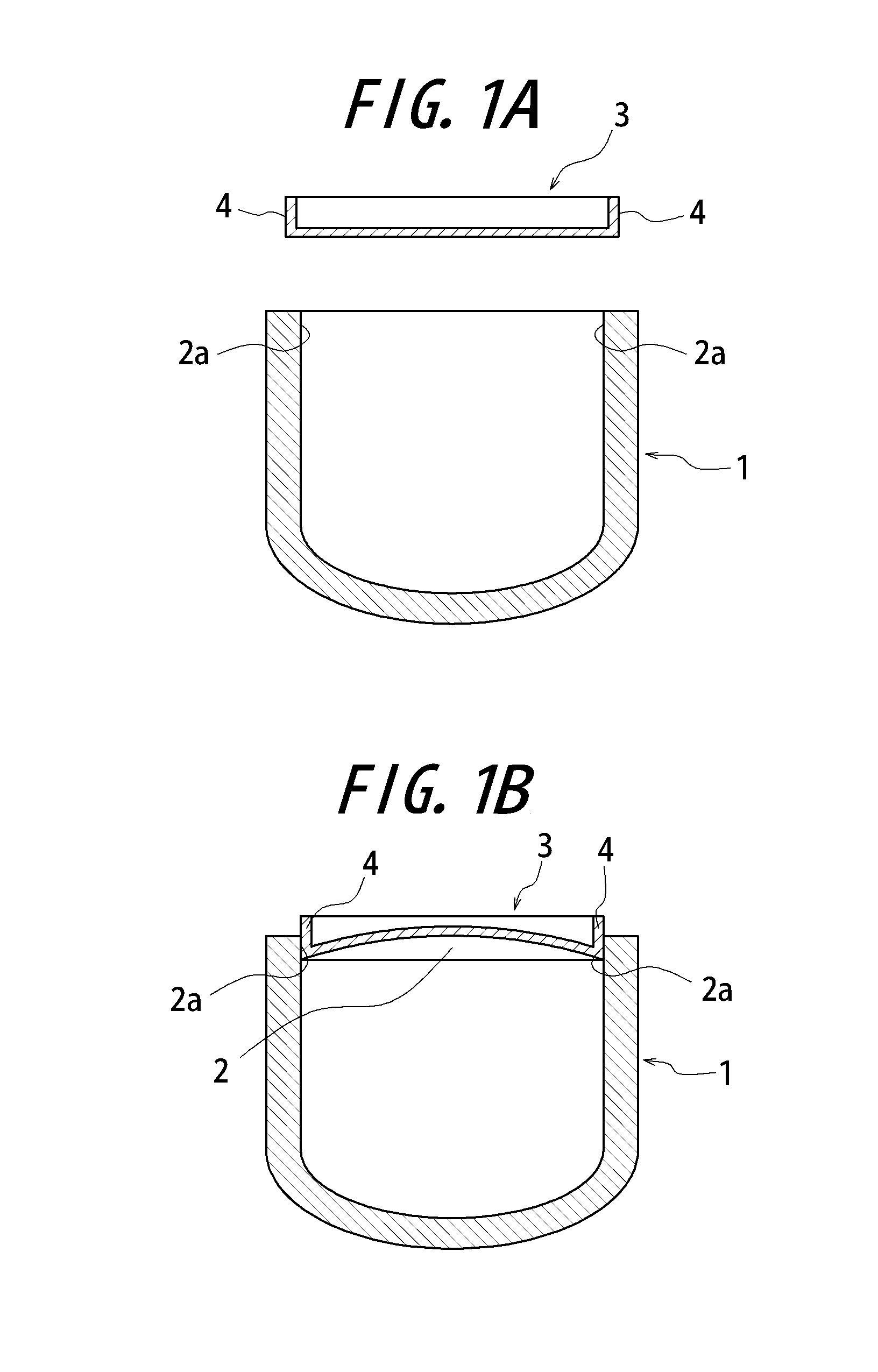

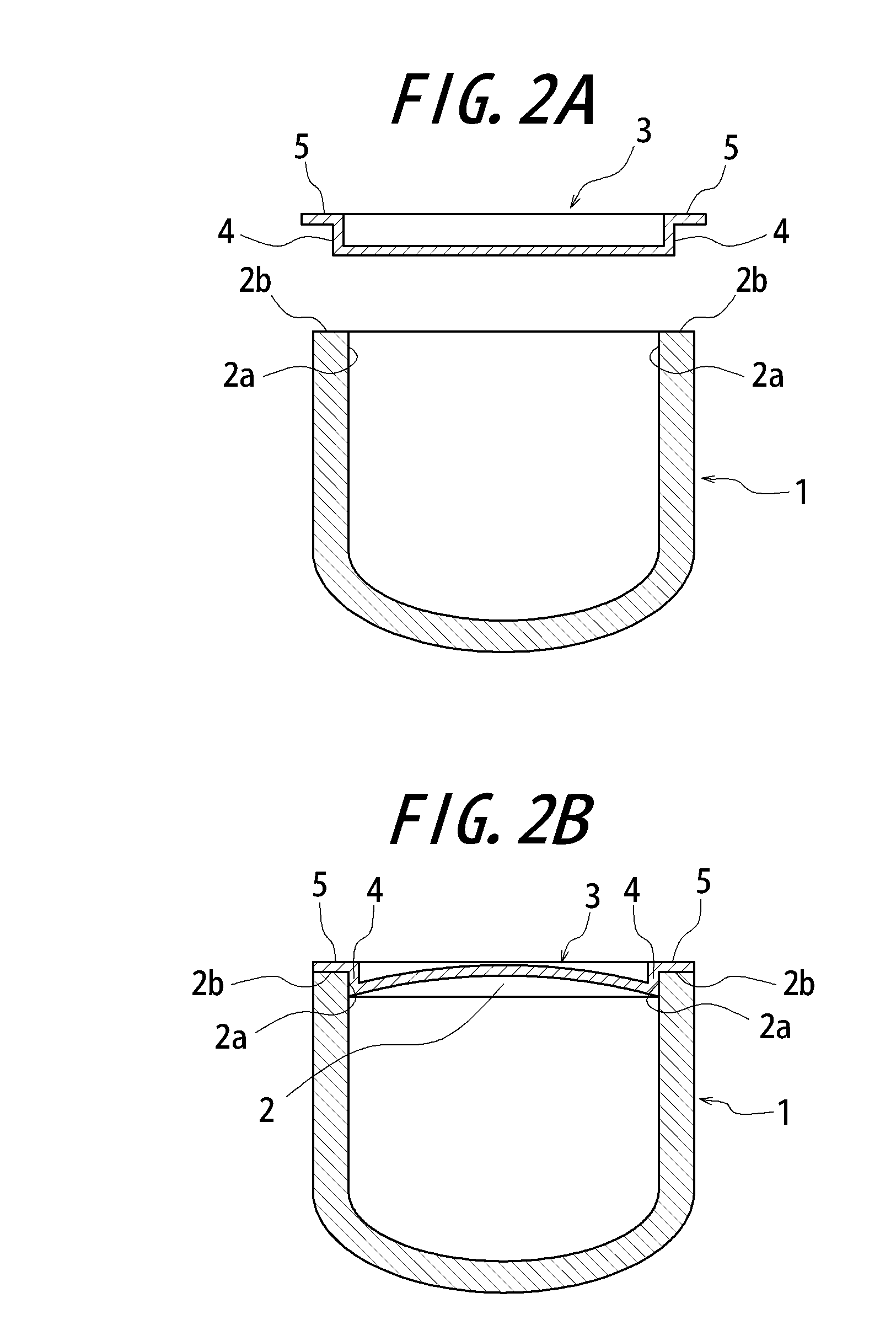

[0045]There are examined the number of silica powder intruded into an inner face of a crucible and the yield of crystal when a closure as shown in FIGS. 1A-1B and 2A-2B is mounted onto an opening portion of the crucible. For the comparison, the same examination is conducted for the case that a crucible is covered with a wrapping sheet and for the case that the opening portion of a crucible is free. The examination results are shown in Table 1.

[0046]Here, the number of silica powder intruded into the inner face of the crucible is obtained by visually observing the number of silica powder and silica pieces adhered to the inner face of the crucible after the crucible is conveyed to a pulling step in the production of single crystalline silicon and the closure is removed therefrom before filling polycrystalline silicon. Moreover, the unit in the number of silica powder is “powders”. The yield of crystal shows a ratio of weight of crystal obtained as a single crystal to weight of raw mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com