Inlet Guide Vane for a Gas Compressor

a gas compressor and guide tube technology, applied in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve the problems of acting elements still being exposed to wear and systems particularly vulnerable to mechanical failure, and achieve the effect of improving reliability and reducing mechanical wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

second embodiment

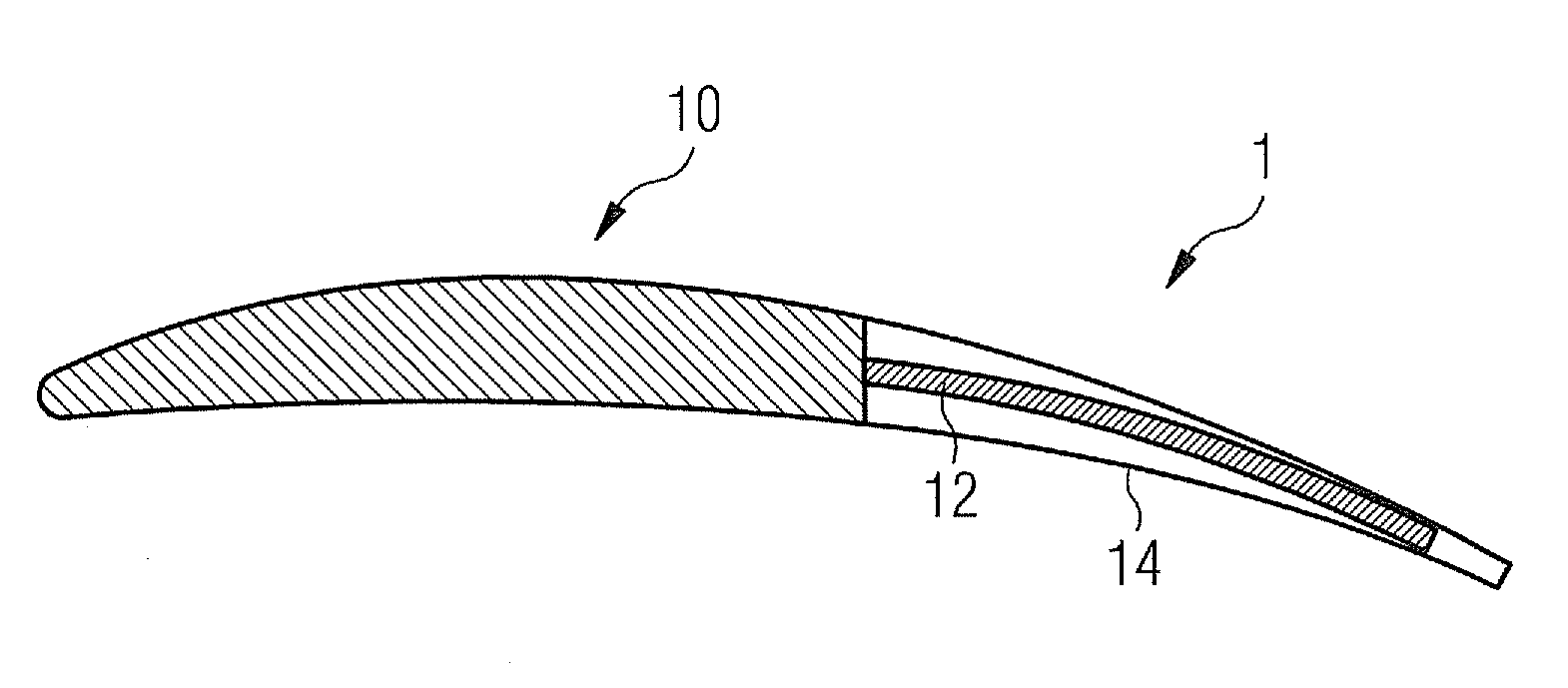

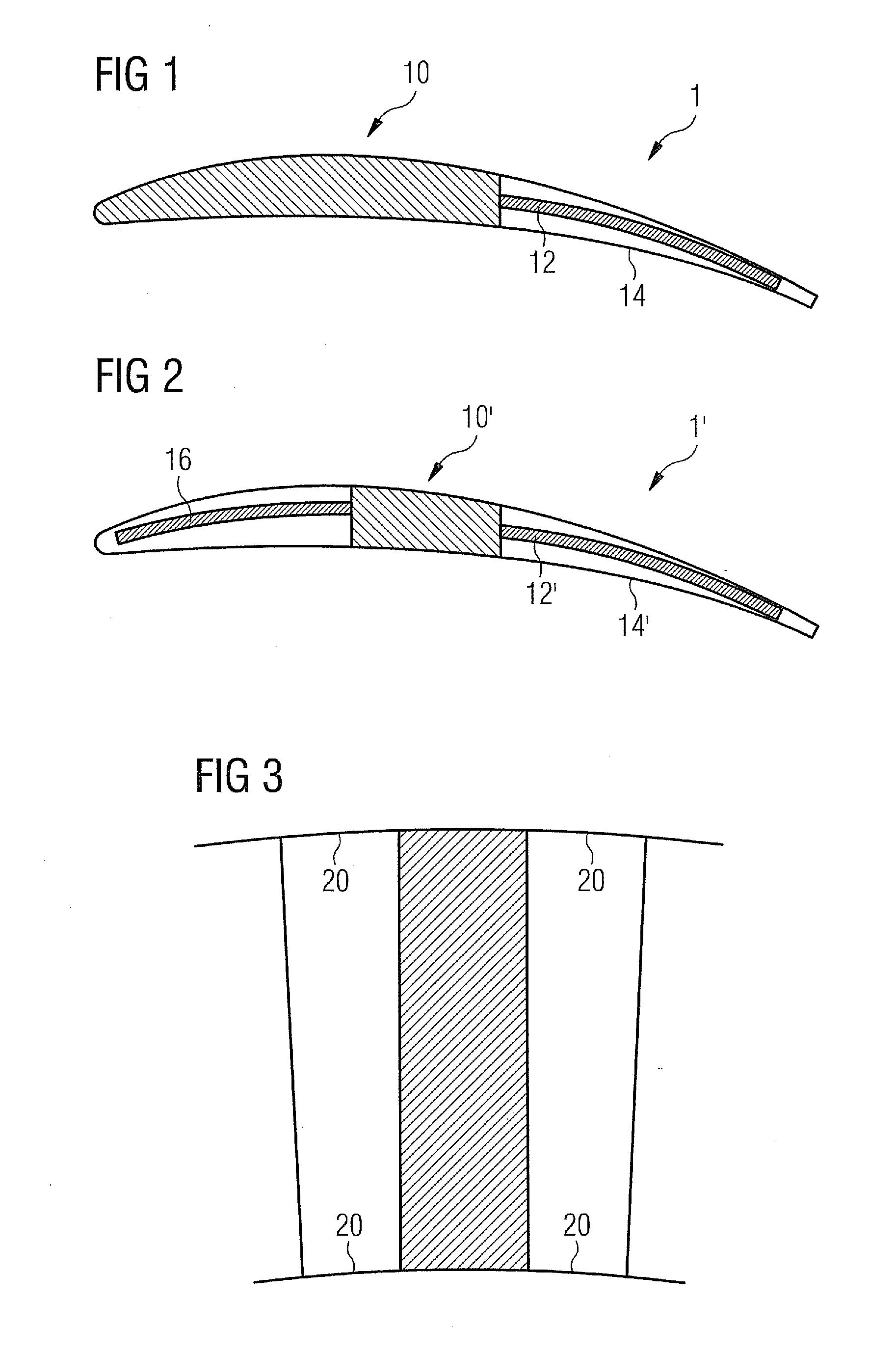

[0035]FIGS. 1 and 2 show a schematic longitudinal section of a first and the invention, which may be used in a compressor, for instance in the compressor of a turbocharger.

[0036]Inlet vane 1 comprises a rigid, structurally fixed portion 10 which is coupled to an aft portion that comprises an electroactive polymer (EAP) member 12 and a flexible skin 14 of metal or polymer materials. In the present embodiment, EAP member 12 is laminated to skin 14, and is supplied with voltage using electrical leads (not shown). The electrical leads can be led through the structural fixed portion 10. Alternatively, the structural fixed portion 10 itself can be electrically conductive so as to replace one or more of the leads. If it replaces more than one lead it would comprise a respective number of conductive portions which are electrically isolated against each other.

[0037]As the person skilled in the art will acknowledge, in the entire description and claims, fore and aft relate to the upstream edg...

fourth embodiment

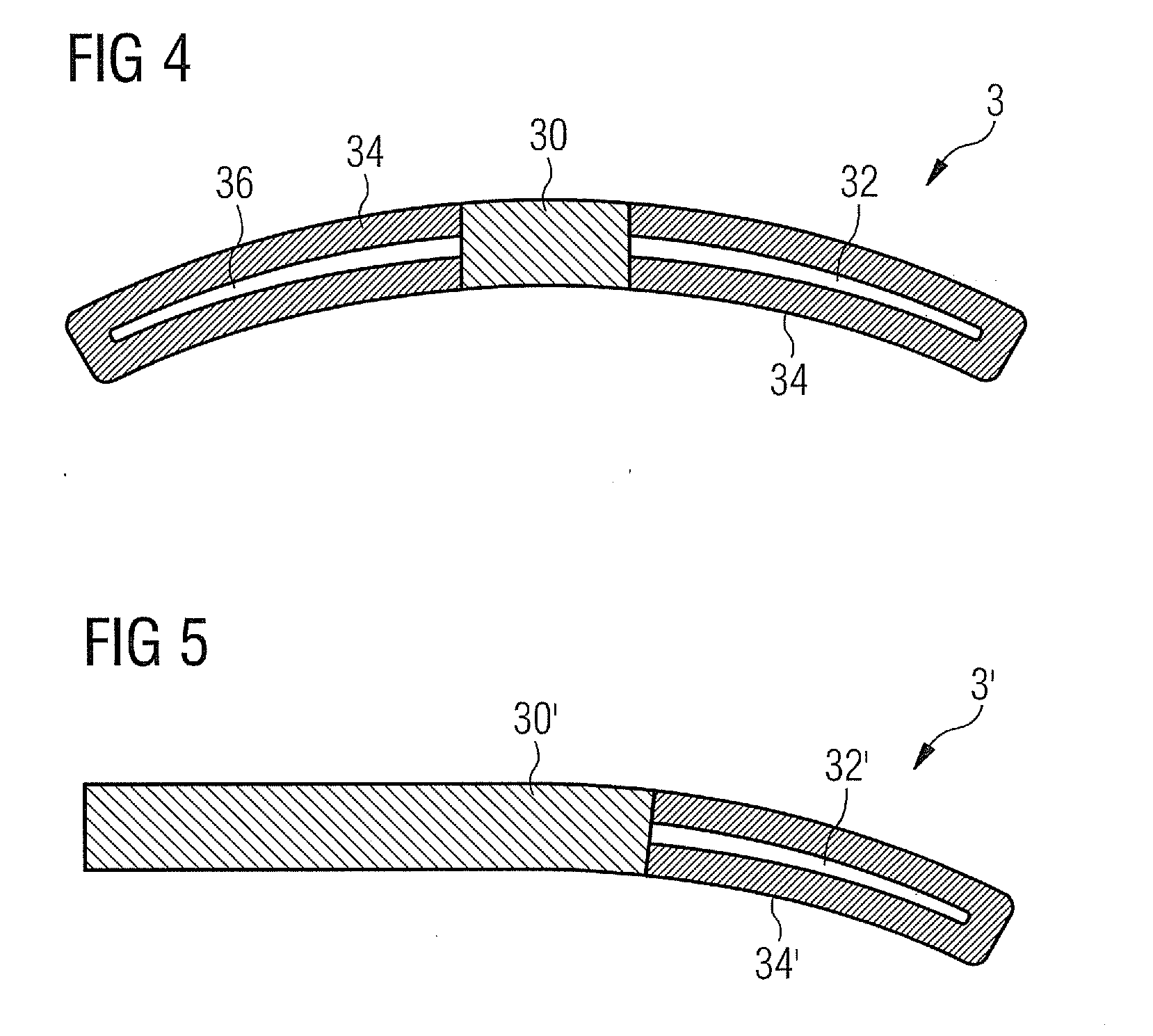

[0043]FIGS. 4 and 5 shows a schematic longitudinal section of a third and the invention, respectively, which may be used in a silencer of a turbocharger.

[0044]The configuration of these embodiments generally corresponds to the configuration of the embodiments described with respect to FIGS. 1 and 2. In particular, what has been said about supplying the EAPs with voltage with respect to the first and second embodiment is also true for the third and fourth embodiment.

[0045]In the silencer vane 3 shown in FIG. 4, a rigid portion 30 is located between and coupled to a fore portion that comprises an EAP layer 36 laminated to covering layer 34, and an aft portion, also comprising an EAP layer 32 laminated to covering layer 34.

[0046]Regarding the contact area between the EAP layers and covering layers of the third and fourth embodiment, the details given with regard to the first and second embodiment of the invention apply respectively.

[0047]In the silencer vane 3′ shown in FIG. 5, the rig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com