Gasifier and gasification methods using thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

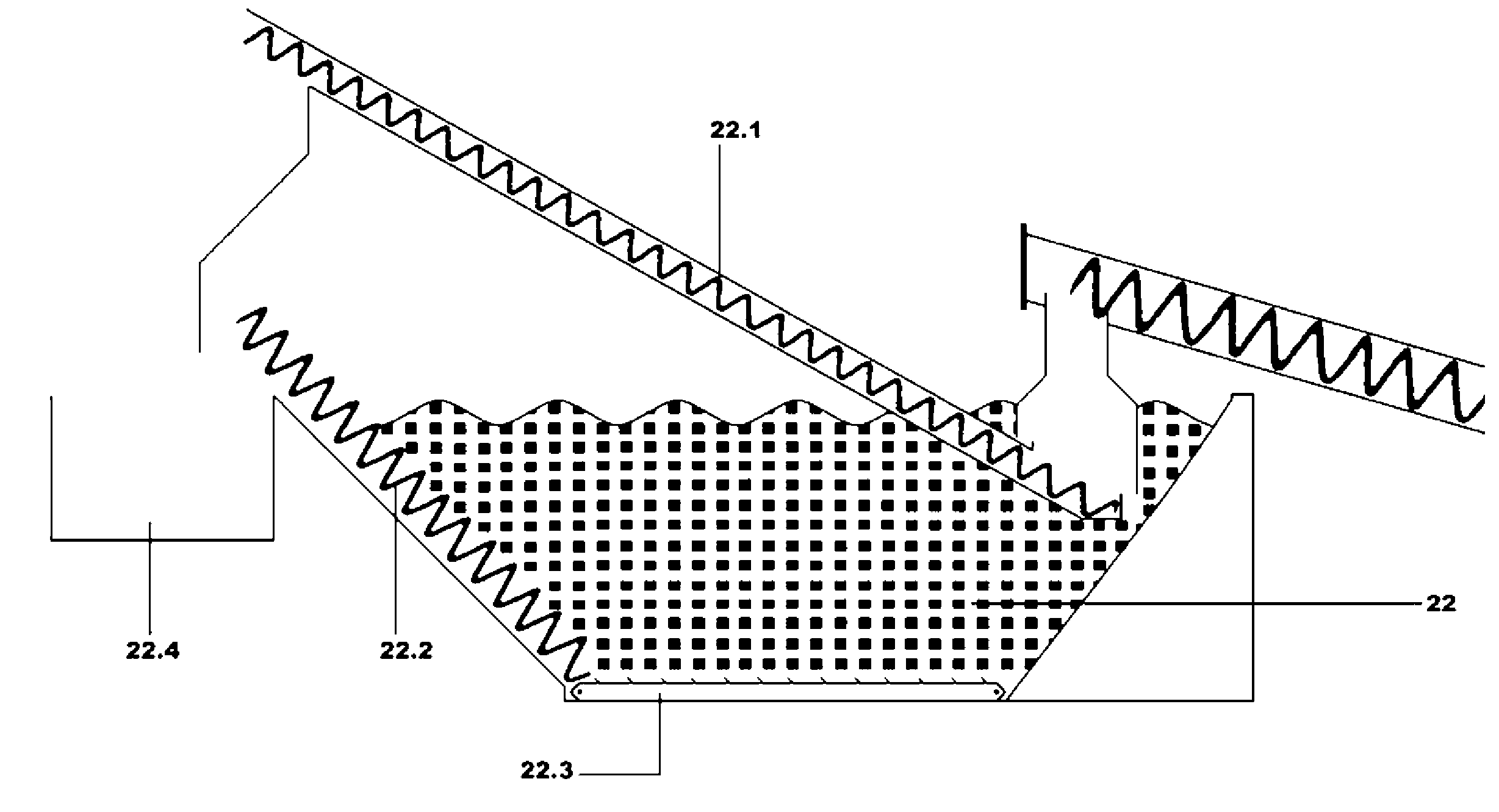

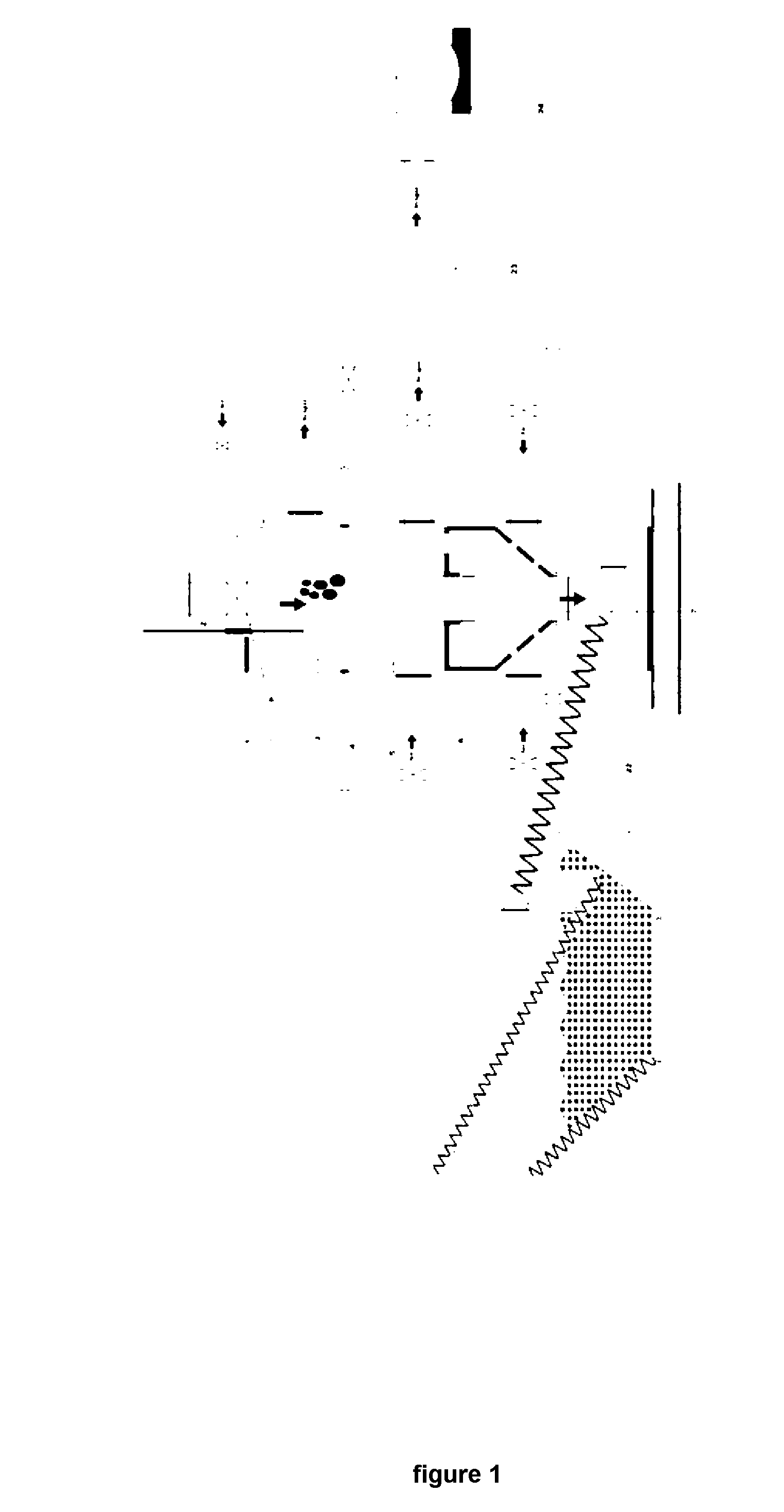

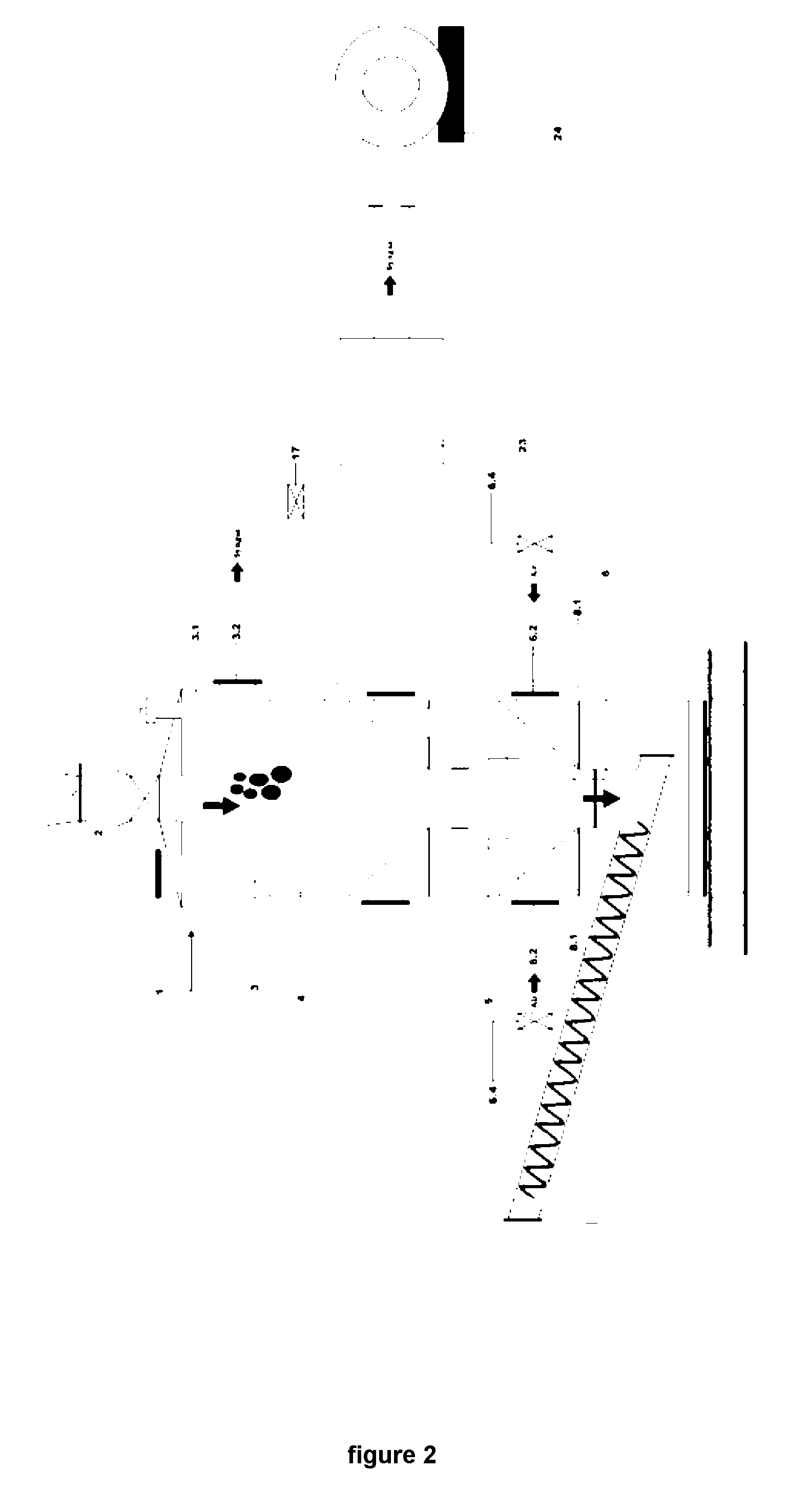

[0024]A gasifier (1) and gasification methods have been developed in order to reach the objects as mentioned above and to eliminate disadvantages of the prior art. With reference to FIG. 1,

[0025]the present gasifier (1) comprises a scale (9.2),

[0026]A bottleneck zone (2) that comprises a double sliding valve (9) and a rotating valve (9.1) where the waste is exposed to heat for the first time in oxygen free environment;

[0027]A drying zone (3.1) located under the bottleneck zone (2) with a diameter bigger than the bottleneck zone comprising a higher syngas outlet zone (3.2), a safety valve (11), a level indicator (12), an inspection glass (12.1), a sliding cover (12.2), a thermocouple (13.2), a pressure forwarder (14), a pressure meter in syngas outlet zone, a proportional valve (19) and a hydraulic piston (21);

[0028]a pyrolysis zone (4) located under the drying zone (3) comprising a preheated air and oxygen inlet (4.1), air nozzles (4.4), a vibrator (10), a thermocouple (13.1), liqui...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap