Process and installation for recovery and purification of ethylene produced by pyrolysis of hydrocarbons, and gases obtained by this process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Example

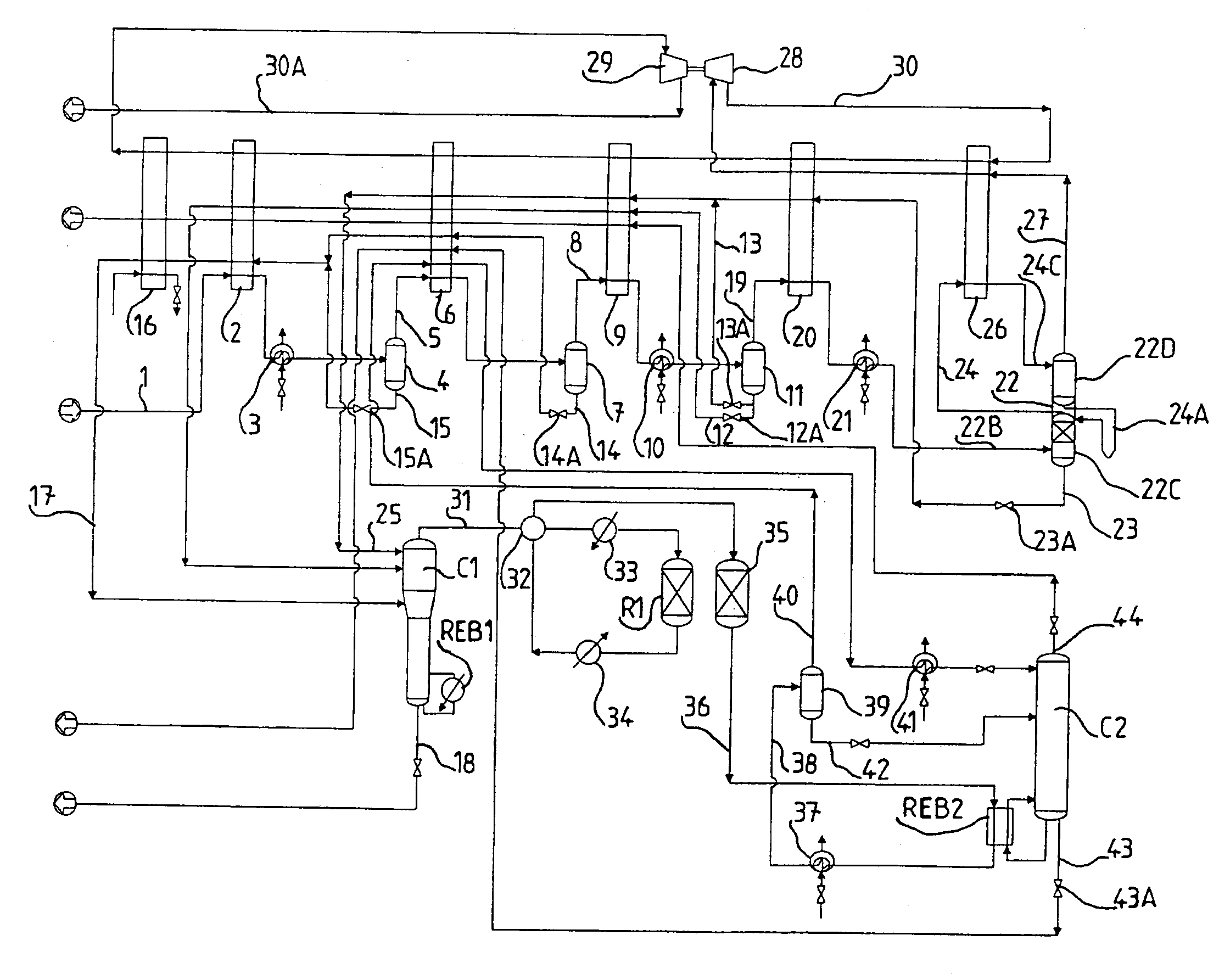

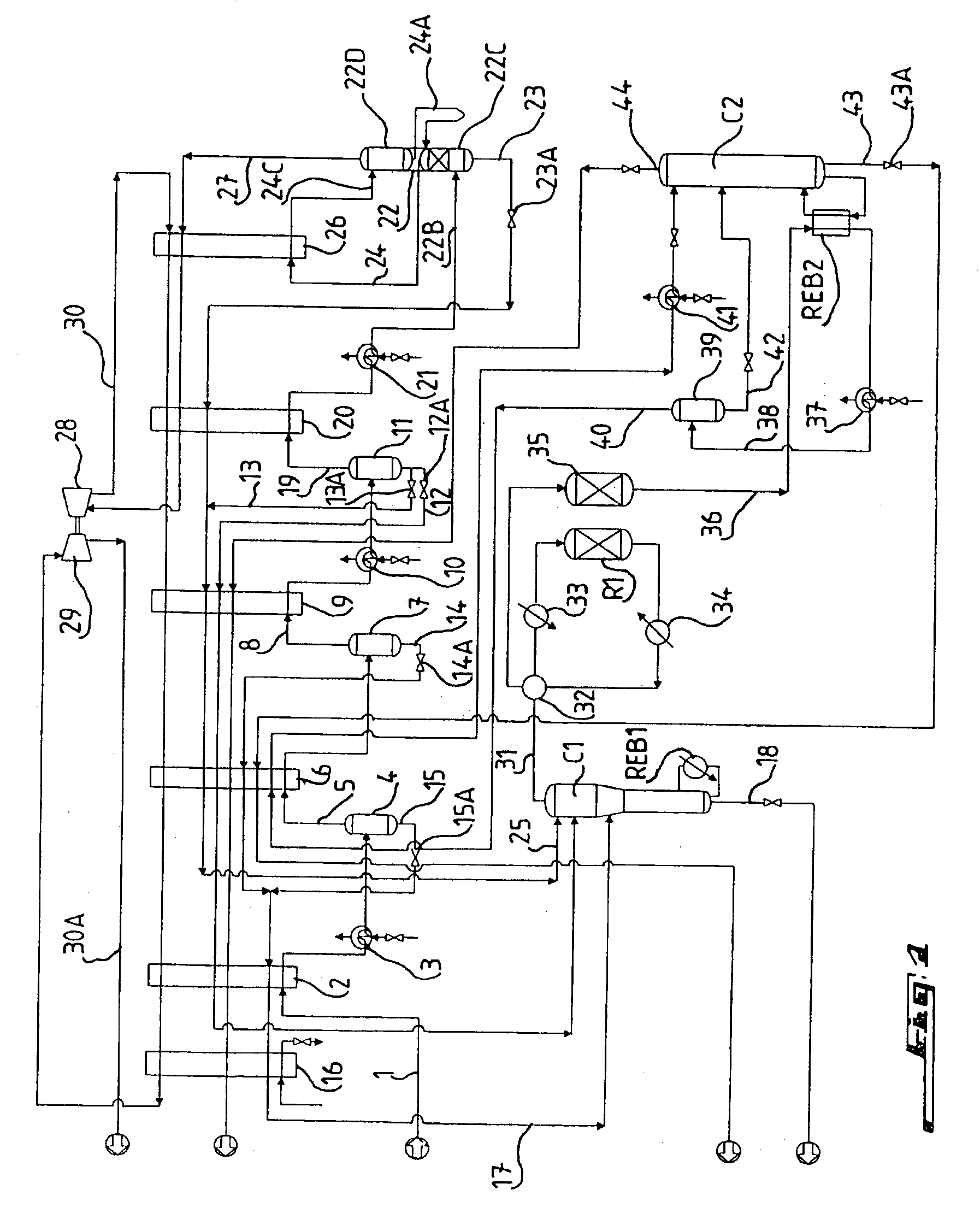

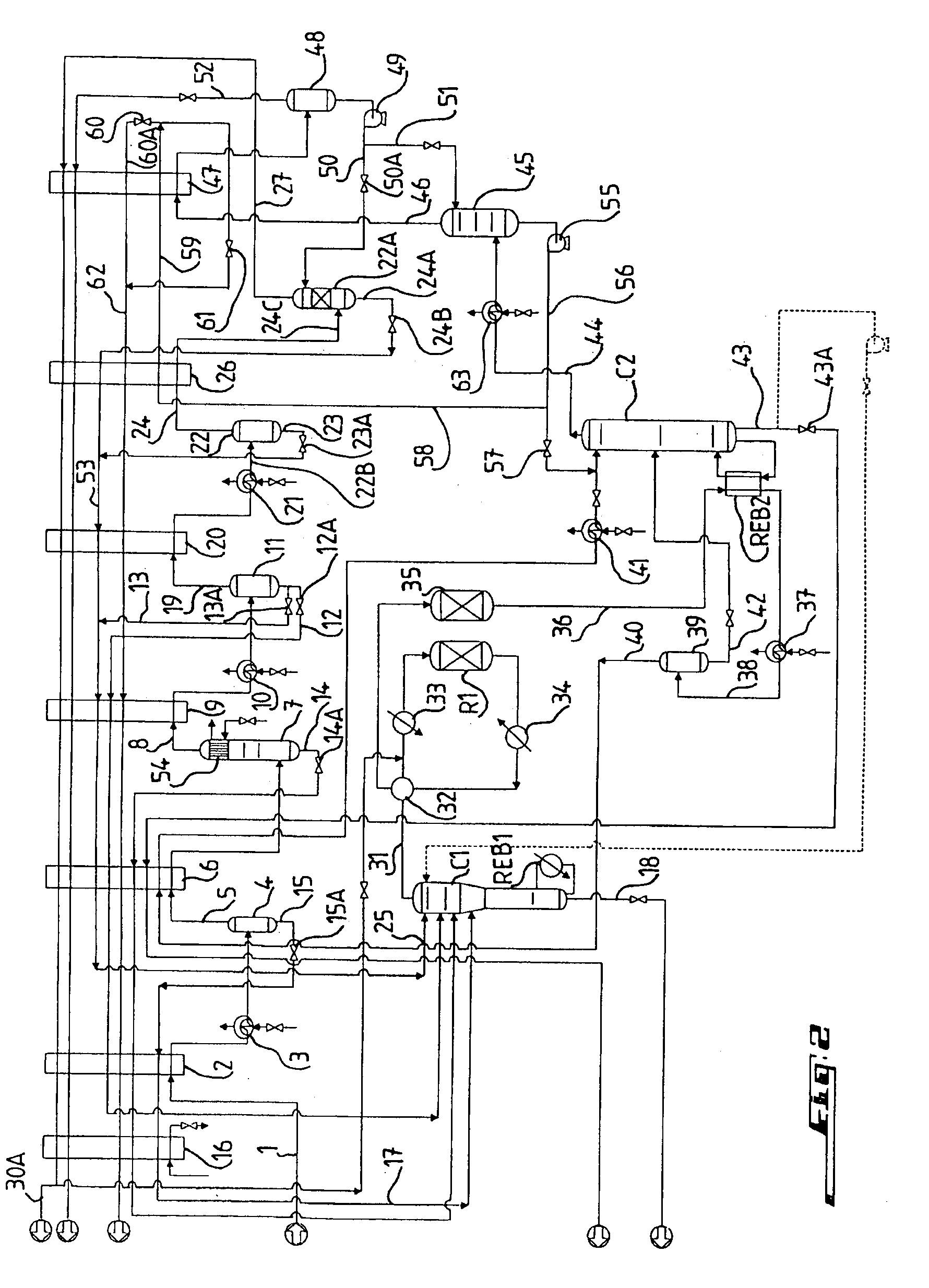

[0039]For FIG. 1, the number 1 designates the feed line of the sufficiently dry pyrolysis gas (for example, 10 ppm water) at a pressure that is selected based on the required hydrogen pressure (for example, 15 to 50 bar, preferably between 28 and 38 bar).

[0040]The typical composition of a gas obtained by ethane cracking is shown in the table below (in mol %):

[0041]CutCutCO / H2CH4C2H2C2H4C2H6C3C4C5+CO2TOTAL36.95.40.334.221.00.60.61.00.6100.00

[0042]This gas is cooled in the multiple-flow beat exchanger 2 and in exchanger 3, respectively, by heat exchange with the cold gases produced by vaporization of the condensates mentioned below and by vaporization of propylene circulating in the traditional cooling loop in a closed circuit.

[0043]The partly condensed gas is supplied to separator 4 at a temperature preferably between −30 and −40° C.

[0044]The gas 5 collected at the head of the separator 4 is further cooled, in the multiple-flow heat exchanger 6, by the cold gases produced by vaporiza...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap