Interlocking type plastic tile structure

a plastic tile and interlocking technology, applied in the direction of construction, covering/lining, building components, etc., can solve the problems of high manufacturing cost, oblique plastic tile obliqueness, and poor so as to reduce the manufacturing cost of plastic tiles and facilitate construction. , the effect of good alignment of two plastic tiles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024]The technical content, objects and effectiveness of the present invention will become more apparent by the detailed description of a preferred embodiment of the present invention in conjunction with the accompanying drawings.

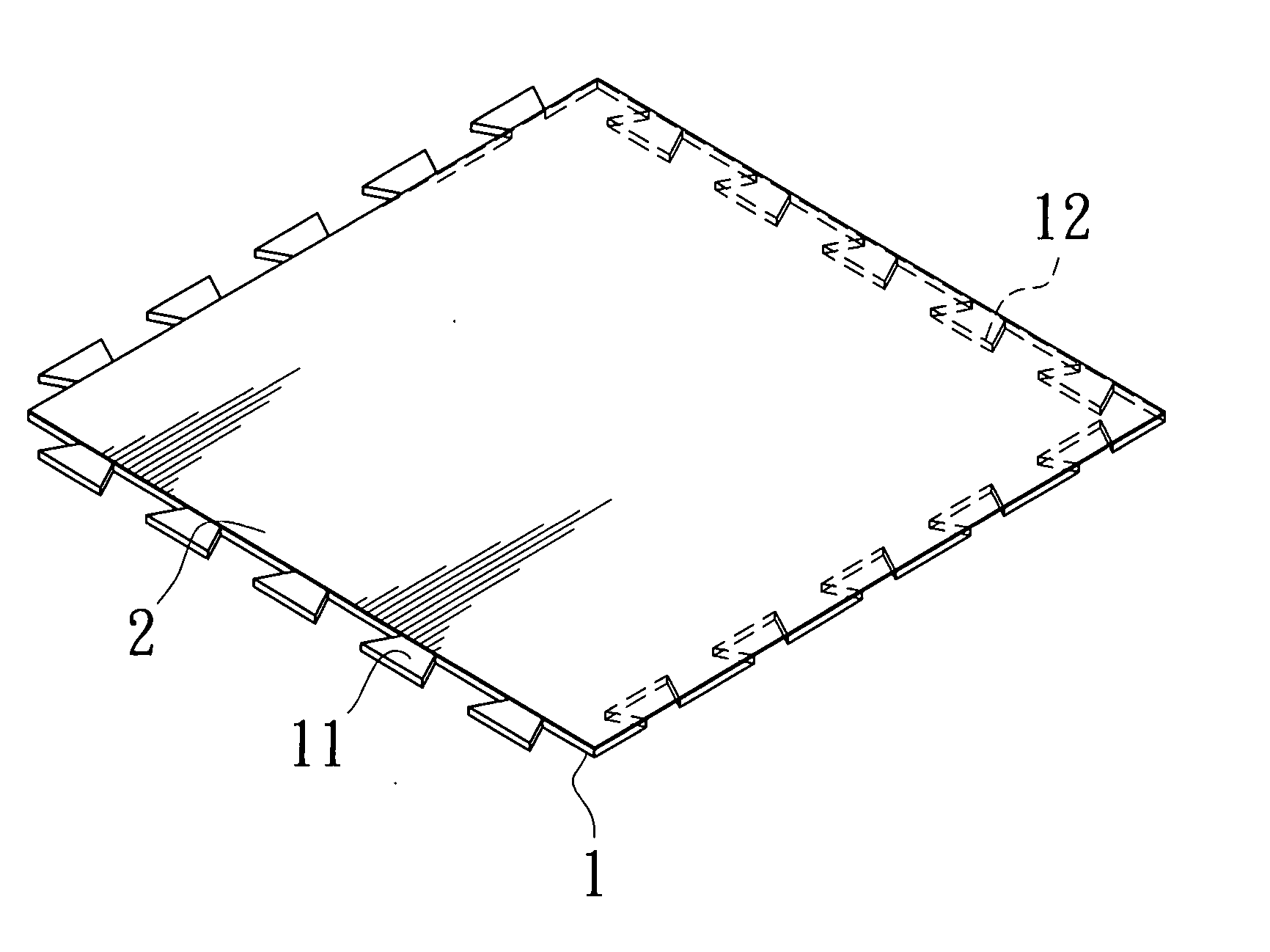

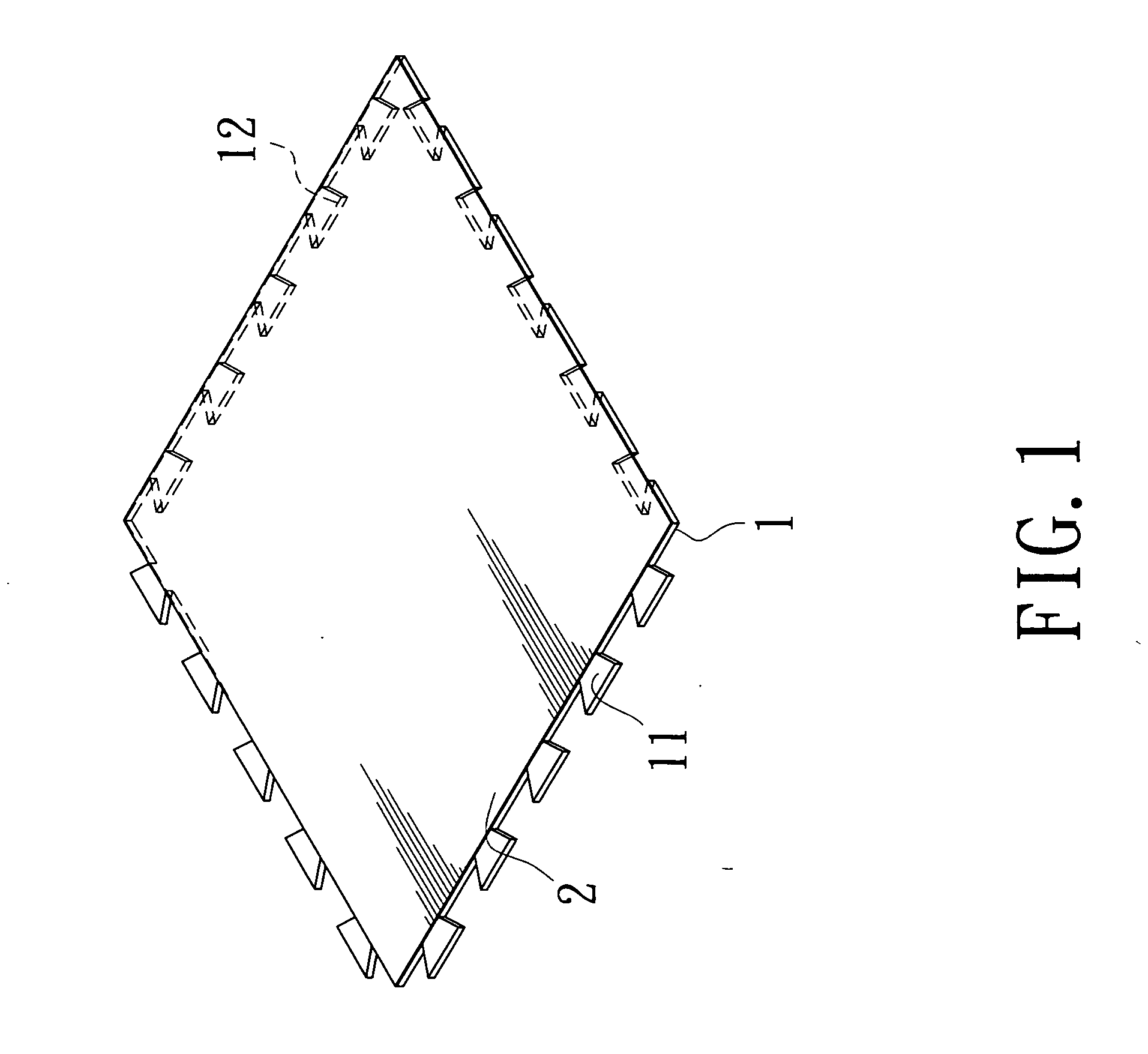

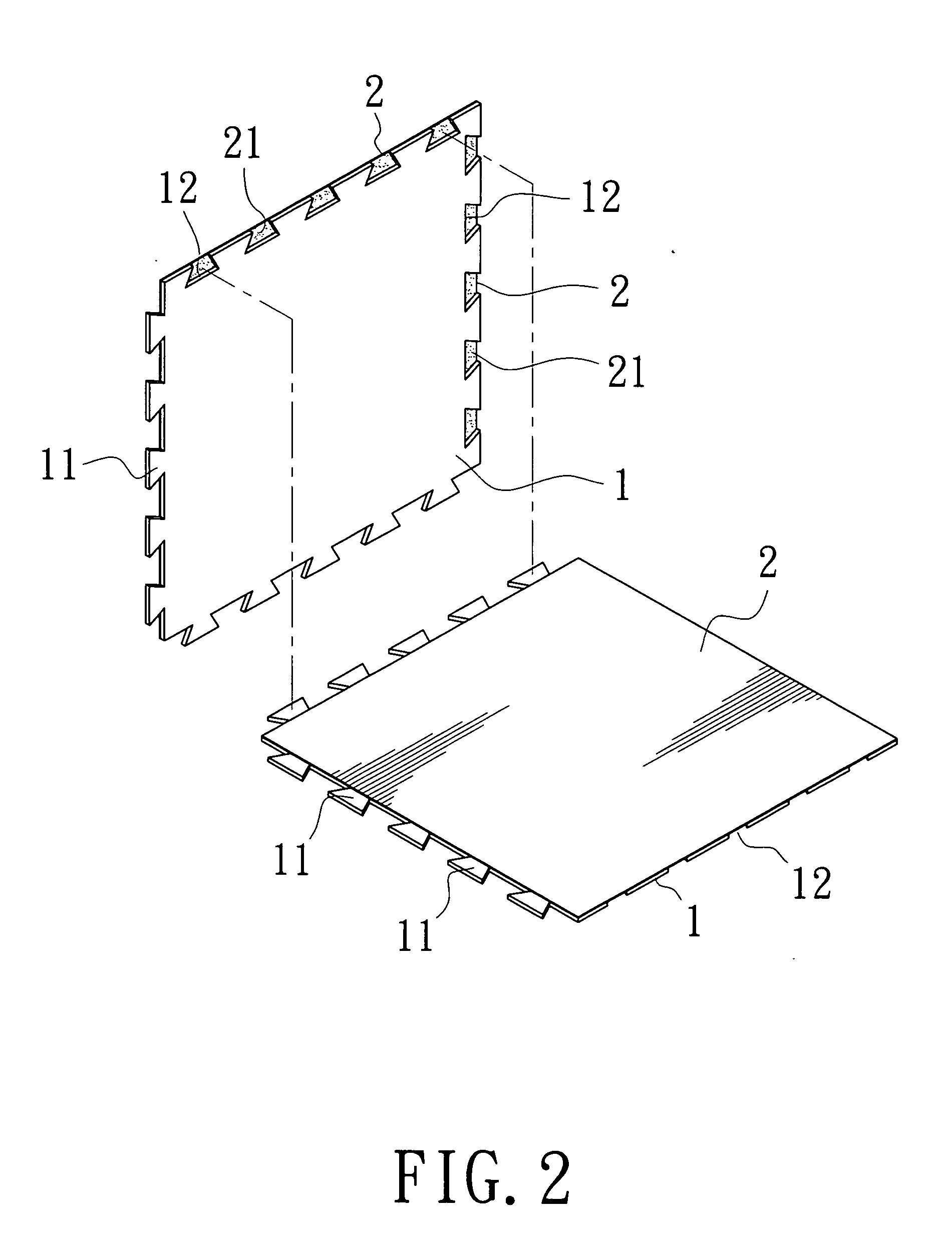

[0025]Firstly referring to FIGS. 1 to 4 showing a perspective appearance and a schematic exploded assembly view of the interlocking type plastic tile structure of the present invention, in which the plastic tile comprises:

[0026]a PVC base layer (1), being a base layer contacted with floor, the PVC base layer (1) can be a rigid PVC material in which a plurality of protruding tongues (11) and notches (12) are provided at respective two adjacent sides;

[0027]a surface layer (2), the lower surface of which is coated with adhesive (21) so as to be adhered with the PVC base layer (1), the adhesive (21) being exposed to the outside at the notches (12) for the purpose of adhering with the corresponding protruding tongue (11) on the PVC base layer (1) of the next pl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transparent | aaaaa | aaaaa |

| shape | aaaaa | aaaaa |

| adhesion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com