Start-up procedure for refrigerant systems having microchemical consensor and reheat cycle

a technology of microchemical consensor and reheat cycle, which is applied in the direction of lighting and heating apparatus, domestic cooling apparatus, heating types, etc., can solve the problems of high discharge operating pressure, instantaneous pressure spike, and microchannel heat exchangers that are more susceptible to refrigerant pressure variations, etc., to achieve the effect of higher operating speed of variable speed compressors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

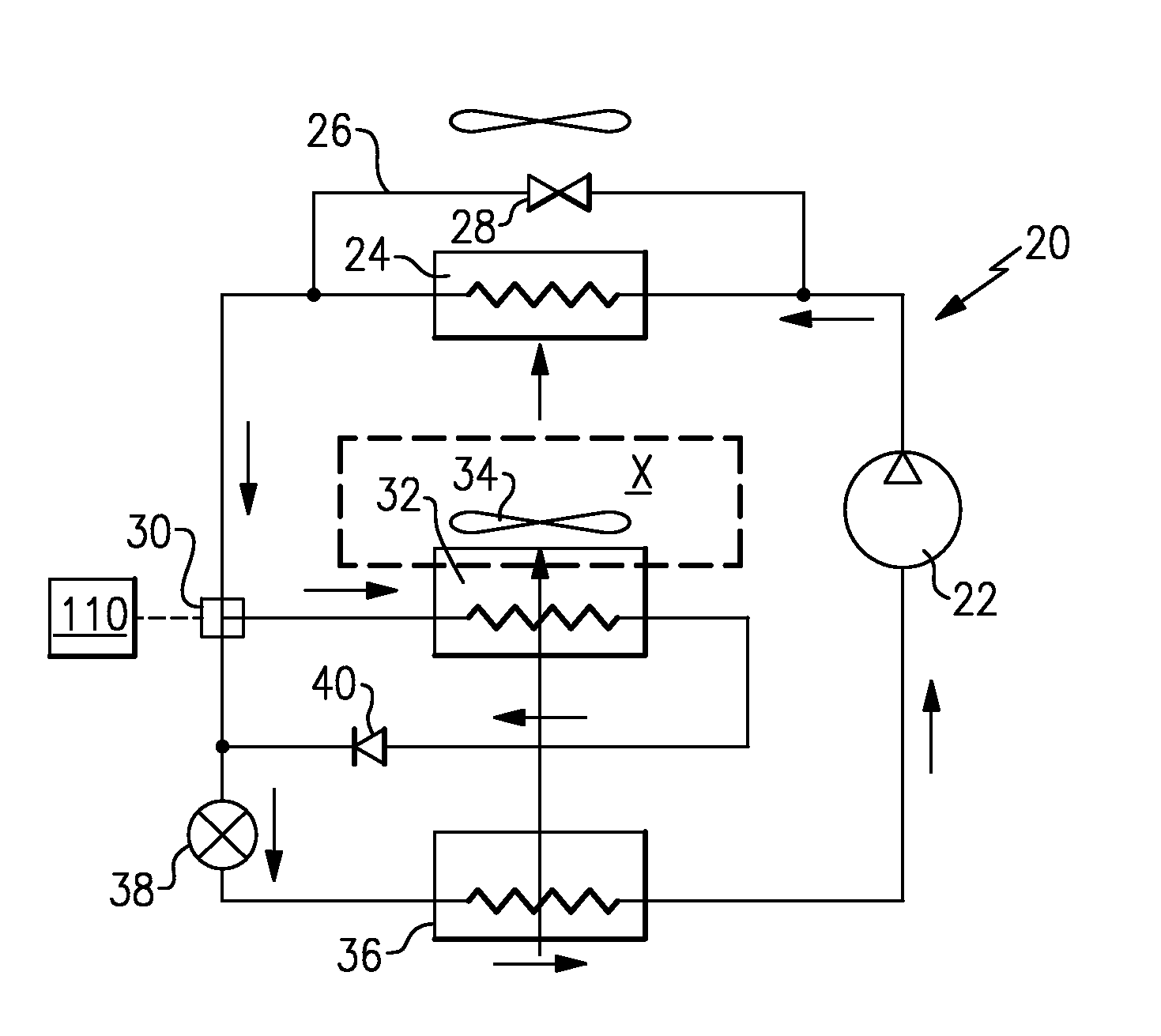

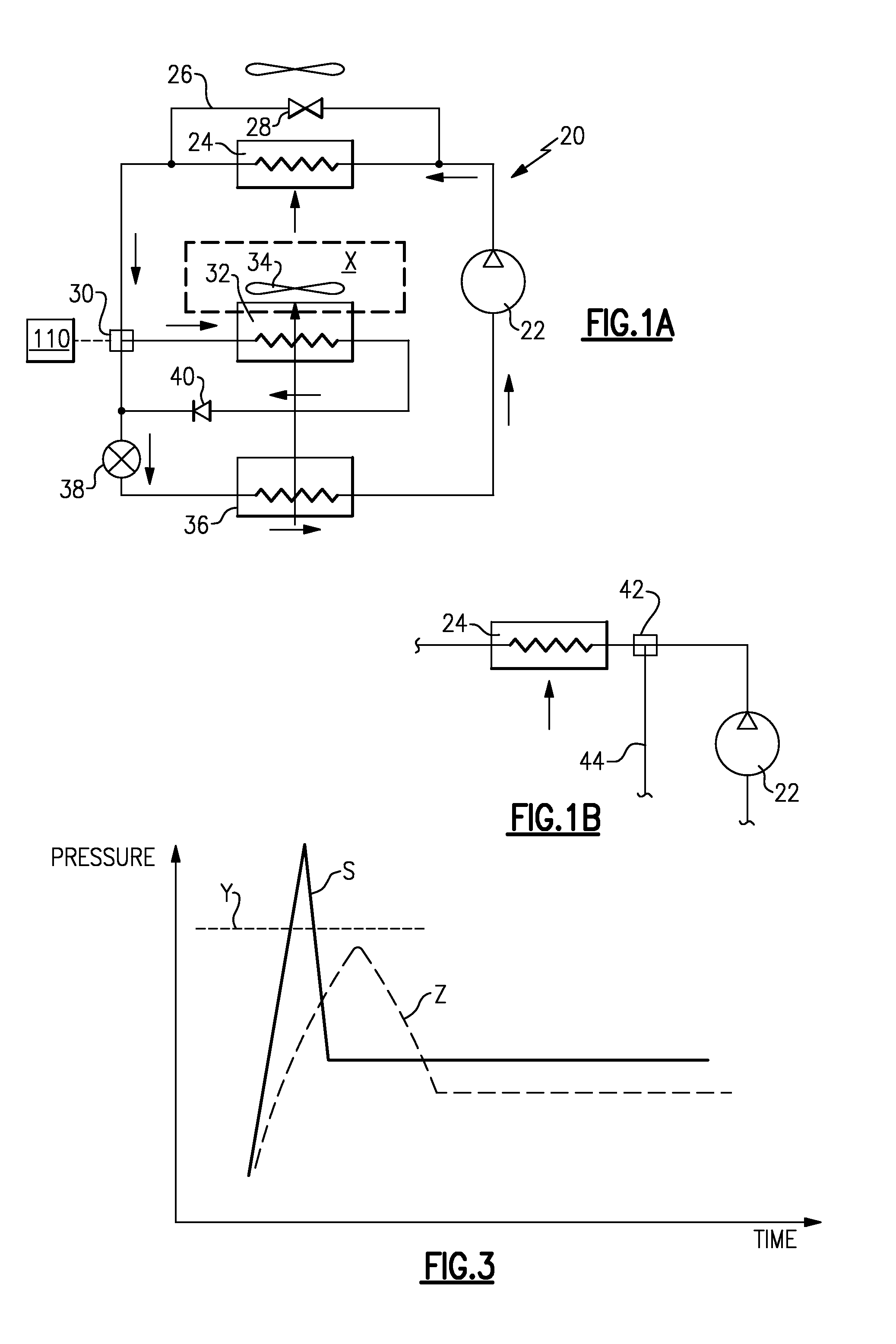

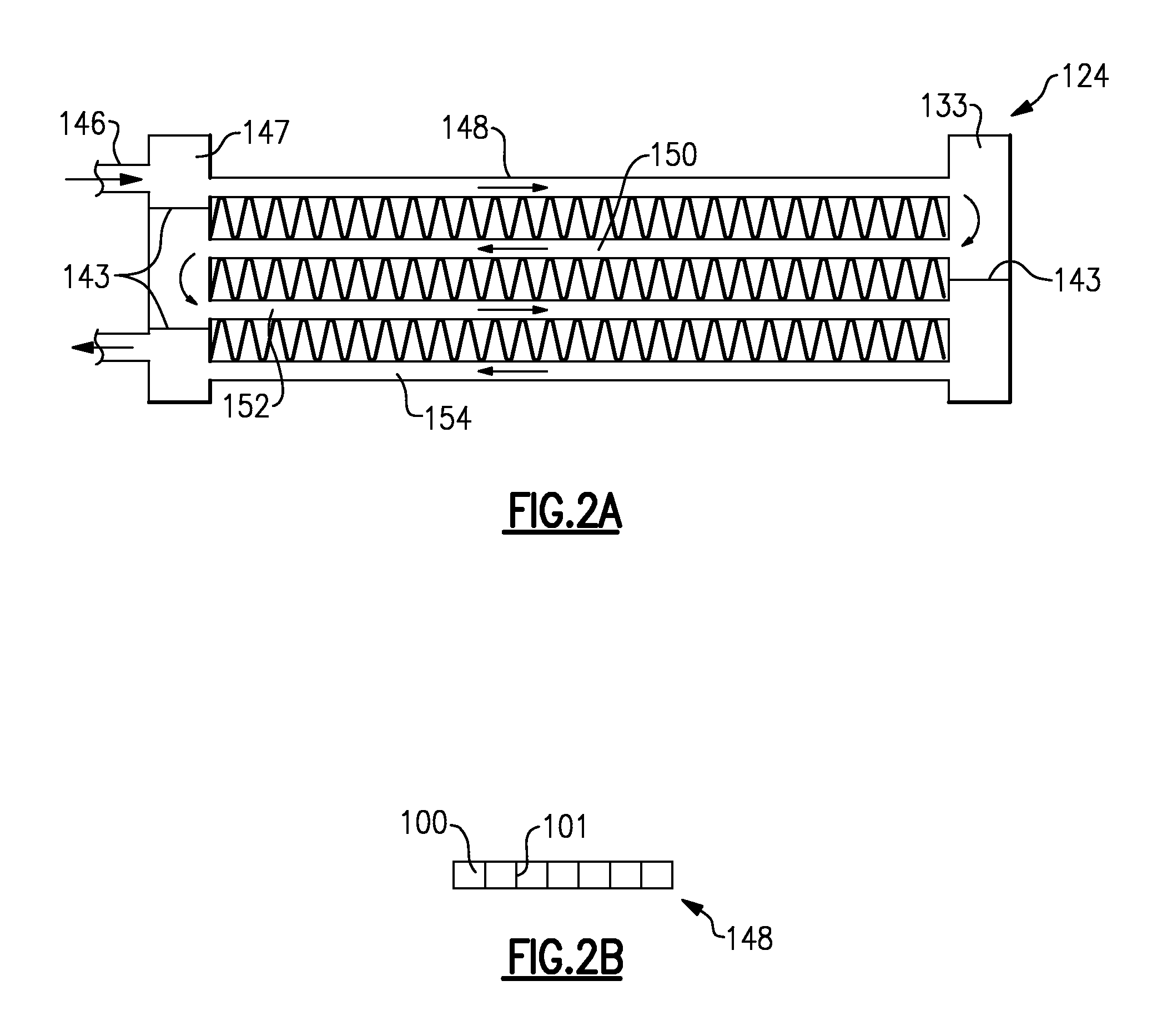

[0015]A refrigerant system 20 is illustrated in FIG. 1A and includes a compressor 22 delivering refrigerant into a discharge line heading to a condenser 24. The condenser 24 is a parallel flow heat exchanger, and in one disclosed embodiment is a microchannel or minichannel heat exchanger. As mentioned above, these terms are used interchangeably here.

[0016]Heat is transferred in the condenser 24 from the refrigerant to a secondary fluid, such as ambient air. The high pressure, desuperheated, condensed and typically subcooled, refrigerant passes from the condenser 24 into an expansion device 38, where it is expanded to a lower pressure and temperature. Downstream of the expansion device 38, refrigerant flows through an evaporator 36 and back to the compressor 22. As known, the heat exchanger 24 operates as a condenser in subcritical applications and as a gas cooler in transcritical applications. Nevertheless, although both applications are within the scope of the invention, the heat e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com