Fuel Cell Apparatus

a fuel cell and apparatus technology, applied in the direction of chemistry apparatus and processes, electrically generating generators, sustainable buildings, etc., can solve the problems of fuel cell deterioration, easy precipitation, and rapid increase of target gas (raw fuel) supplied to the reforming portion, and achieve the effect of efficient starting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

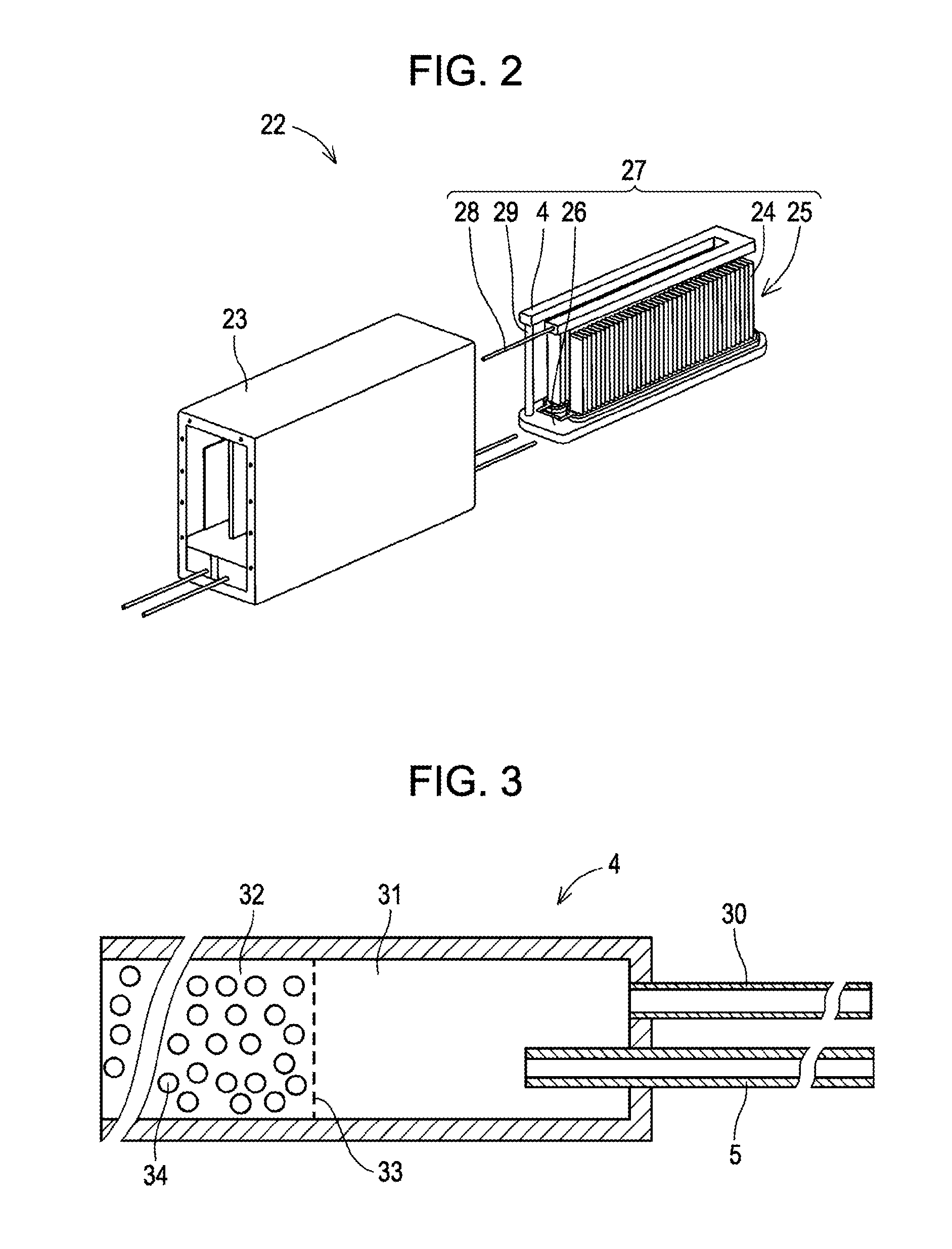

[0019]Preferred embodiments of the present invention will now be described in detail with reference to the drawings.

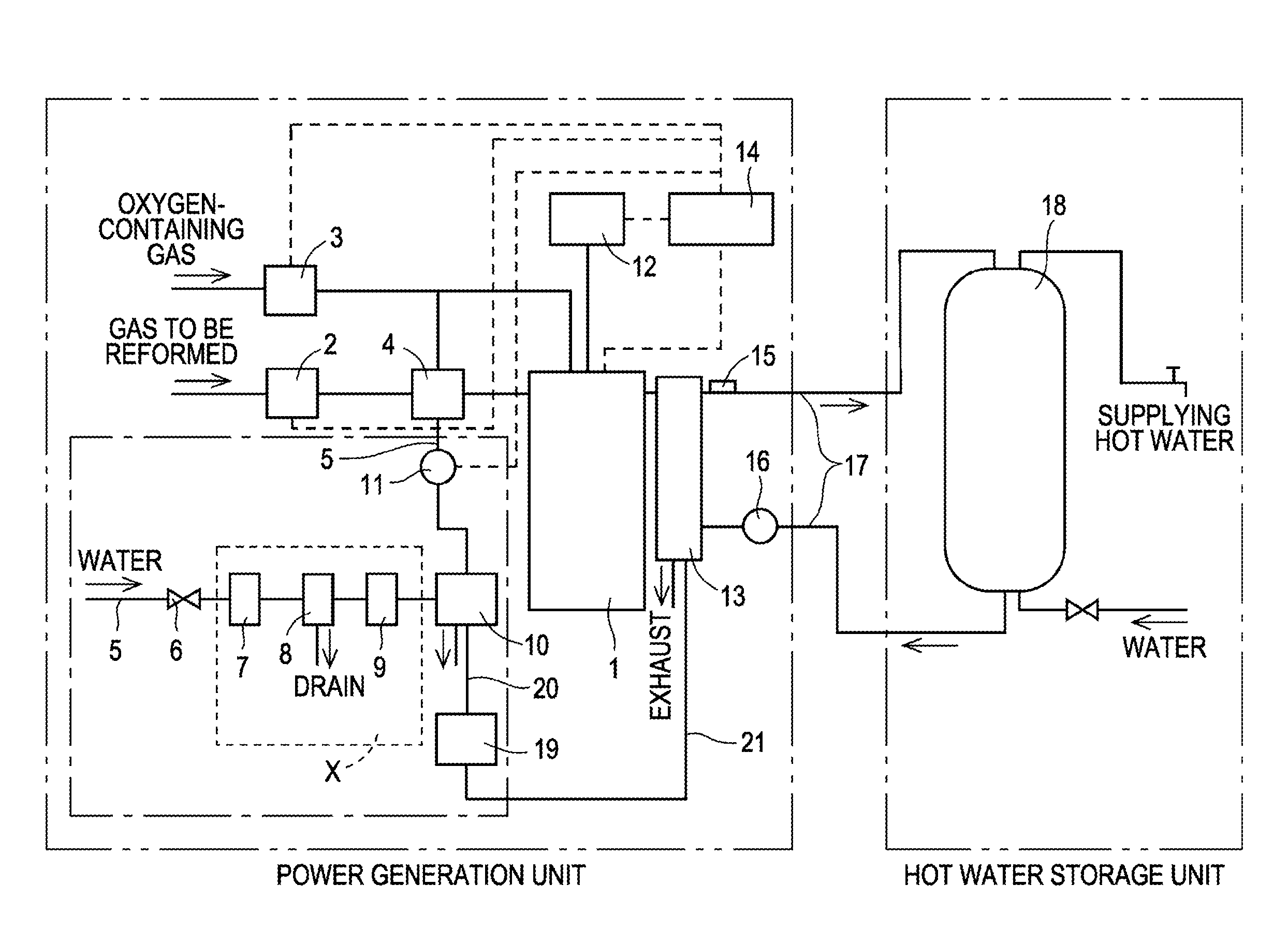

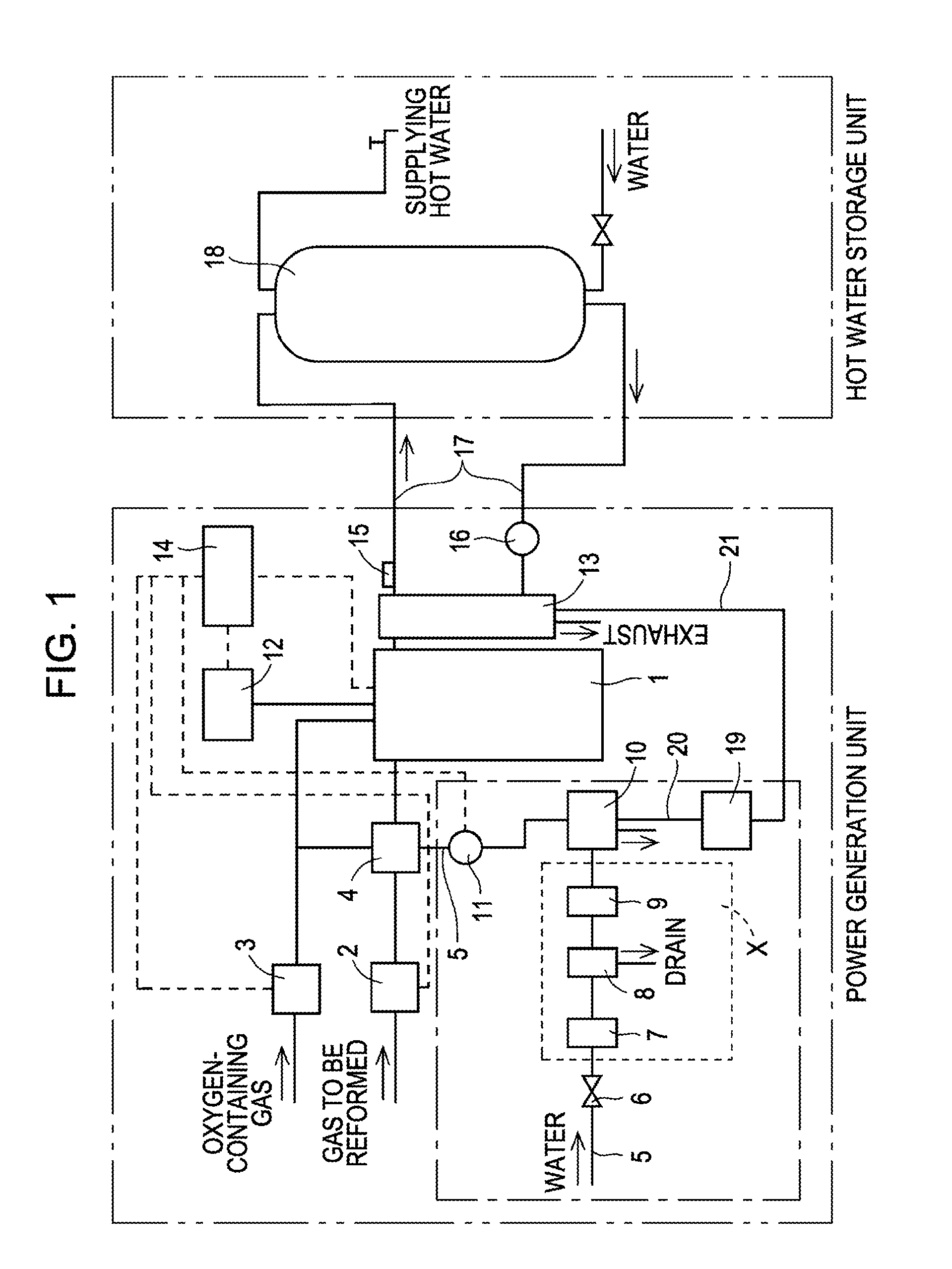

[0020]FIG. 1 is a block diagram of a fuel cell system comprising a fuel cell apparatus according to the present invention. The fuel cell system comprises a power generation unit generating electric power, which is the fuel cell apparatus of the present invention, a hot water storage unit in which heat-exchanged hot water is stored, and circulation piping through which water circulates between these units.

[0021]The fuel cell apparatus shown in FIG. 1 comprises a reforming target gas supply portion 2 supplying a raw fuel, such as natural gas or kerosene (corresponding to the reforming target gas if natural gas is used), a reformer 4 integrally comprising a reforming portion comprising a reforming catalyst for reforming the reforming target gas and a vaporizing portion generating steam to be supplied to the reforming portion, and an oxygen-containing gas supply portion 3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com