Exhaust gas treatment apparatus

a gas treatment apparatus and exhaust gas technology, applied in the direction of magnetic separation, machines/engines, electric supply techniques, etc., can solve the problems of increased pressure loss of gas treatment apparatus, insufficient agglomeration effect, and difficulty in manufacturing apparatus, so as to increase the pressure, and reduce the number of particulates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

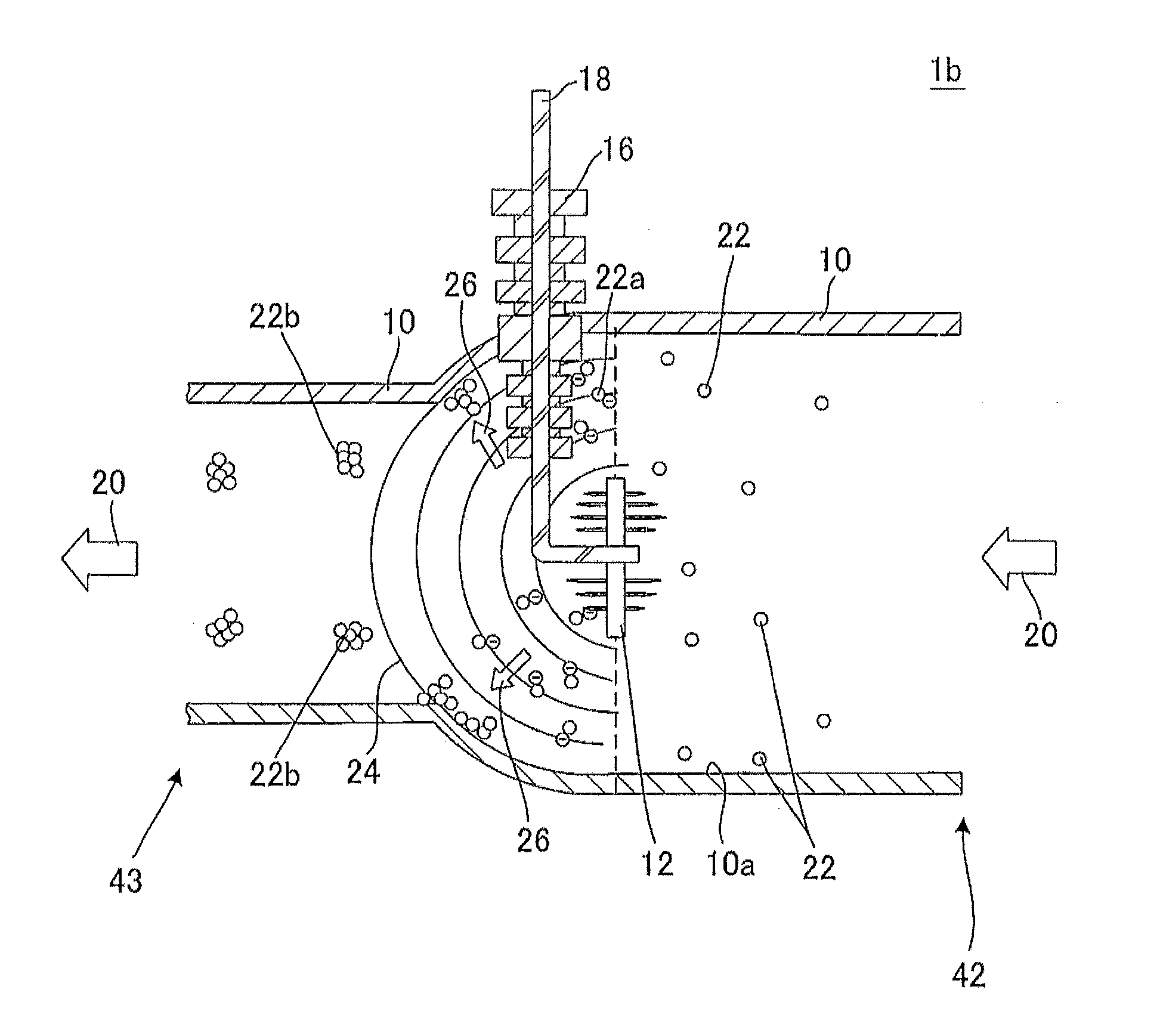

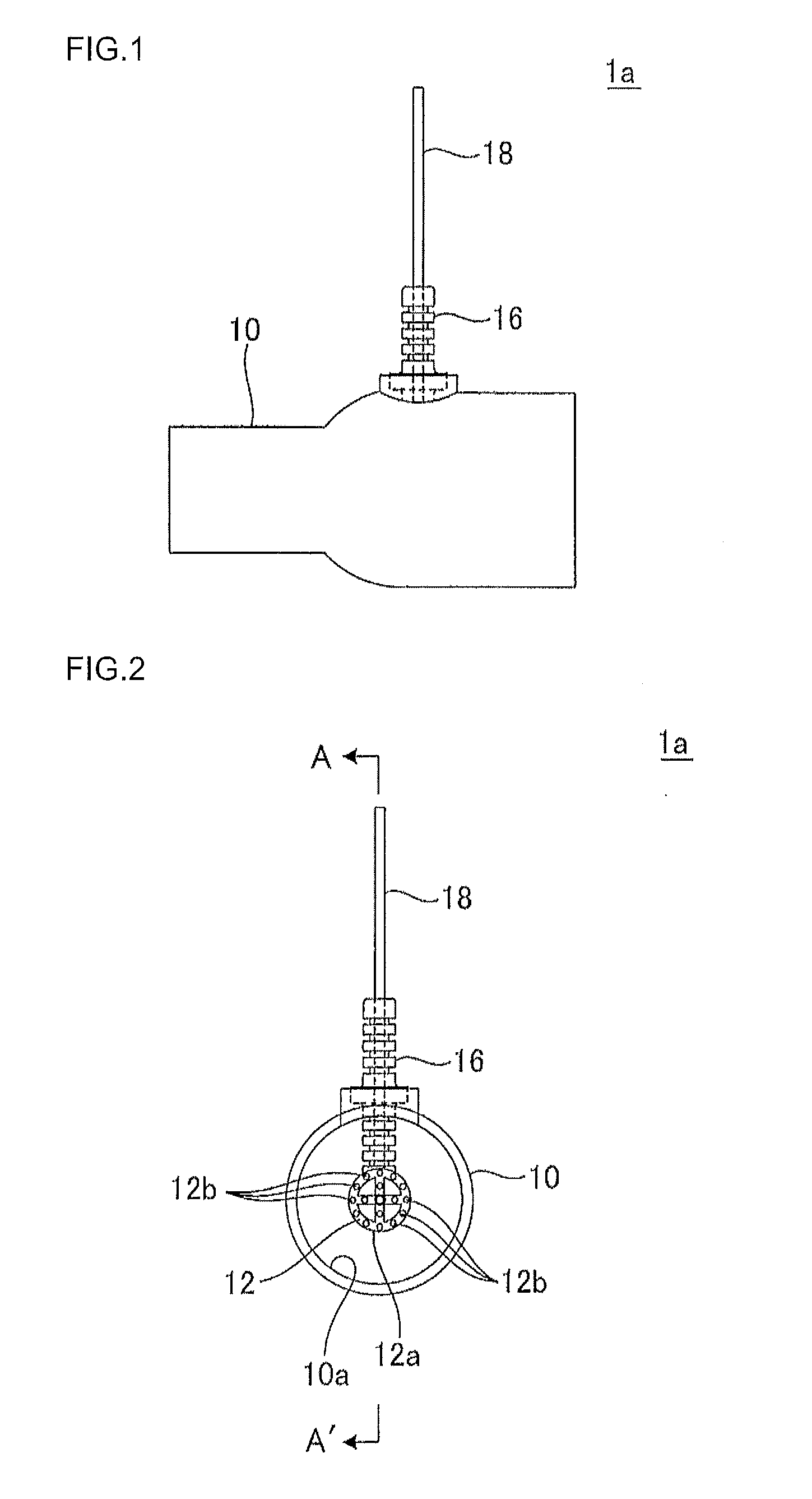

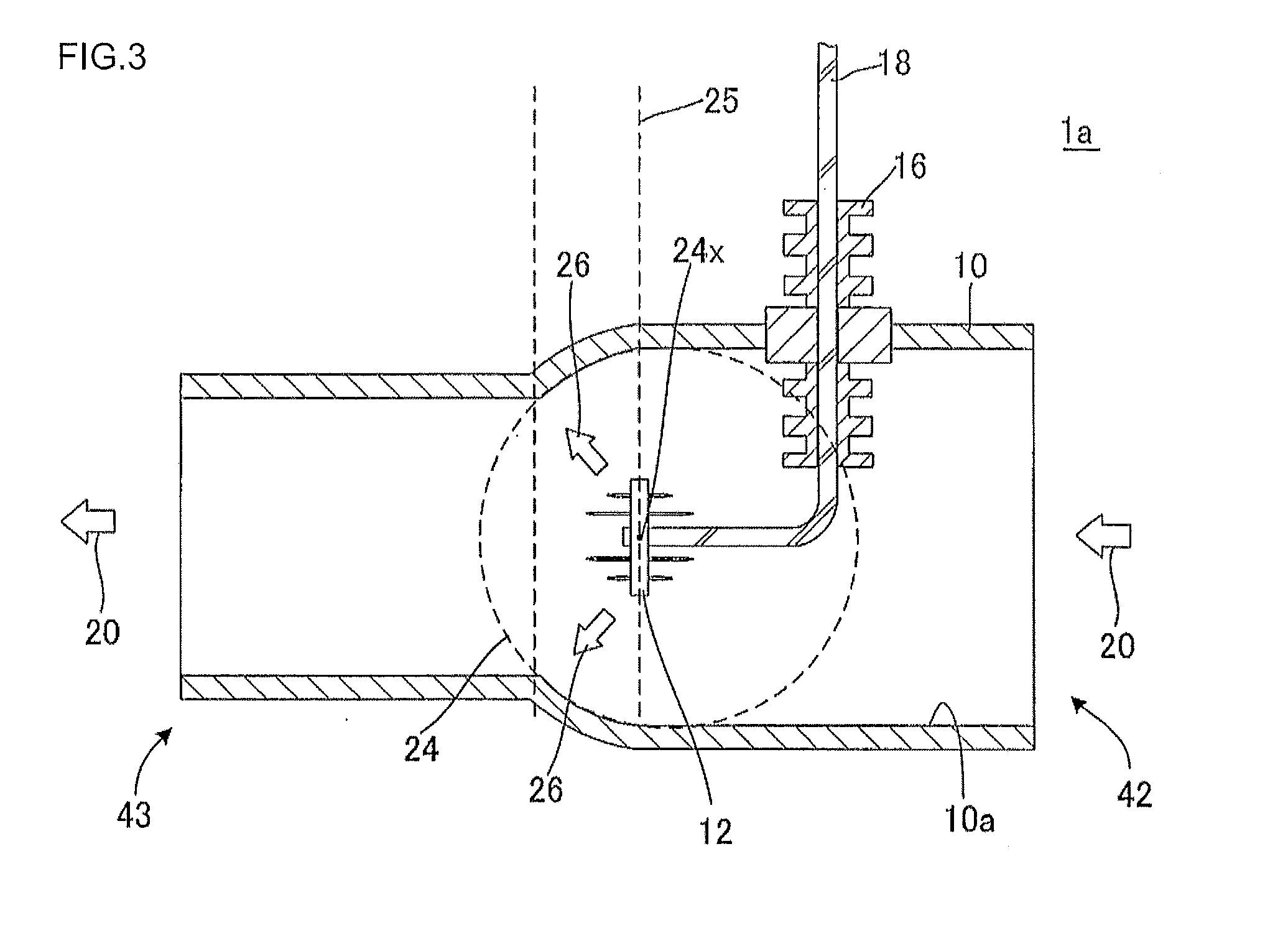

[0105]There was manufactured an exhaust gas treatment apparatus 1a as shown in FIGS. 1 to 3. The tubular body 10 had a circular cylindrical shape having a length of 300 mm in the exhaust gas flow direction, an outer diameter of 60.5 mm, and an inner diameter of 53.5 mm, and the material of the tubular body was stainless steel.

[0106]An alumina porcelain bushing 16 was disposed in the position of 30 mm from the end face on the upstream side of the flow direction of the tubular body 10 so that it passed through the tubular body 10, and a voltage introduction portion 18 was disposed inside the porcelain bushing 16. A discharge electrode 12 was connected to the voltage introduction portion 18 to fix the discharge electrode 12 inside the tubular body 10.

[0107]As shown in FIGS. 7 and 8, the discharge electrode 12 was constituted by the disc-like electrode support 12a and the 16 dischargers 12b (12 dischargers at an angle of 30° outside, and 4 dischargers at an angle of 90° inside) disposed...

example 2

[0129]There was manufactured an exhaust gas treatment apparatus constituted in the same manner as in Example 1 except that the inner diameter of the tubular body was formed to be generally reduced in the range from the face containing the central point of generation of corona discharge to the position of 20 mm toward the downstream side of the flow passage, and exhaust gas was treated in the same manner as in Example 1. The measurement results of the mass (g / hour) of particulate matter on the inlet side of the exhaust gas treatment apparatus and the number (×107 particulates / sec.), mass (g / hour), and average particle diameter (μm) of particulates on the outlet side during the exhaust gas treatment are shown in Table 2.

example 3

[0130]There was manufactured an exhaust gas treatment apparatus constituted in the same manner as in Example 1 except that the inner diameter of the tubular body was formed to be generally reduced in the range from the face containing the central point of generation of corona discharge to the position of 25 mm toward the downstream side of the flow passage, and exhaust gas was treated in the same manner as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com