Separation method and apparatus

a separation method and air technology, applied in lighting and heating apparatus, solidification, refrigeration and liquid storage, etc., can solve problems such as on-going operational costs, achieve the effects of reducing the amount of nitrogen vapor, increasing the capacity of the lower pressure column, and improving purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

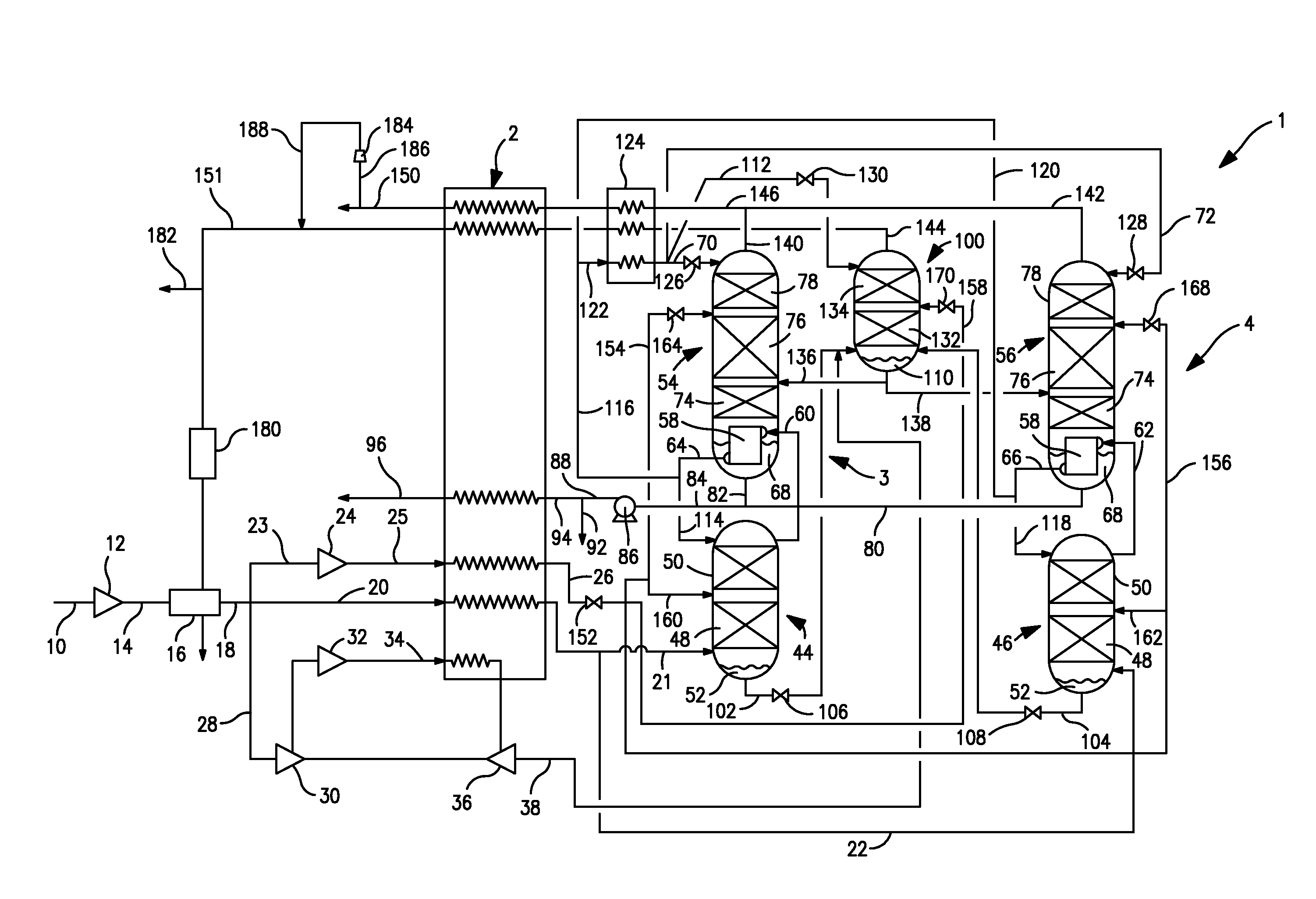

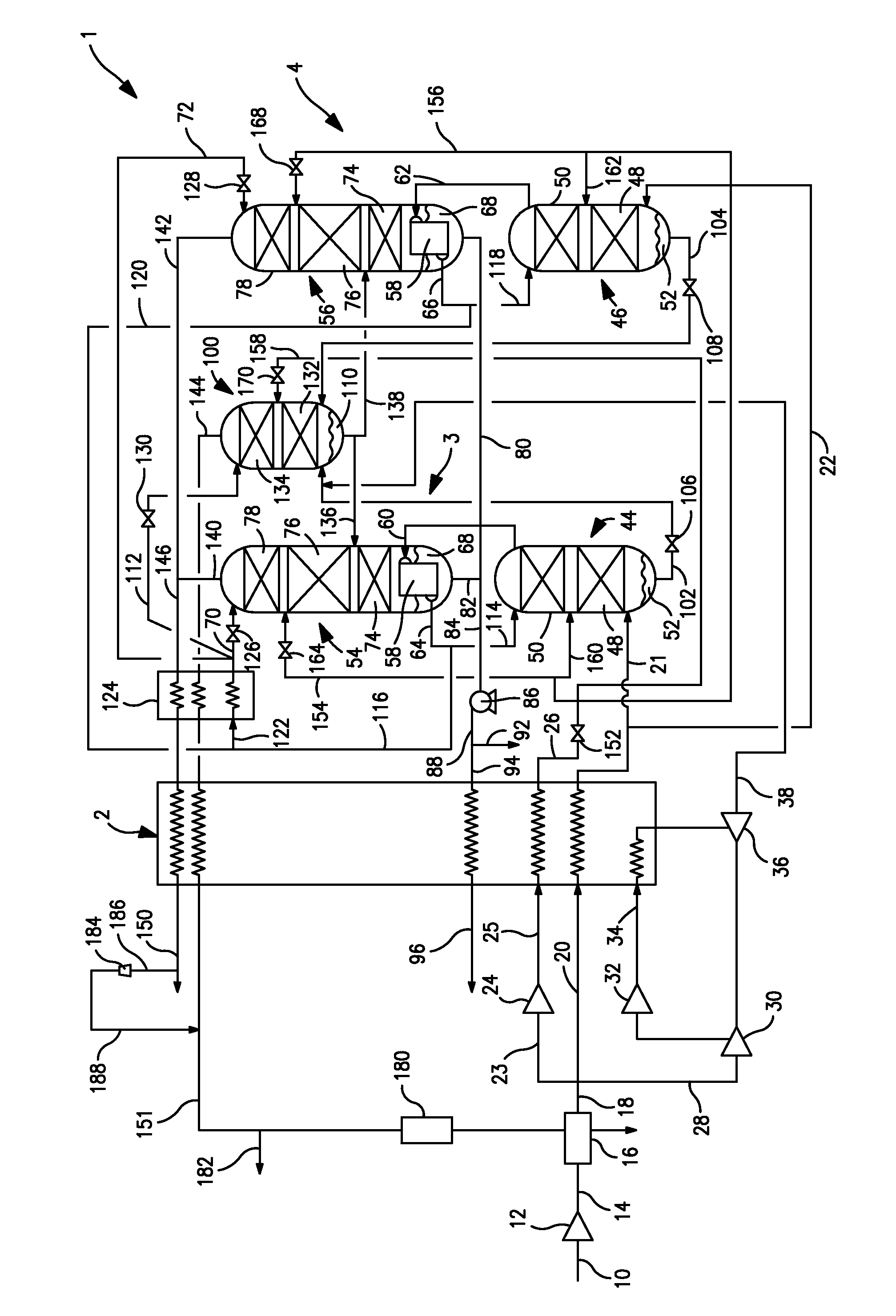

[0027]With reference to the FIGURE, a cryogenic rectification installation 1 is illustrated that is designed to separate air and thereby to produce an oxygen product. Cryogenic rectification installation 1 is provided with a main heat exchanger 2 to cool the air to a temperature suitable for its rectification within air separation units 3 and 4 and thereby produce an oxygen product that is discharged from the main heat exchanger 2 as an oxygen product stream 96 and a nitrogen product stream 150, to be discussed in more detail hereinafter. It is understood that air separation unit 4 as well as other possible air separation units that would be operatively associated with an auxiliary column 100, also to be discussed in more detail hereinafter, are optional in that the present invention could be practiced with a single air separation unit 3.

[0028]The air to be separated is introduced into apparatus 1 as an air stream 10 that is compressed in a main compressor 12 to produce a main compr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com