Fluid end

a technology of fluid end and pump, which is applied in the direction of pump components, positive displacement liquid engines, liquid fuel engine components, etc., can solve the problems of limiting the pressure rating of the reservoir, affecting the economic production of hydrocarbons, and affecting the use of the reservoir, so as to achieve the effect of ensuring the use and being easy to manufactur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

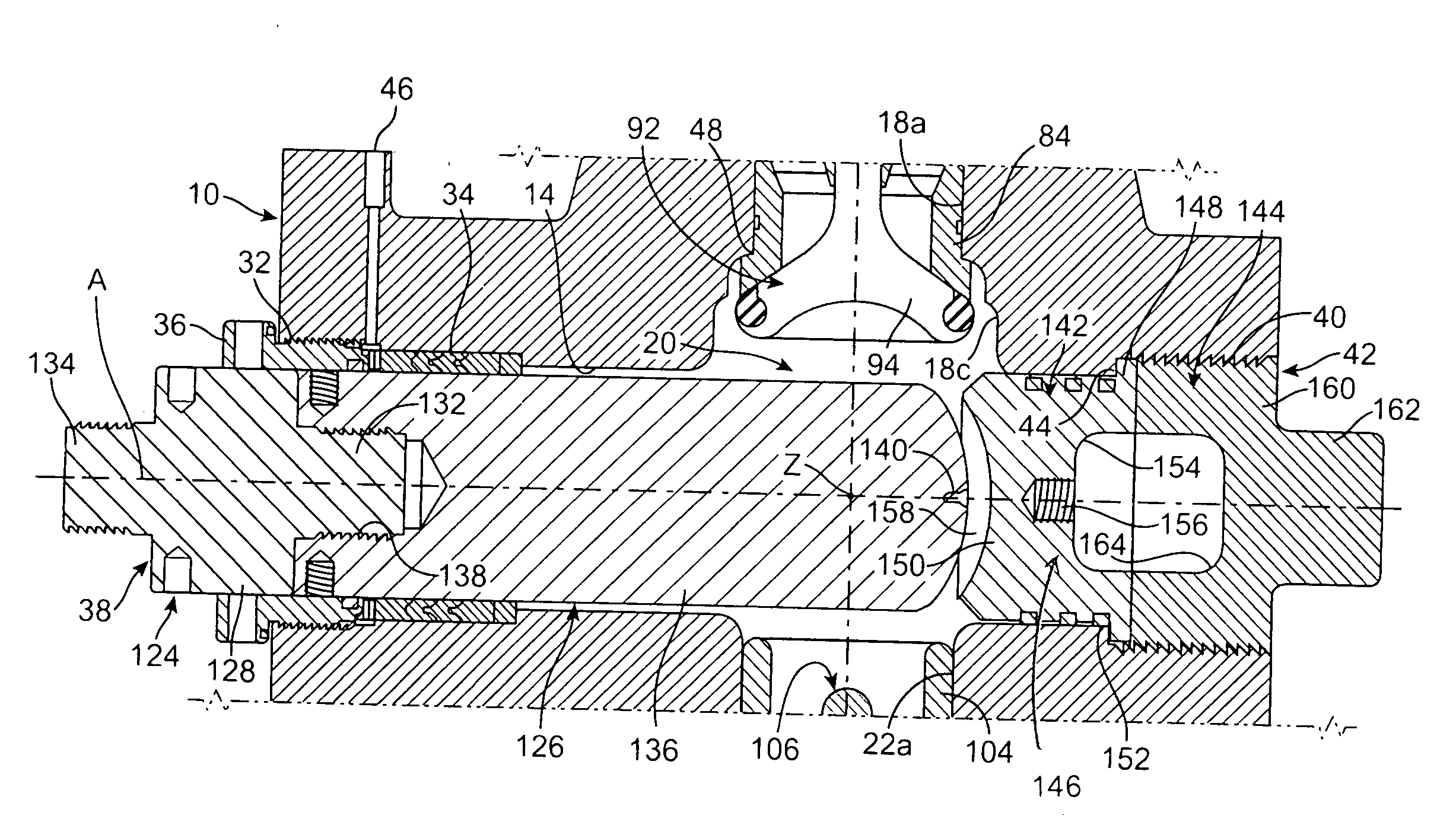

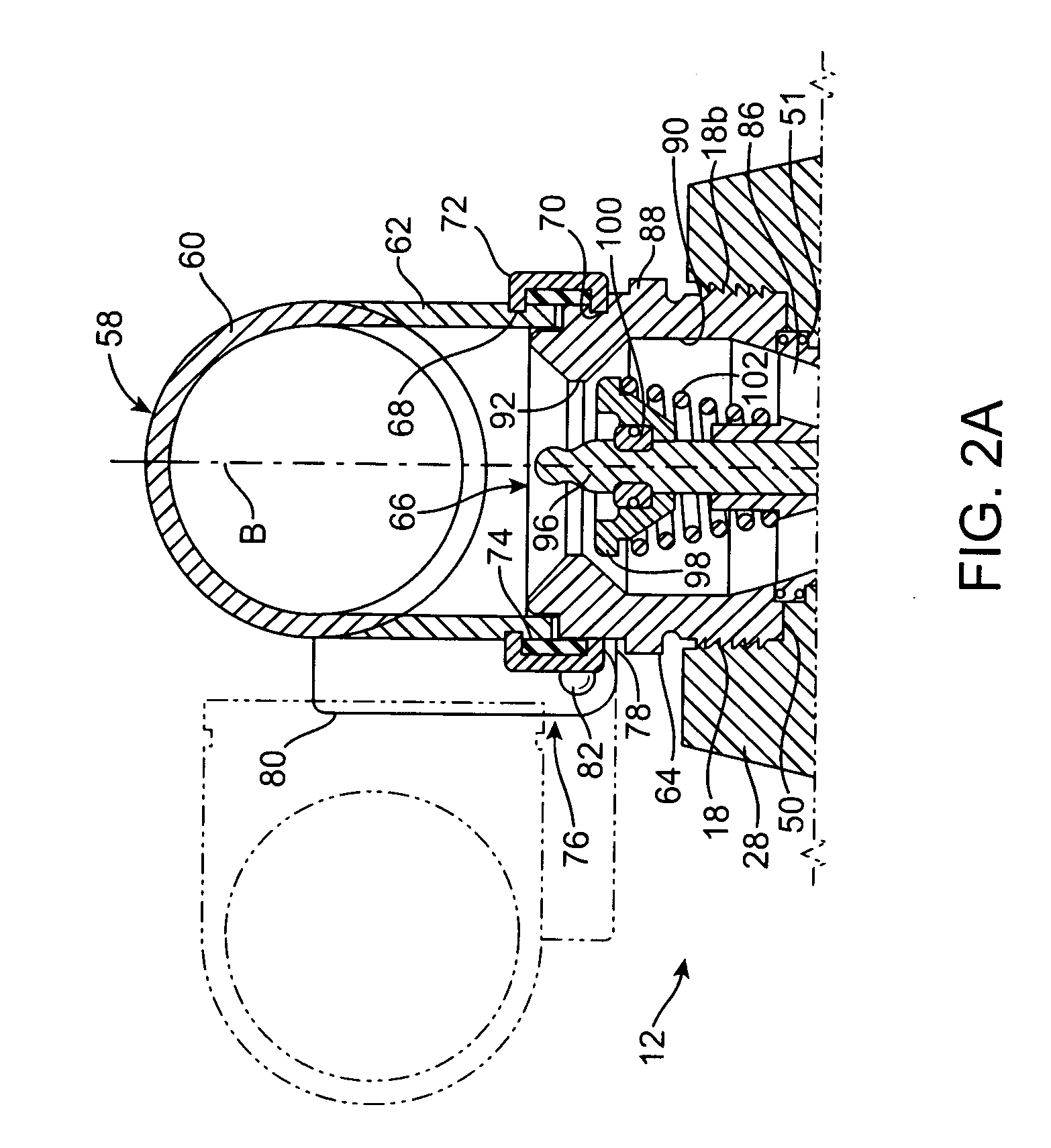

[0017]Referring now to the FIGS., the body 10 of my fluid end 12 is shown. Body 10 has a horizontal, plunger passage 14 that extends from its front to its back. Body 10 also has a horizontal, outlet passage 16 that extends from one of its sides to the other and that is positioned beneath, and oriented at right angles to, plunger passage 14. A suction passage 18 extends vertically downward from the top of body 10 to intersect plunger passage 14 and to define a pumping chamber 20 at the point of intersection. A discharge passage 22 extends vertically downward from pumping chamber 20 to the bottom of body 10 and past outlet passage 16. A horizontal, connector passage 24 places discharge passage 22 and outlet passage 16 in fluid communication with one another.

[0018]Body 10 is a metallic block, a machined forging. To lower its weight and increase its strength, body 10 is provided with a plunger section 26 of reduced height that contains the outer end of plunger passage 14 and is adapted ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com