Method of synthesizing metal -based composite material by melt reaction in coupling magnetic field and ultrasonic field

a composite material and magnetic field technology, applied in the field of composite material synthesis, can solve the problems of difficult control of the reaction process, easy growth, uneven distribution, etc., and achieve the effect of improving the thermodynamic conditions of in-situ reaction and improving the dynamic conditions of synthesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

Preparing Particle Reinforced Al Matrix Composite Material (Al3Zr(s)+ZrB2(s)) in Coupling High-Power Pulse Magnetic Field and Ultrasonic Field

[0041]Raw material: metal matrix: pure Al; reaction salt: K2ZrF6+KBF4 power, refined deaerating agent and slag skimming agent.

[0042]The preparation comprises two steps:

[0043](1) Melting metal and preparing powder:

[0044]Melting 50 g of pure Al in a 60 kW resistance furnace till the temperature raises to 900° C., and then carrying out deaeration and slag skimming Fully drying the reagents at 250° C.-300° C., in which K2ZrF6+KBF4 is ground into fine powder (particle size is less than 200 mesh) and packaged by an aluminum foil for use after weighing, and the weight of the added K2ZrF6+KBF4 powder being 20 percents of the weight of metal.

[0045](2) Synthesizing composite material melt by in-situ reaction:

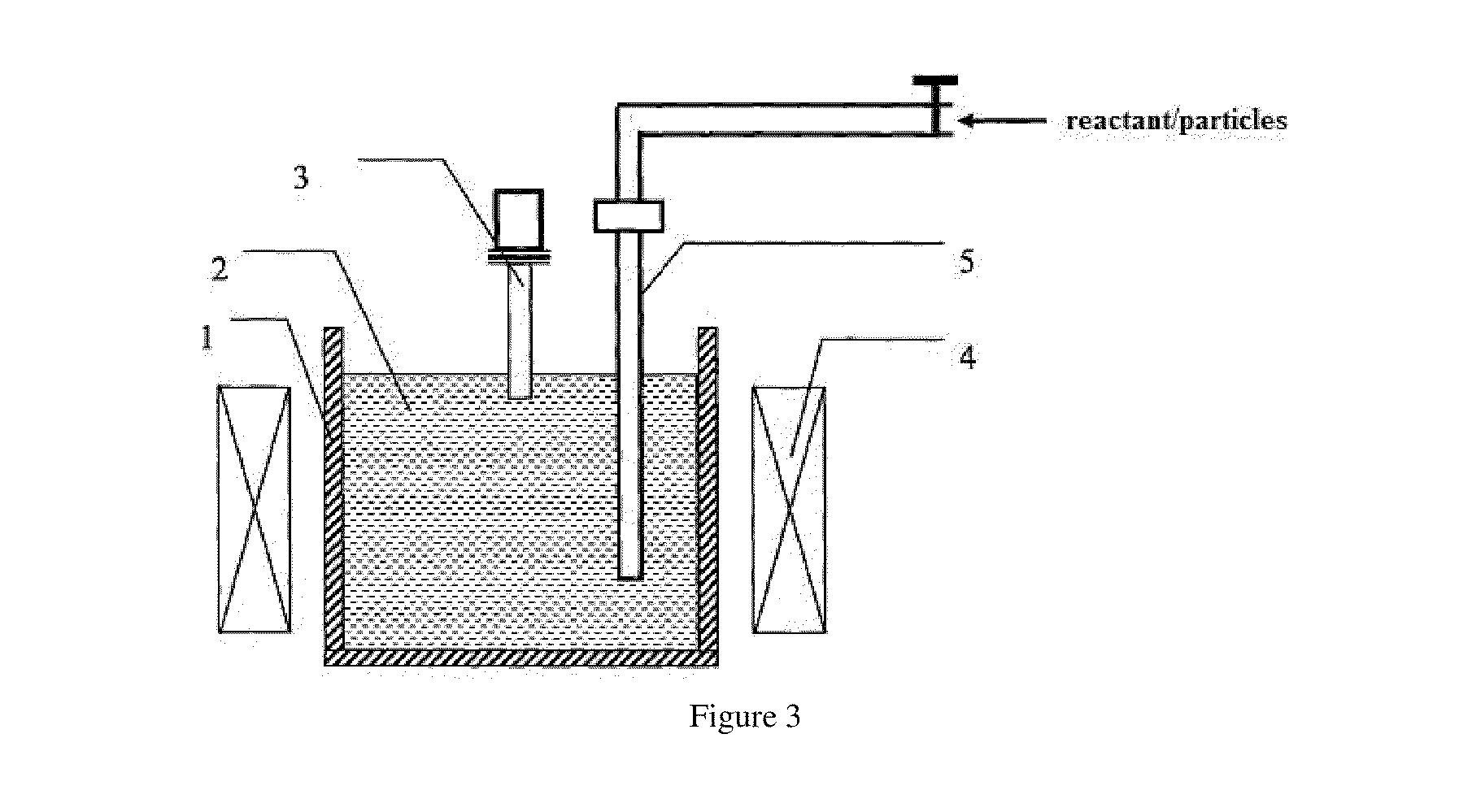

[0046]Refined metal liquid in accordance with reaction starting temperature (900° C.), compressing K2ZrF6+KBF4 into aluminum liquid in a melt pot b...

embodiment 2

Preparing Particle Reinforced Al Matrix Composite Material (Al3Zr(s)+ZrB2(s)) in Coupling High-Frequency Oscillating Magnetic Field and Ultrasonic Field

[0048]Raw material: metal matrix: pure Al; reaction salt: K2ZrF6+KBF4 power, refined deaerating agent and slag skimming agent.

[0049]The preparation comprises two steps:

[0050](1) Melting metal and preparing powder:

[0051]Melting 50 Kg of pure Al in a 60 kW resistance furnace till the temperature raises to 900° C., and then carrying out deaeration and slag skimming; fully drying the reagents at 250° C.-300° C., in which K2ZrF6+KBF4 is ground into fine powder (particle size is less than 200 mesh) and put into an injecting pot after weighing, and the weight of the added K2ZrF6+KBF4 powder being 20 percents of the weight of metal.

[0052](2) Synthesizing composite material melt by in-situ reaction:

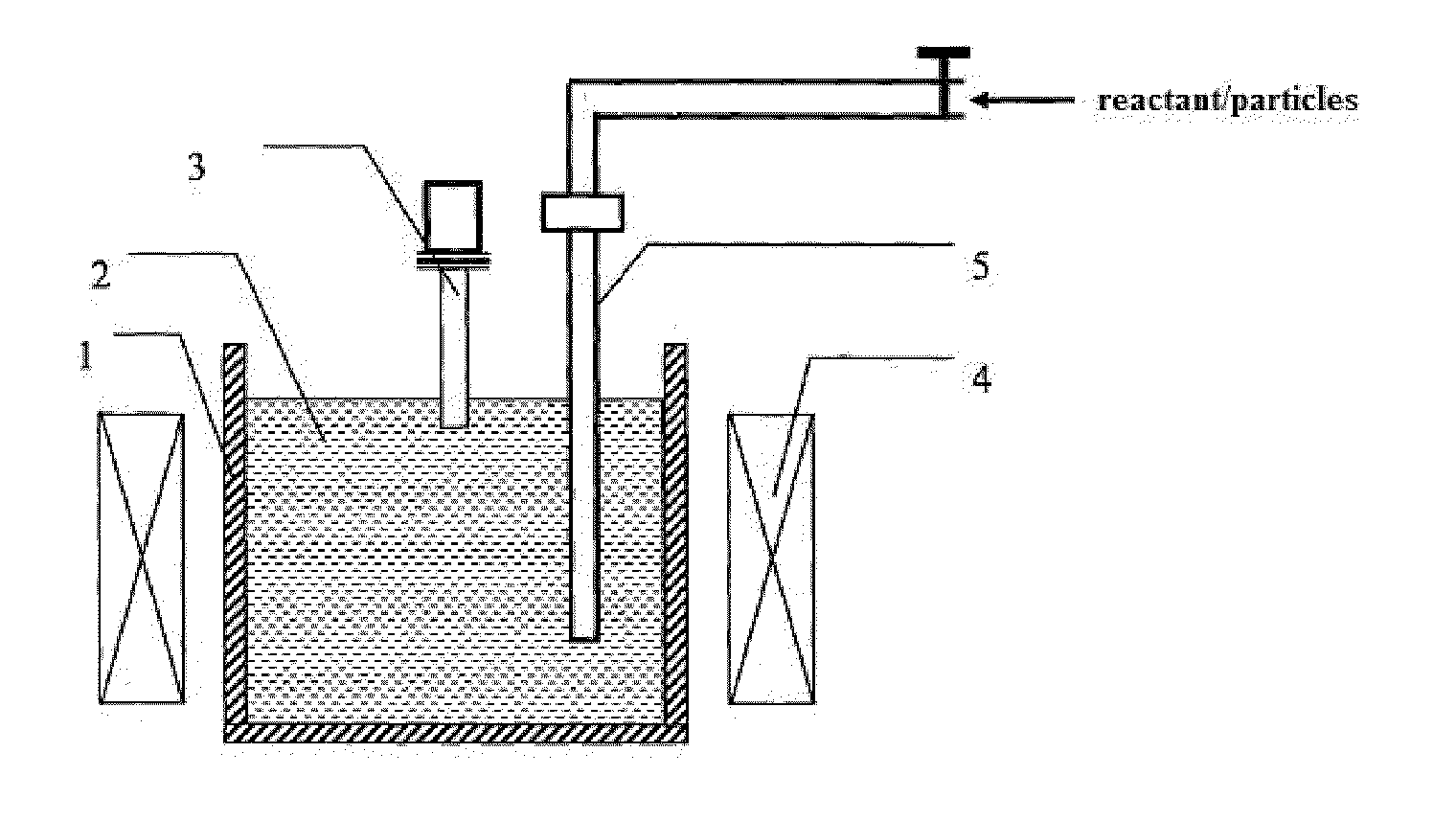

[0053]A device as shown in FIG. 2, pouring refined metal liquid in accordance with requirement of starting temperature (900° C.) into a thermal-in...

embodiment 3

Preparing Particle Reinforced Al Matrix Composite Material (Al3Zr(s)+Al2O3(s)) in coupling low-frequency stirring magnetic field and ultrasonic field

[0055]Raw material: metal matrix: pure Al; solid powder: industrial zirconium carbonate (Zr(CO3)2) power, refined deaerating agent and slag skimming agent.

[0056]The preparation comprises two steps:

[0057](1) Melting metal and preparing powder:

[0058]Melting 50 Kg of pure Al in a 60 kW resistance furnace till the temperature raises to 900° C., and then carrying out deaeration and slag skimming; fully drying the reagents at 250° C.-300° C., in which (Zr(CO3)2) is ground into fine powder (particle size is less than 200 mesh) and put into an injecting pot, and the weight of the added (Zr(CO3)2) powder being 20 percents of the weight of metal.

[0059](2) Synthesizing composite material melt by in-situ reaction:

[0060]Pouring refined metal liquid in accordance with requirement of reaction starting temperature (900° C.) into a thermal-insulated com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com