Lower emergency marine riser(LEMR) and method of installation preventing catastrophic product spills

a technology of emergency riser and product, which is applied in the direction of drilling pipes, drilling well accessories, sealing/packing, etc., can solve the problems of many backup systems in place, few means of controlling the disastrous and uncontrolled output of oil, and many failures of products from the sea floor. , to achieve the effect of quick replacement of failed bops, easy installation and convenient manufactur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

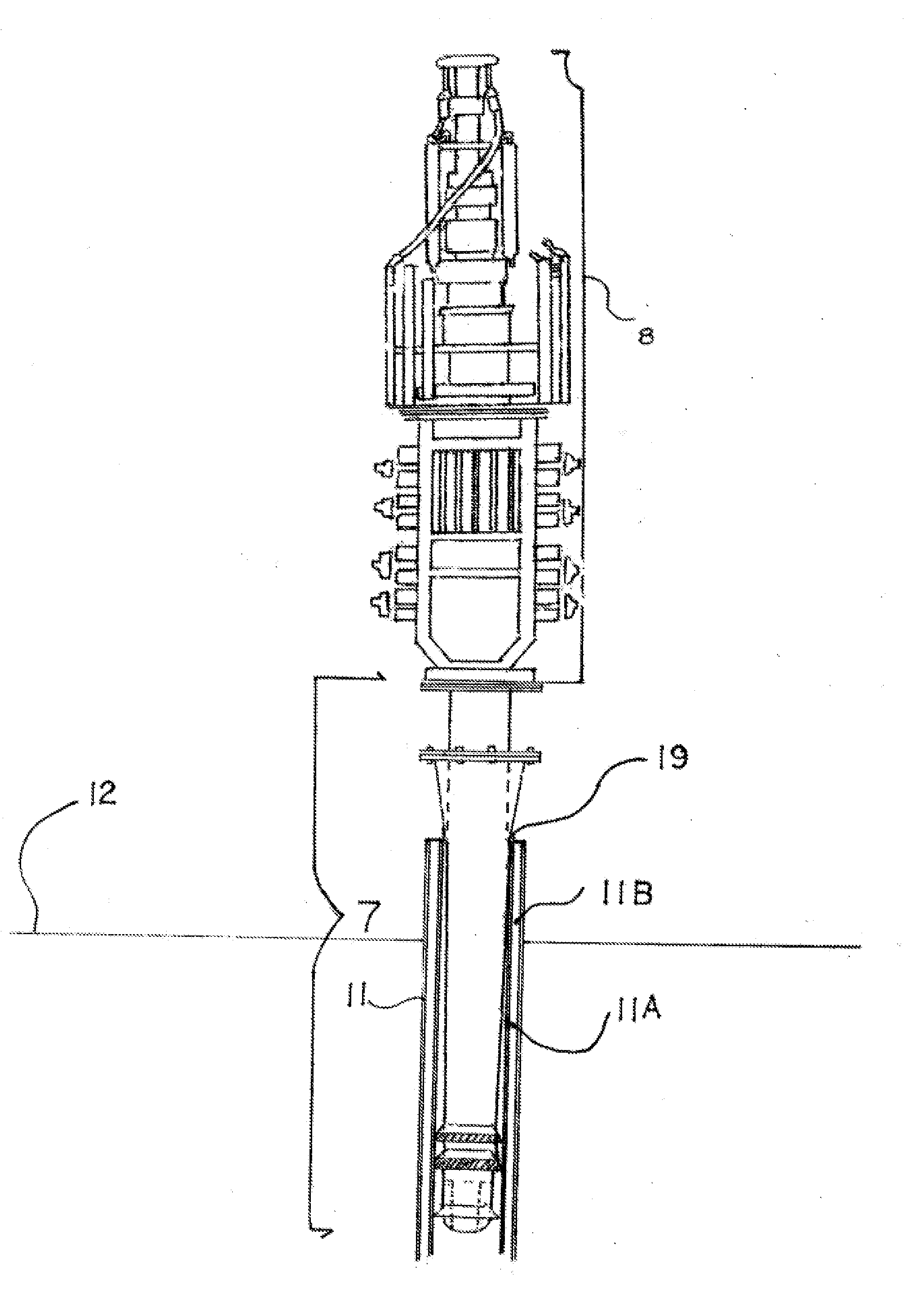

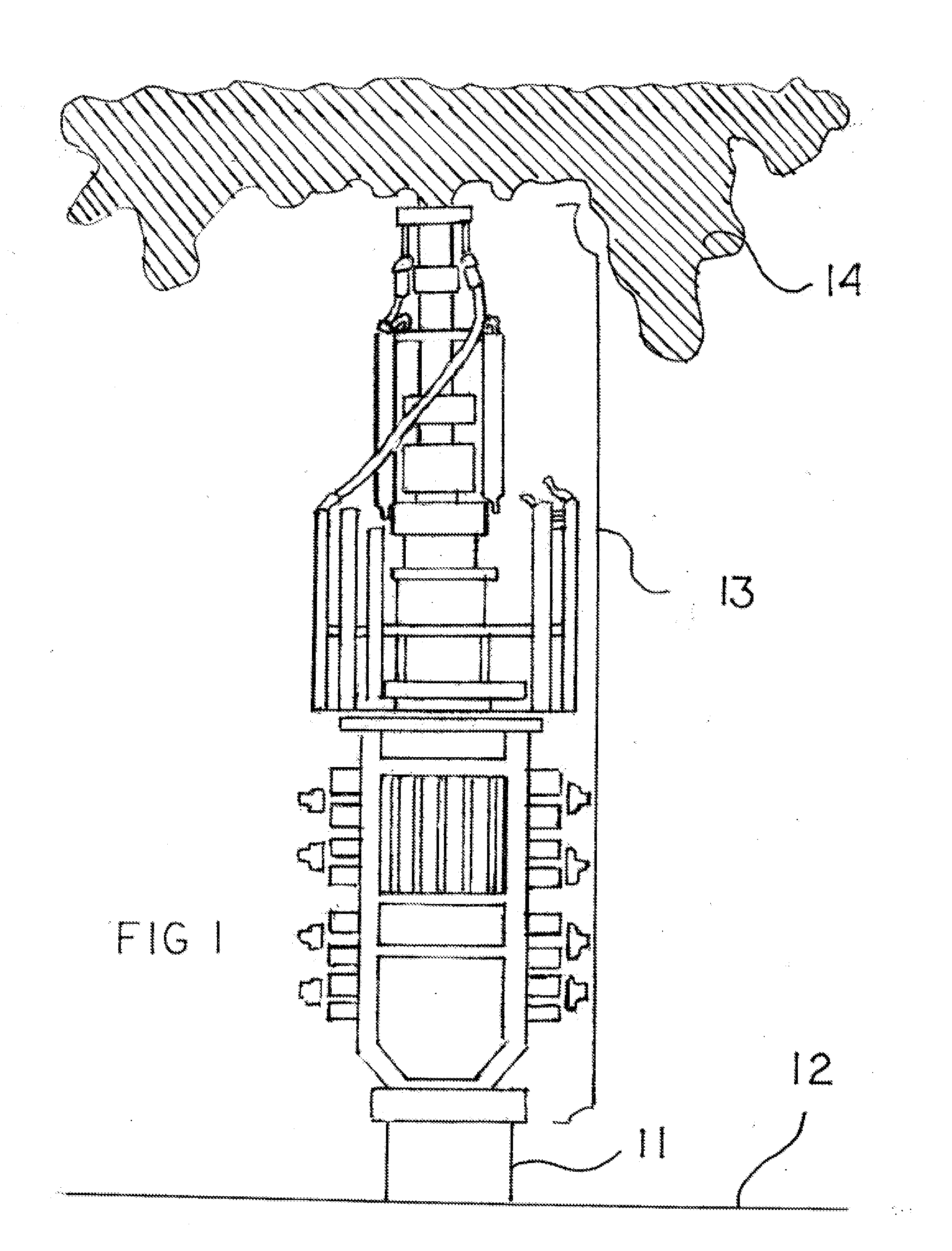

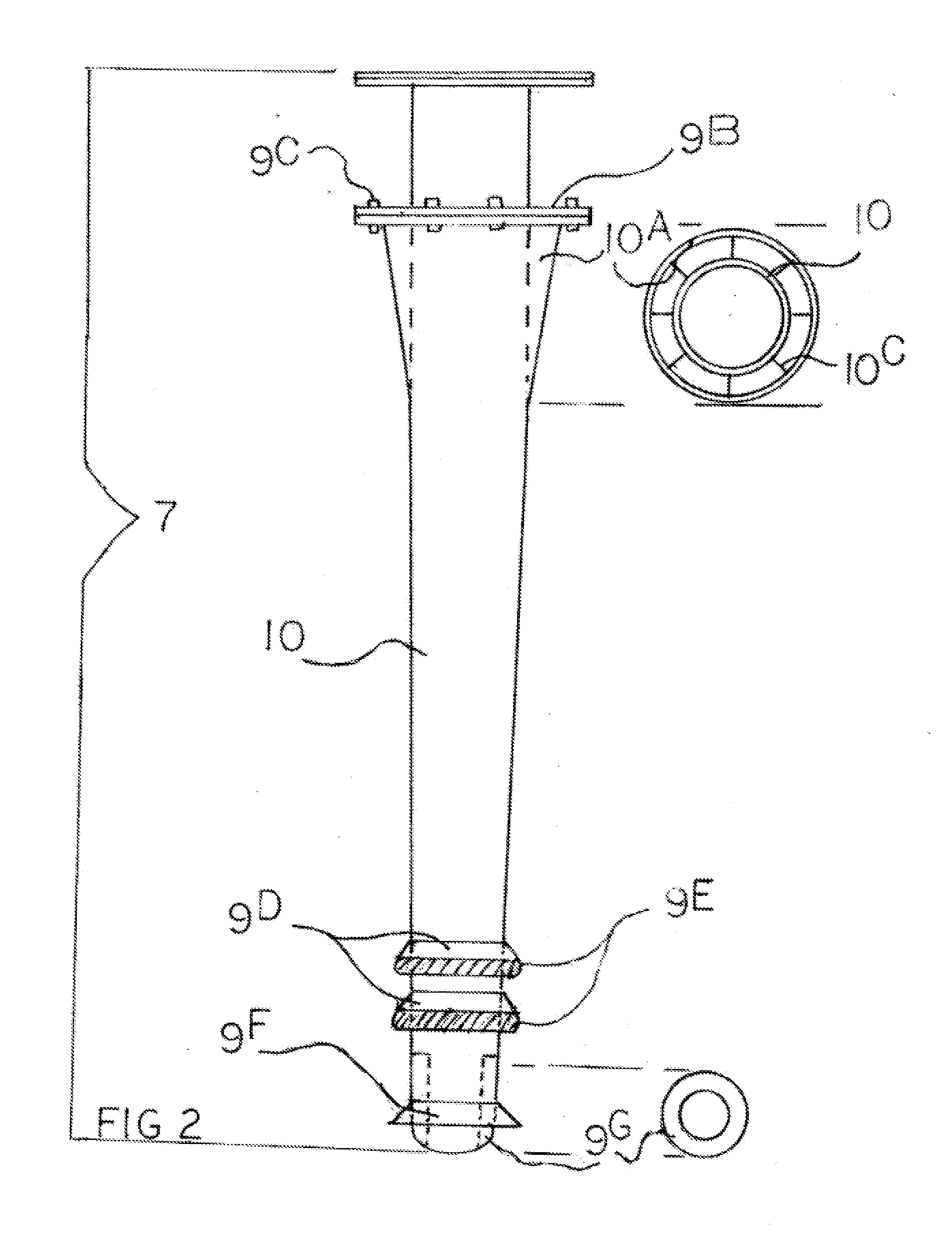

[0029]Illustrated in FIG. 1, is the now infamous defective Blow Out Preventer (BOP) found within a Lower Marine Riser Package (LMRP) 13 is connected to the wellhead 11 on the seafloor 12 as product 14 uncontrollably spills into the gulf. My unique Lower Emergency Marine Riser or LEMR 7 attaches to the base of the LMRP 8. LEMR is comprised of a specialized conduit or metal piping 10 having an upper coupling or flange 9A to connect to a LMRP, normally where the LMRP would be directly slipped over a wellhead 11 and can be welded as a slip in coupling or bolted with the flange 9A. Just below the coupling or flange 9A is an emergency rapidly disconnecting connector or flange 9B having explosive bolts 9C or other quick disconnecting application. Just under the backup flange 9B is a tapered shroud 10A which is a large, reinforced downwardly exaggerated, and somewhat elongated tapered cone of sorts, welded just under the emergency flange 9B and wraps around the upper portion of the speciali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com