Ground flare

a flare and ground technology, applied in the field of ground flares, can solve the problems of high cost of refractory material that forms the incinerator main body, unsuitable flammable exhaust gas for gas turbine fuel, and high cost of air blower b>2/b>, and achieve the effect of preventing resonating and vibrating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

Shifting Natural Frequency to Higher Pitch

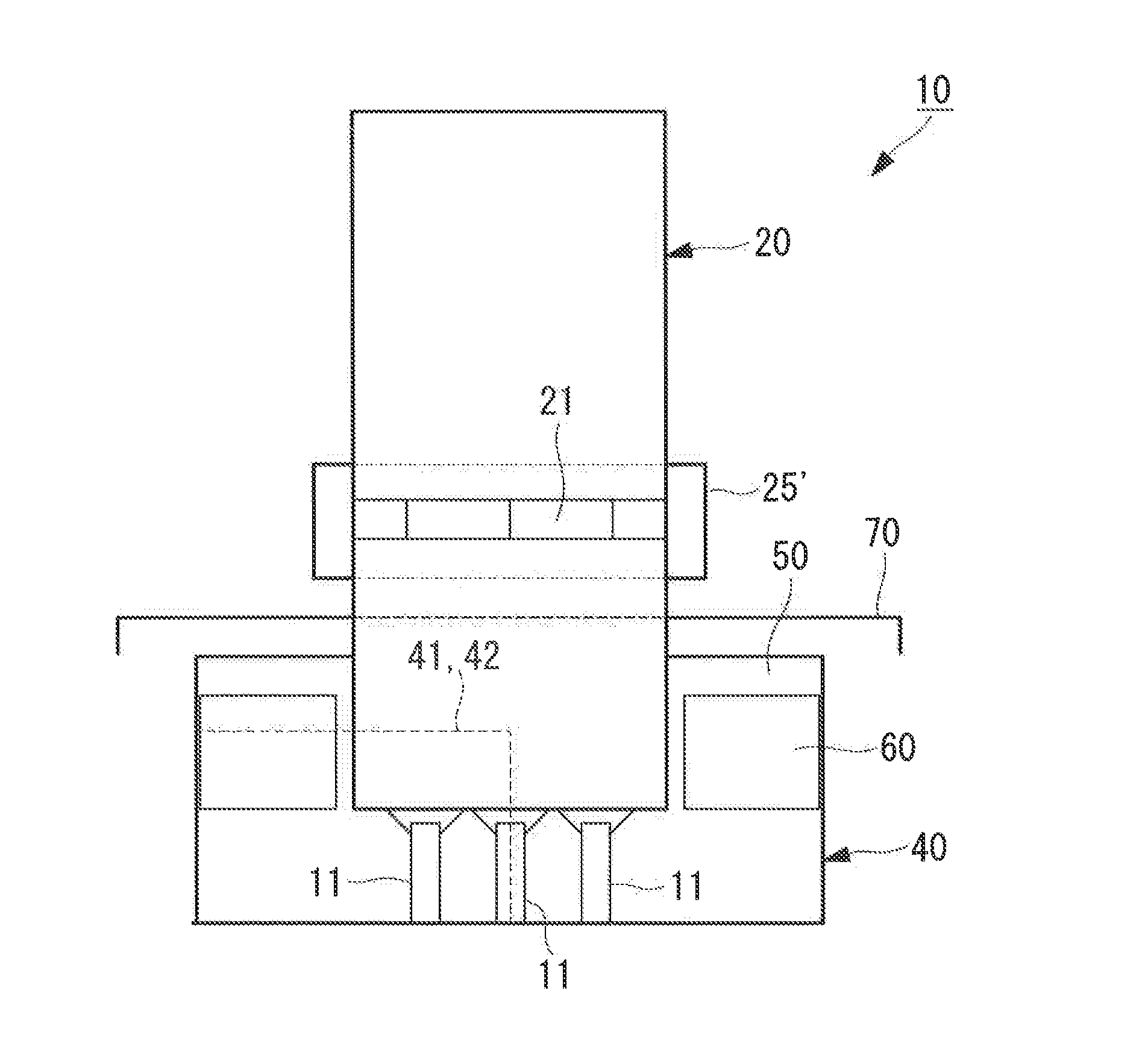

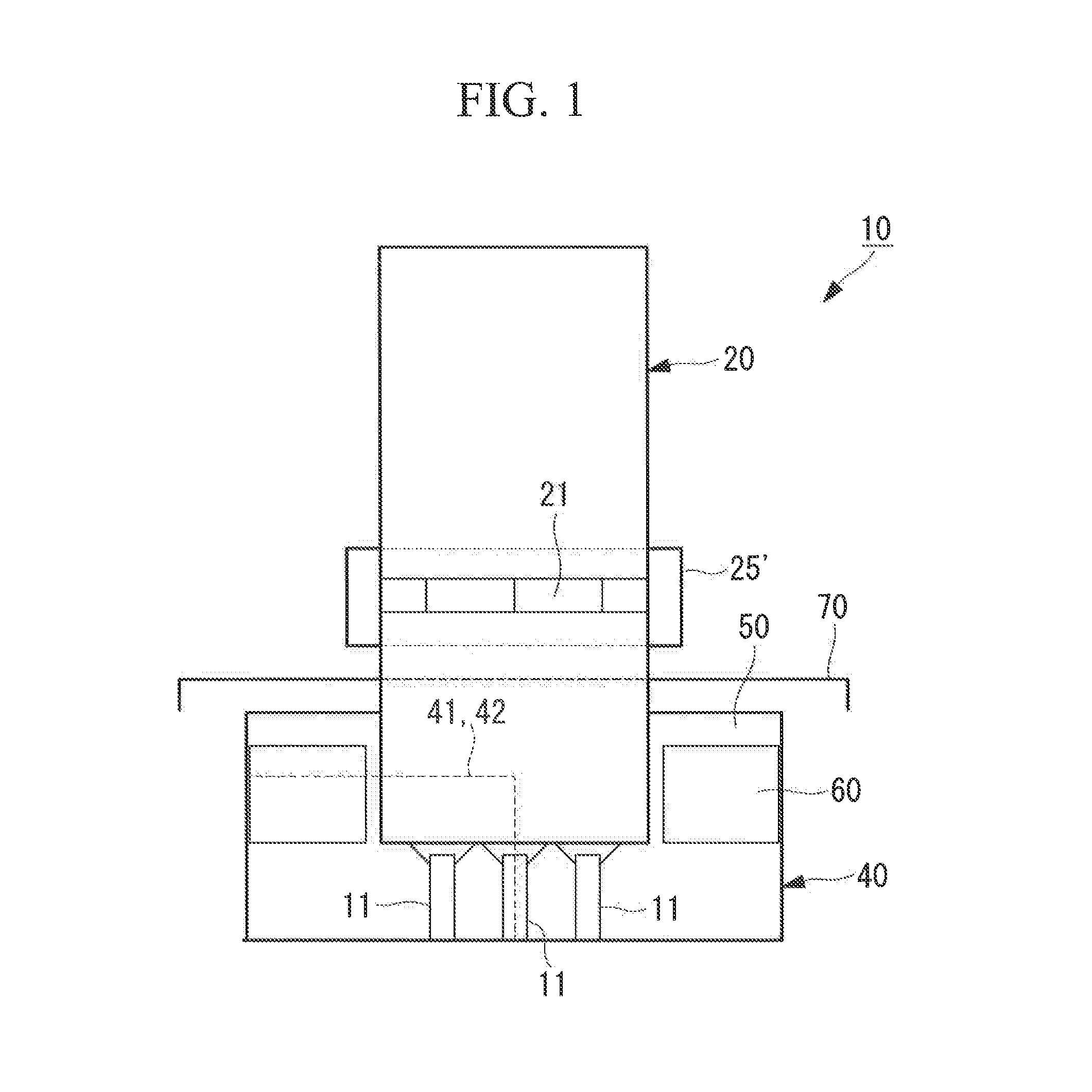

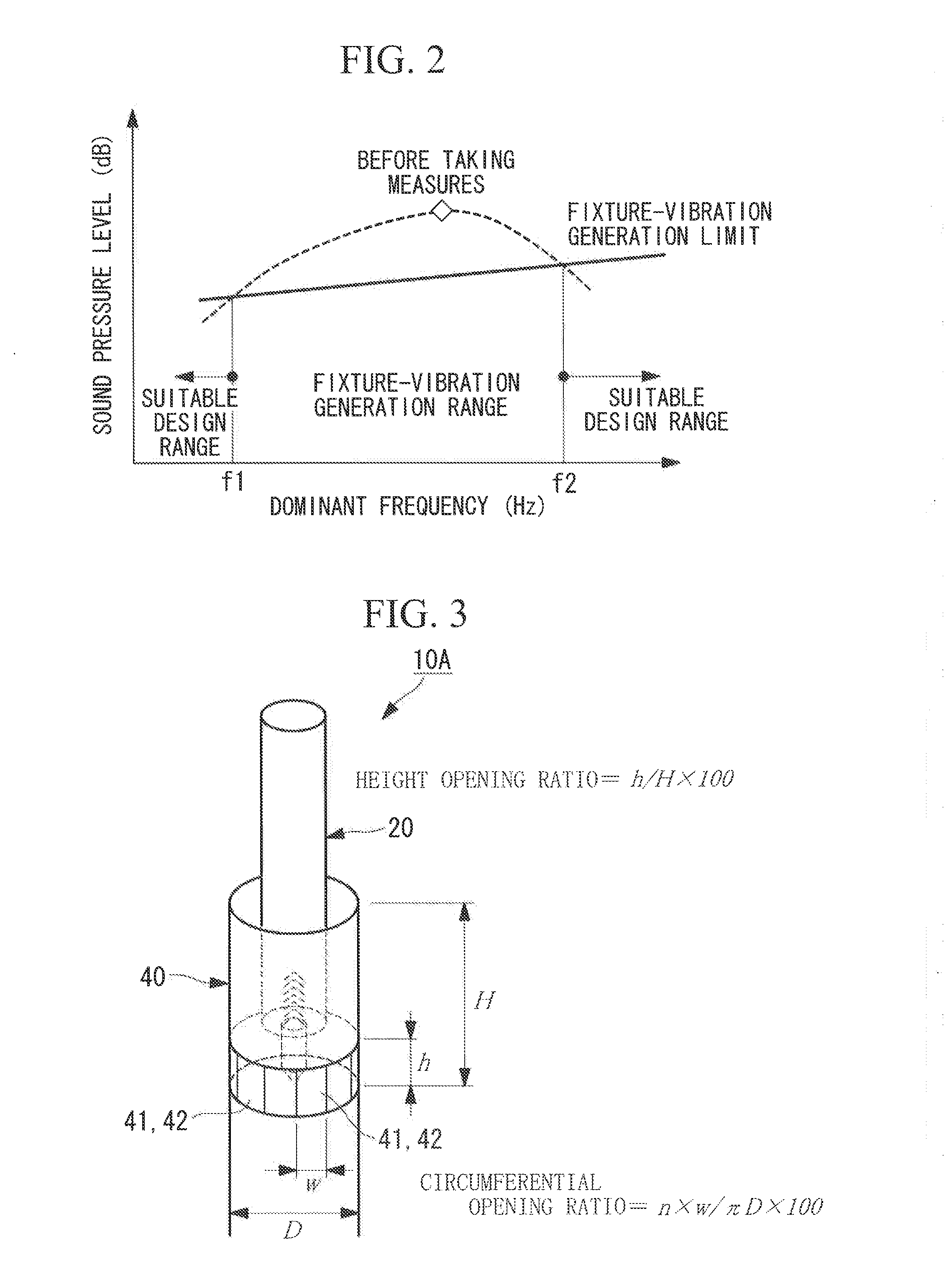

[0085]An embodiment described below shifts the natural frequency of a low-frequency sound generated from the ground flare tower to a higher pitch to prevent resonance with the natural frequency of burner combustion.

[0086]A ground flare 10A shown in FIG. 3 changes the natural frequency by providing windbreak openings 41 at part of the windbreak 40 and closing the windbreak openings 41 with non-wall sheets 42. That is, after part of the windbreak 40 is cut out to form the windbreak openings 41, the non-wall sheets 42 are mounted over the windbreak openings 41 to close them. The non-wall sheets 42 used here break the wind and prevent an audible sound from leaking out, and also prevent, flames from being viewed from the outside through the windbreak openings 41, and should be formed of a material, that does not function as a wall against a low-frequency sound.

[0087]The windbreak openings 41 provided by removing part of the windbreak 40 are desir...

second embodiment

Shift of Natural Frequency to Lower Pitch

[0116]An embodiment described below shifts the natural frequency of a low-frequency sound generated from the ground flare tower to a lower pitch to prevent resonance with the natural frequency of burner combustion. That is, as shown in FIG. 12A to FIG. 15, the windbreak portion is extended to decrease a frequency to be generated, and the sound pressure level of a low-frequency noise is reduced.

[0117]In this method, the burner position ç′ of the burners 11, which is found using FIG. 15 and [Formula 1] shown below, falls within a range of 2.2 to 3.4 from the inlet Wi of a windbreak 40A with respect to a length (entire guide length) including the chimney 20 and the windbreak 40A.

ϛ′=(1-L1+0.6d1c2×f)×4(Formula1)[0118]L1: chimney height (m)[0119]d1: chimney diameter (m)[0120]c: velocity of sound (m / s)[0121]f: measured frequency (Hz)

[0122]In. [Formula 1], L1 is chimney height (m), d1 is the diameter of the chimney (m), c is the velocity of sound (m / ...

third embodiment

Multiple Towers

[0127]An embodiment described below adopts multiple ground flare towers and combines towers having different dominant frequencies to reduce the sound pressure level.

[0128]This embodiment is provided with two separated ground flares 10a and 10b so as to satisfy the required capacity, as shown in FIG. 16, for example. In this case, the two separated ground flares 10a and 10b are set so that the respective dominant frequencies differ by changing the chimney lengths of chimneys 20a and 20b; the dominant frequency of the ground flare 10b, having a long air column, produces a low-pitched sound, and the dominant frequency of the ground flare 10a, having a short air column, produces a high-pitched sound. That is, the two ground flares 10a and 10b having different primary frequencies are placed side by side. In this example of separation, both the chimney and the windbreak are separated into two. Reference signs 40a and 40b in the drawing denote windbreaks.

[0129]Disposing the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com