Post-ash sidewall healing

a sidewall and ash technology, applied in the field of post-ash sidewall healing, can solve the problem that the etching process may be easily timed, and achieve the effect of convenient timed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

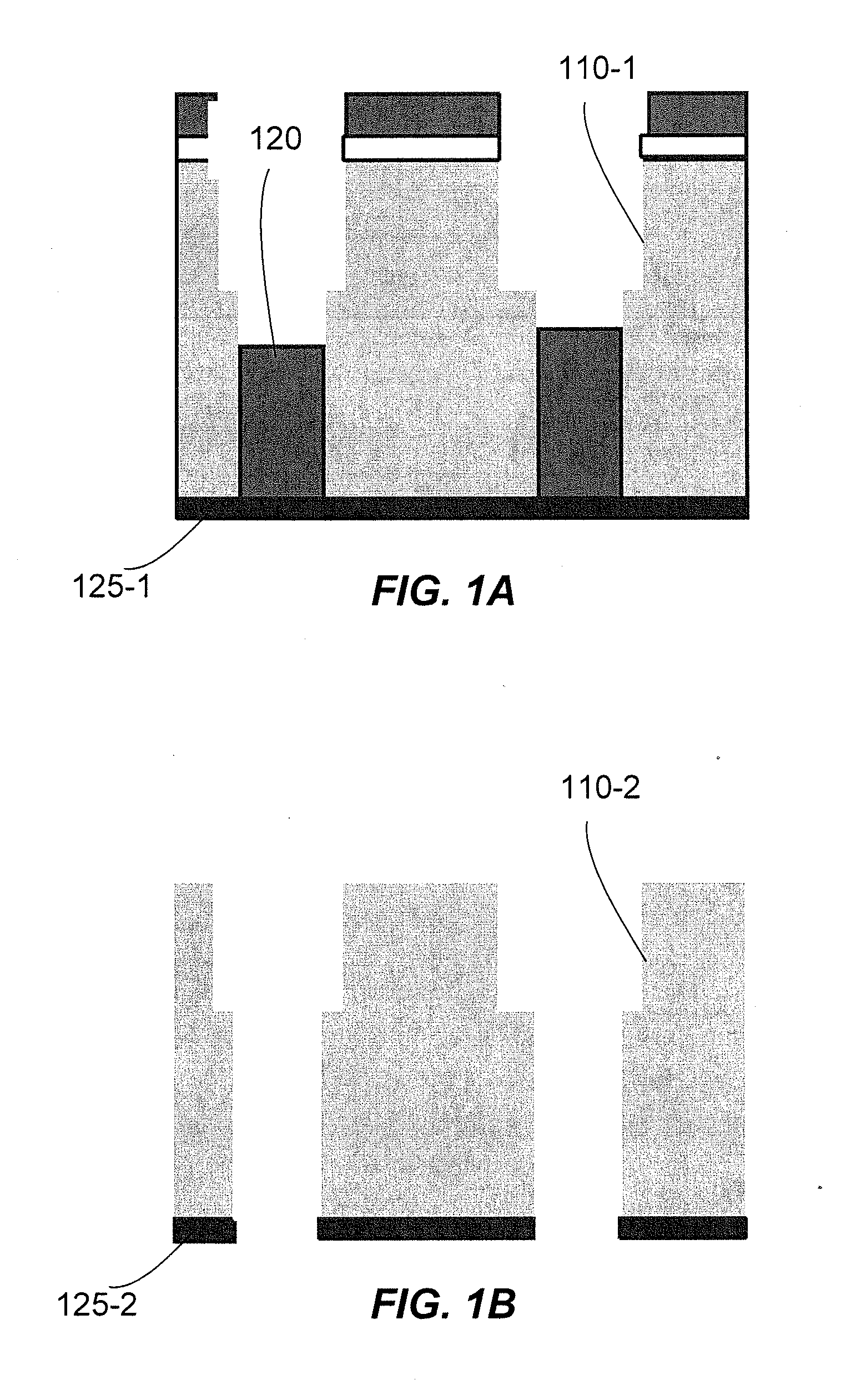

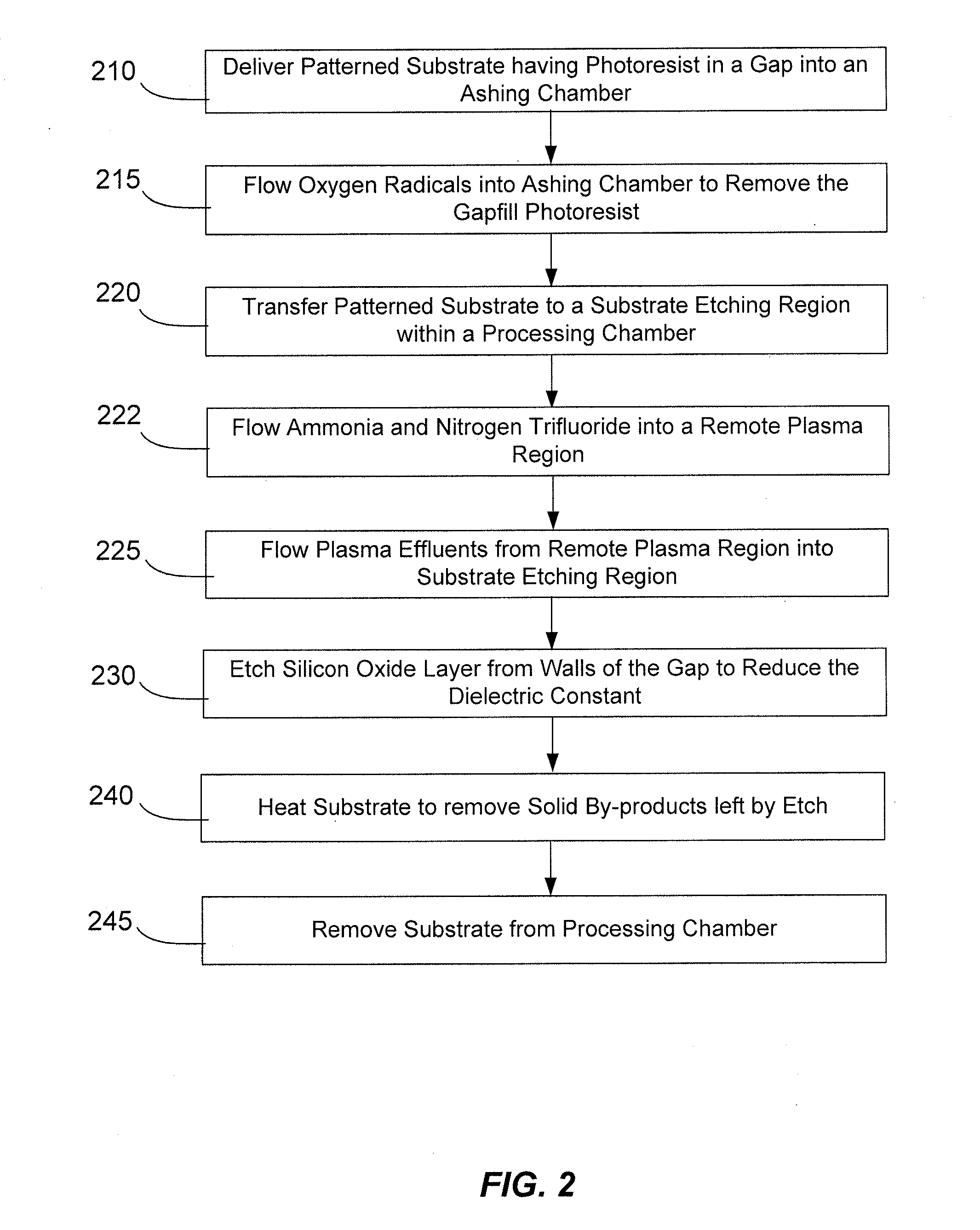

[0015]Methods of decreasing the effective dielectric constant present between two conducting components of an integrated circuit are described. The methods involve the use of a gas phase etch which is selective towards the oxygen-rich portion of the low-K dielectric layer. The etch rate attenuates as the etch process passes through the relatively high-K oxygen-rich portion and reaches the low-K portion. The etch process may be easily timed since the gas phase etch process does not readily remove the desirable low-K portion. Gas phase etches are preferable to liquid buffered oxide etches especially for processing patterned substrates. Gas phase etchants are more easily removed from confined structures than liquid etchants.

[0016]Embodiments of the invention are directed to methods of etching a low-K material on a patterned substrate to increase the effective dielectric constant thereby improving device performance. An exemplary process flow which benefits from methods presented herein...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com