Fan structure

a technology of a fan and a frame, applied in the direction of positive displacement liquid engines, piston pumps, machines/engines, etc., can solve the problems of structural resonance, increased manufacturing costs, and inability to completely prevent structural resonance, so as to strengthen the frame, eliminate cogging torque, and hinder the effect of vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

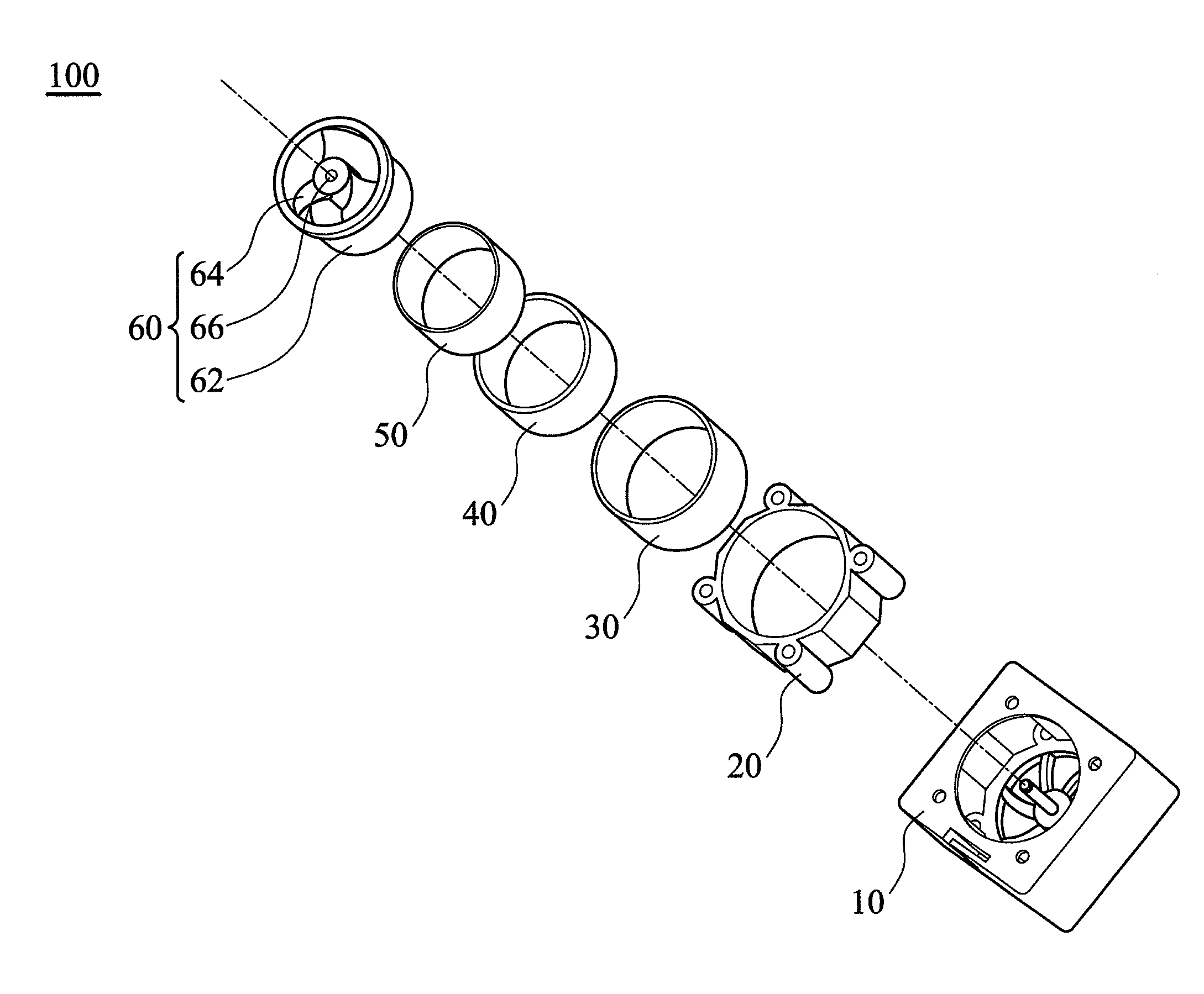

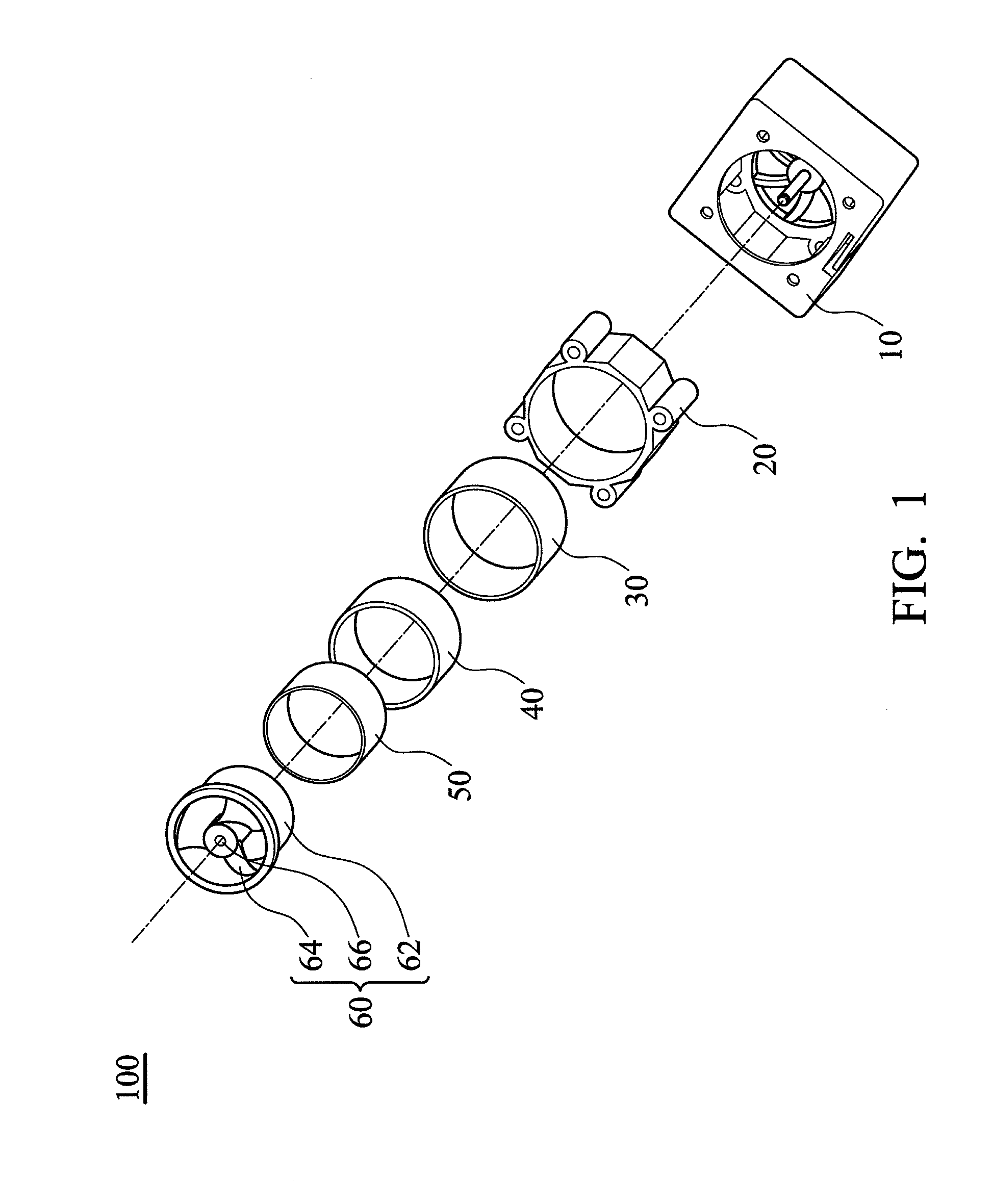

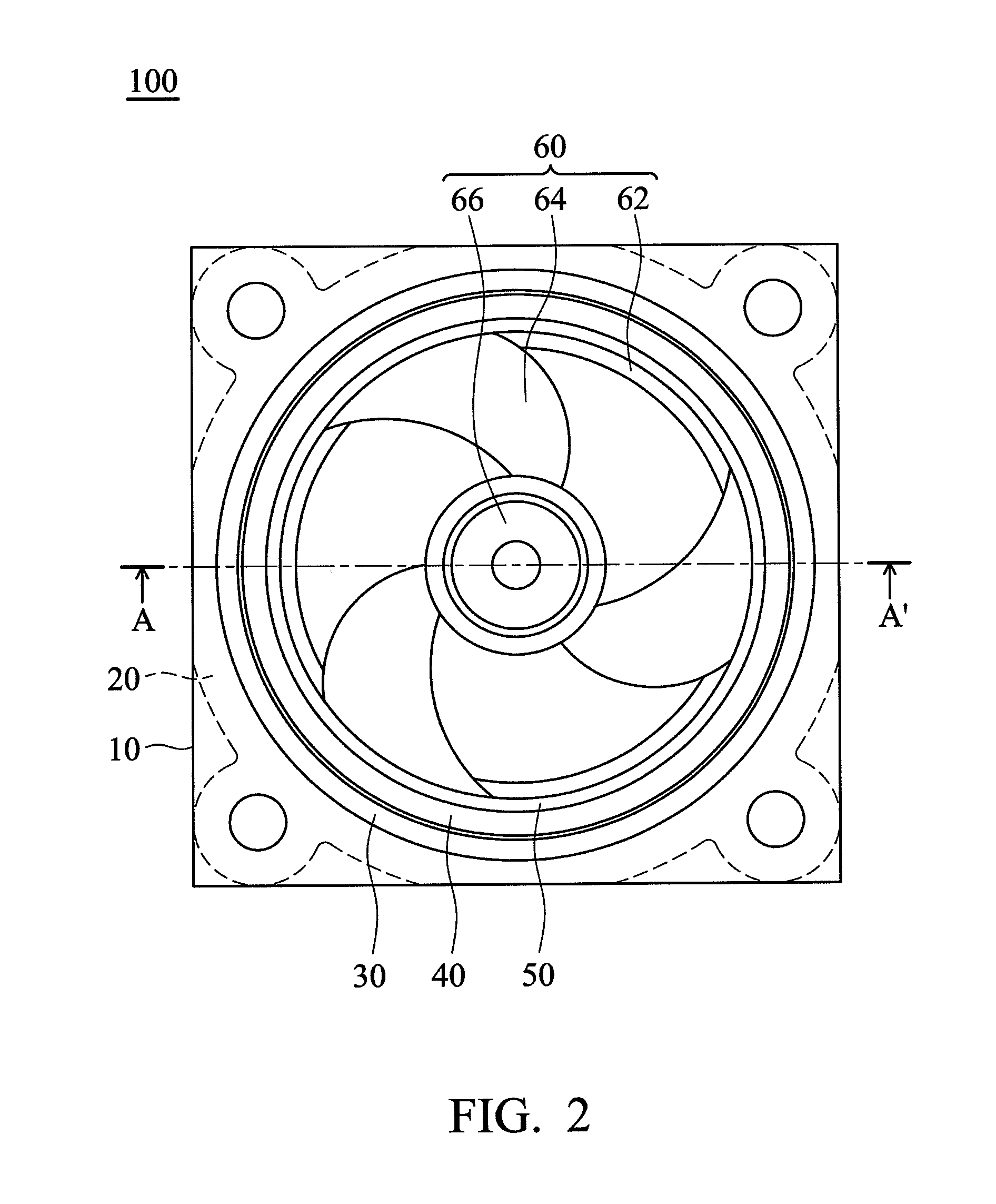

[0038]FIG. 1 is an exploded view of an embodiment of a fan structure of the present invention. FIG. 2 is a plane view of an assembled fan structure according to FIG. 1. FIG. 3 is a cross-sectional view of FIG. 2 along the line AA′. As shown in FIGS. 1, 2 and 3, the fan structure 100 of the present invention includes a frame 10, a silicon steel plate set (permeable element) 20, a coil 30, a permanent magnet 40, an iron ring 50 and a fan 60. The frame 10, the silicon steel plate set 20 and the coil 30 constitute a stator of the fan structure 100, and the permanent magnet 40, the iron ring 50 and the fan 60 are formed as a rotor assembly. The structure of the stator is described below.

[0039]The silicon steel plate set 20 is made from a plurality of arranged silicon steel plates by stamping. After the stamping process, the silicon steel plate set 20 is disposed in a mold of an injection-molding machine. Then, the molding material is injected into the mold to form the frame 10, wherein t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com