Grinding or polishing apparatus and method for operating it

a technology of grinding or polishing apparatus and operating method, which is applied in the direction of grinding/polishing apparatus, grinding machine components, grinding machines, etc., can solve the problems of reducing the penetration resistance of workpieces, insensitivity to power supply failure, and low energy consumption, so as to reduce the setup time and downtime, and the effect of cost-effective operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

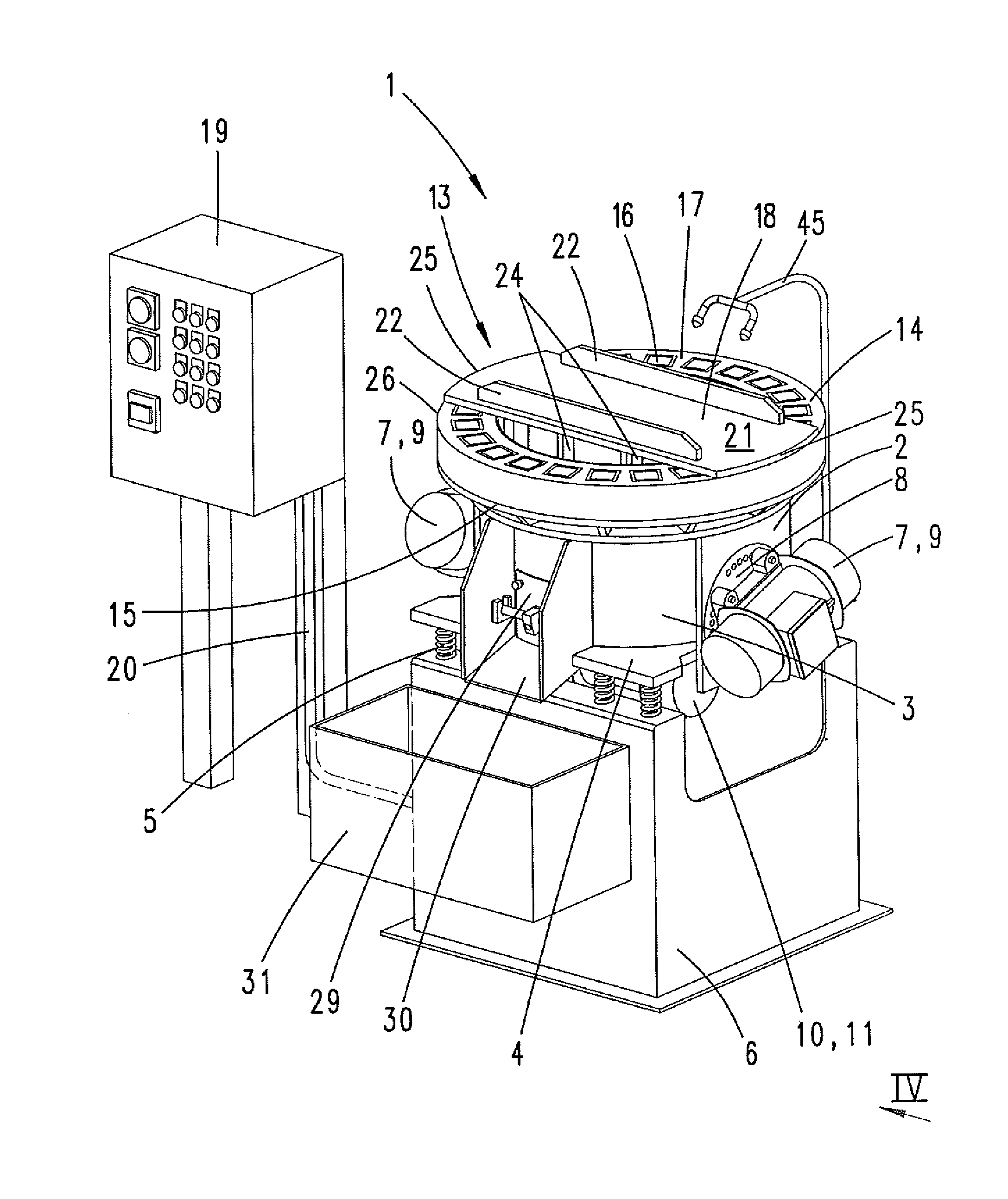

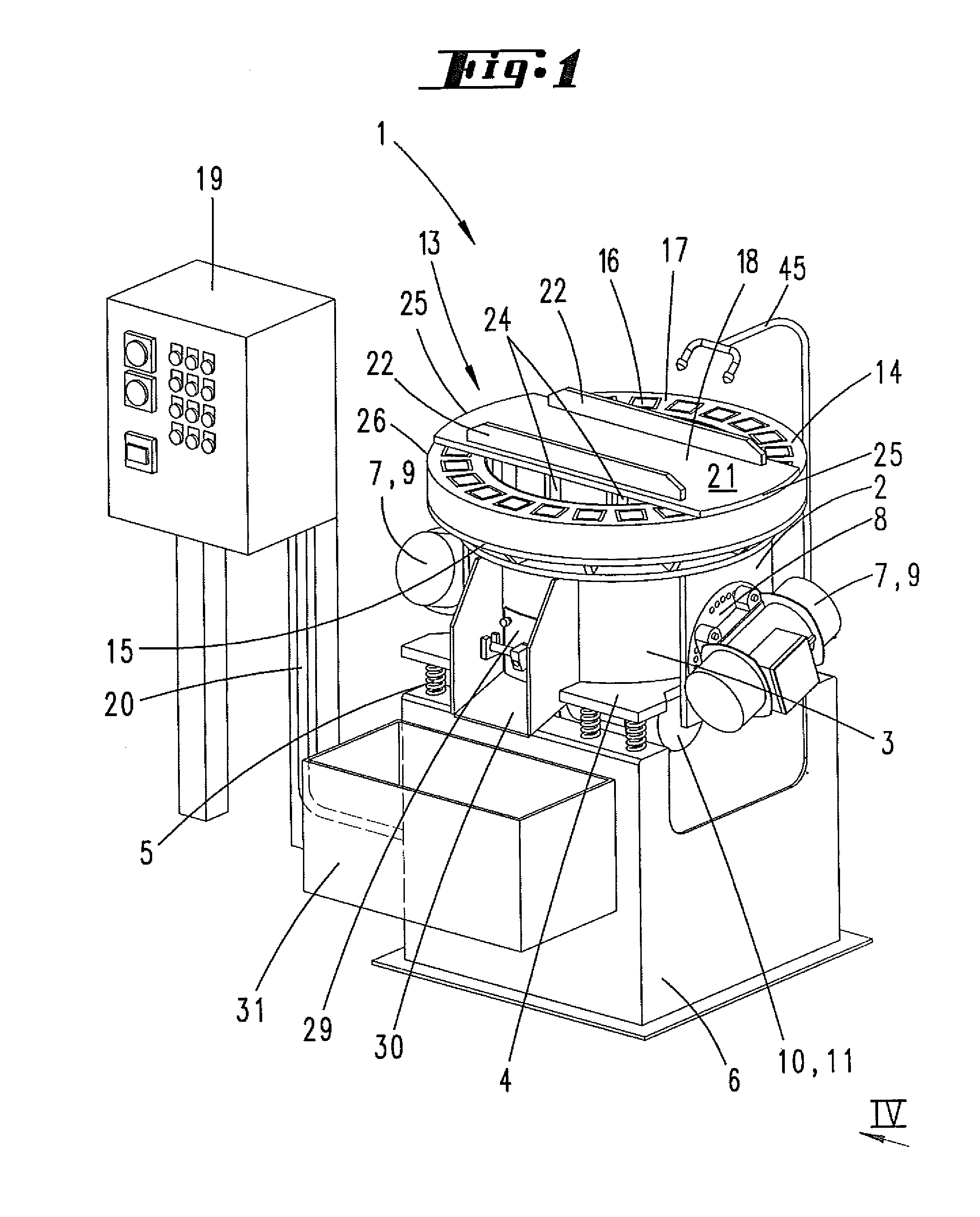

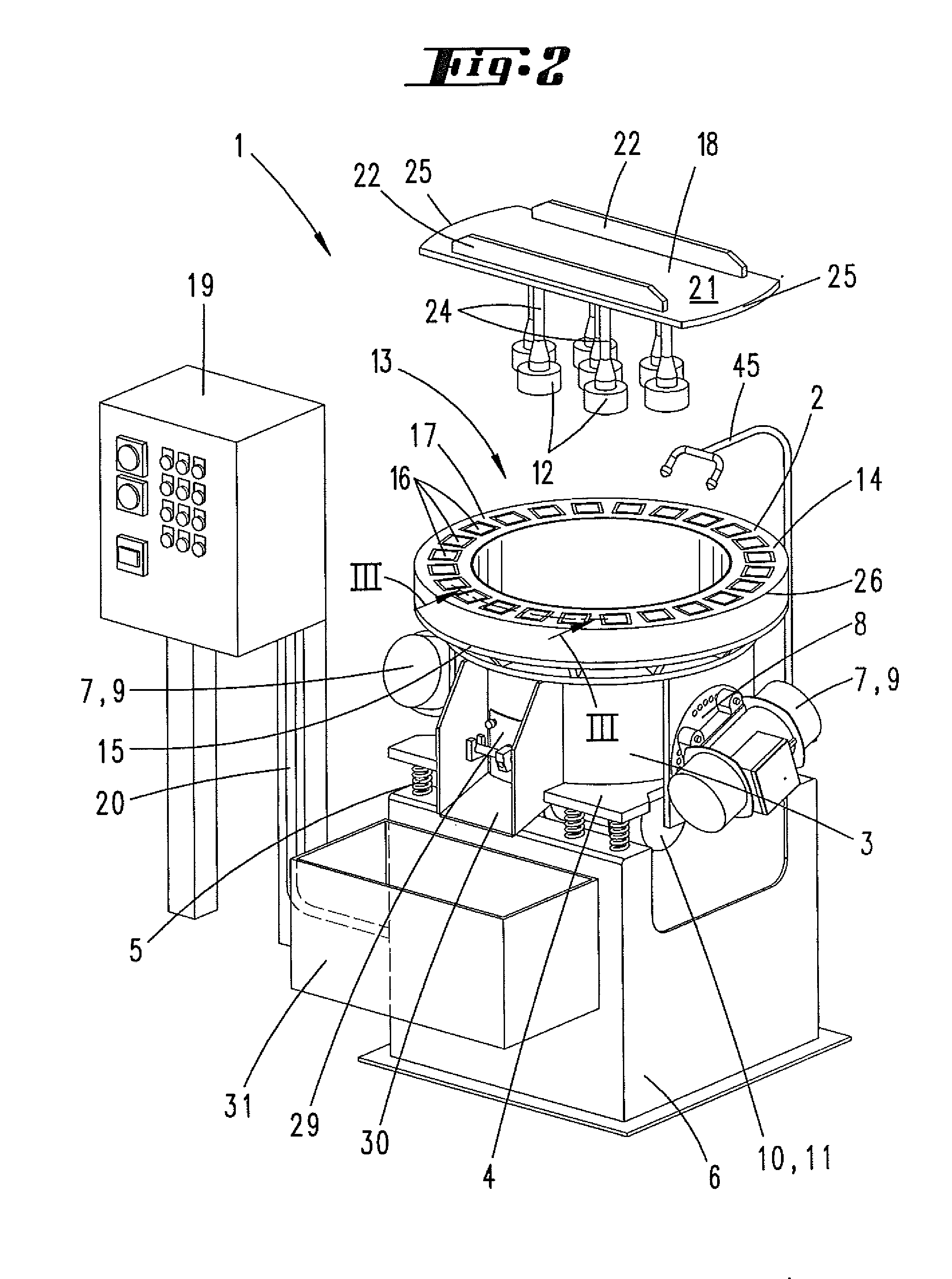

[0027]With reference to FIGS. 1 to 6, a grinding or polishing apparatus 1 according to the invention as provided by a first preferred exemplary embodiment is firstly presented. This apparatus has a pot-like treatment container 2. This comprises a cylindrical side wall 3 and a plate-shaped bottom 4, which on the underside is supported at two opposite edges on a respective group of four cylindrical compression springs 5 on a base 6. At diametrically opposite regions of the side wall 3, an unbalanced drive 7 is respectively mounted on a flange 8, the pattern of holes in which allows the unbalanced drive 7 to be fixedly connected to the treatment container at different angles of inclination (for example with respect to a horizontal reference plane). Alternatively, a stepless adjustment of the angle of inclination would also be conceivable, for example by means of clamping by workholding claws. The two unbalanced drives 7 together form a first oscillation exciter 9. Attached to the under...

PUM

| Property | Measurement | Unit |

|---|---|---|

| ferromagnetic property | aaaaa | aaaaa |

| magnetic field | aaaaa | aaaaa |

| polarity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com