Co2 refrigeration system

a refrigeration system and co2 technology, applied in the field of refrigeration systems, can solve the problems of high flammability of refrigerants and represent a risk to local safety, and achieve the effect of relieving the pressure of co2 refrigerants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

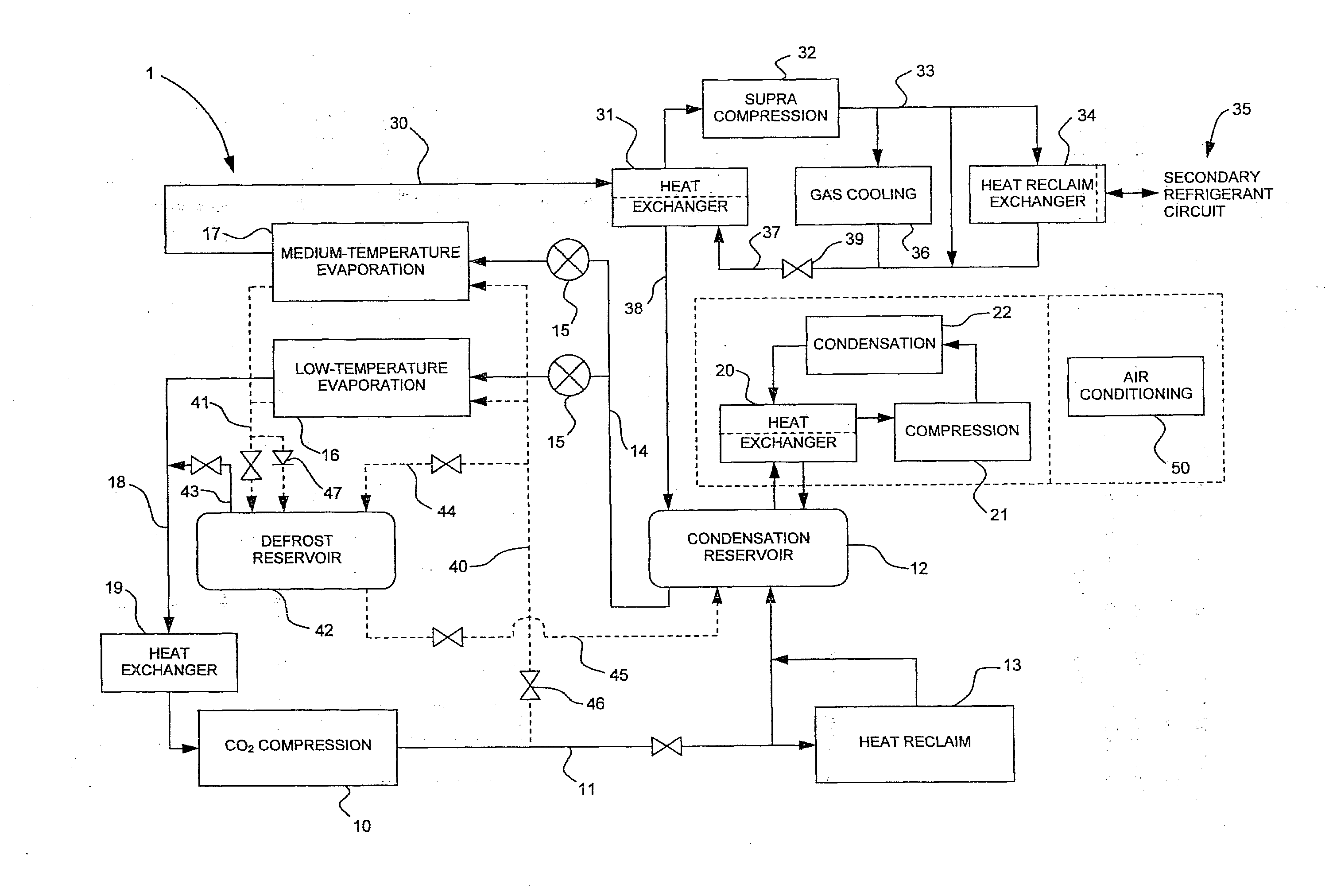

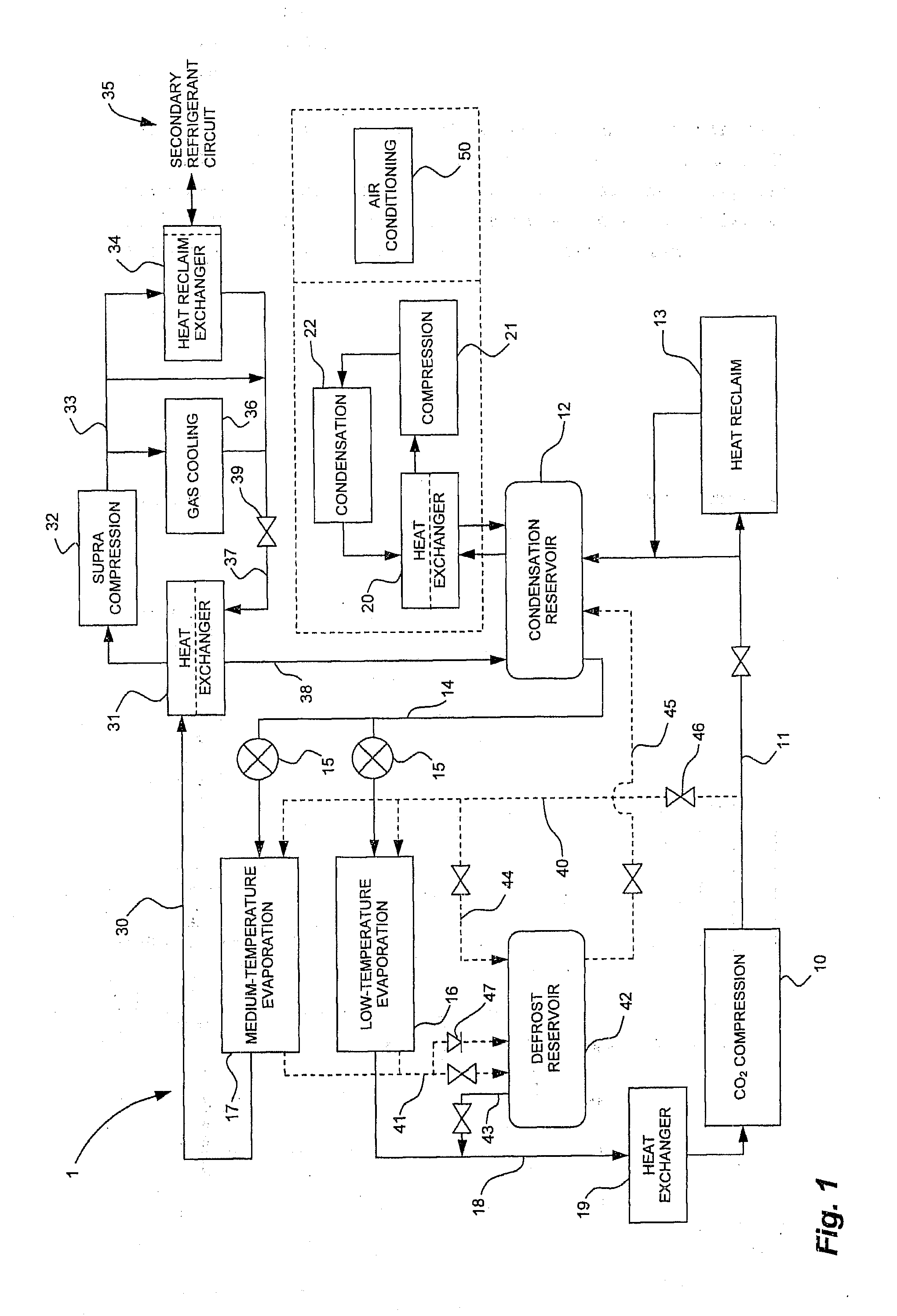

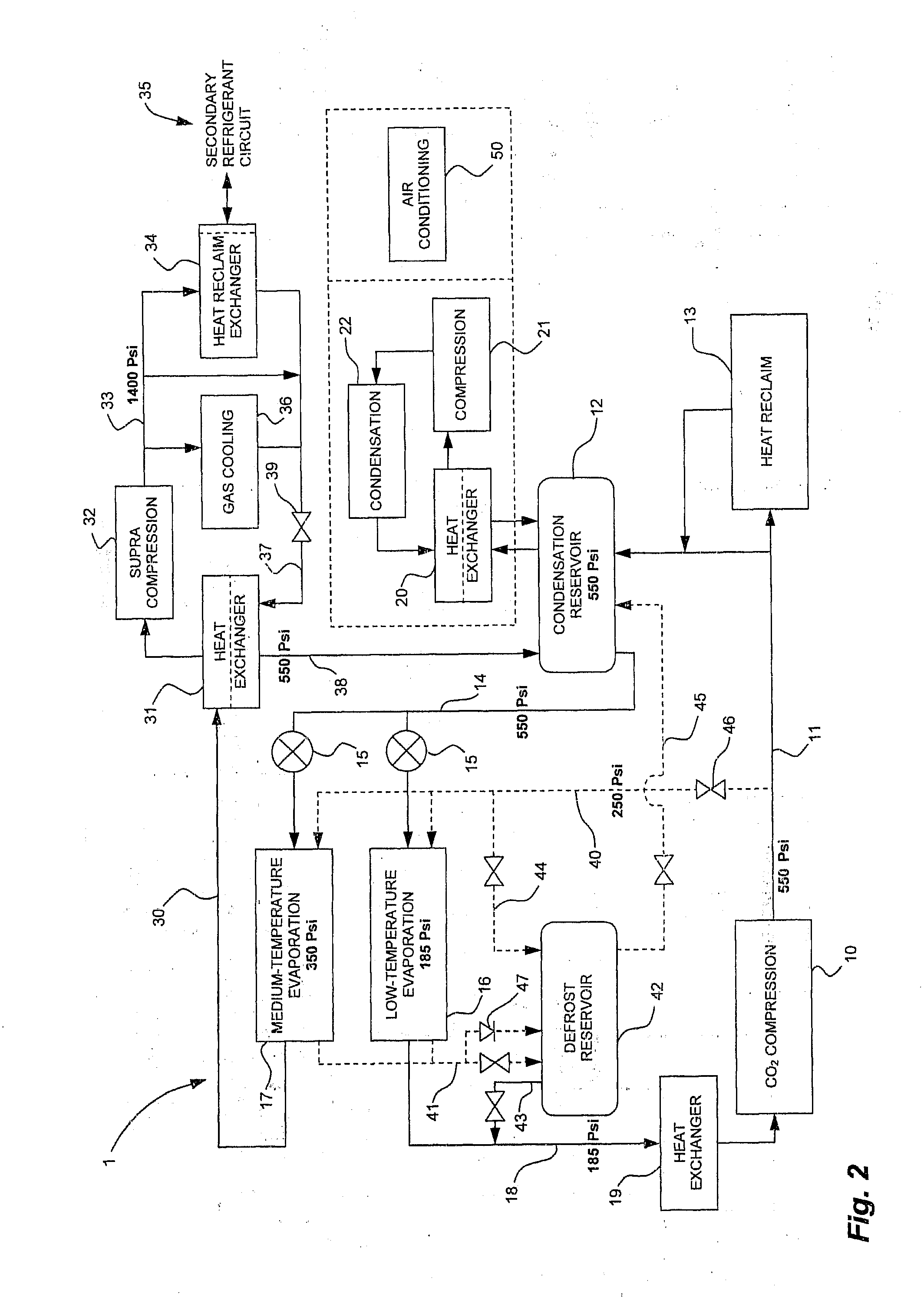

[0041]Referring to FIG. 1, a CO2 refrigeration system in accordance with an embodiment is illustrated at 1. The CO2 refrigeration system 1 has a CO2 refrigeration circuit comprising a CO2 compression stage 10. CO2 refrigerant is compressed in the compression stage 10, and is subsequently directed via line 11 to a condensation reservoir 12, or to a heat-reclaim stage 13.

[0042]The condensation reservoir 12 accumulates CO2 refrigerant in a liquid and gaseous state, and is in a heat-exchange relation with a condensation circuit that absorbs heat from the CO2 refrigerant. The condensation circuit is described in further detail hereinafter. Moreover, a transcritical circuit and a defrost circuit may supply CO2 refrigerant to the condensation reservoir 12, as is described in further detail hereinafter.

[0043]The heat-reclaim stage 13 is provided to absorb heat from the CO2 refrigerant exiting from the compression stage 10. The heat-reclaim stage 13 may take various forms, such as that of a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com