System and Method for Rescuing a Malfunctioning Subsea Blowout Preventer

a technology for blowout preventers and subsea, which is applied in the field of system and method for rescuing a malfunctioning subsea blowout preventer, can solve the problems of ineffective shutting down of a malfunctioning shear ram, inability to operate a blowout preventer, and loss of life,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

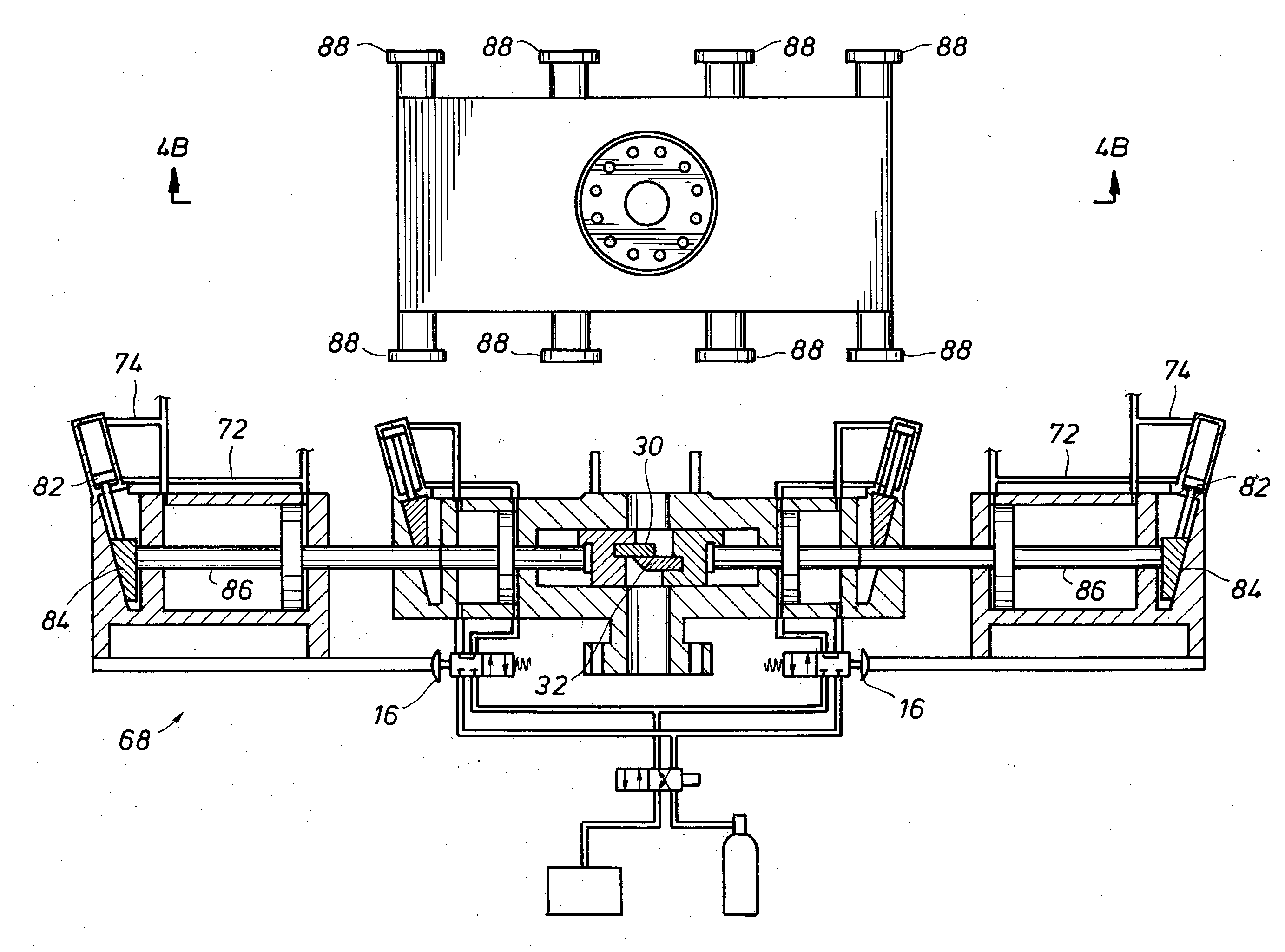

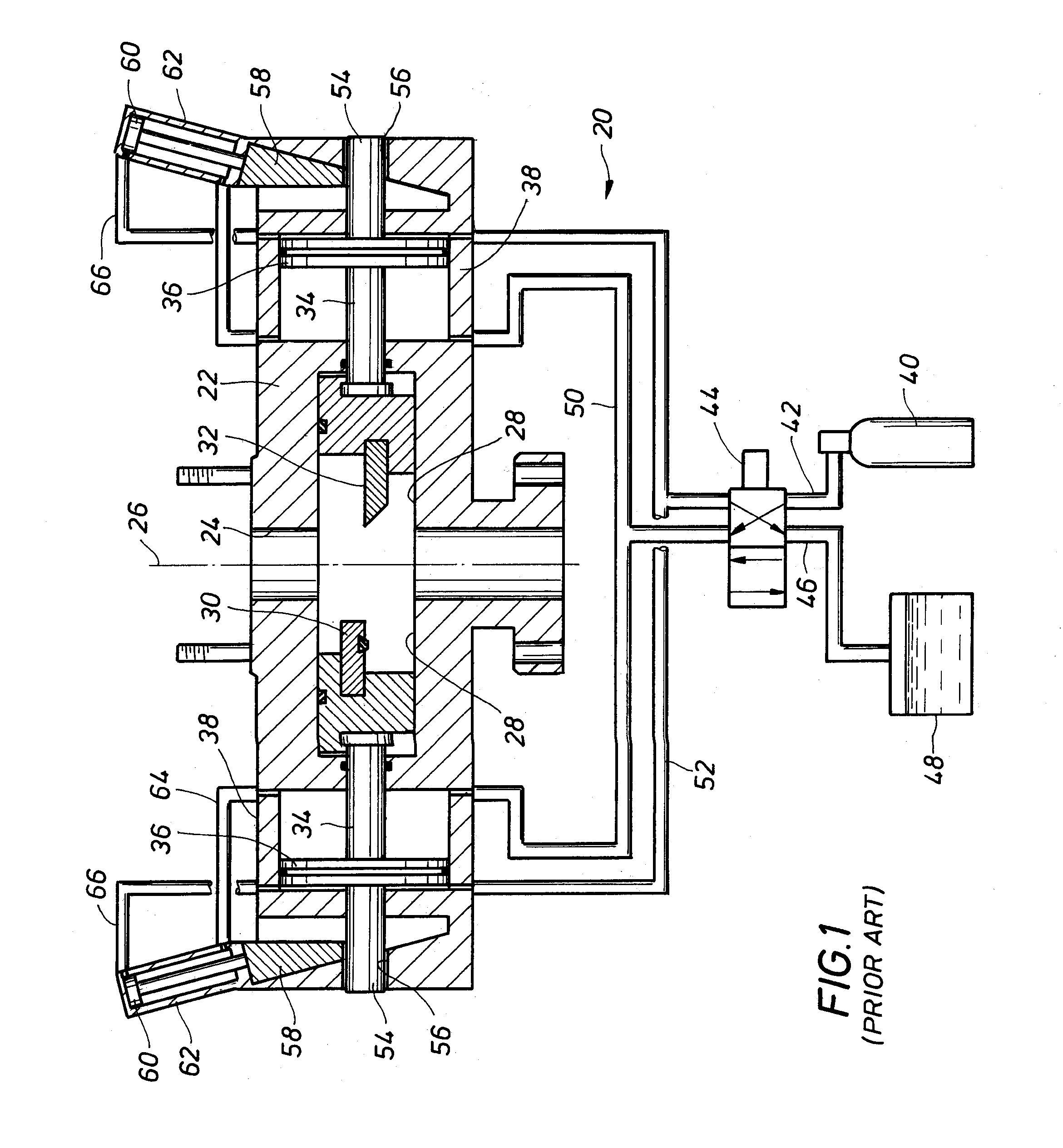

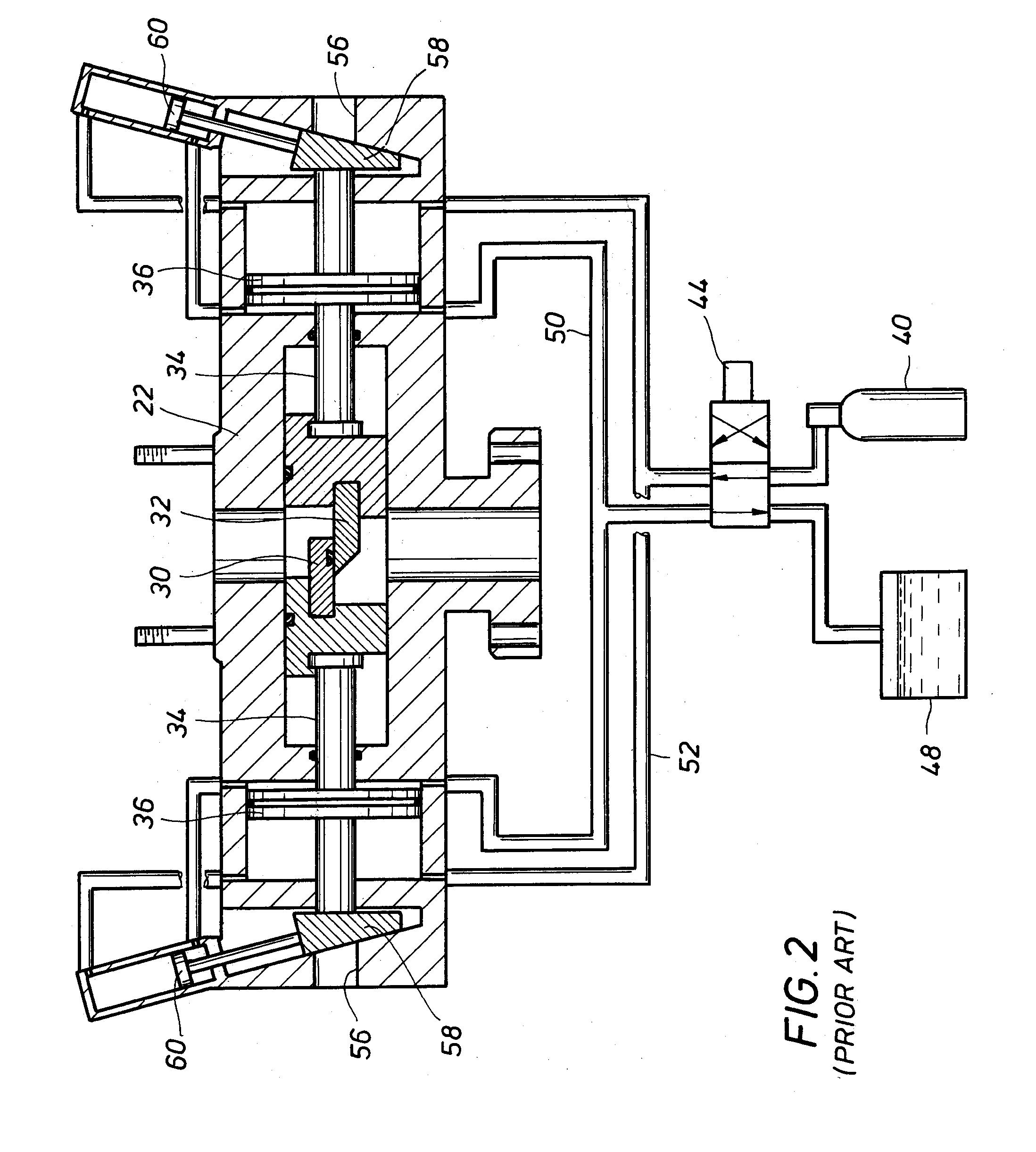

[0031]FIG. 1 is a schematic drawing of the shear ram portion of a known BOP 20. The

[0032]BOP comprises a body 22 including an axial bore 24 arranged along an axis 26. Drill pipe, coiled tubing, or the like (not shown) is run through the bore 24. A pair of bores 28 extend laterally from the bore 24 and retain two halves 30 and 32 of a shear ram. The shear ram halves 30 and 32 are each attached to a respective rod 34 which is attached to or integrally formed with a respective piston 36. Each piston is retained within its own cylinder 38. As used herein, the term “ram” alone may represent the two ram halves, whether a shear ram, a slip ram, or other type.

[0033]Throughout the following description, it is to be understood that the BOP includes a pair of opposing shear ram halves, and thus substantially identical structure is called for on either side of the BOP, including the structure of the rescue system of the present invention. For example, a structural element may be identified in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com