Compression/expansion process that allows temperature to vary independent of pressure

a technology of compression/expansion and temperature variation, applied in the direction of positive displacement liquid engine, piston pump, servomotor, etc., can solve the problems of increasing temperature and pressure, less efficient adiabatic compression, and fast process for compressing a gas, so as to increase the gas pressure and reduce the effect of thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

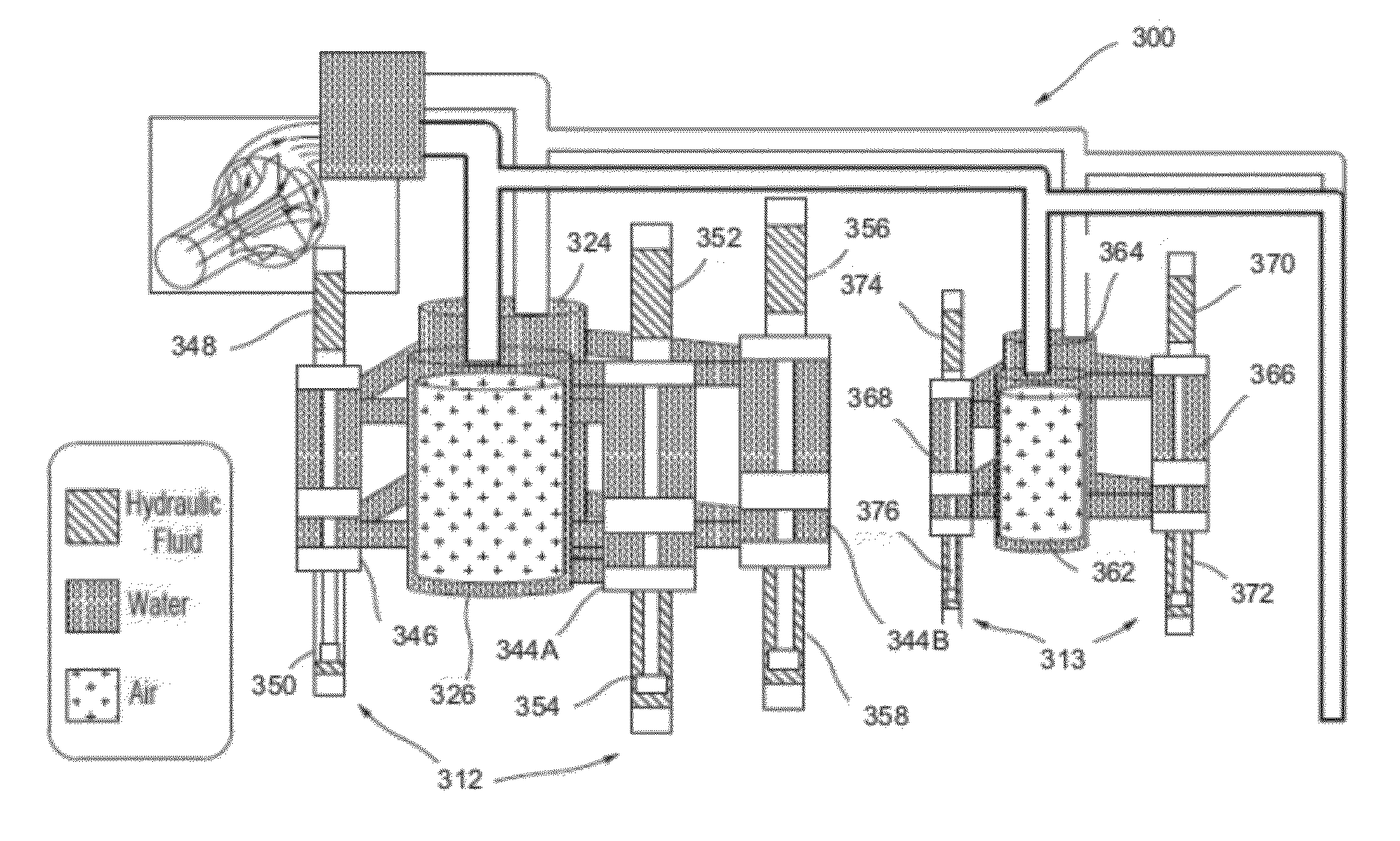

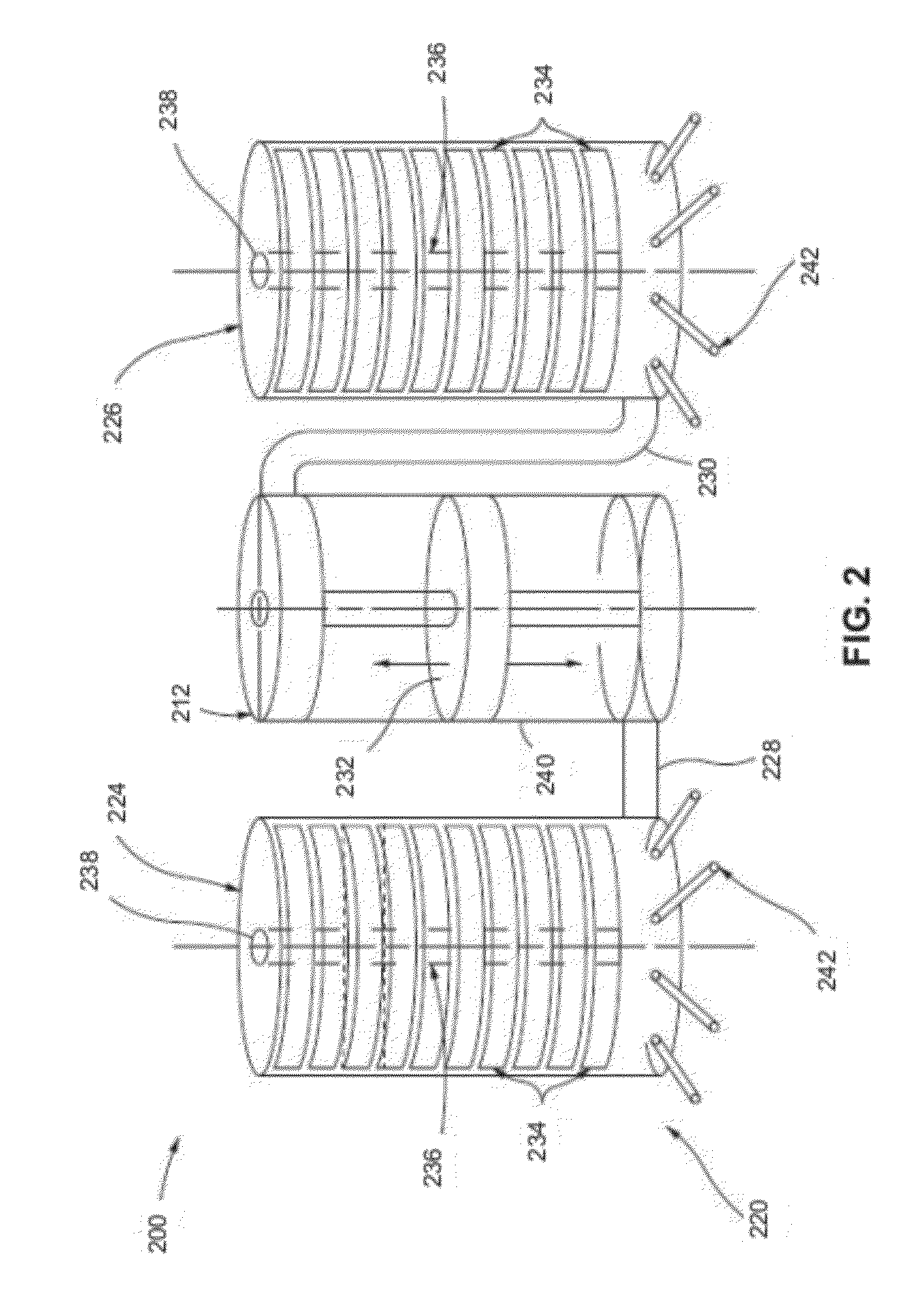

[0024]Systems, methods and devices used to compress and / or expand a gas, such as air, and / or to pressurize and / or pump a liquid, such as water, are described herein. Such devices and systems can be used, for example, within a compressed air energy storage (CAES) system. In some compression and / or expansion devices and systems, a hydraulic actuator can be used to move or compress a gas within a pressure vessel. For example, an actuator can move a liquid within a pressure vessel such that the liquid compresses the gas in the pressure vessel. Such compression devices and systems are described in U.S. patent application Ser. No. 12 / 785,086; U.S. patent application Ser. No. 12 / 785,093; and U.S. patent application Ser. No. 12 / 785,100, each titled “Compressor and / or Expander Device” (collectively referred to as “the Compressor and / or Expander Device applications”), incorporated herein by reference in their entirety. The Compressor and / or Expander Device applications describe a CAES system ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com