Spraying Device and Refill Therefor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

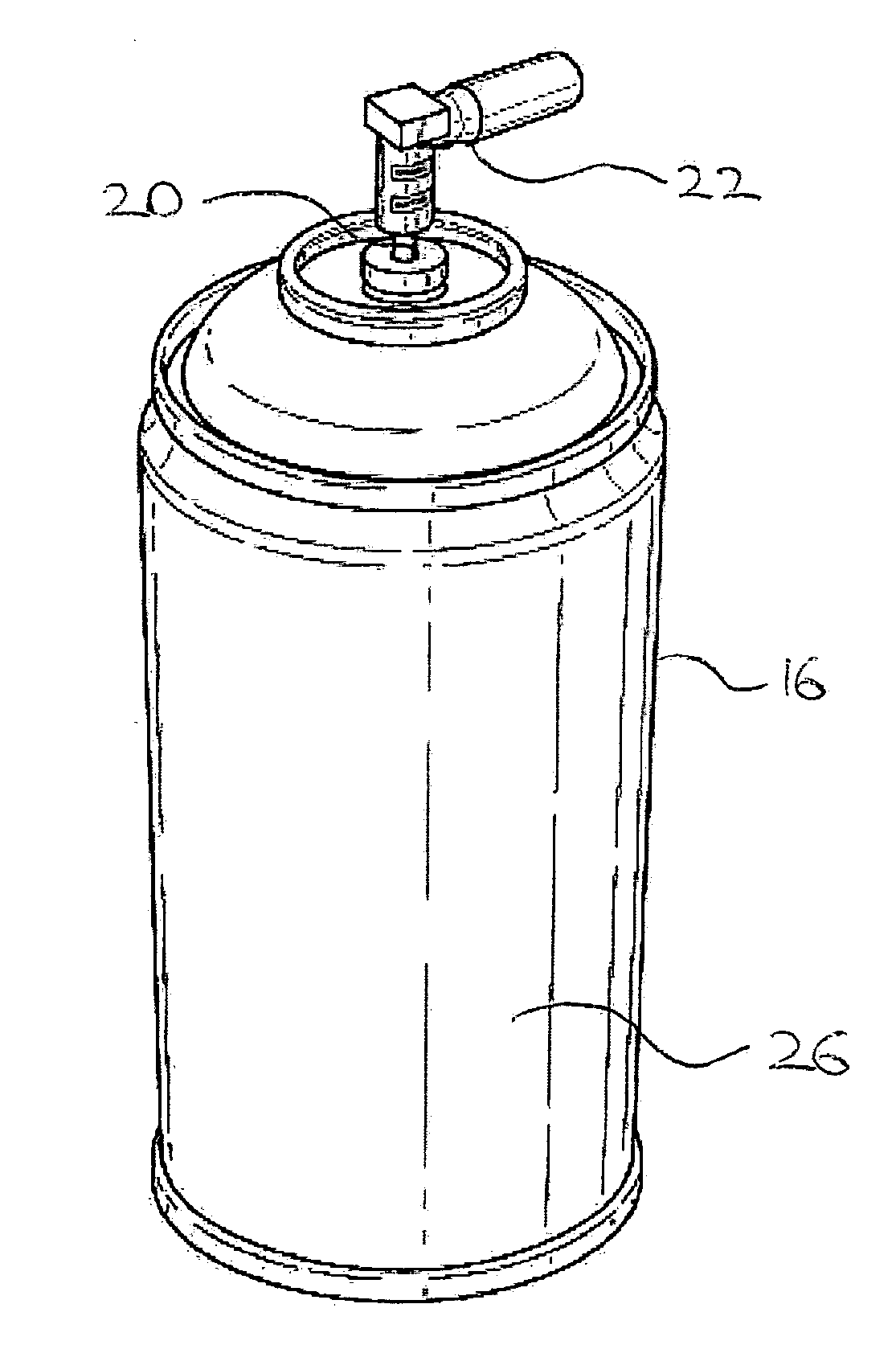

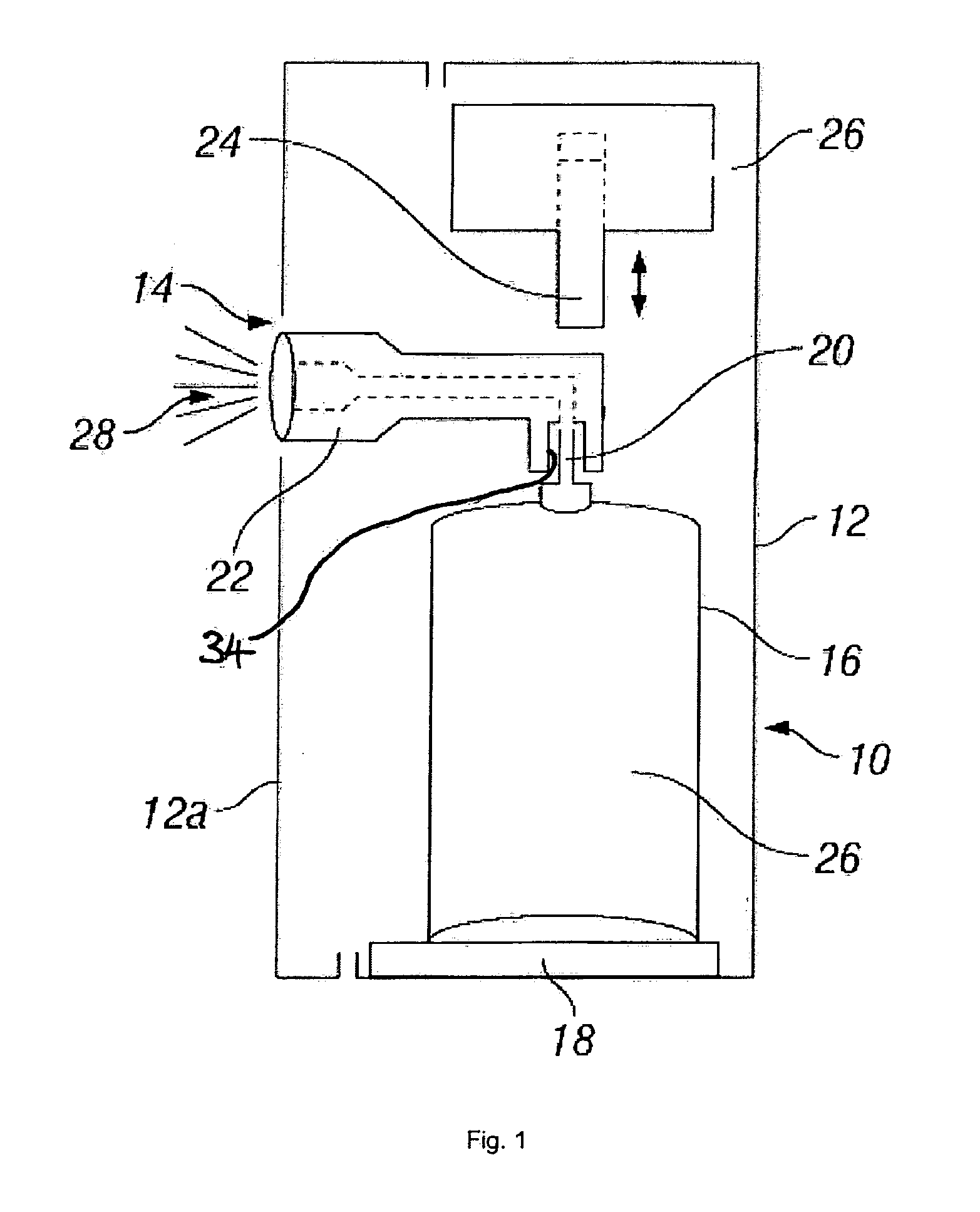

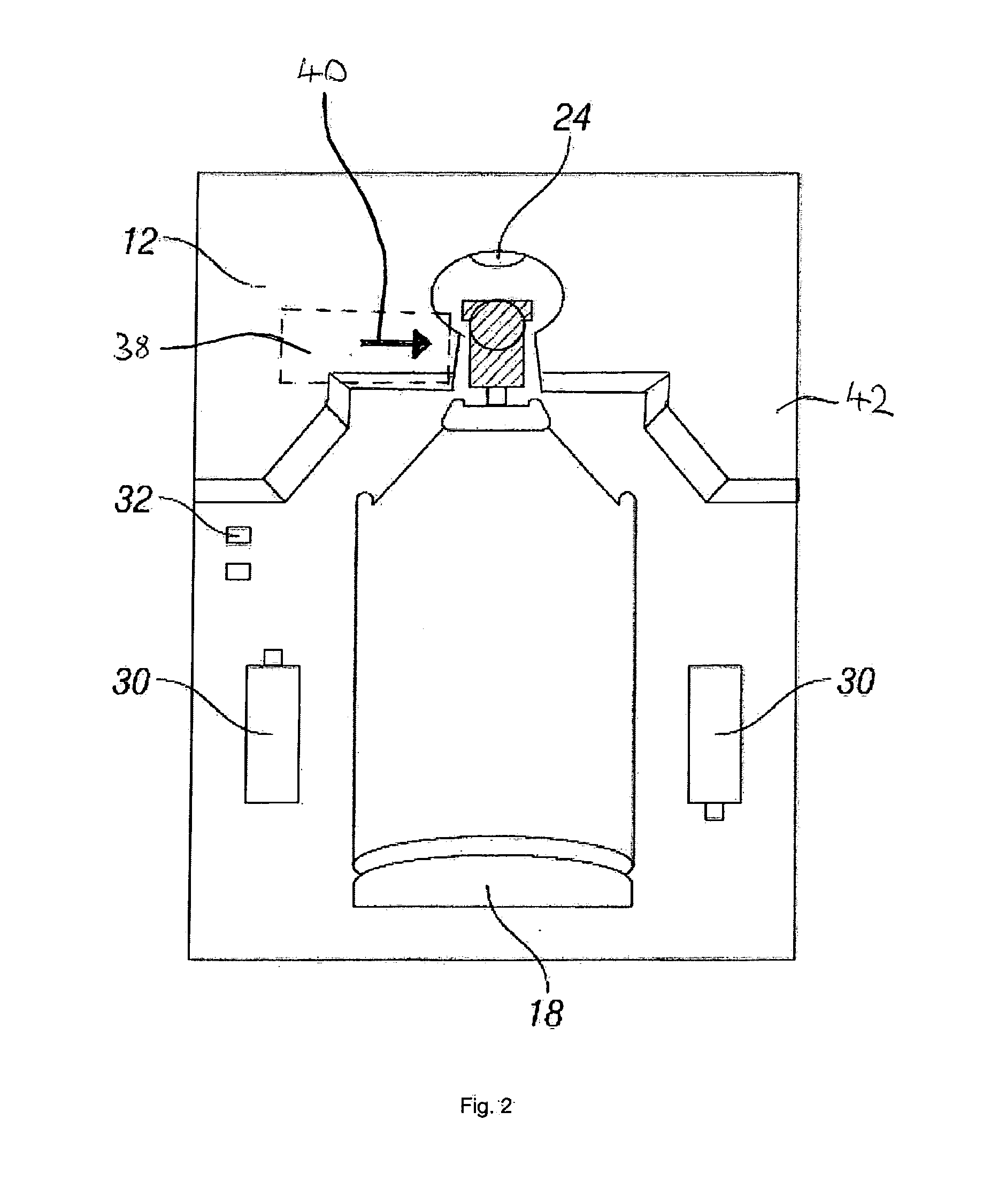

[0078]As shown in FIGS. 1 and 2 a fragrance spraying device 10 comprises an outer housing 12 with a removable front section 12a through which there is an opening 14. The front section 12a may be hinged to permit access to the interior of the device 10. A replaceable refill 16, in this example an aerosol spray canister, is held within the outer housing 12 on a platform 18. The device 10 is also provided with an inner housing 42. An outlet stem 20 of the refill 16 is received in a lower opening of a spray head 22, when the refill 16 is held within the device 10 a proportion of the spray head 22 is located within the inner housing 42. An actuation means 24 is located within the inner housing 42 and above the refill 16 and possesses an arm 24 that is moveable to apply substantially downward pressure on the spray head 22 and cause actuation of the refill 16. During actuation of the refill, fluid held within the body 26 of the refill 16 is forced through the valve stem 20, into the spray ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com