Multilayer body and container

a multi-layer body and container technology, applied in the field of multi-layer bodies and packaging materials, can solve the problems of insufficient adhesion prevention effect of the material of patent documents 1 and 2, and achieve excellent and lasting non-adhesive properties, and good water repellency and non-adhesive properties. good and lasting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0216]The first through fourth inventions are explained in more detail below using examples and comparative examples. However, the scope of the present invention is not limited by these examples.

examples of first invention

Examples 1-1 to 1-9 and Comparative Example 1-1

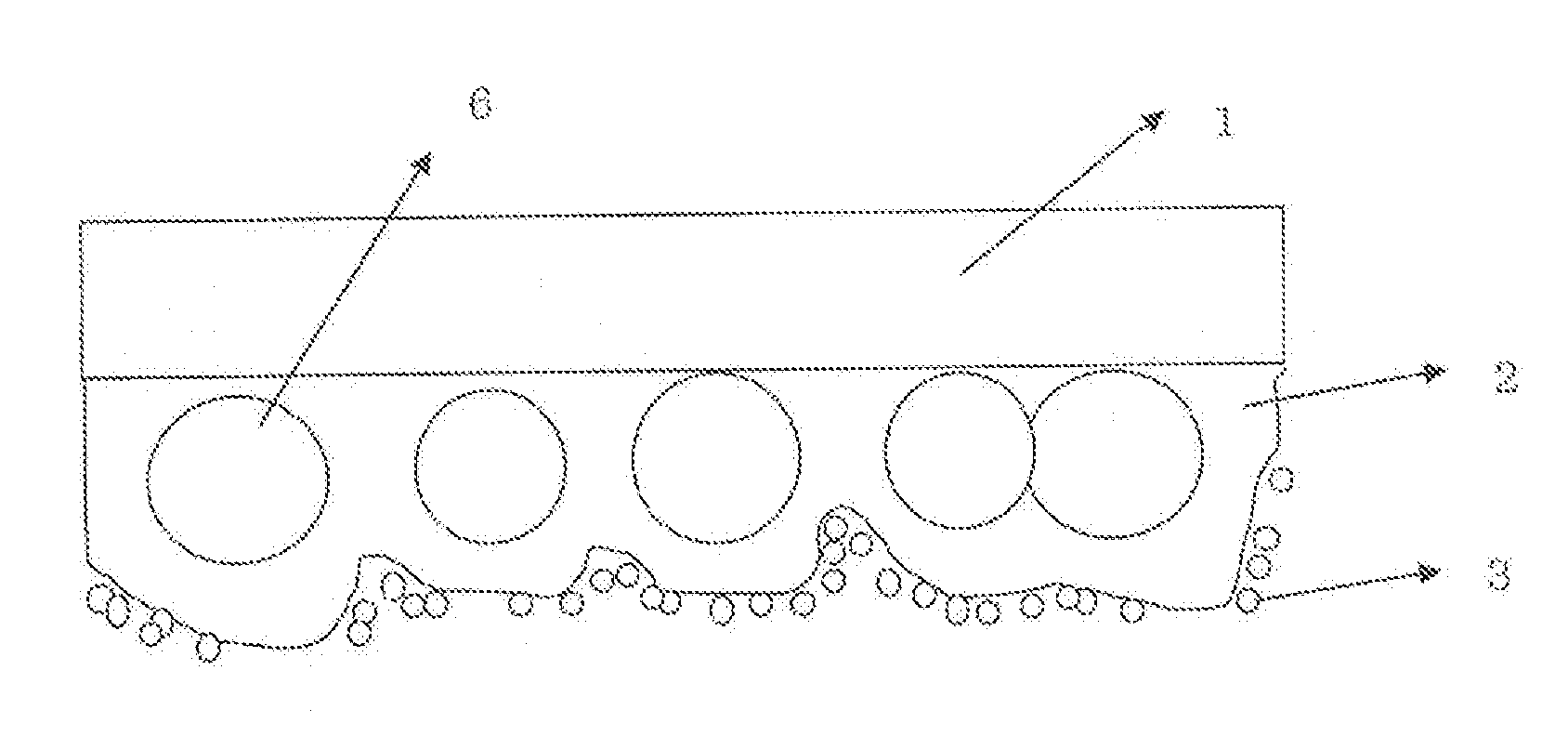

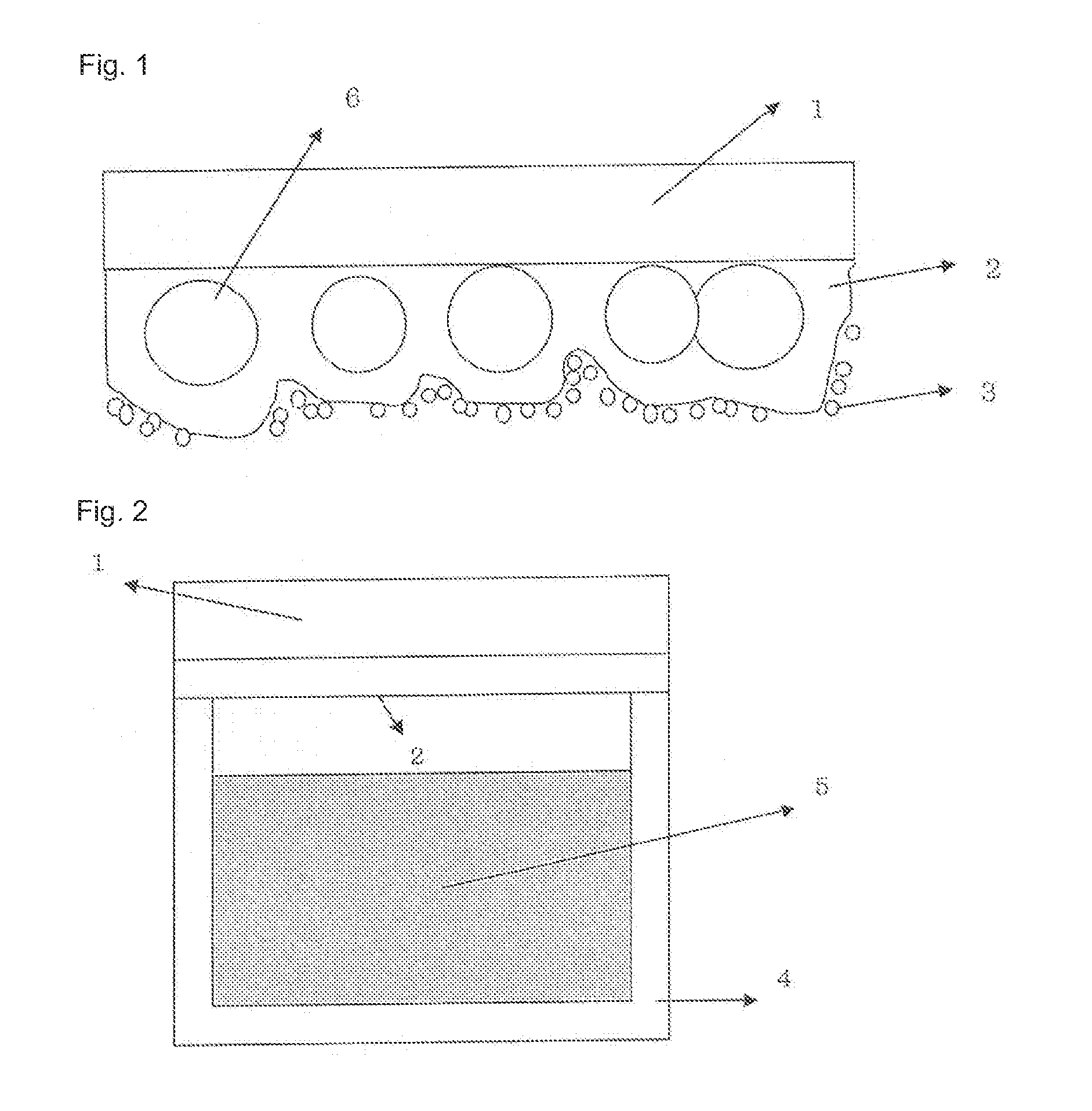

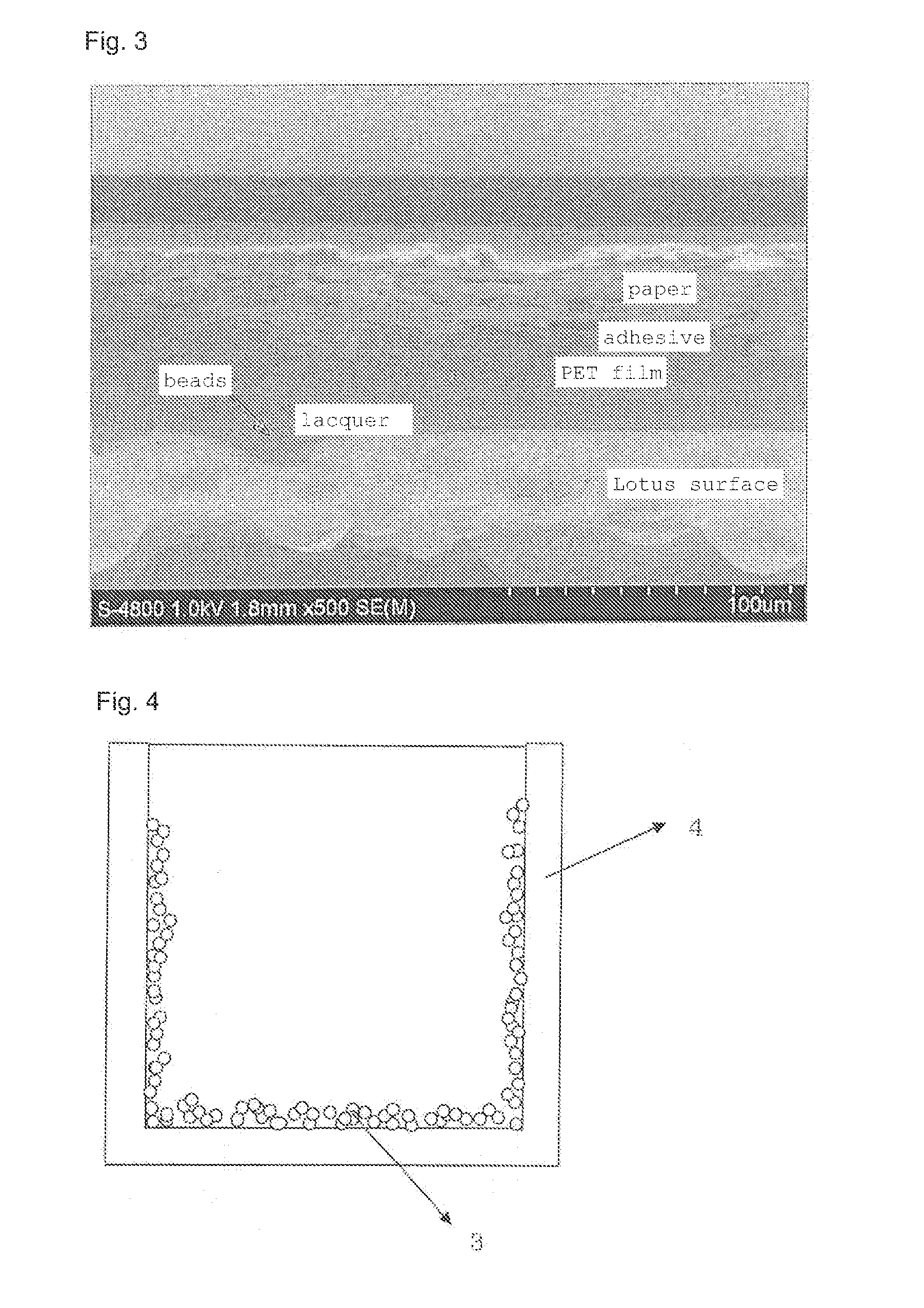

[0217]Samples were prepared by causing hydrophobic oxide fine particles to attach to multilayer bodies having thermoplastic resin layers. Specifically, the various samples were prepared as follows.

(1) Preparation of Multilayer Bodies

example 1-1

, Comparative Example 1-1

[0218]One side of paper having a basis weight of 55 g / m2 was printed and OP (overprint) coated, while the other side was bonded with a polyurethane dry laminate adhesive (abbreviated as “D”; dried weight 3.5 g / m2) to the surface of a 16 μm-thick aluminum-deposited polyethylene terephthalate film (abbreviated as Al-deposited PET). A heat seal lacquer (“lacquer”; principal components 160 parts by weight polyester resin+10 parts by weight acrylic resin+40 parts by weight solvent (mixed toluene+MEK solvent)) was coated as a thermoplastic resin layer on the polyethylene terephthalate film of this bonded material to a dried weight of about 3 g / m2 (drying conditions 150° C.×10 seconds). A multilayer body composed of “OP / printing / paper / D / Al-deposited PET / lacquer” was obtained in this way.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Nanoscale particle size | aaaaa | aaaaa |

| Particle diameter | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com