Battery charger having non-contact electrical switch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

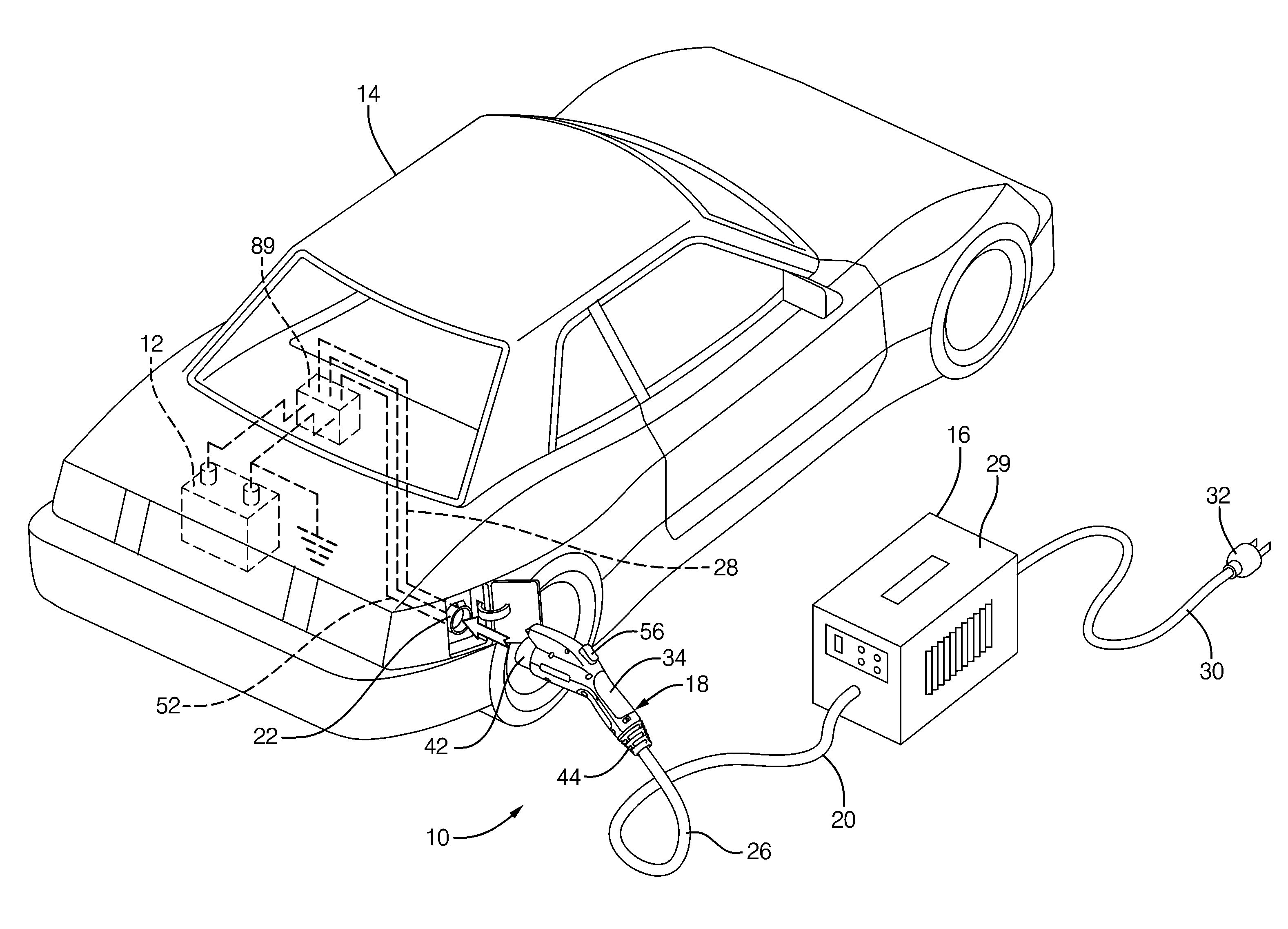

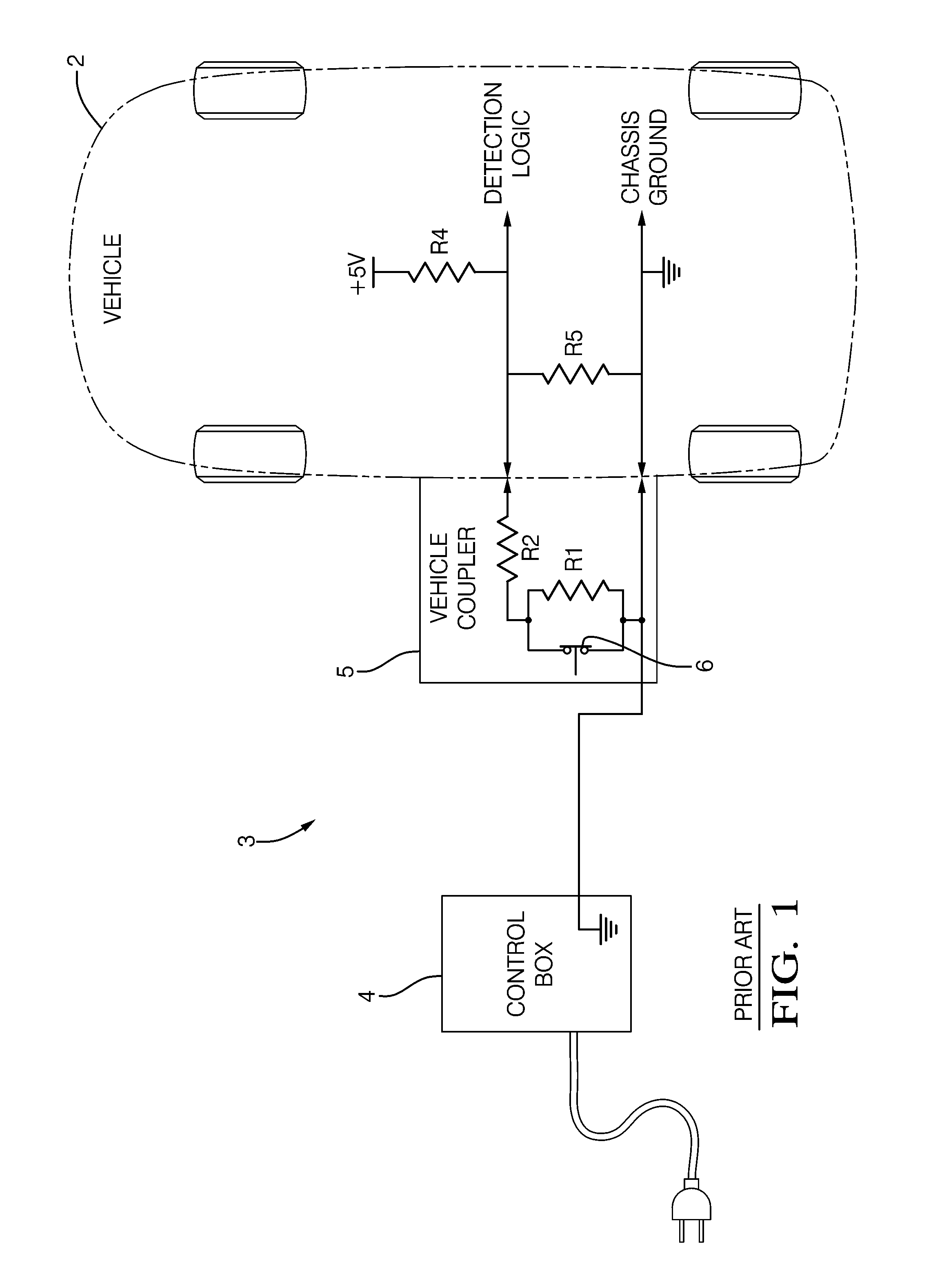

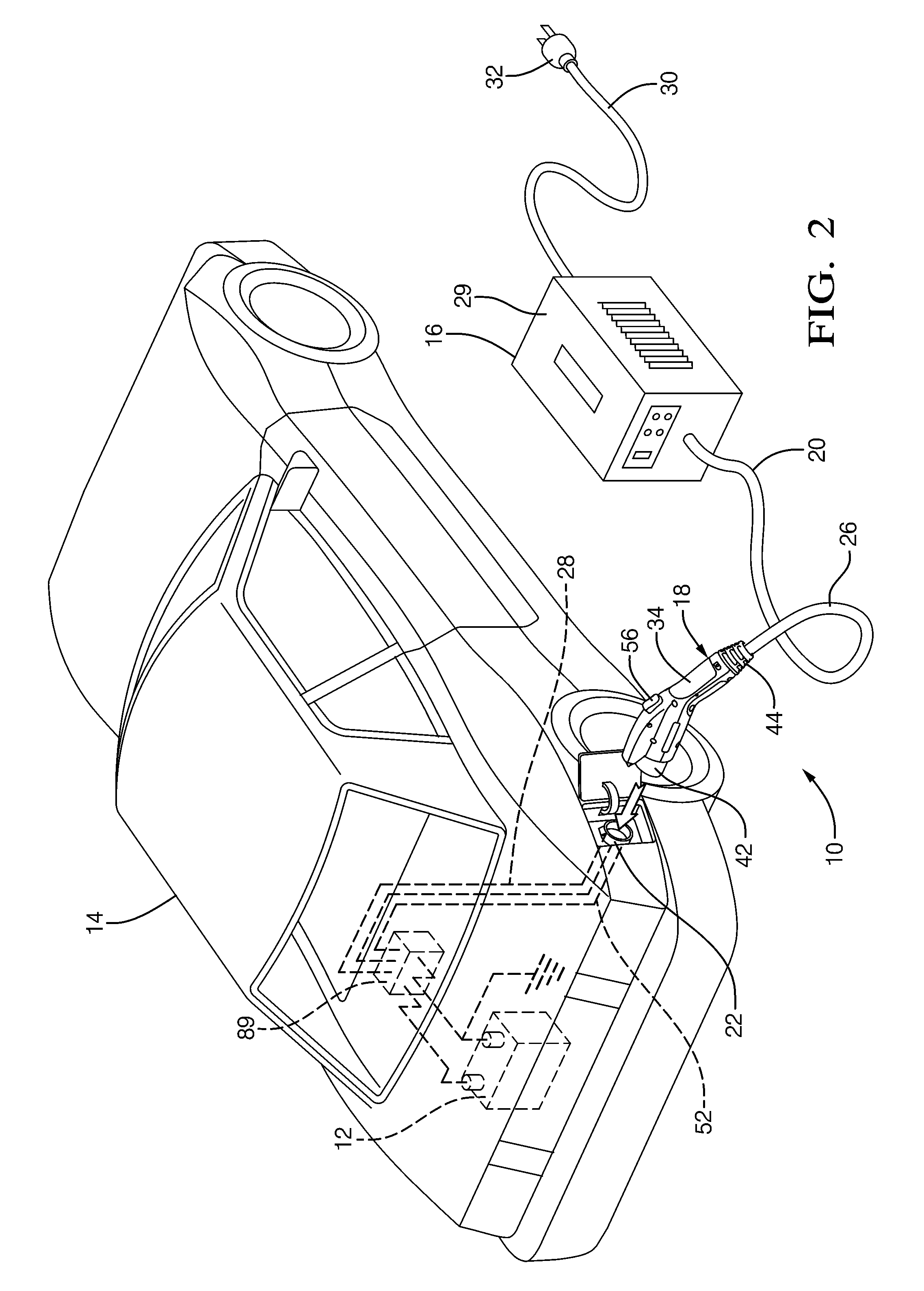

Embodiment Construction

[0021]A drivetrain of a vehicle is a group of components in the vehicle that generate power and deliver this power through the wheels of the vehicle to a road surface. A hybrid electric vehicle and an electrical vehicle each use a battery to power the drivetrain of their respective vehicles. A hybrid electrical vehicle uses a hydrocarbon fuel engine in combination with a battery disposed on the vehicle to power the drivetrain of a vehicle. An electric vehicle powers the drivetrain solely by using energy from a battery. The battery of the hybrid electric vehicle and the electric vehicle may include a plurality of batteries connected in series or parallel connection to form a single battery. As the vehicle is driven, or otherwise used by a human operator of the vehicle such as when powering the radio or windshield wipers apart from powering the drivetrain, the electrical charge on the battery may decrease such that the battery needs to be electrically recharged back to a fully charged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com