Method for diagnosing an exhaust gas post-treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

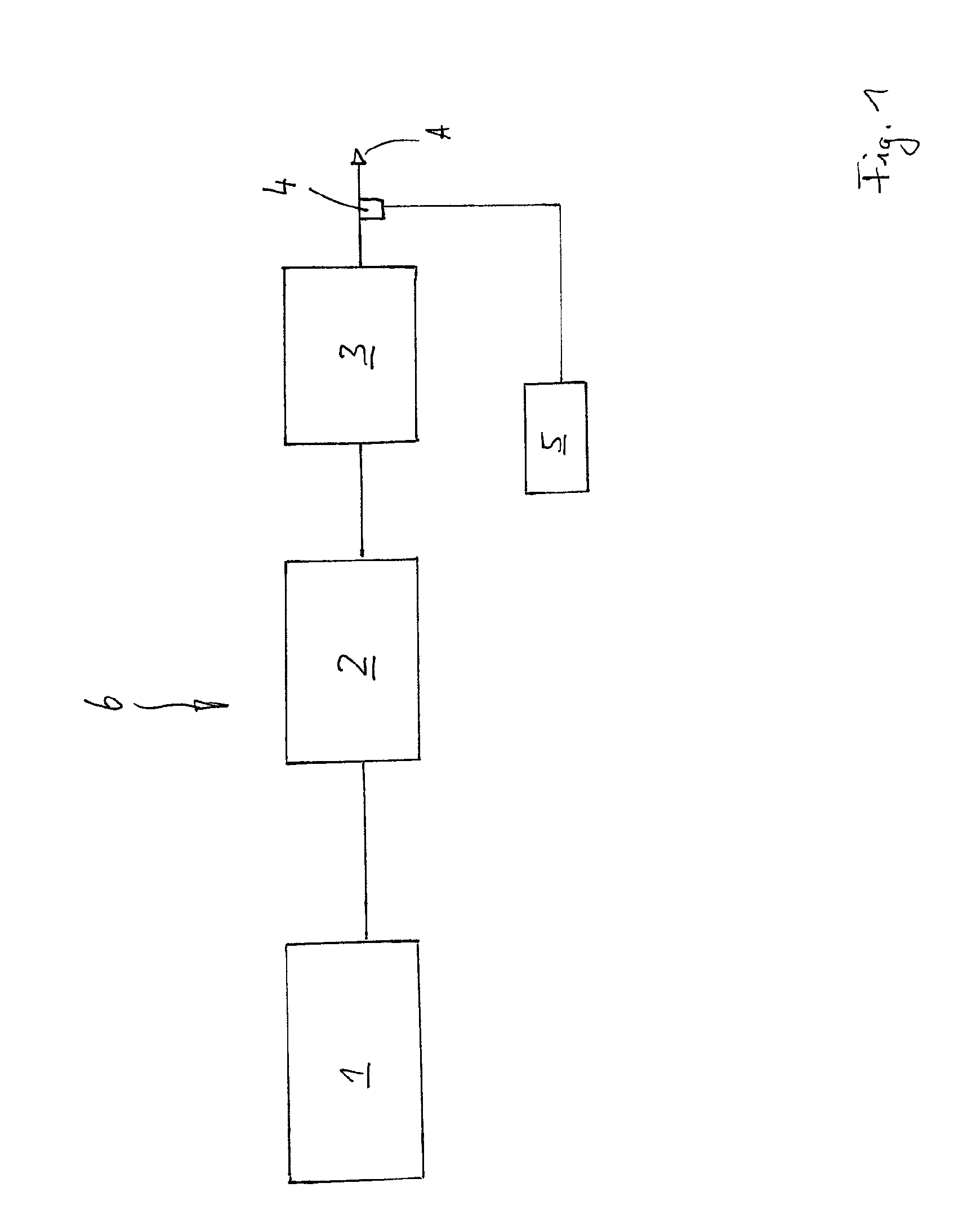

[0023]FIG. 1 shows a principal representation of a common exhaust-system branch 6 with a combustion engine 1, which operates, for example, according to the Diesel principle, and is, when seen in flow direction A, arranged downstream of an oxidation catalyst 2, a carbon particle filter 3 and a carbon monoxide sensor 4, which is connected to a control device 5 for monitoring the sensor signals. The combustion engine can also be a lean operated Otto-engine (petrol engine). In the manner, which is not described in more detail, but generally known, the control device is at least part of a system for the on-board-diagnosis (OBD). The carbon particle filter 3 is provided with a catalytic coating on its inside, which is not shown in detail in FIG. 1 because of the principal representation.

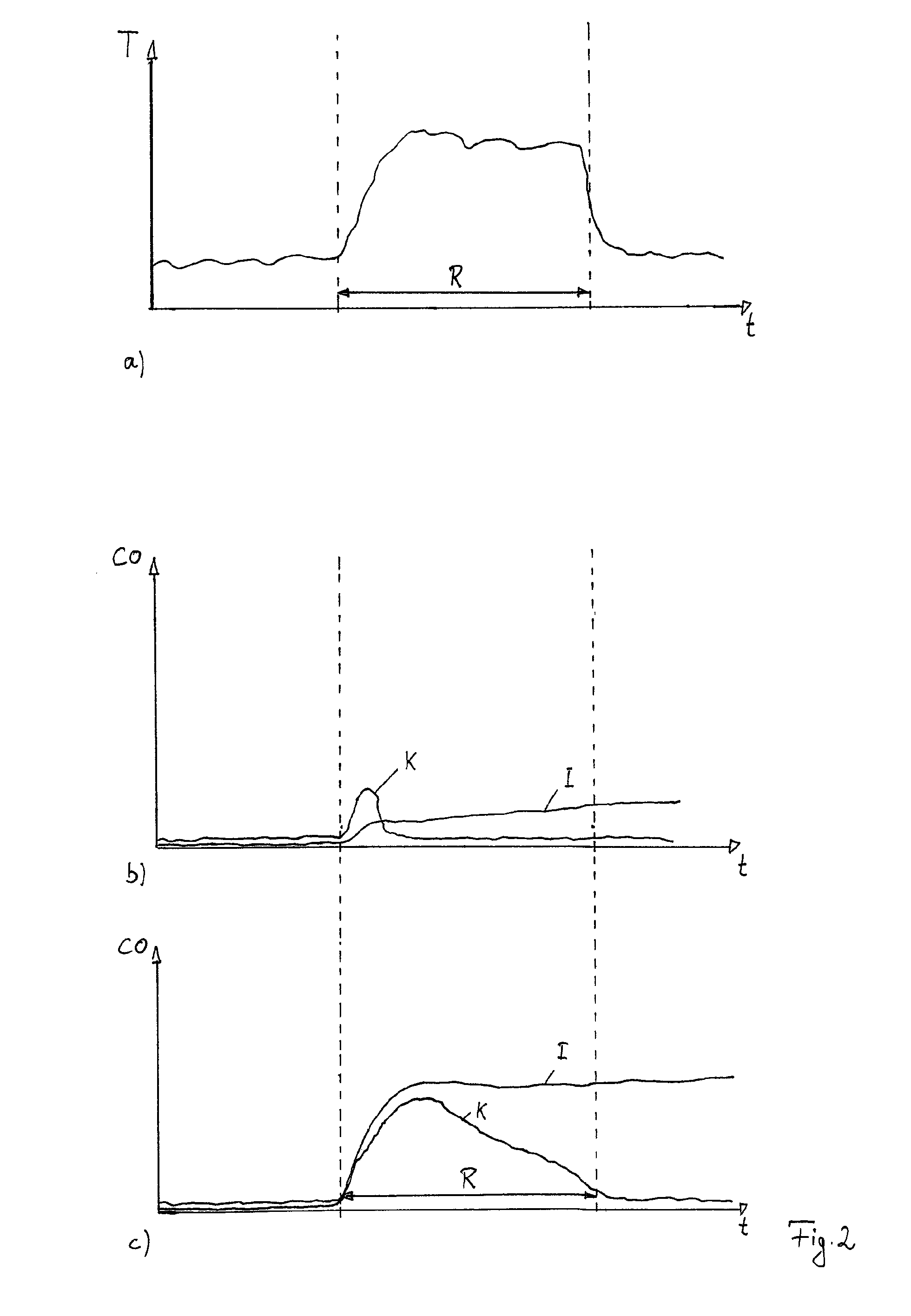

[0024]Furthermore, a possibility for the temperature measurement can be provided downstream of the oxidation catalyst 2. Thus, a diagnosis of the oxidation catalyst 2 is achieved by evaluating a temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com