Reactor Feedwater Pump Control System

a technology of pump control and reactor feedwater, which is applied in the direction of machines/engines, positive displacement liquid engines, lighting and heating apparatus, etc., can solve the problems of short time period of output of the above-described decelerating operation instruction, the actual rotational speed of each reactor feedwater pump is limited, and the feedwater flow of feedwater supplied to the steam generator cannot be rapidly decreased. , to achieve the effect of suppressing the decrease in water level of the steam generator and minimizing th

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

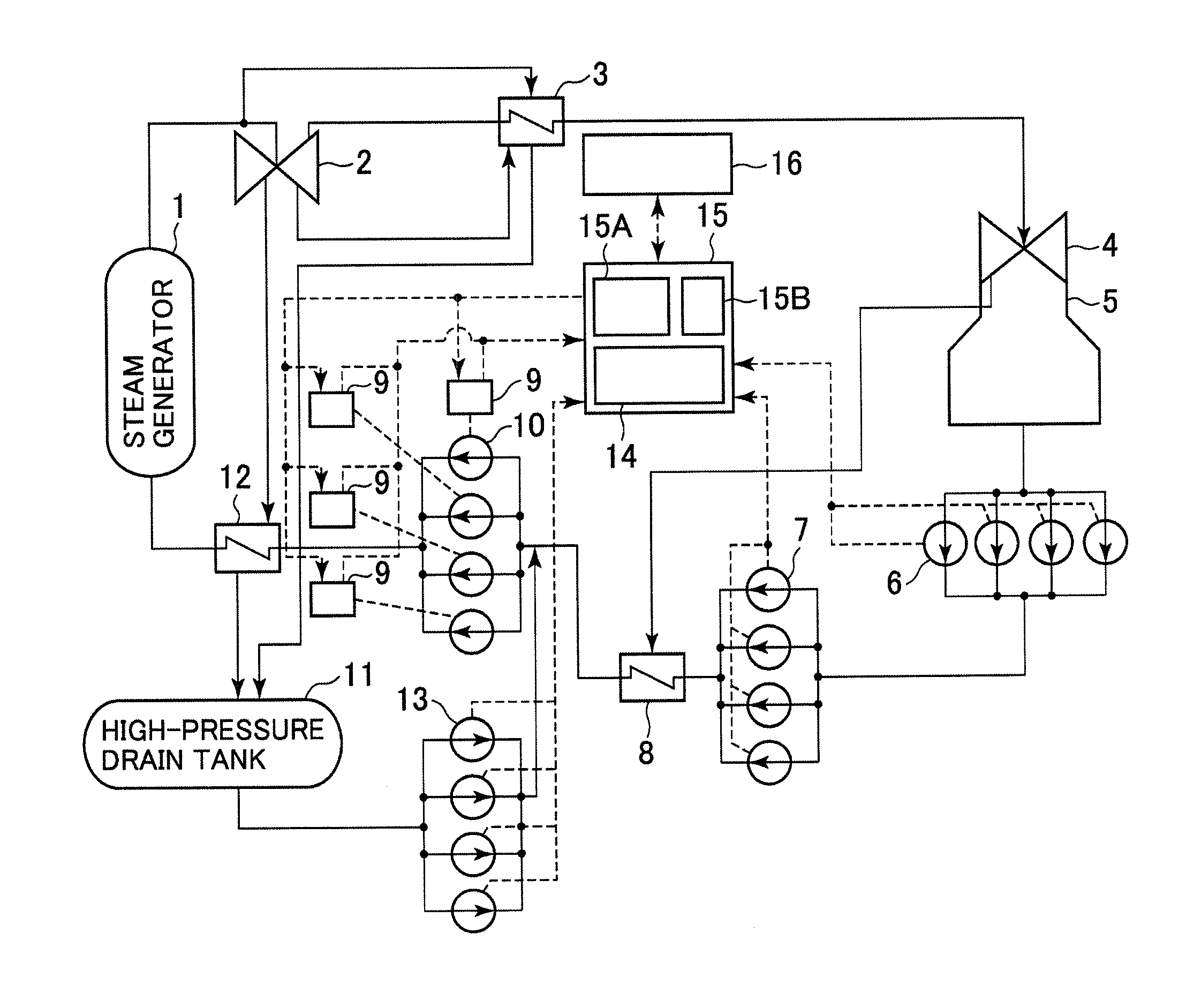

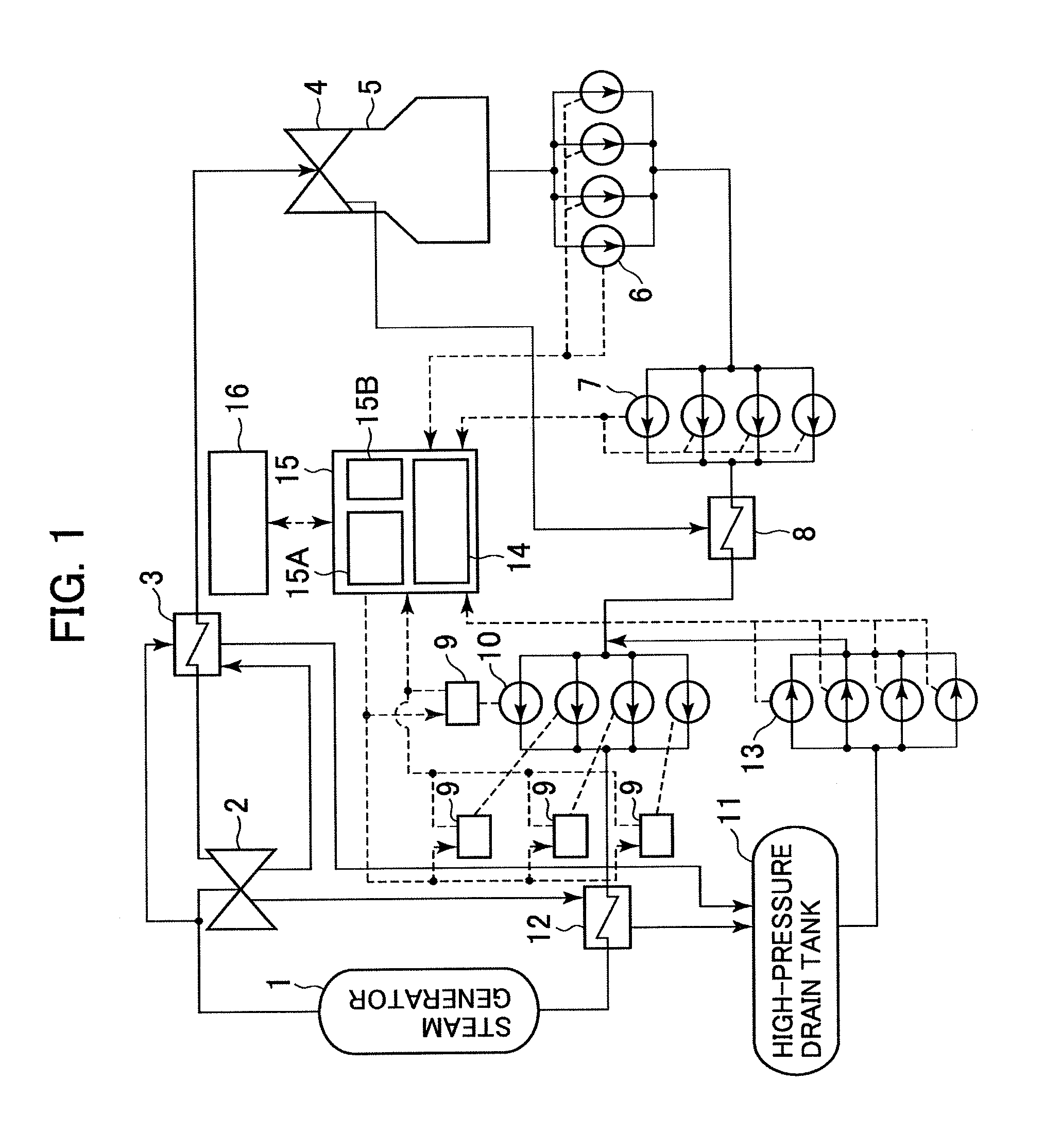

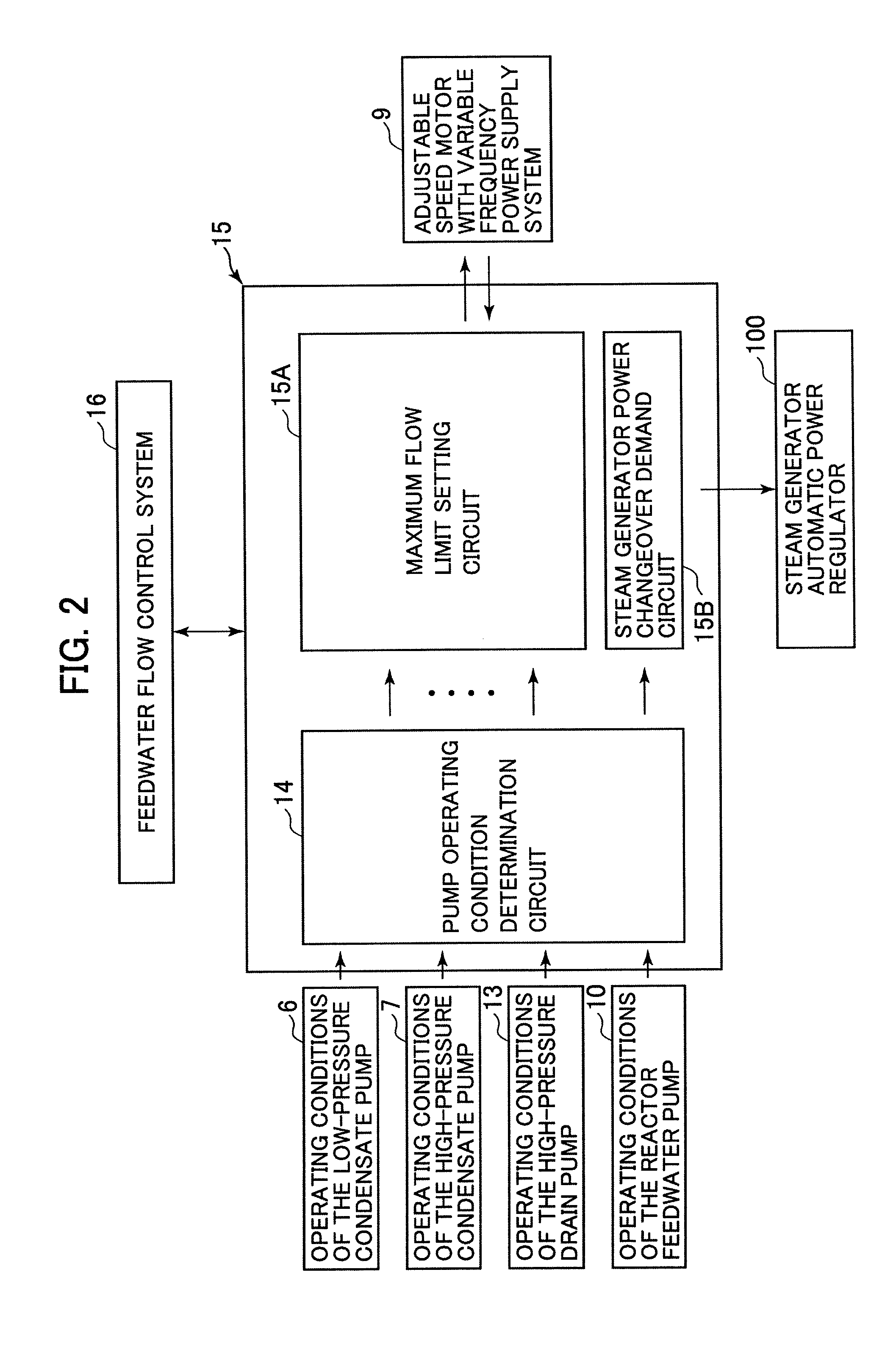

[0045]FIG. 1 is a systematic diagram illustrating a steam turbine facility to which a first embodiment of the reactor feedwater pump control system of the present invention is applied. FIG. 2 is a block diagram illustrating a configuration of the reactor feedwater pump control system according to the first embodiment of the present invention. FIG. 3 is a characteristic chart illustrating the operation during start-up of a standby condensate pump for tripping in the first embodiment of the reactor feedwater pump control system of the present invention.

[0046]In FIG. 1, steam generated by a steam generator 1 is supplied to a high-pressure turbine 2 through a supply pipe. The steam expanded by the high-pressure turbine 2 is passed through a steam pipe to a moisture separator reheater 3. The moisture separator reheater 3 reheats the steam and then supplies the reheated steam to a low-pressure turbine 4. The steam expanded by the low-pressure turbine 4 is condensed by a condenser 5 so as ...

second embodiment

[0064]A second embodiment of the reactor feedwater pump control system of the present invention will be described below with reference to the accompanying drawings. FIG. 4 is a characteristic chart illustrating the operation where a standby pump does not start up even required upon tripping of a condensate pump in the second embodiment of the reactor feedwater pump control system of the present invention. In the description referring to FIG. 4, reference numerals that are same as those shown in FIGS. 1 to 3 represent similar parts. Therefore the detailed description thereof will be omitted.

[0065]In the first embodiment, it was assumed that a standby pump started up when one of the plurality of low-pressure condensate pumps 6 tripped. Meanwhile in this embodiment, it is assumed that the standby pump would not start up even when one of the plurality of low-pressure condensate pumps 6 is tripped. The turbine facility, the reactor feedwater pump control system 15 and the like are config...

third embodiment

[0070]A third embodiment of the reactor feedwater pump control system of the present invention will be described below with reference to the accompanying drawings. FIG. 5 is a characteristic chart illustrating the operation where a standby pump would not start up even when a condensate pump is tripped in the third embodiment of the reactor feedwater pump control system of the present invention. In the description referring to FIG. 5, reference numerals that are same to those shown in FIGS. 1 to 4 represent similar parts. Therefore the detailed description thereof will be omitted.

[0071]The second embodiment discloses the example in which the standby pump would not start up even when one of the plurality of low-pressure condensate pumps 6 is tripped. This embodiment discloses another example of the operation in which the standby pump would not start as well. The turbine facility, the reactor feedwater pump control system 15 and the like are configured similarly to those disclosed in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com