Micro vapor chamber

a technology of vapor chamber and micro-vapor chamber, which is applied in the direction of basic electric elements, semiconductor devices, lighting and heating apparatus, etc., can solve the problems of increasing the performance of electronic elements, increasing the heat generation of electronic elements during their operation, and affecting the cooling of electronic products, etc., and achieves high thermal conductivity efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031]The above objectives and structural and functional features of the present invention will be described in more detail with reference to preferred embodiments thereof shown in the accompanying drawings

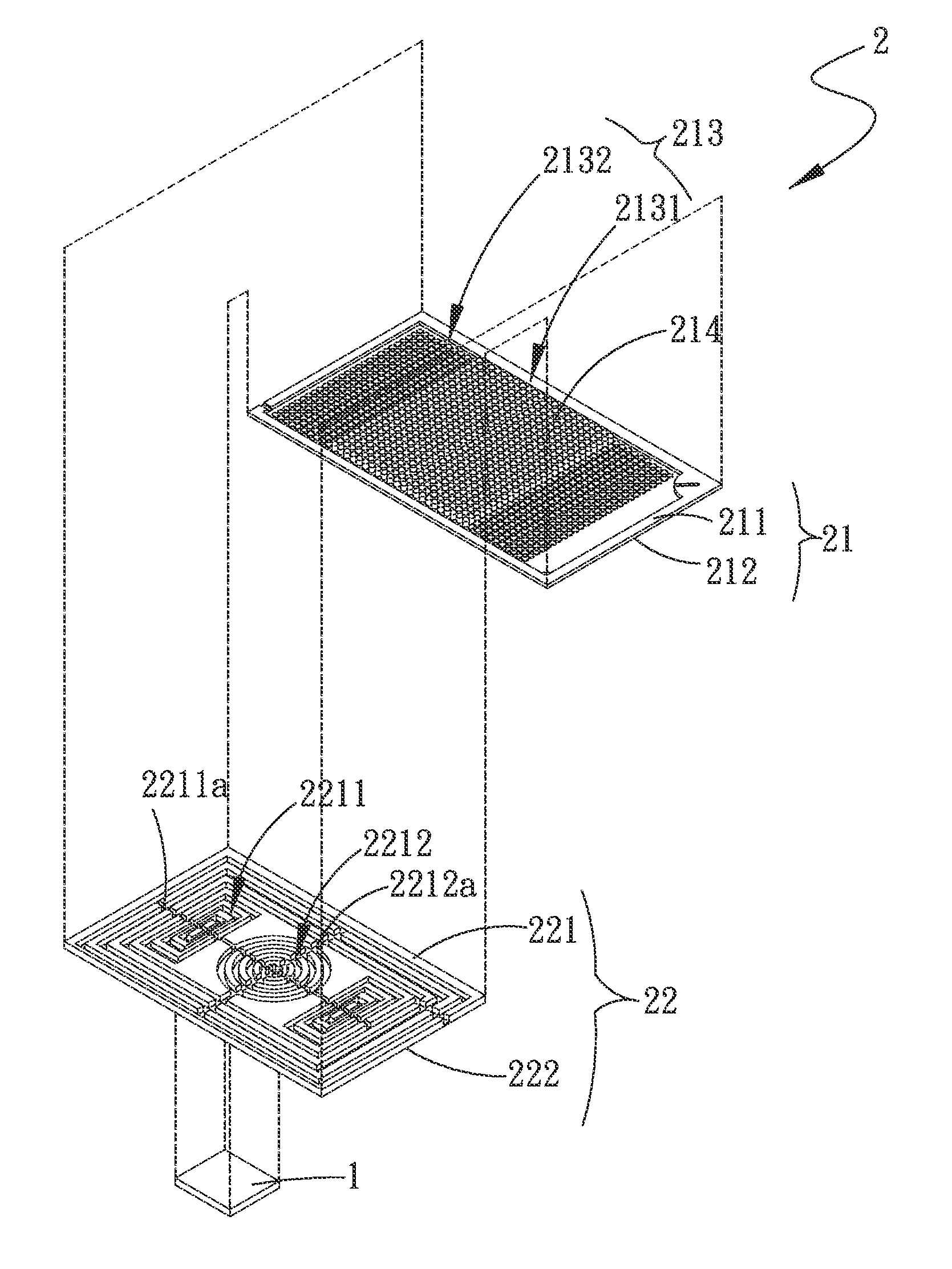

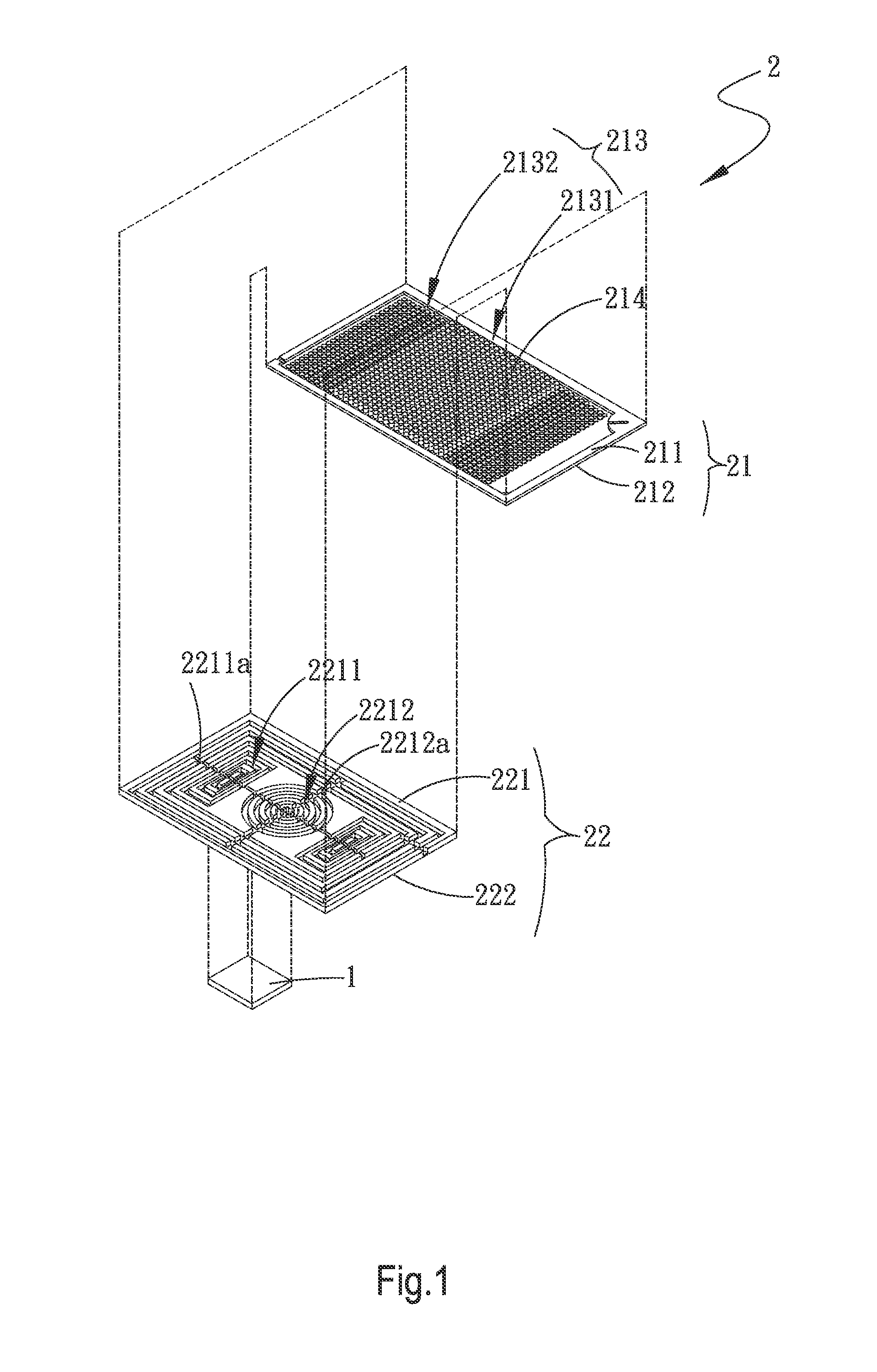

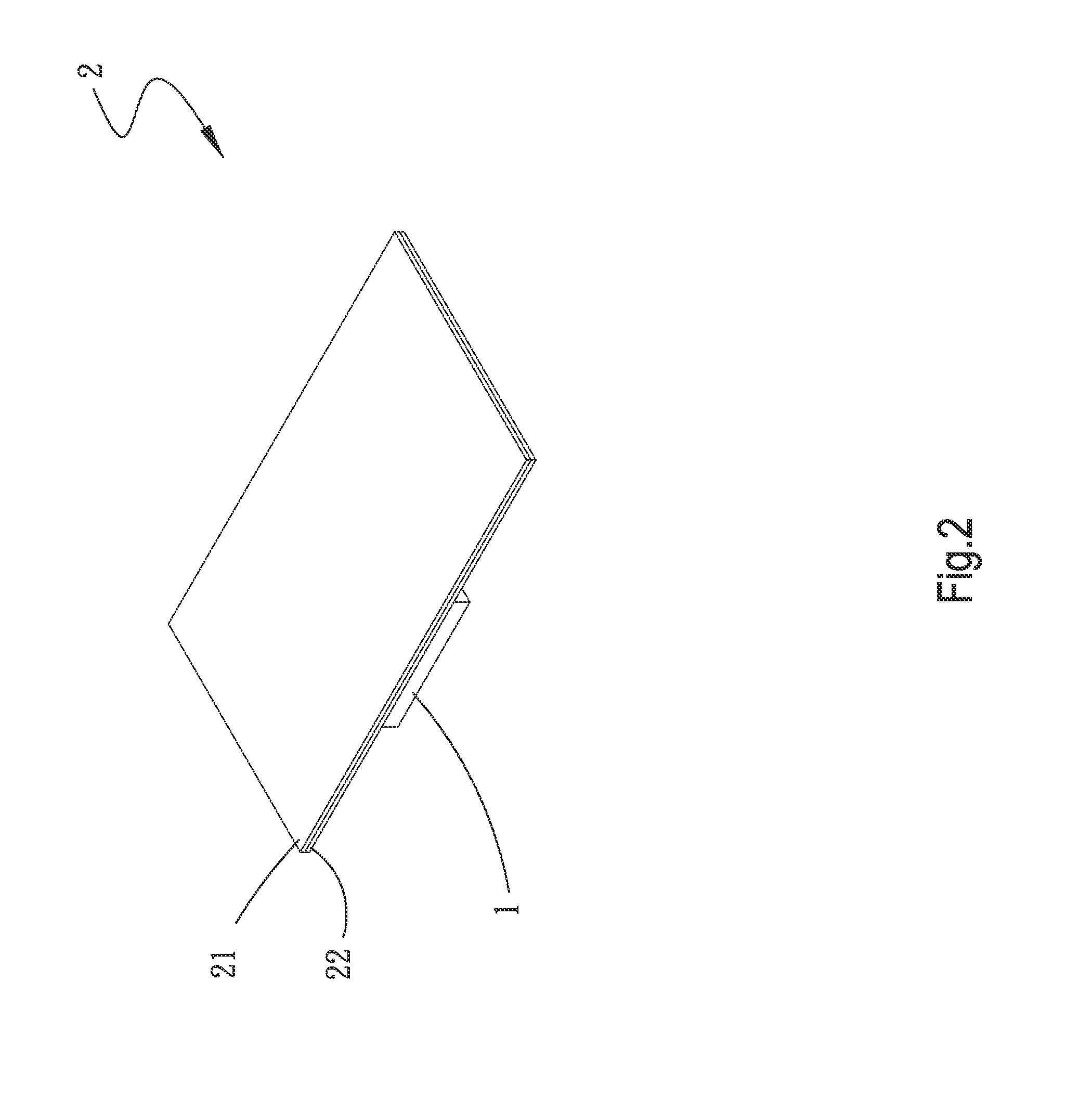

[0032]FIGS. 1, 2, 3 and 3a are an exploded perspective view, an assembled perspective view and two cross-sectional views of the first embodiment of the micro vapor chamber of the present invention respectively. As shown in these figures, the micro vapor chamber 2 of the present invention is configured to cooperate with at least one heat source 1. The micro vapor chamber 2 comprises a first plate 21 and a second plate 22.

[0033]The first plate 21 has a first side surface 211 and a second side surface 212. The first side surface 211 has at least one condensing region 213. The condensing region 213 has a plurality of protrusions 214. The protrusions 214 may have different diameters. As shown in FIG. 3a, the distal end of each protrusion 214 may be formed into a sharp end to facilitate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com