Water bagging system

a technology of water bagging and water bagging, which is applied in the direction of water/sewage multi-stage treatment, water/sewage treatment by oxidation, packaged goods type, etc., to achieve the effect of reliable production and extended shelf li

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

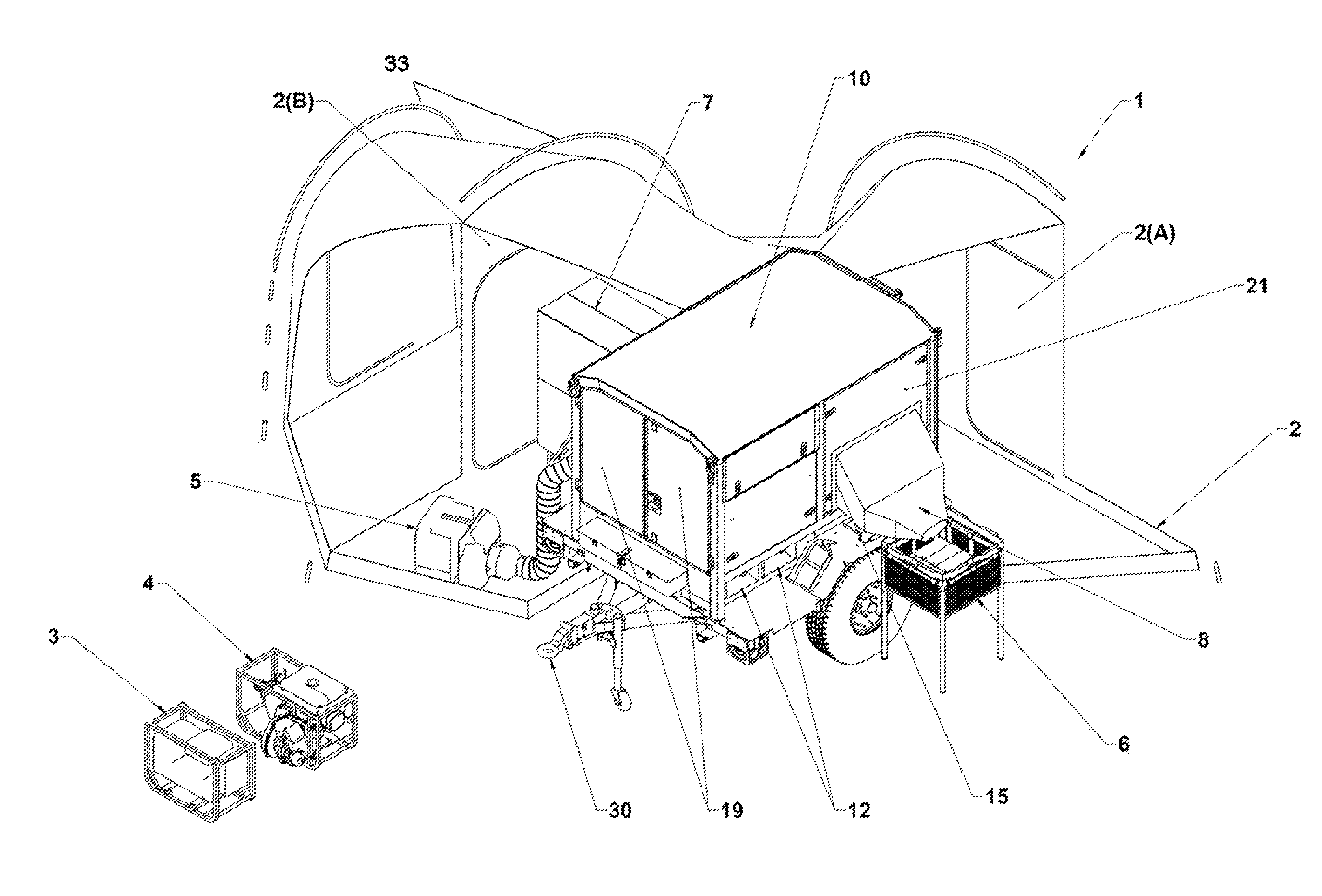

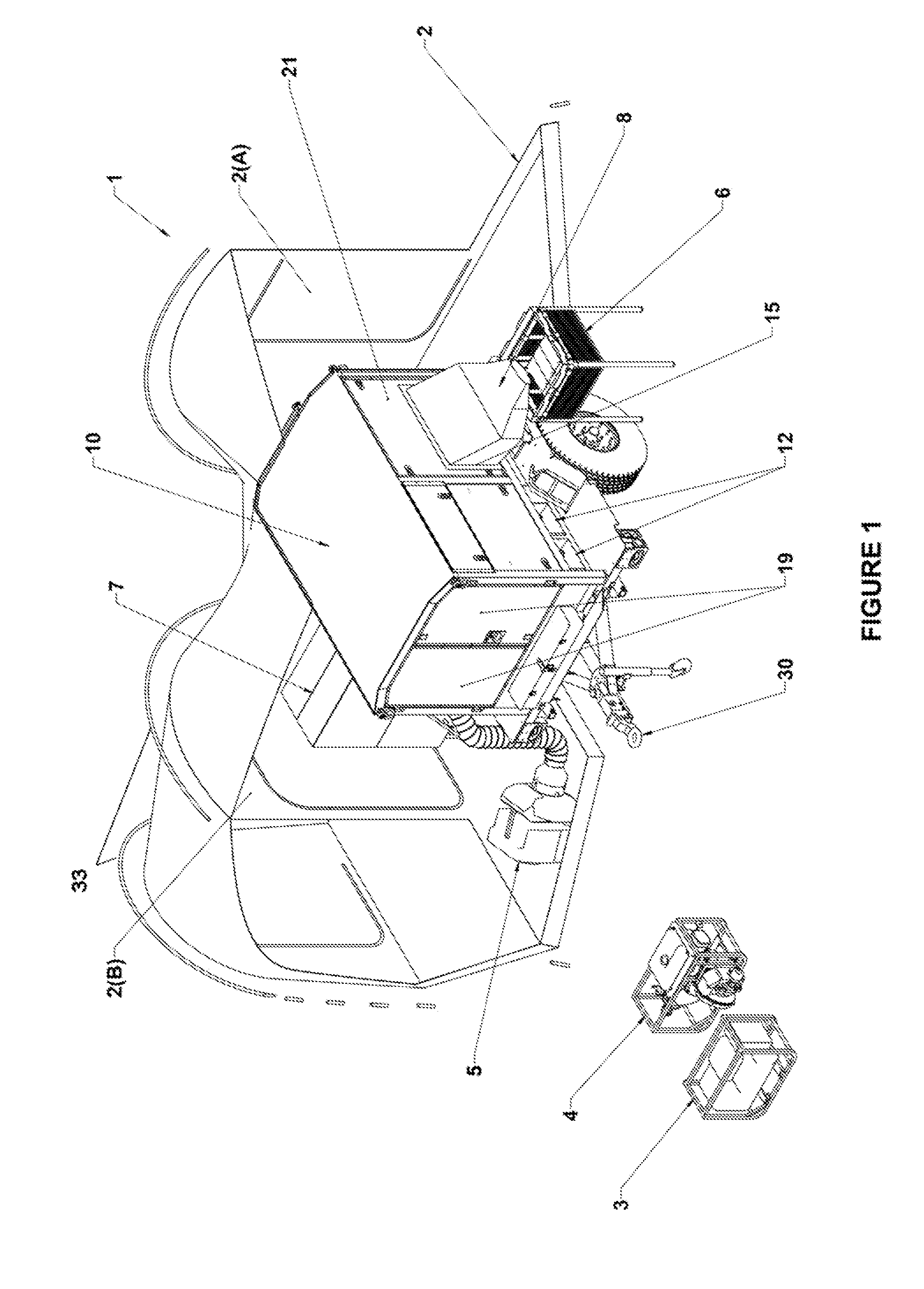

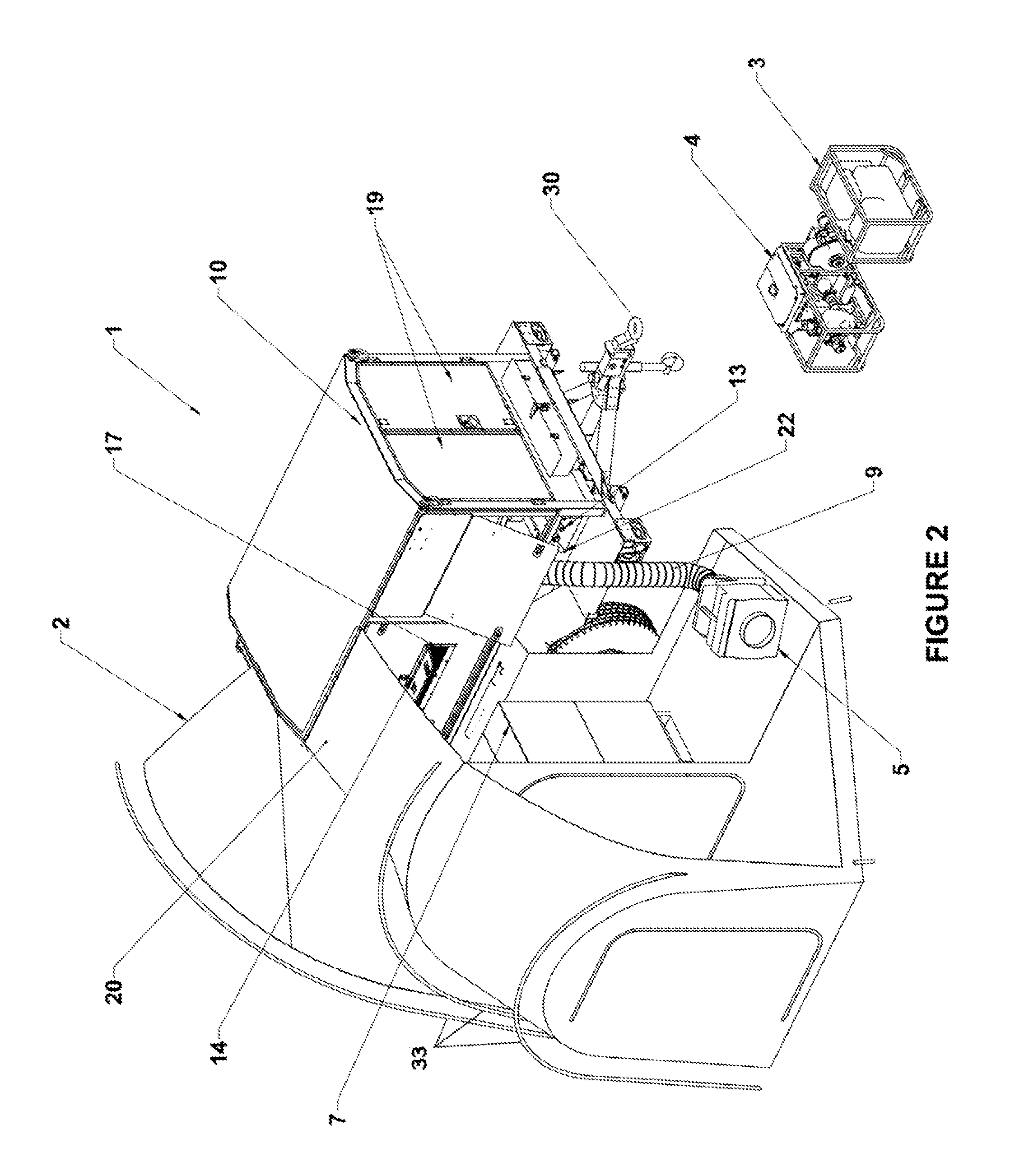

[0024]Reference will now be made in detail to the preferred embodiment of the present invention, examples of which are illustrated in the accompanying drawings. Wherever possible, the same reference numbers will be used throughout the drawings to refer to the same or like parts.

[0025]The present invention is a field-portable tactical water bagging system capable of drawing water from a TWPS or other potable water source, applying secondary filtering and UV-sterilization, and of auto-feeding empty water bags from a shipping box of pre-manufactured water bags (pre-equipped with fitments) placed proximate the system, for producing filled and sealed water bags for distribution. Specifically, the design and components used in the invention provide a compact energy efficient controlled environment for a commercial automatic bag filling machine that allows it to operate without problems in the harsh military and disaster relief environments.

[0026]FIG. 1 is a roadside-top perspective view o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com