Container Candle with Enhanced Candle Performance and Candle Insert for Container Candle

a container candle and candle technology, applied in the field of container candle inserts, can solve the problems of inefficient combustion and disruption of flames, and achieve the effects of improving burn control, accelerating the delivery of active scent, and enhancing the performance of candles during burning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

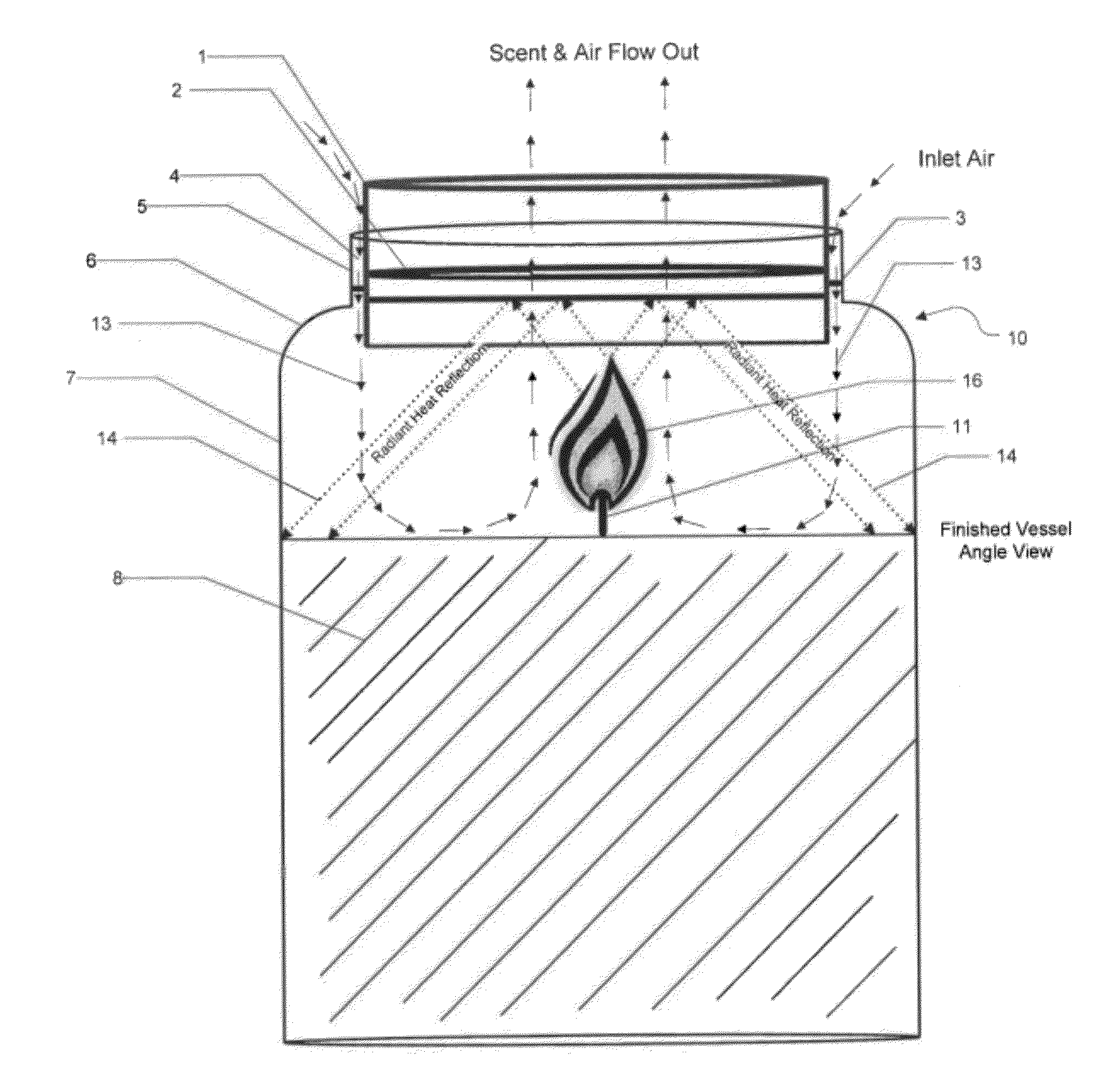

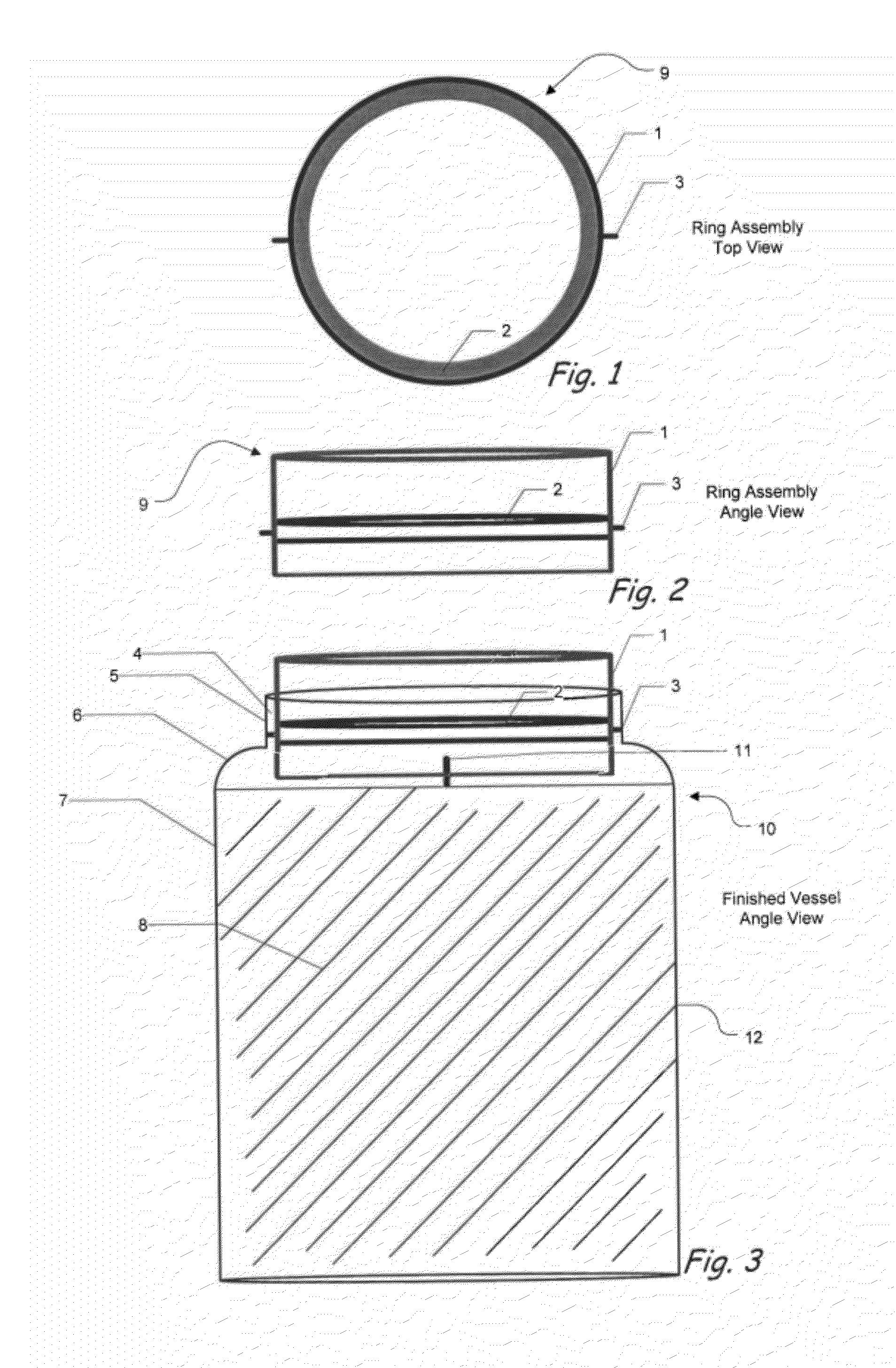

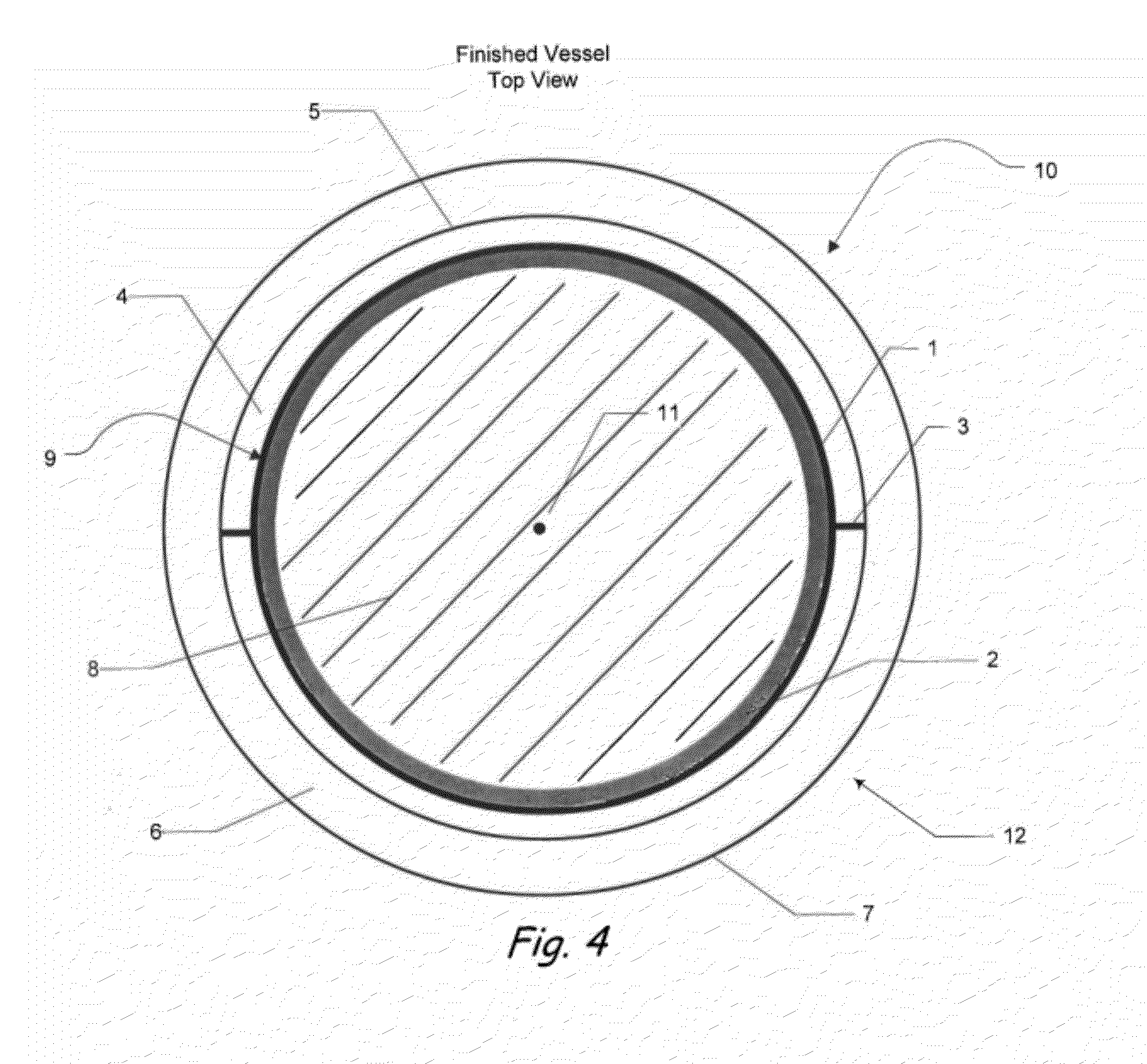

[0018]Referring to the embodiment shown in FIGS. 1-5, a container candle 10 of the present invention includes a container 12, which can be of any shape with an opening at the top of the container. Typically, container 12 would be made of glass, but container 12 could also be made of other non-combustible materials. A chimney-like cylindrical ring assembly 9, shown in FIGS. 1 and 2 is inserted in the container 12. The ring assembly 9 includes an air diverter cylinder 1, a heat reflection ring 2, and contact points 3.

[0019]FIGS. 3 and 4 illustrate a finished container candle 10 with the integrated ring assembly 9 inserted therein. The design of this container candle 10 enhances performance of the candle during burning by controlling the flame and reflecting heat. The ring assembly 9 is connected to the finished container 10 by one or more contact points 3 that are secured to the container by an adhesive. The ring assembly 9 is sized and positioned to allow the formation of an air gap ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com