Flame retardant poly(siloxane) copolymer compositions, methods of manufacture, and articles formed therefrom

a polycarbonate and composition technology, applied in the field of polymer compositions, can solve the problems of difficult formulation, limited set of polycarbonates used in aircraft and other directions, and achieve the effect of reducing the number of polycarbonates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

Materials.

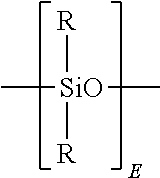

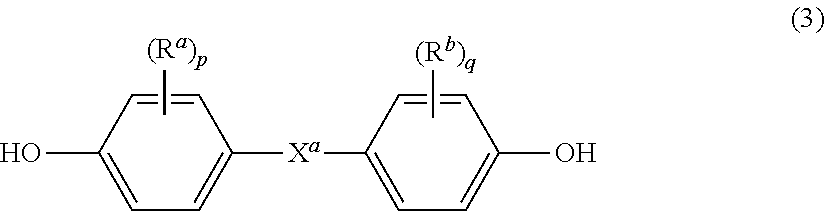

[0118]The descriptions of the polycarbonates and polycarbonate copolymers used in the Examples are described in Table 1. Methods for preparing the brominated polycarbonates and the poly(siloxane-carbonate) copolymers are described after Table 1.

[0119]In Table 1, a reference to D10, D30, or D45 means a dimethylsiloxane block having an average length of 10.5+ / −2.5, with two additional terminal silicon group (with silicon hydride levels of less than 20 ppm, volatiles of less than 0.4%), 30+ / −4 with two additional terminal silicon groups (with silicon hydride levels of less than 20 ppm, volatiles of less than 0.4%, and D3 and D4 levels of less than 10 and 1000 ppm respectively), or 45+ / −5 with two additional terminal silicon groups (with silicon hydride levels of less than 20 ppm, volatiles of less than 0.4%, and D3 and D4 levels of less than 10 and 1000 ppm respectively.). The values of D and wt % siloxane for the copolymers in Table 1 were as charged to the reactor.

[0120]The...

examples 46-49

[0193]These Examples show the synergistic effect of siloxane from a poly(etherimide-siloxane) and a brominated polymer on heat release and smoke density in polycarbonate compositions. Results are shown in Table 15. Results showing the effect of poly(etherimide-siloxane) concentration on DsMax are plotted in the FIG. 1, and results showing the effect of poly(etherimide-siloxane) concentration on OSU heat release are plotted in FIG. 2.

TABLE 15ComponentsEX 46EX 47EX 48CEX 49TBBPA-BPA40.0040.0040.0040.00SILTEM7.005.002.500.00PC53.055.057.560.0Additive0.060.060.060.0Total FormulationWt % Siloxane2.61.90.90.0Wt % Bromine10.410.410.410.4PropertiesMVR 6 minutes5.55.65.76.8NI-125, RTDuctility0.00.00.00.0J / m13011911790.8ft-lbs / in2.42.22.21.7MAI, RTDuctility100100100100Energy to maxJ75.075.878.278.1Energy to failureJ81.681.883.684.3Energy, Total-AJ81.781.983.784.3Density, average1.2851.2861.2871.289HDT-ASTM-G1.8 MPa138.4139.7139.7141.5OSU Test FAR 25.853 (d) Appendix F, Part IV2 Min OSUAverage...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wt % | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| mole % | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com