Use of methylhydroxyethyl cellulose as cement additive

a technology of methylhydroxyethyl cellulose and cement additive, which is applied in the direction of clayware, sealing/packing, and well accessories, etc., can solve the problems of weakening the structure, affecting the quality of cement, so as to reduce the potential incompatibility and simplify the operation in the field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples 1-13

[0043]Cementitious slurries of desired density were prepared by mixing neat Joppa Class H Portland cement, optionally mixed with fly ash, with fresh tap water at room temperature. To the slurry was added methylhydroxyethyl cellulose (MHEC) and, optionally, sodium lignosulfonate (“SLS”) as set retarder. (Comparative slurries were also prepared using, in place of MHEC, HEC from one of three suppliers.) The resultant slurry was kept agitated by occasional stirring. The free fluid content of the slurries was determined in accordance with procedures in API Recommended Practice 10B-2, First Edition, July 2005. The amount of fluid loss was determined at a designated temperature in accordance with procedures in API Recommended Practice 10B, Twenty-Second Edition, December 1997, incorporated herein by reference. Standard API viscosity reading readings were taken on a Fann 35 viscometer, at 120° F., 160° F. or 170° C. The results are tabulated in Table I:

TABLE IFluidFreelossExampleDensityAddi...

examples 14-16

[0044]Cementitious slurries of 15.6 ppg density were prepared by mixing at room temperature 50 / 50 (v / v) fly ash / Joppa Cement H cement mix with fresh tap water. To the slurry was added 0.2% BWOC polynaphthalene sulfonate dispersant admixture (commercially available as CD-32 from Baker Hughes Incorporated) and 0.2 gallons per sac (gps) of an ammonium salt of ethoxylated alcohol sulfate foaming agent, commercially available as FAW-20 from Baker Hughes Incorporated. Further, to one slurry was added 0.2% BWOC MHEC and to another slurry was added 0.2% BWOC HEC. The stability of the foam was determined starting at a 15.6 ppg density and foamed down to 11.6 ppg. The results are shown in Table II. Further, the density of the cured cement was determined in a BP settling tube at 120° F. and the results shown in Table III, below. The tests were conducted in accordance with the protocol set forth in API Recommended Practice 10B-2 and ISO 10426-2.

TABLE IIFoamHomogenousstabilityStabledensitytestAd...

examples 16-17

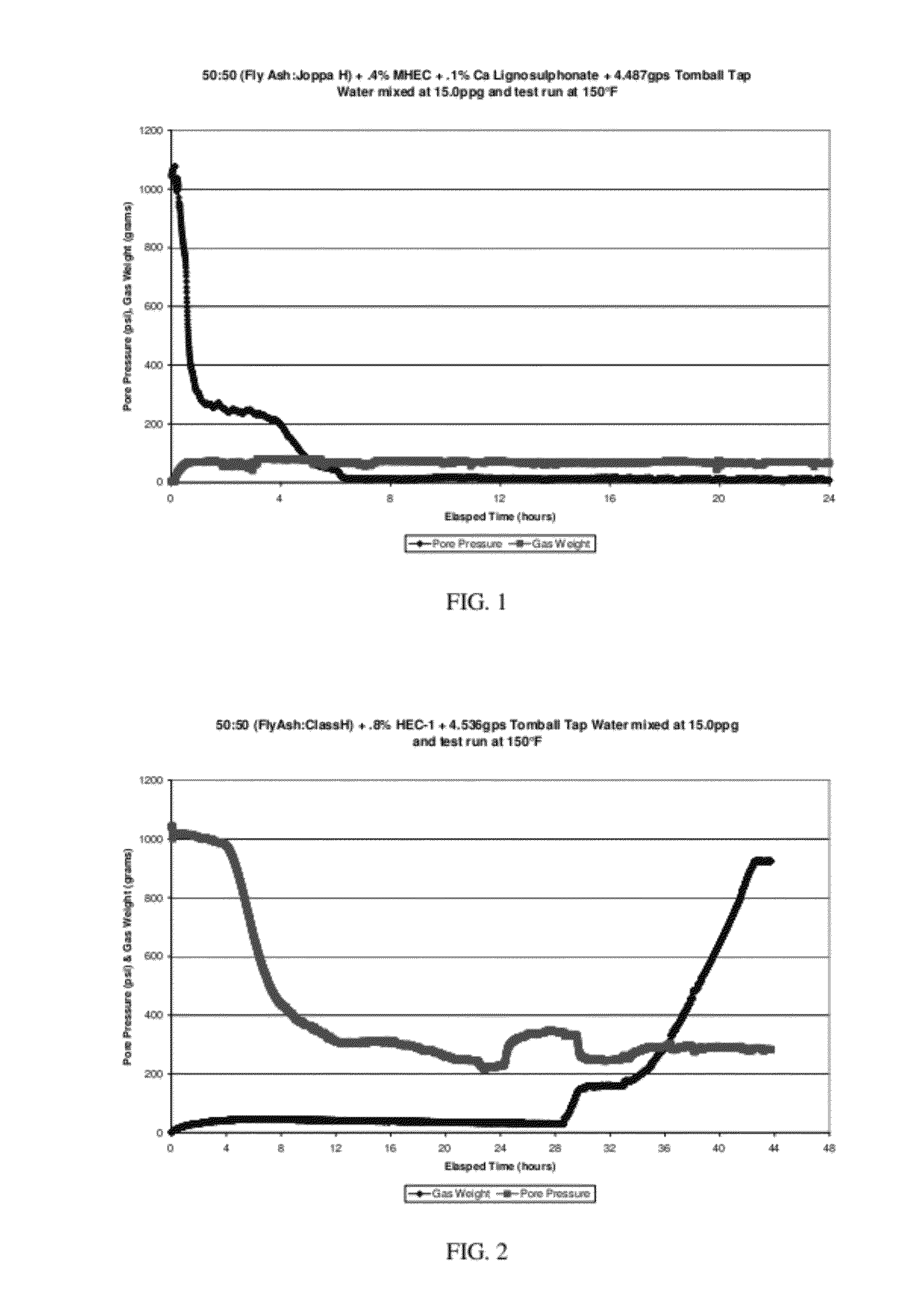

[0045]Cementitious slurries having a density of 15.0 ppg were prepared by mixing neat Joppa Class H Portland cement and fly ash (50:50 v / v) with fresh tap water at room temperature. To one slurry was added methylhydroxyethyl cellulose (MHEC) and to the second slurry was added hydroxyethyl cellulose (HEC). Sodium lignosulfonate (“SLS”) as set retarder was further added to one of the slurries in accordance with Table IV below:

TABLE IVMHEC,HEC,SLS,Amt Water,Ex. No.[BWOC][BWOC][BWOC]gps160.4—0.14.487Comp. Ex. 17—0.8—4.536

The gas volume and pore pressure of the cementitious slurries were determined over an extended period of time. These were determined by a Gasflow Model which was used to simulate the well configuration where the cemented annulus is between pressurized gas sand and a low pressure permeable zone. (In a typical well configuration where the cementitious slurry in the annulus between the casing and the formation, the cement is exposed to a highly permeable gas zone and a low...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com