Patents

Literature

33results about How to "Good slurry stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

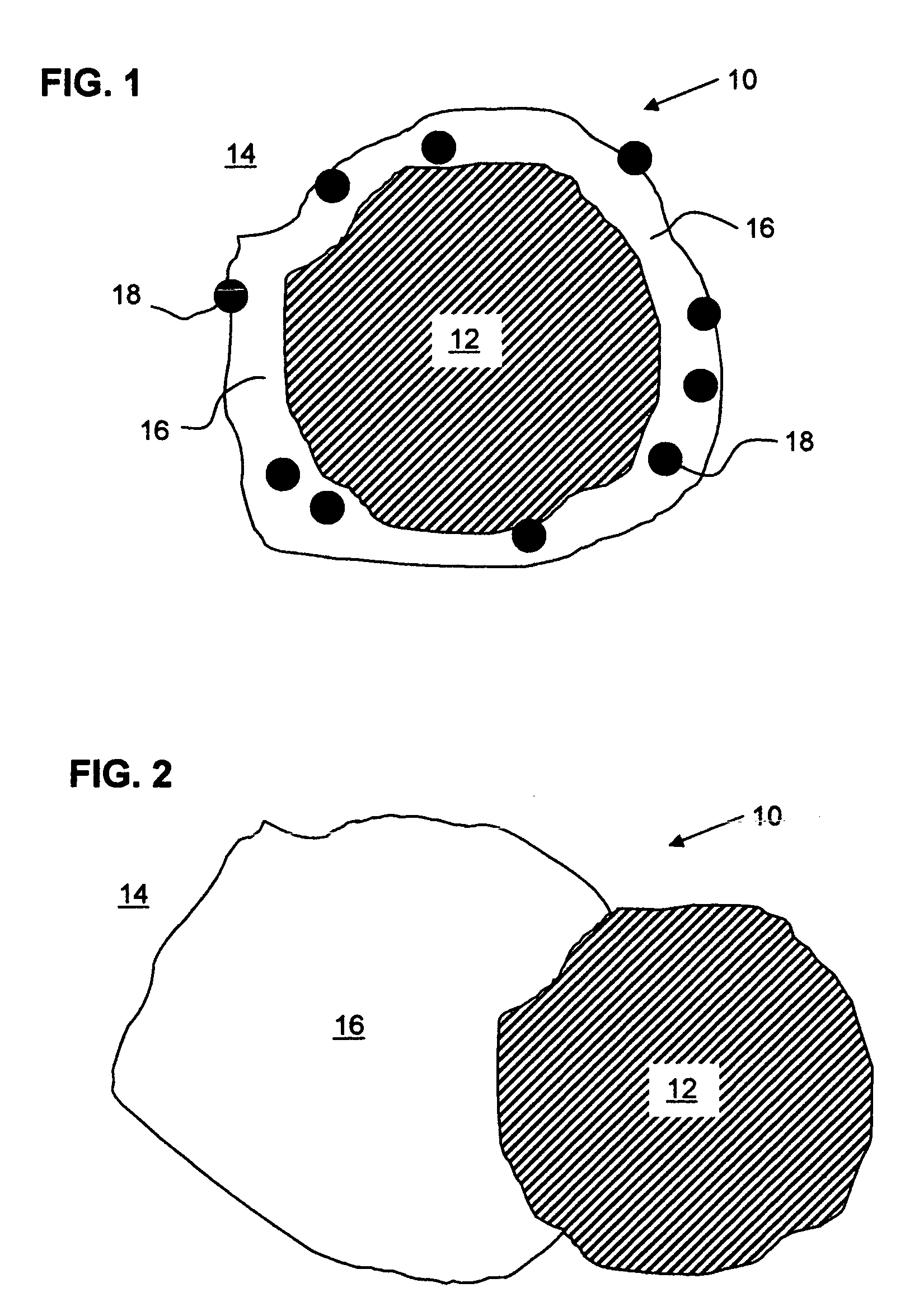

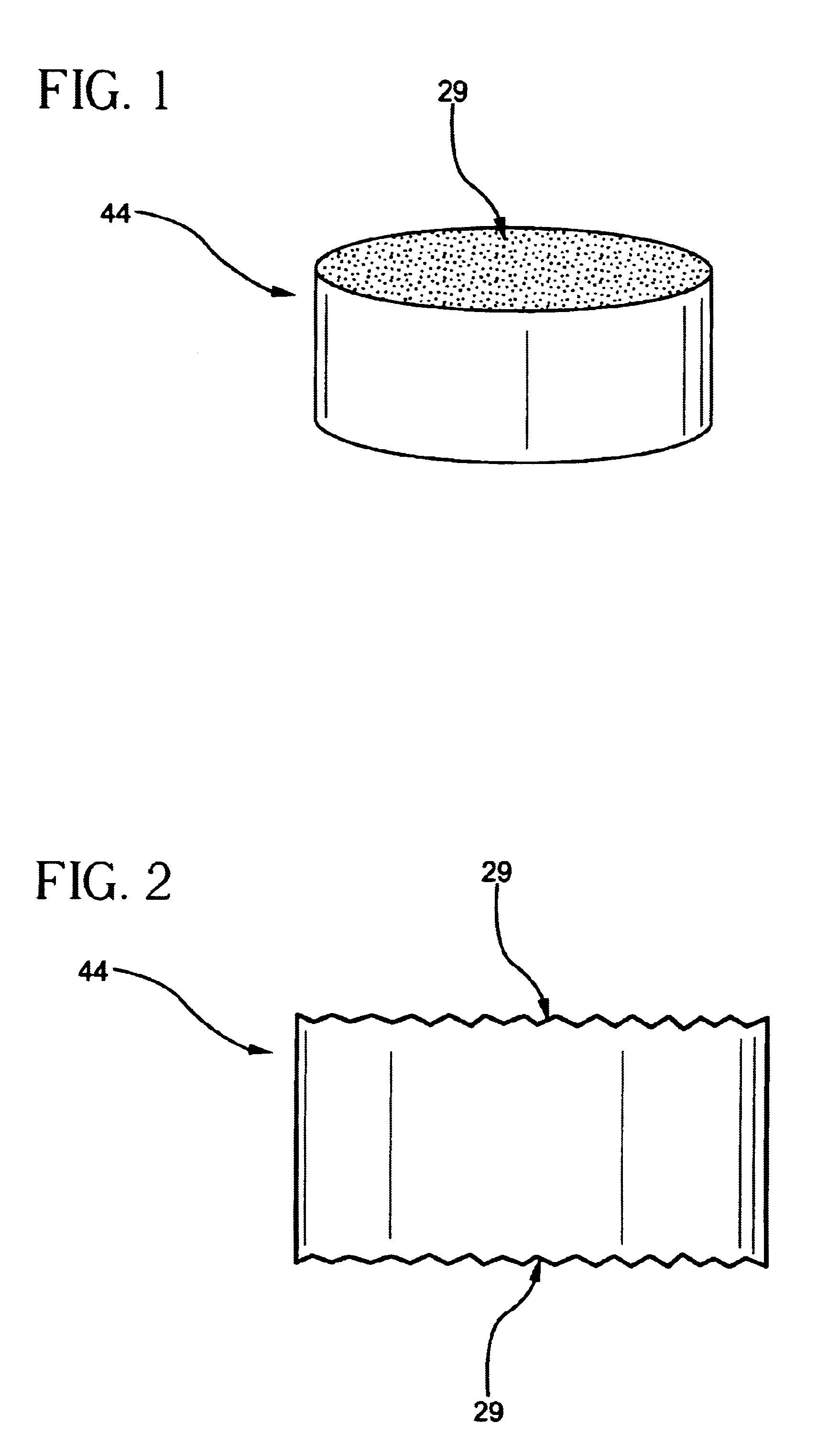

Density-matched polymer slurries

ActiveUS20060058437A1Readily transported and introducedGood slurry stabilityPaper coatingCoatingsParticulatesPolymer science

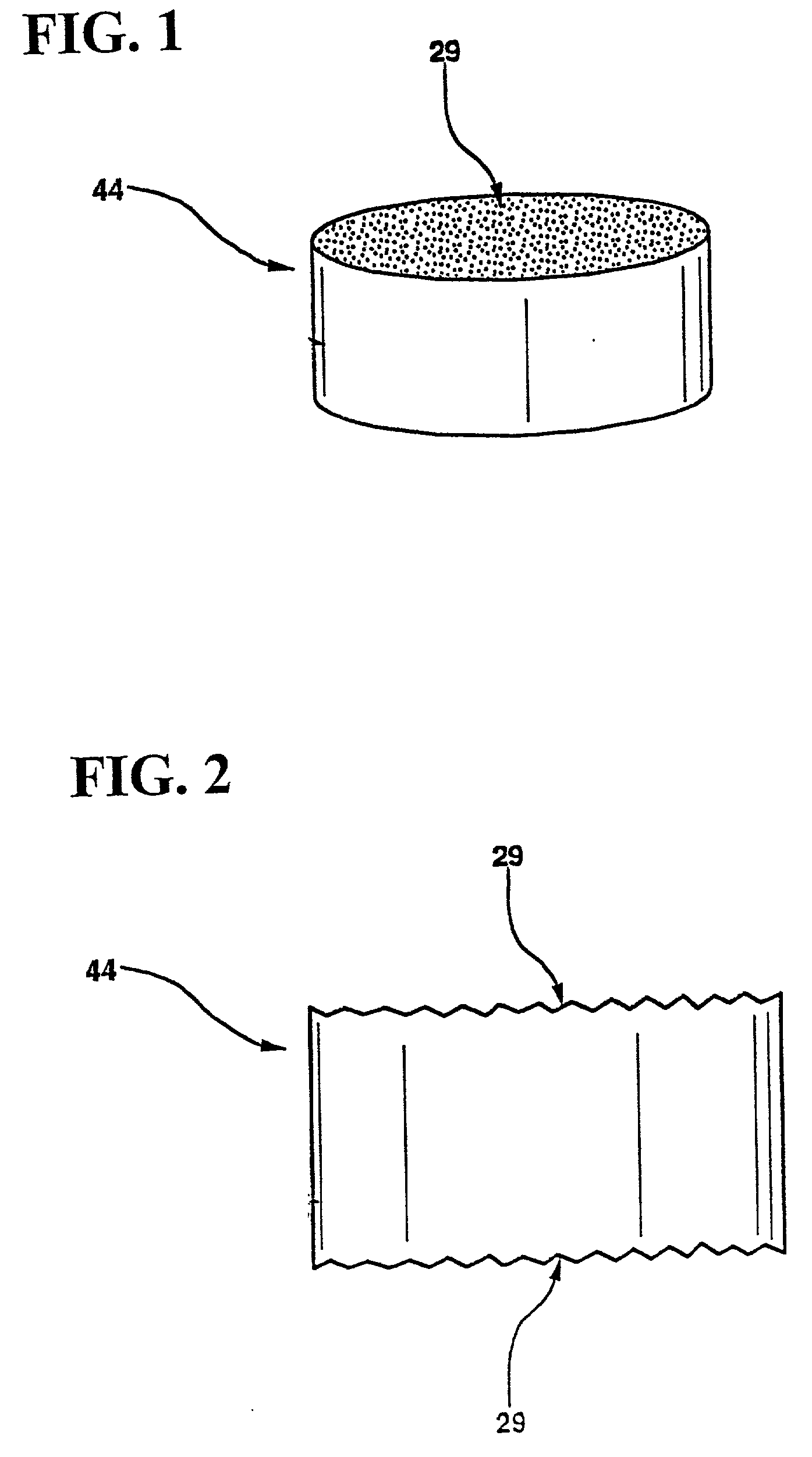

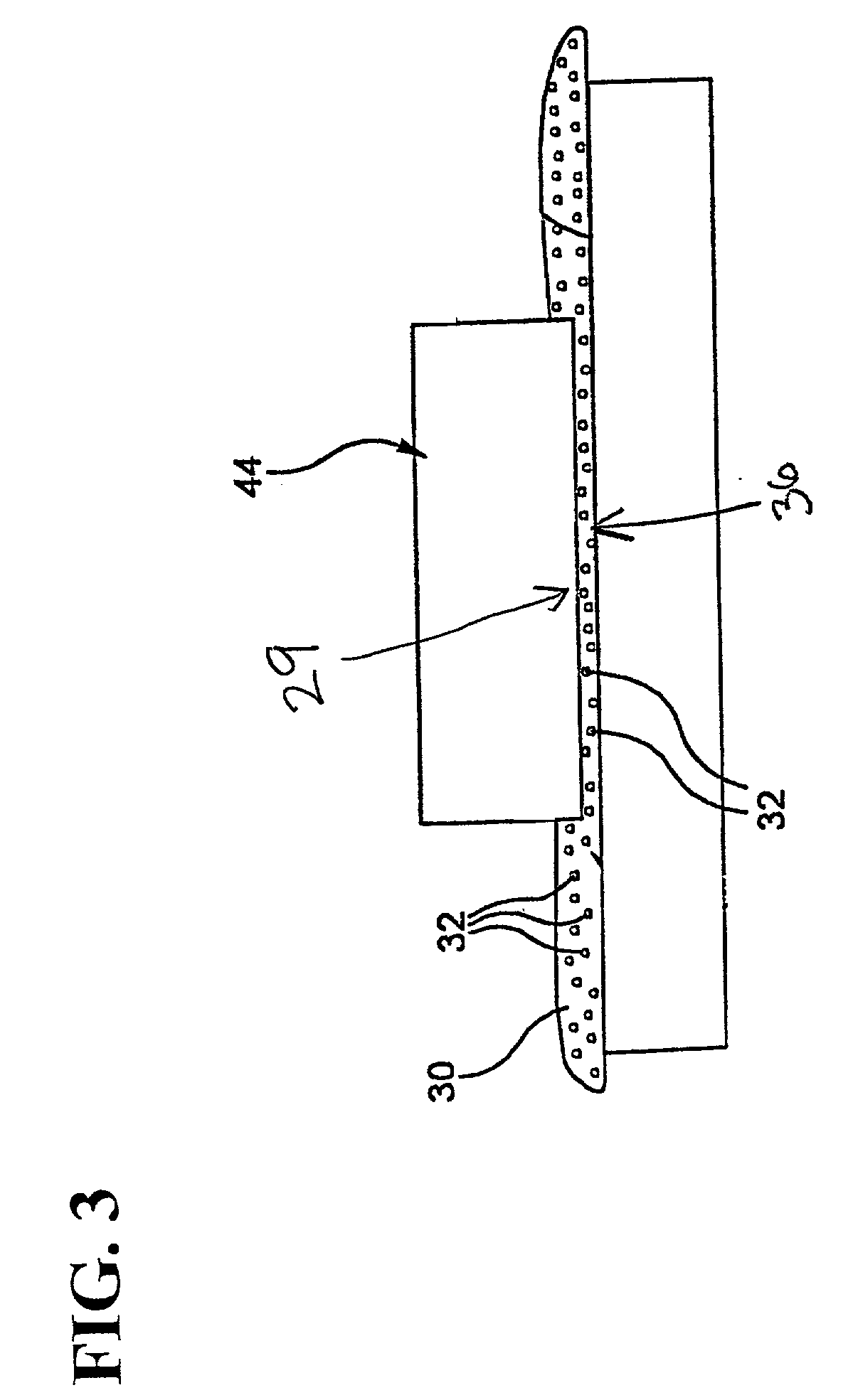

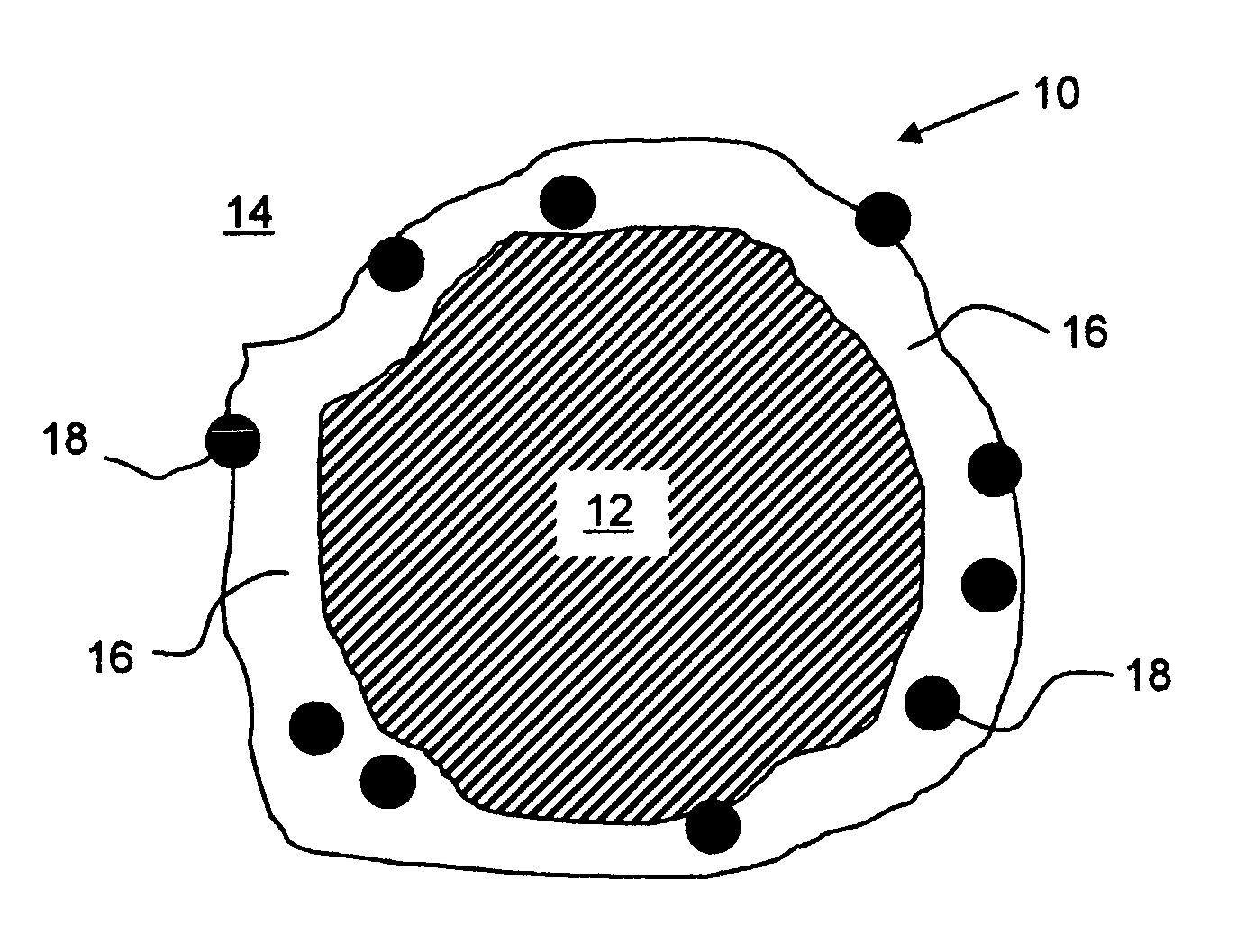

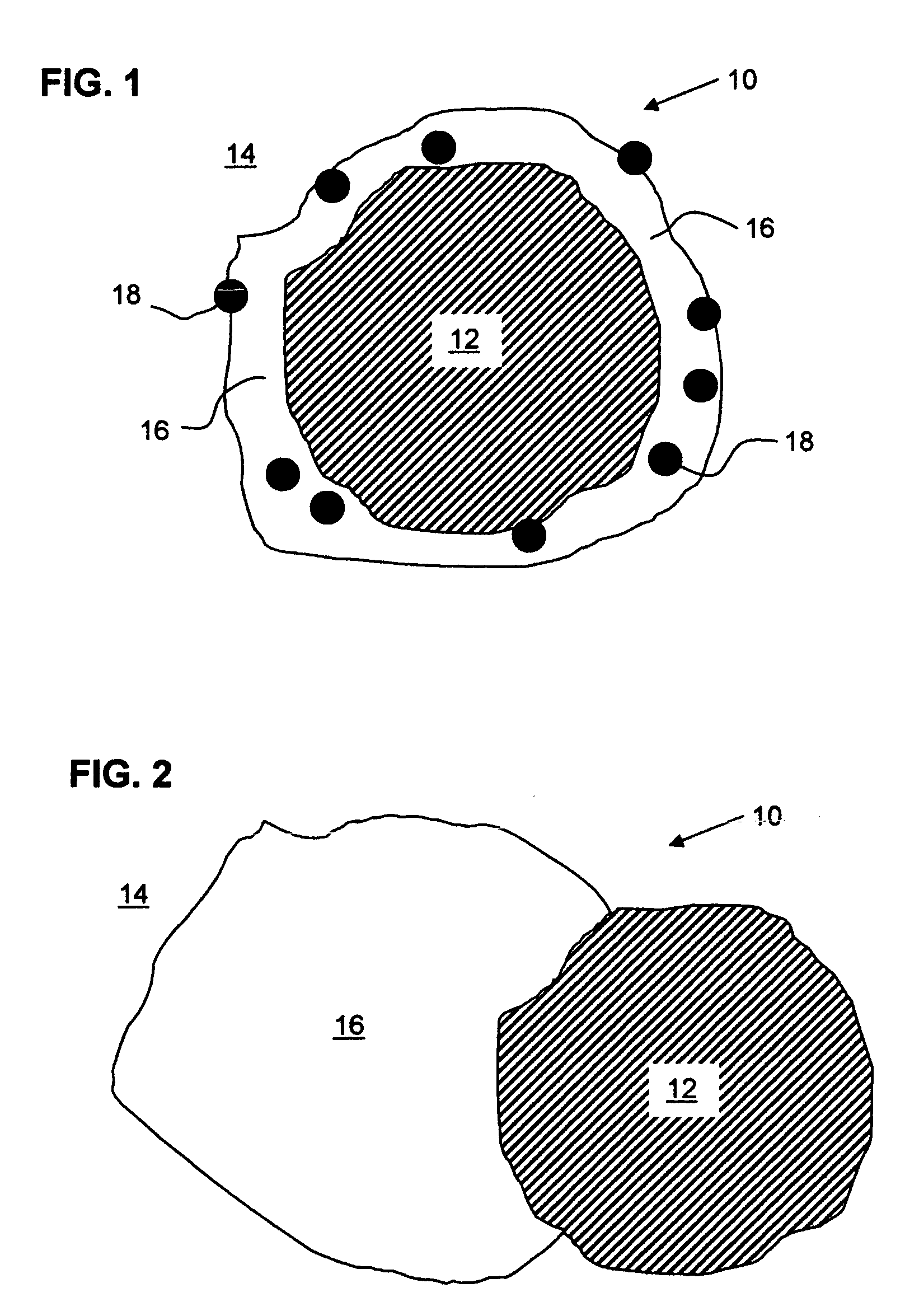

Polymer slurries of ultrahigh molecular weight polyalpha-olefins are made stable toward settling, separation and agglomeration by surface treatment with a combination of wax and optional relatively high-density particulates. The selection of the surface coating acts not only as an anti-blocking agent, or partitioning aid to keep the tacky polymer particles separated, but also provides the suspended polymer particle with a density that matches the carrier. This prevents separation of the slurry components over time. Such materials, ultimately used as pipeline additives to reduce the fluid drag and increase the volumetric throughput, can be stored and shipped for extended periods of time without degradation of the slurry quality. Upon injection into the pipeline, the polymer particle dissolves quickly, unhindered by the coating.

Owner:BAKER HUGHES INC

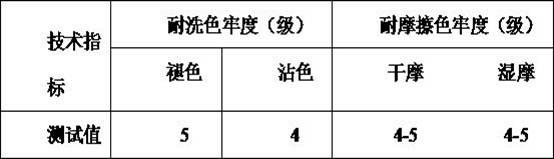

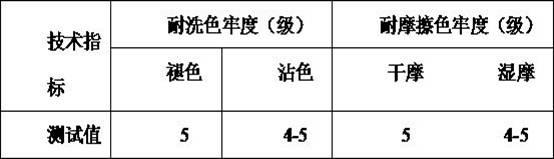

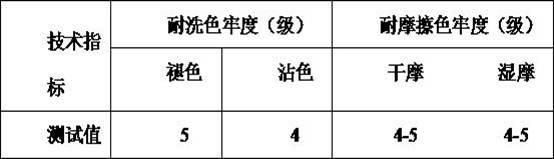

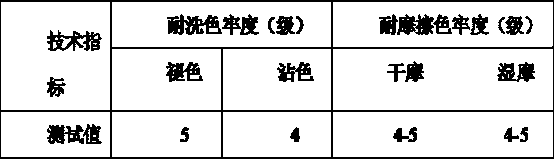

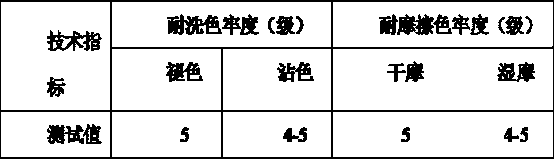

Printing gum for polyester fabrics and novel low-gum printing method

The invention relates to printing gum for polyester fabrics and a novel low-gum printing method. The novel low-gum printing method is realized by the aid of a combination synergia effect of a printing gum composition for the polyester fabrics. The printing gum composition is used for replacing high-concentration sodium alga acid gum for printing polyester fabrics, and problems that the conventional printing gum is difficult to clean, utilization quantity is high, wastewater COD (chemical oxygen demand) is high, disperse dye fixation degree is low, dyeing fastness is poor, color mixing is severe, efficient soaping process flow is long, and the like are resolved. By the aid of the printing gum composition for the polyester fabrics and the novel low-gum printing method, the process flow of a printing processing procedure of fabrics is reasonable, the quantity of wastewater is reduced, a production process is clean and environment-friendly, the quality of products is table, and dye color yield is high.

Owner:浙江嘉欣兴昌印染有限公司

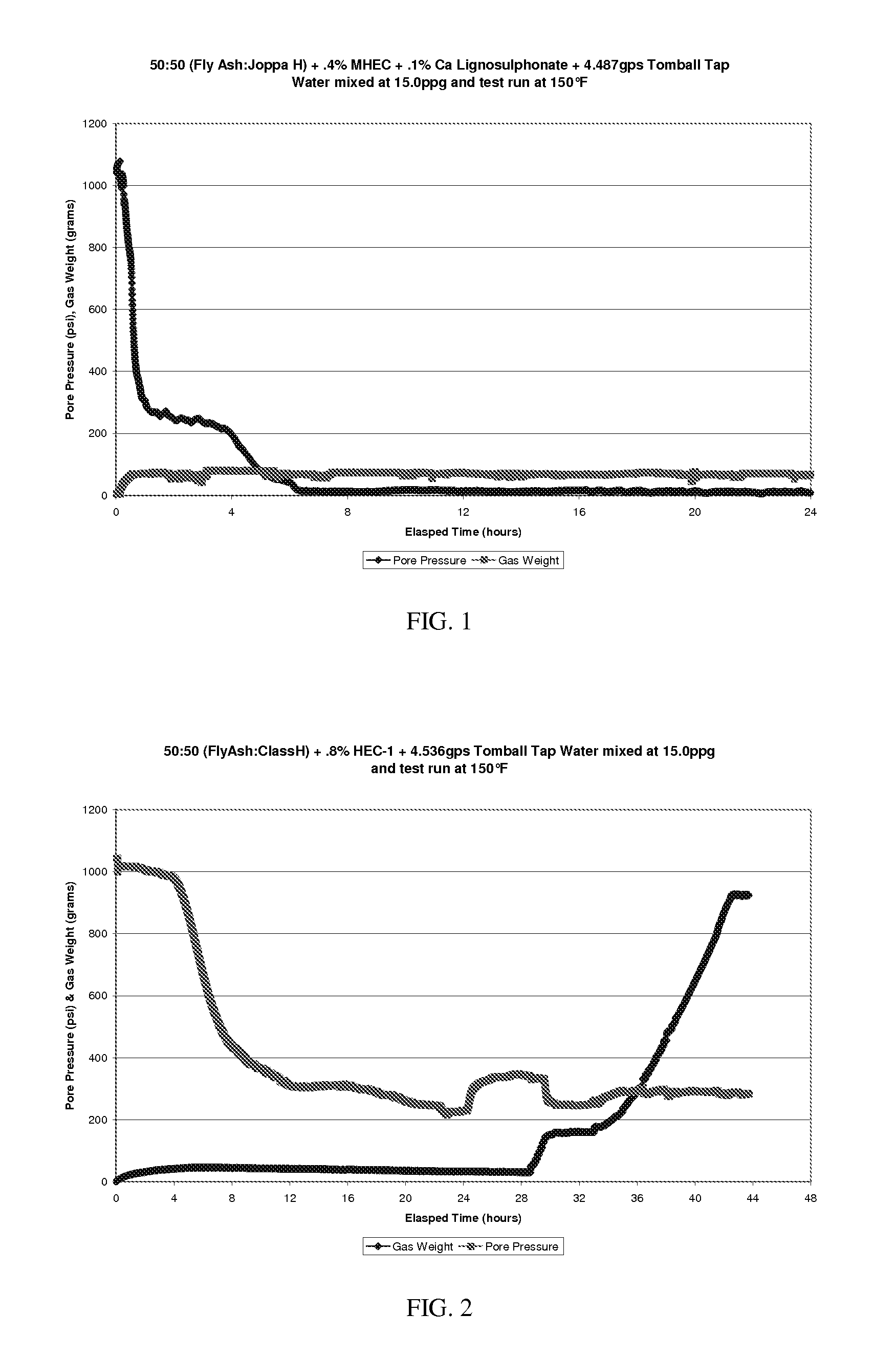

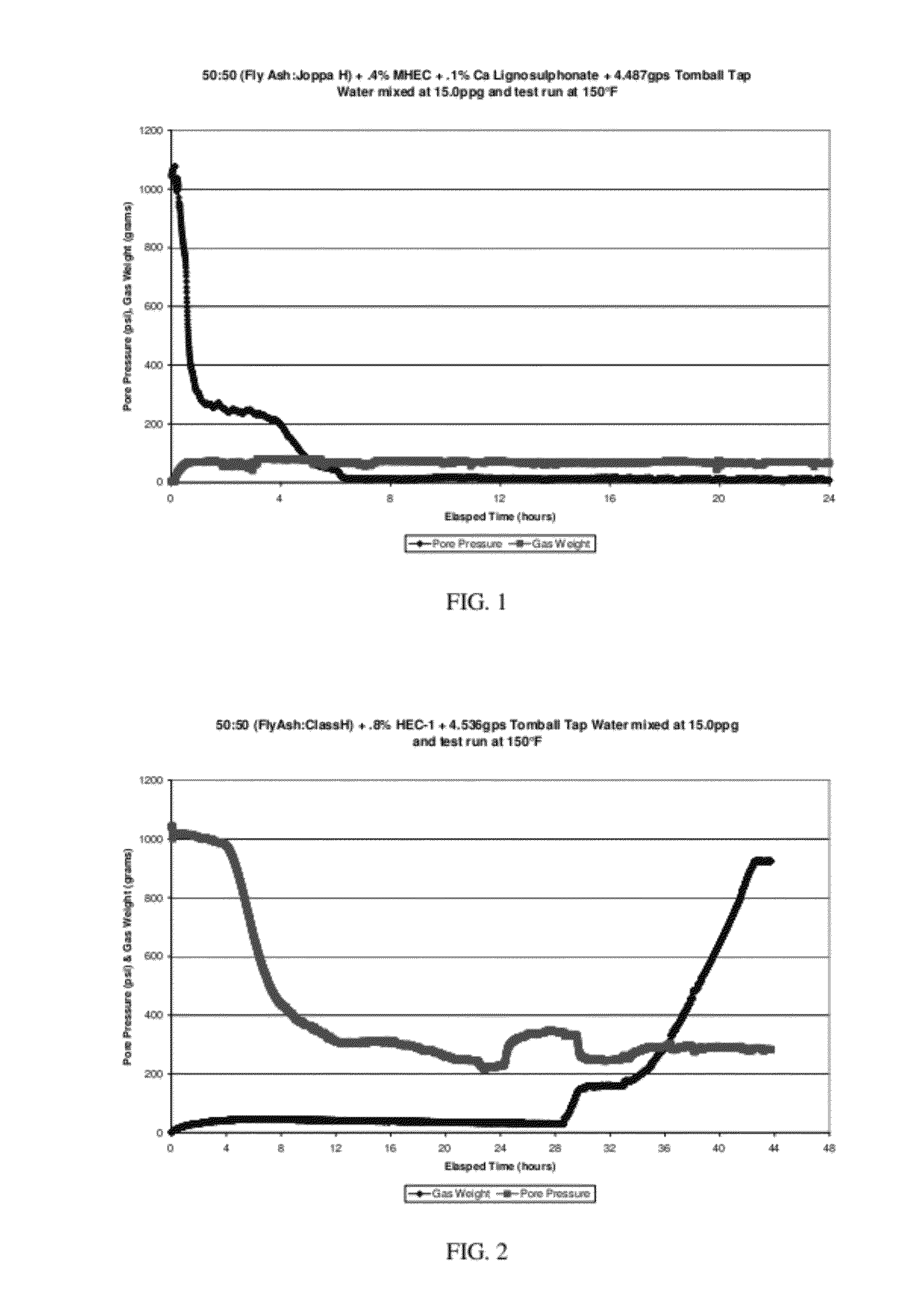

Use of methylhydroxyethyl cellulose as cement additive

ActiveUS8689870B2Prevent and reduce occurrenceMinimizes free fluidFlushingDrilling compositionCelluloseCement slurry

Owner:BJ SERVICES LLC

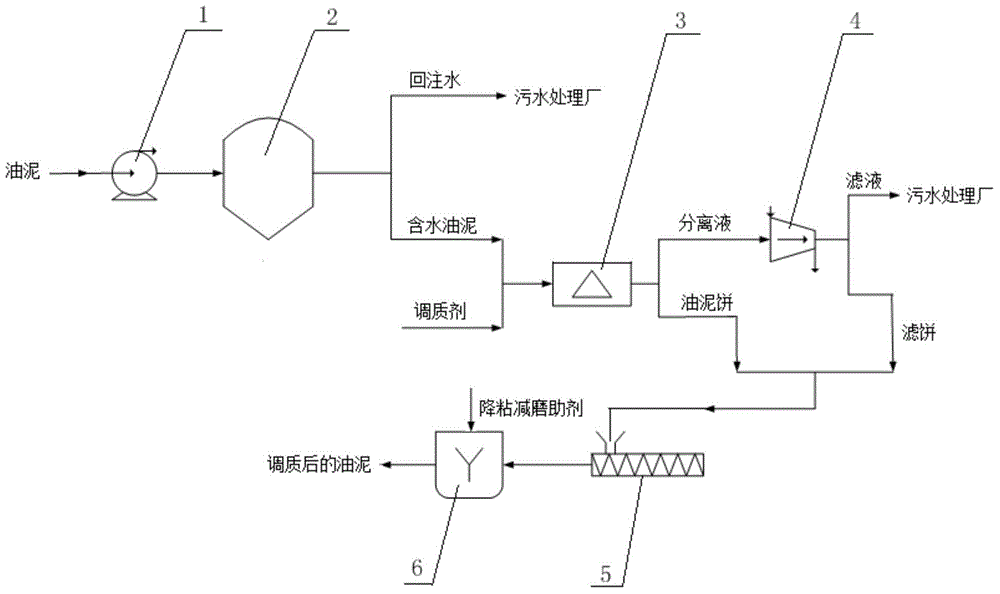

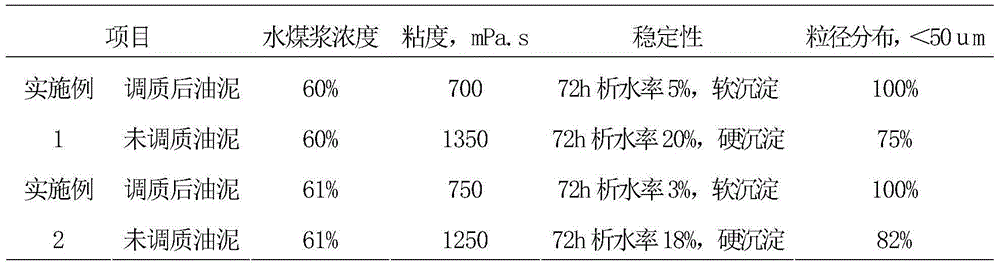

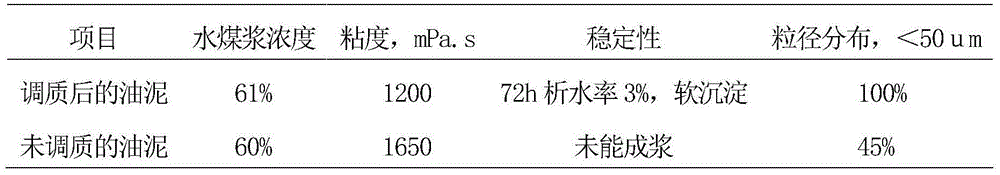

Method for tempering oily sludge blended with coal water slurry

ActiveCN103979768AEasy to separateLow viscositySludge treatment by de-watering/drying/thickeningLiquid carbonaceous fuelsReduction treatmentPolyolefin

The invention discloses a method for tempering oily sludge blended with coal water slurry. A fluorine-containing water-soluble macromolecule copolymer and a surfactant are dorpwise added for tempering treatment in the oily sludge centrifugal reduction treatment process; polyol ester lubricating oil, a polysulfide lubricating oil and a polyolefin drag reducing agent are added into the oily sludge subjected to the reduction treatment; and ultrasonically intensified mass transfer dispersion is carried to finally obtain the tempered oily sludge. The oily sludge tempering equipment needed in the method is simple, the treatment efficiency is high, the tempered oily sludge can be directly added into a conventional coal water slurry preparation system for preparing coal water slurry which has relatively high slurry concentration, good flowability and relatively good slurry preparation stability; therefore, relatively high industrial application values are achieved, meanwhile a guarantee is provided for harmless treatment and resource utilization of the oily sludge, and remarkable comprehensive economic and environmental-friendly benefits are achieved.

Owner:SHAANXI YANCHANG PETROLEUM GRP

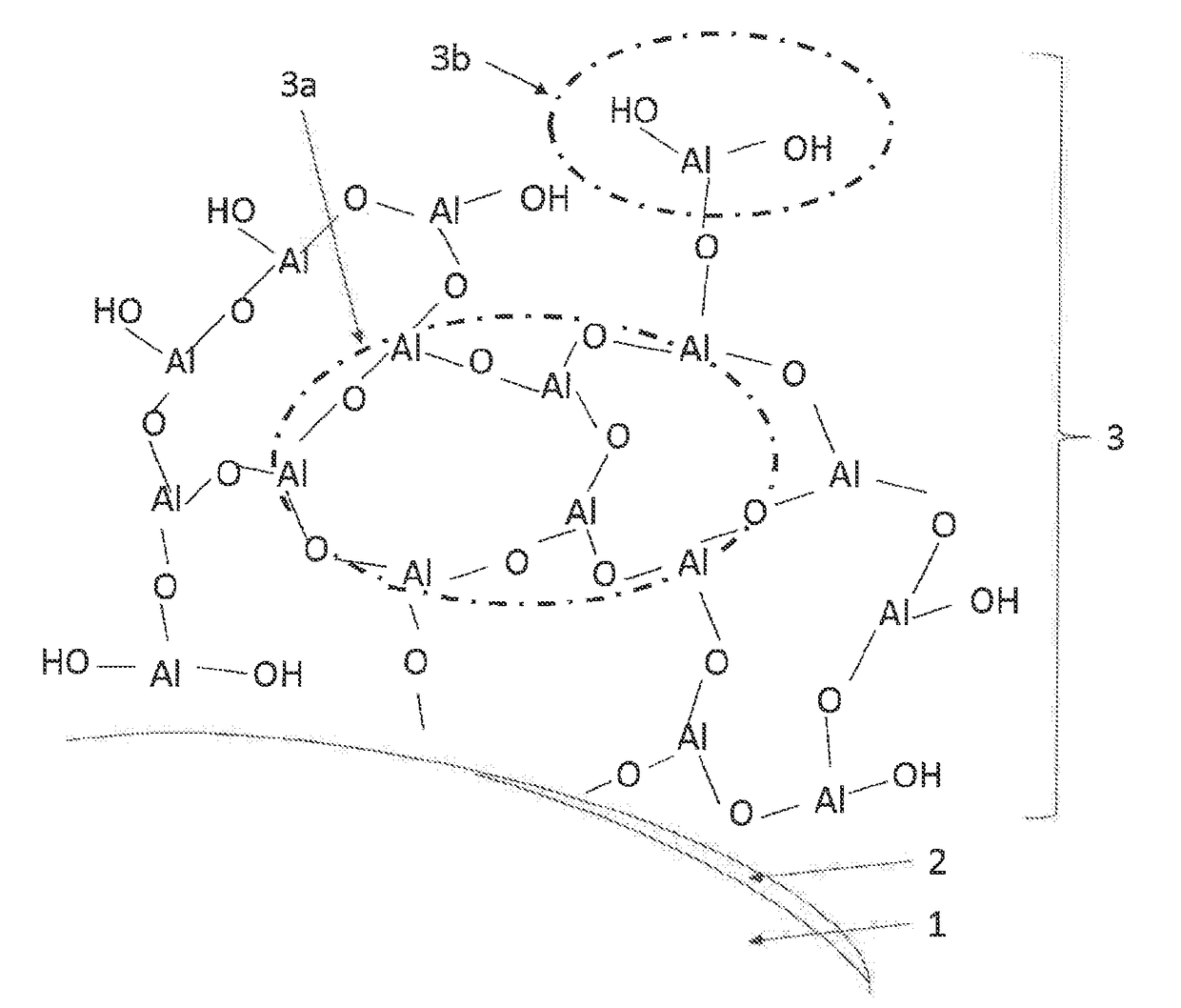

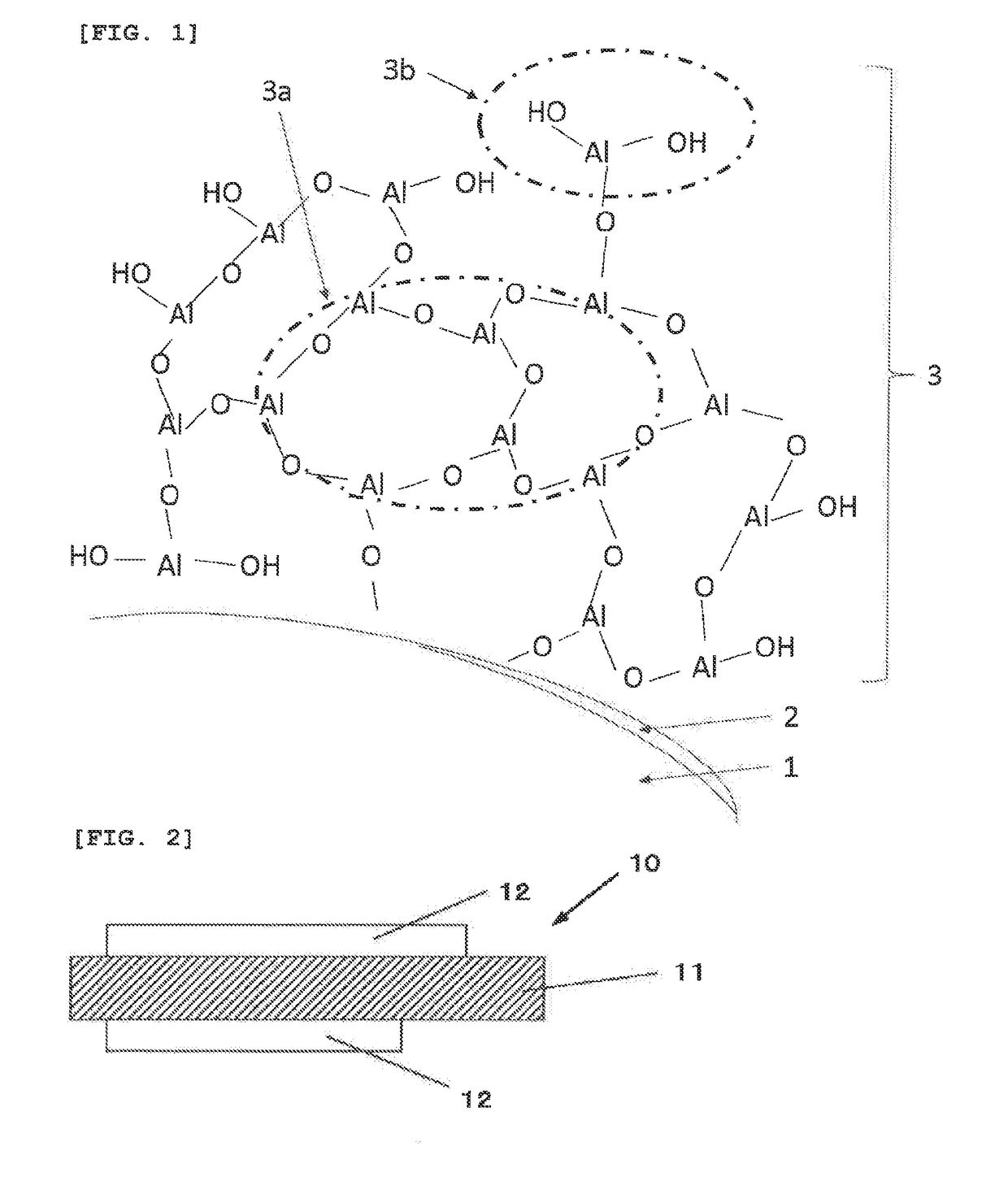

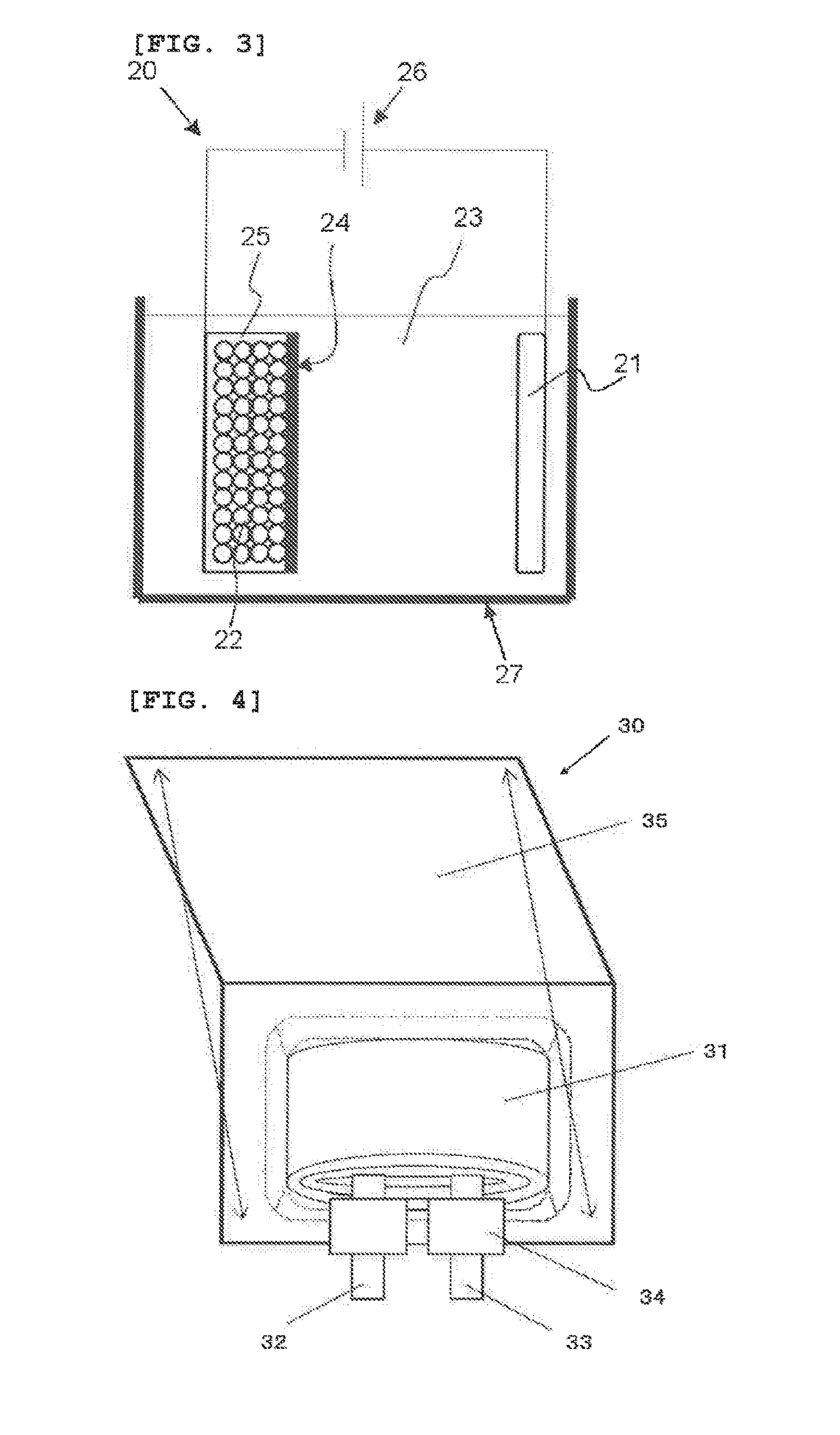

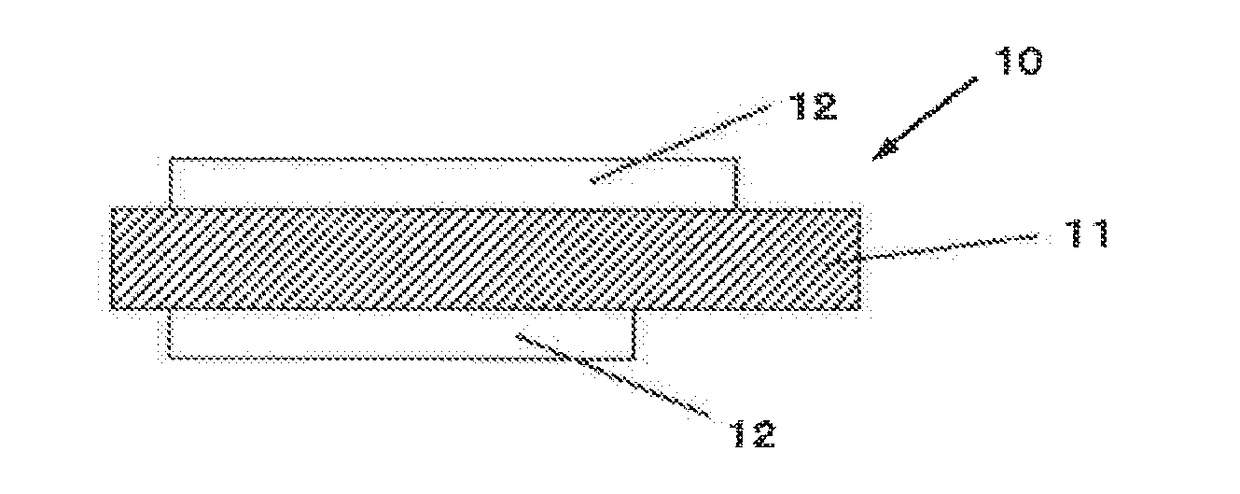

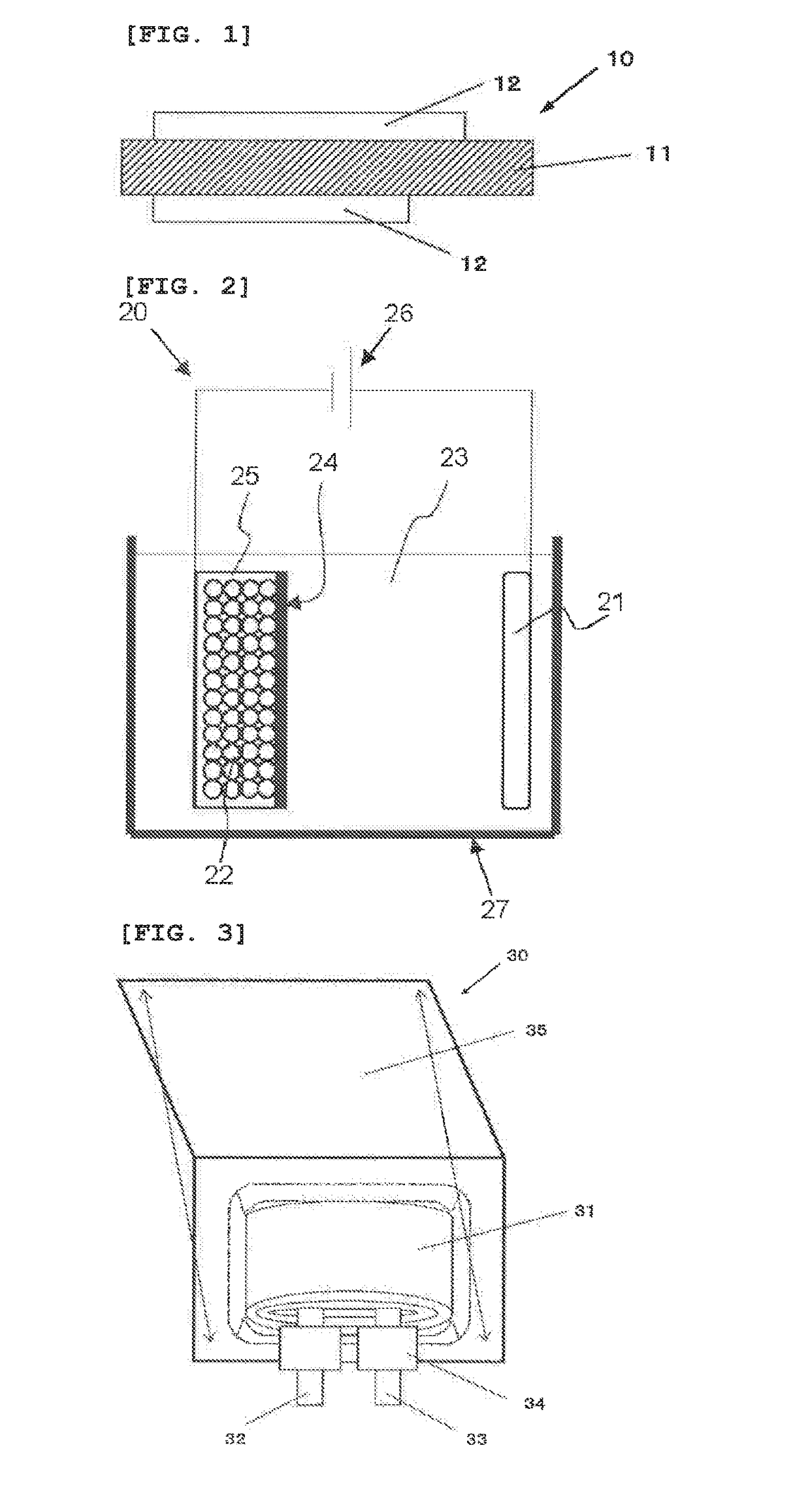

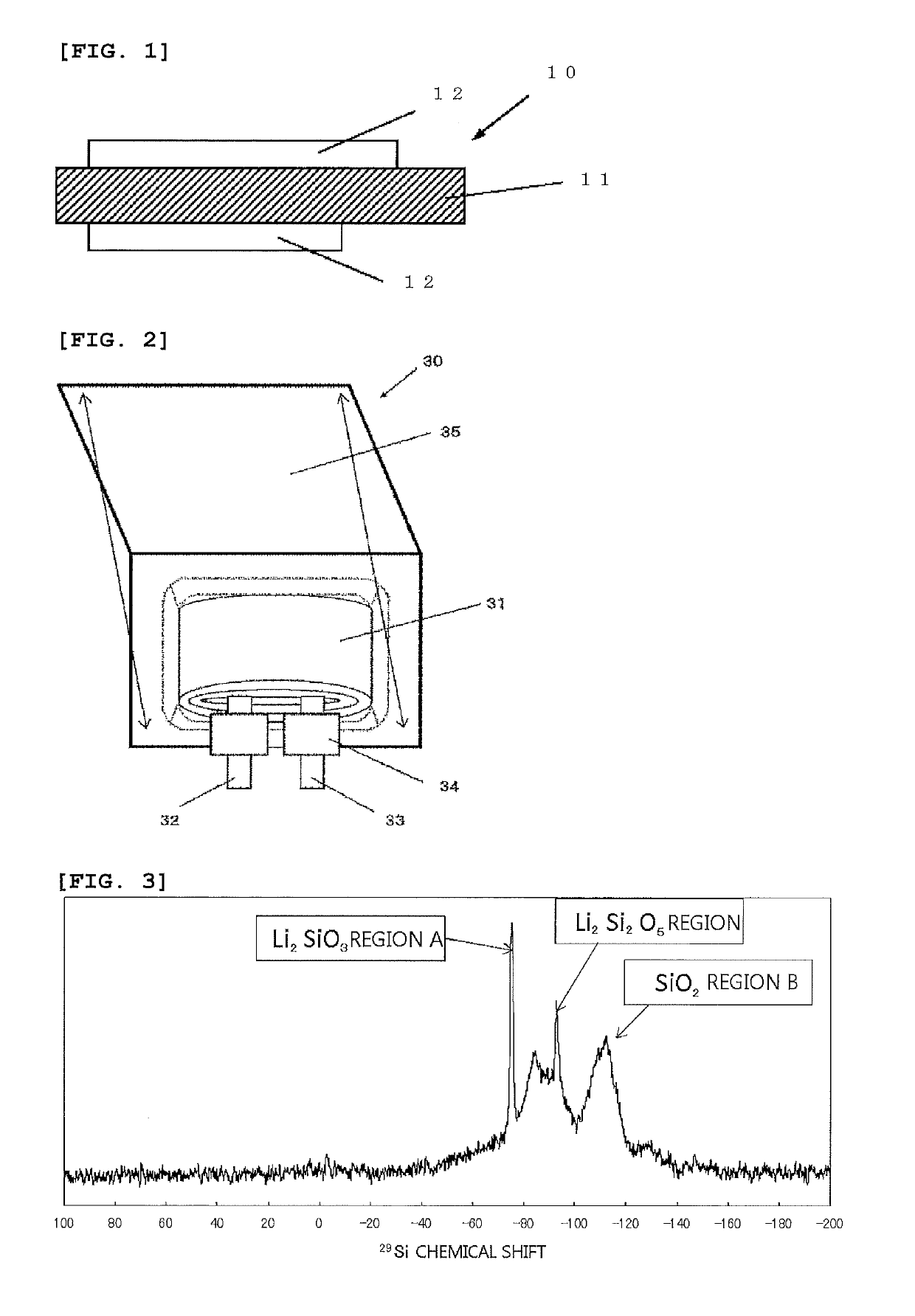

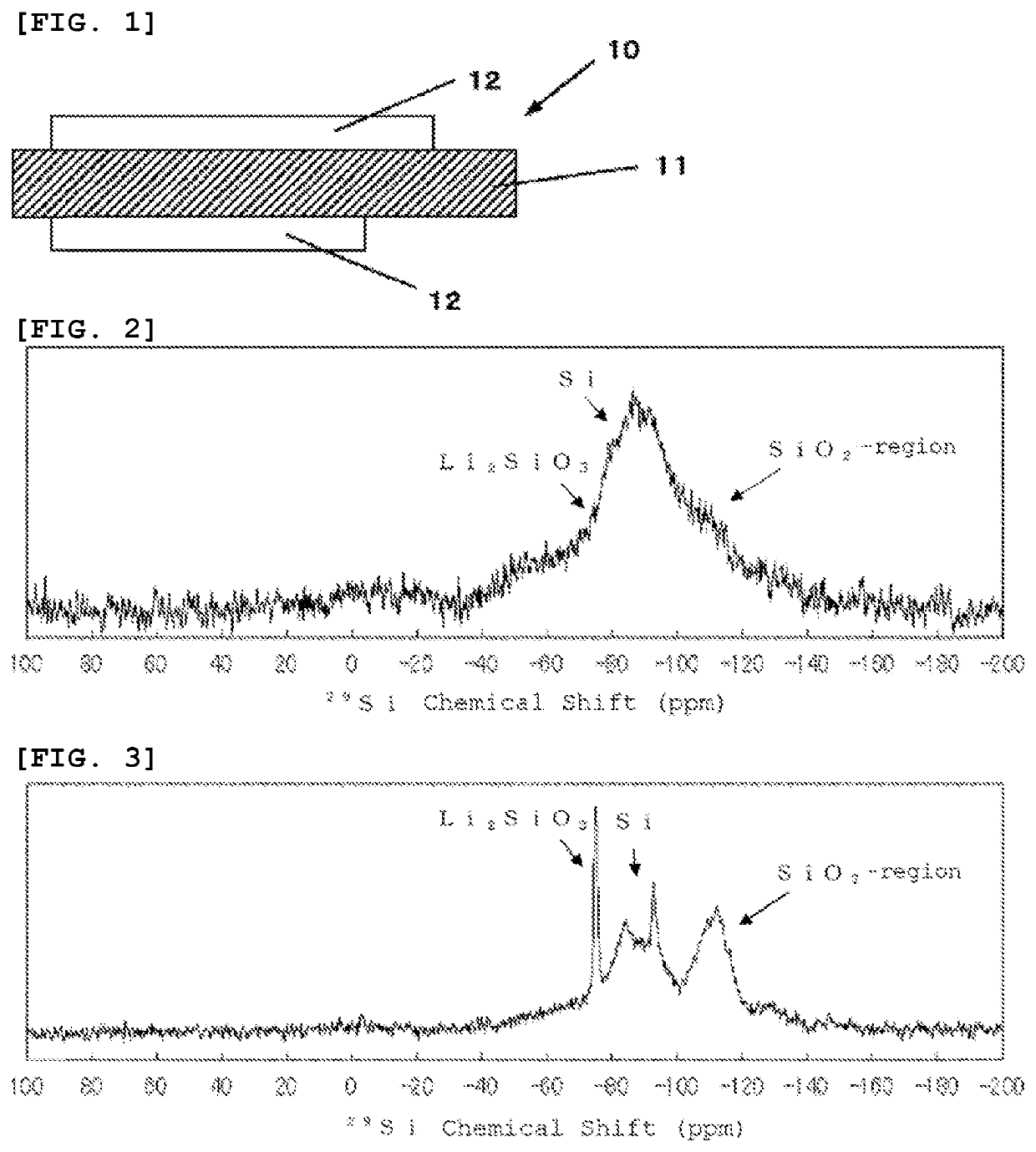

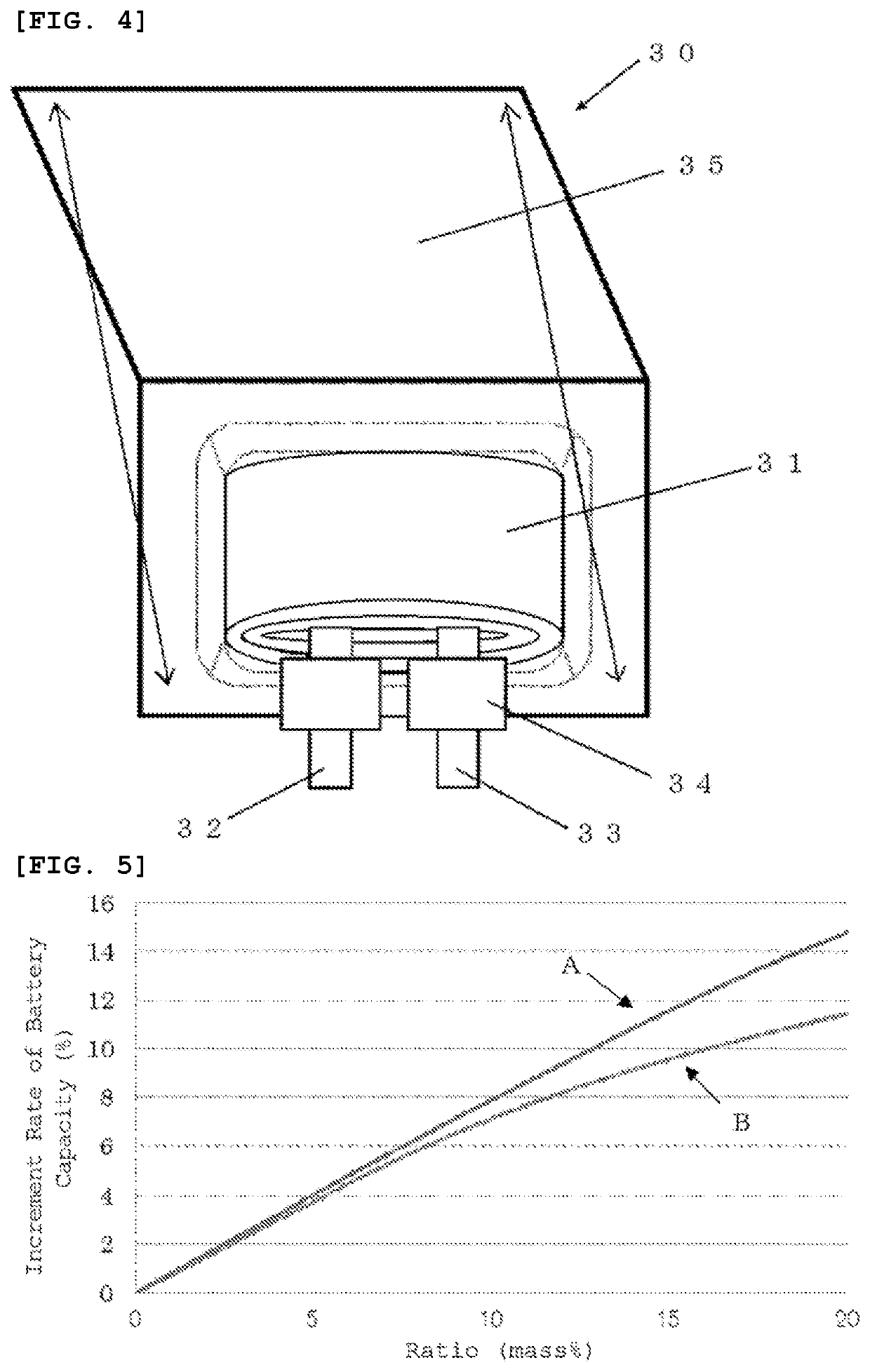

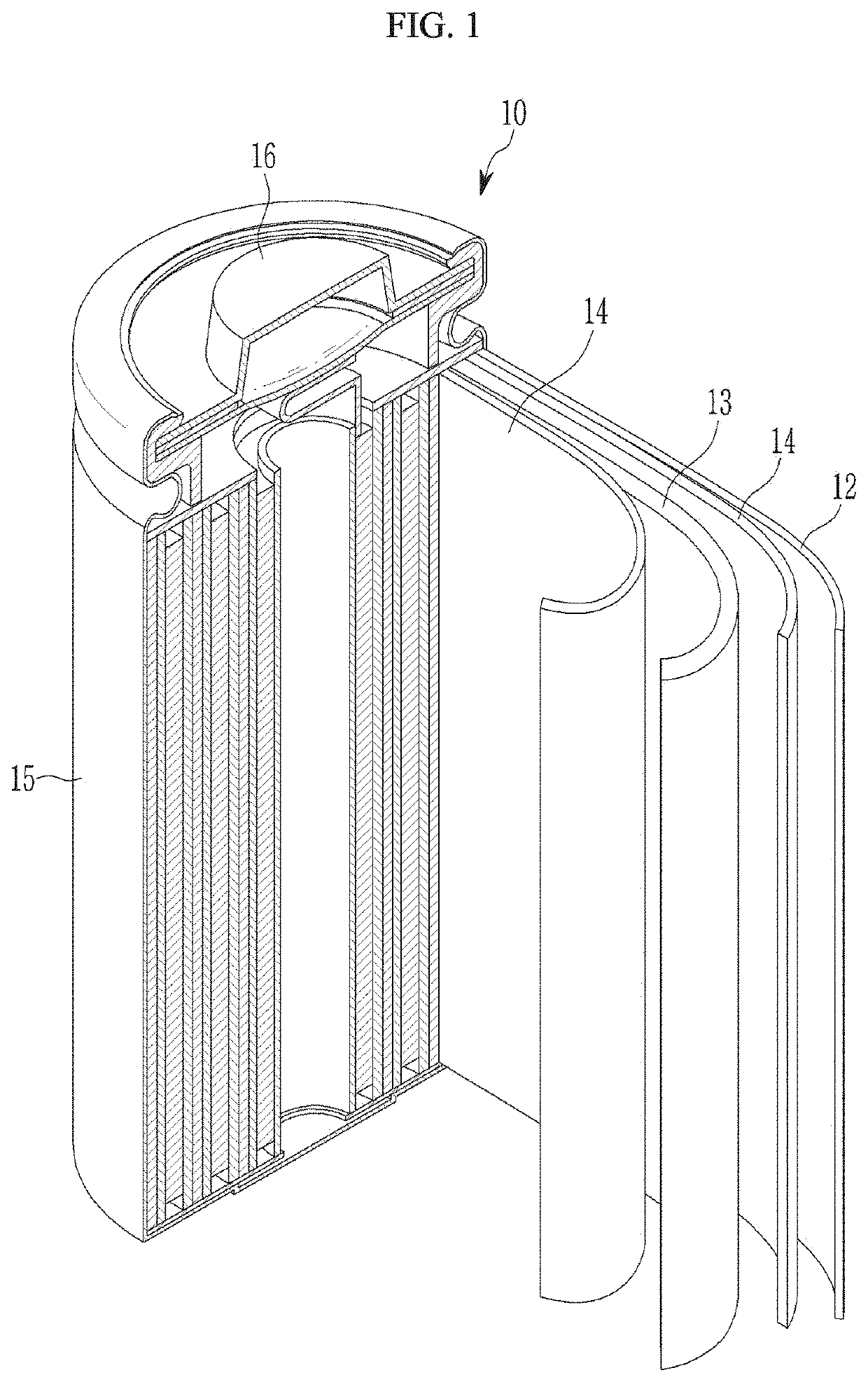

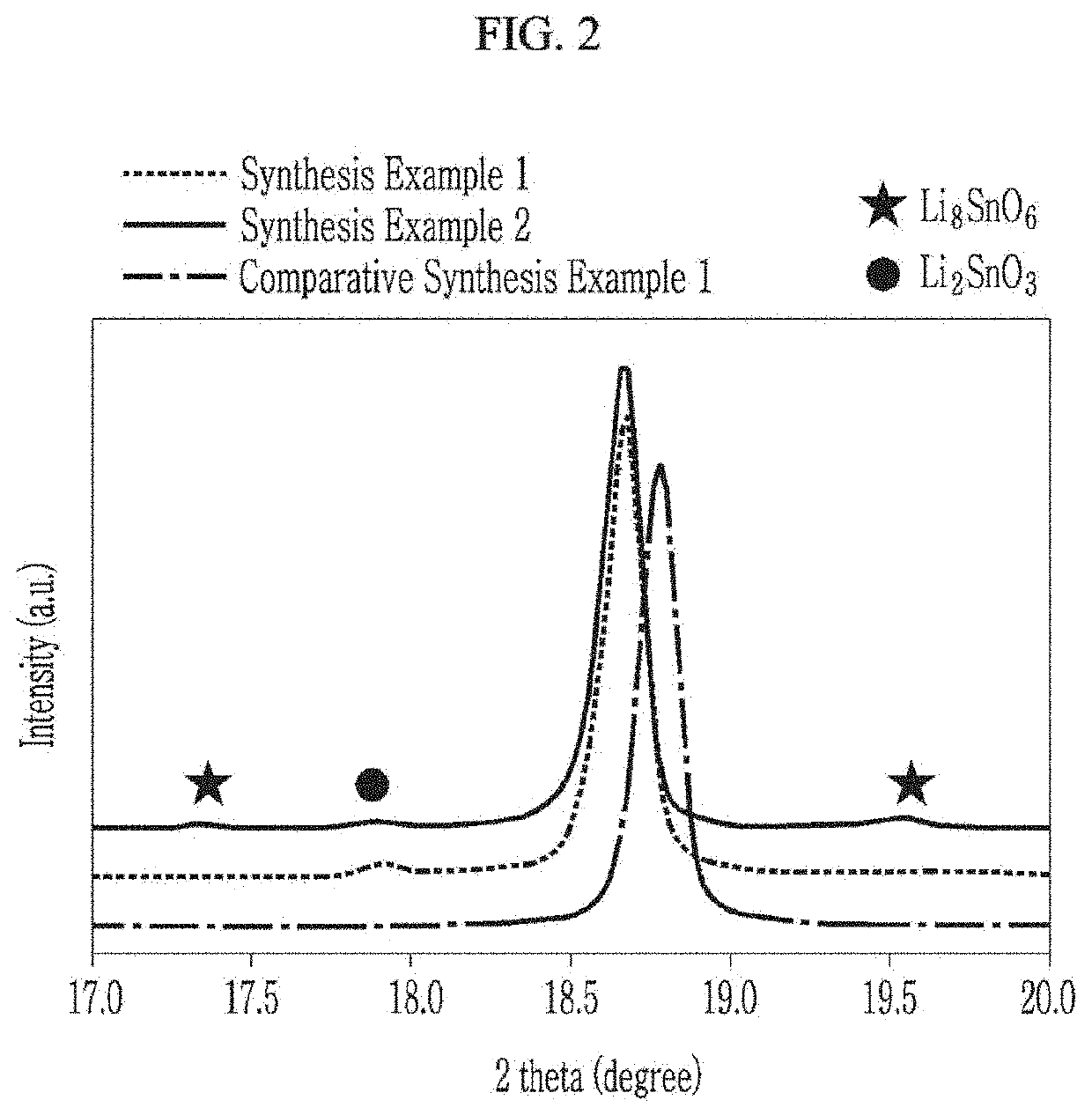

Negative electrode active material for non-aqueous electrolyte secondary battery, non-aqueous electrolyte secondary battery, and method of producing negative electrode material for non-aqueous electrolyte secondary battery

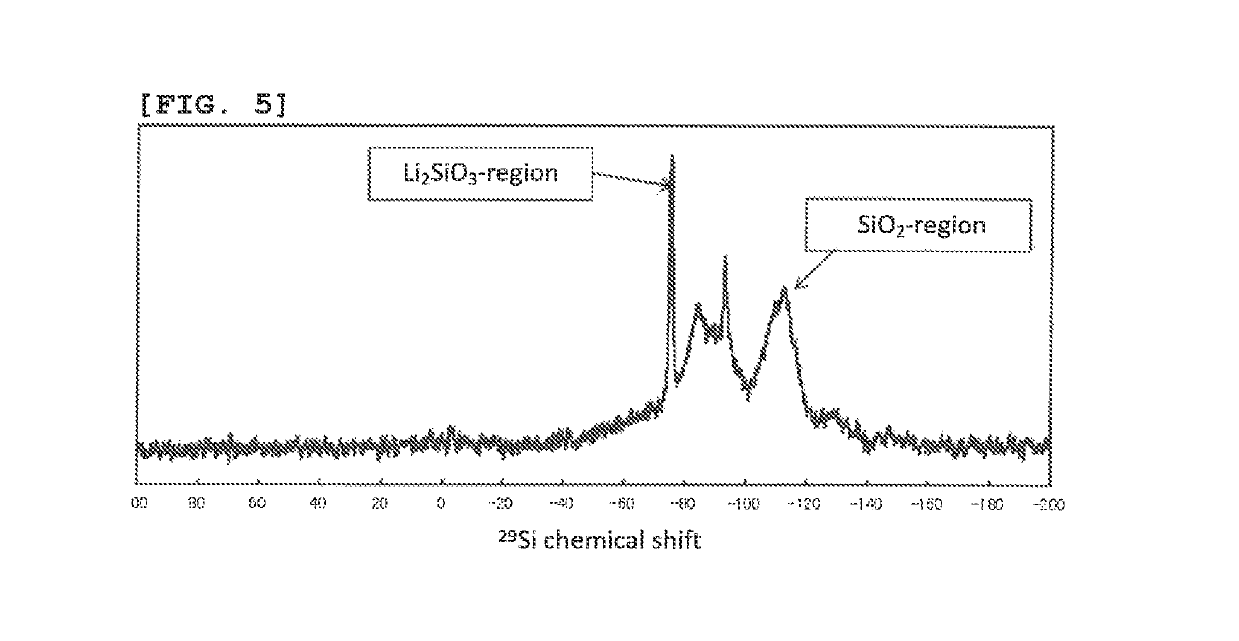

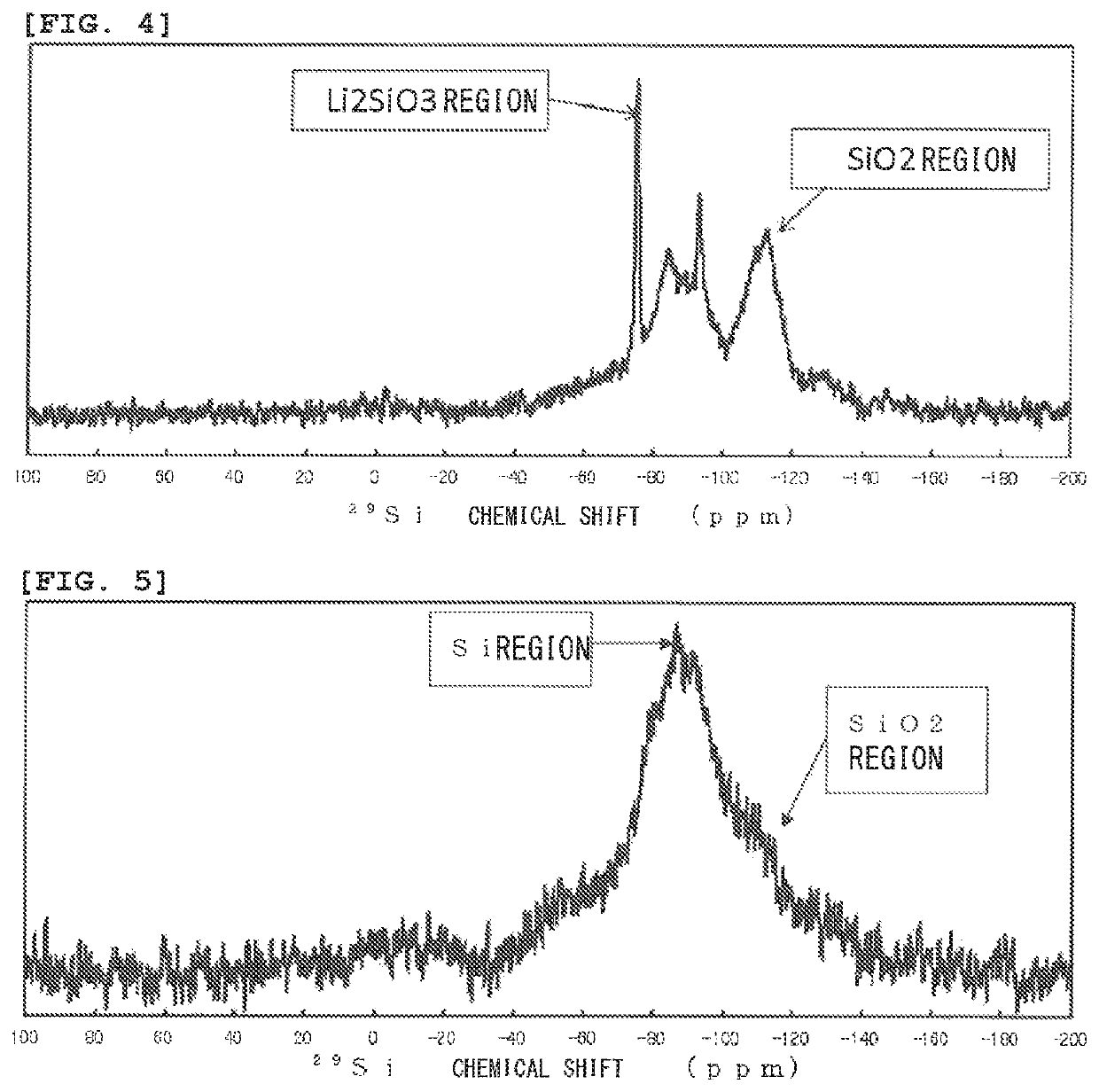

ActiveUS20180175377A1Good slurry stabilityIncrease capacityElectrode thermal treatmentNegative electrodesCarbon coatingSlurry

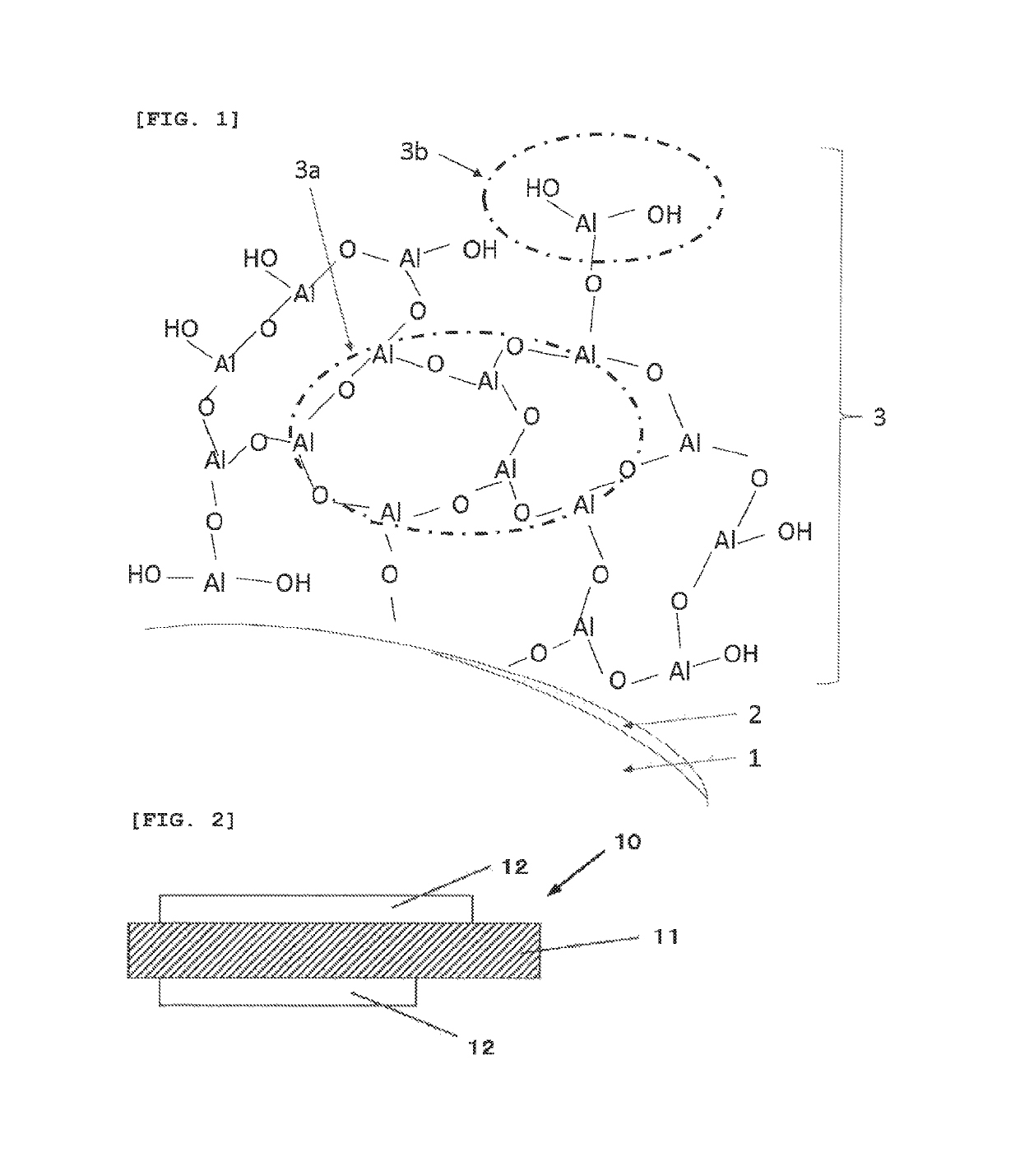

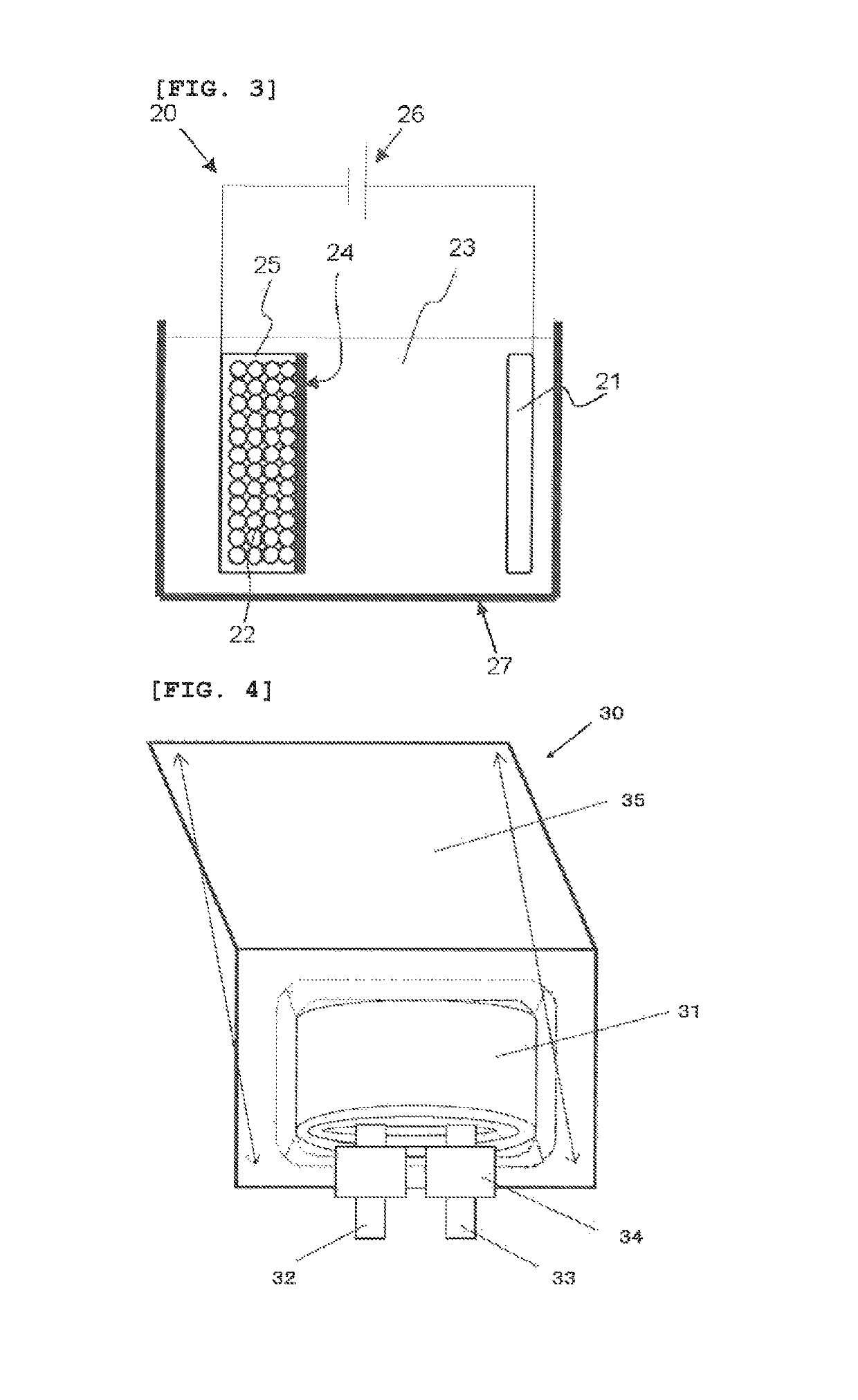

A negative electrode active material for a non-aqueous electrolyte secondary battery, includes: negative electrode active material particles that contain a silicon compound (SiOx: 0.5≤x≤1.6) containing a Li compound, wherein the silicon compound is at least partially coated with a carbon coating, and at least a part of a surface of the silicon compound, a surface of the carbon coating, or both of them are coated with a composite layer that contains a composite composed of amorphous metal oxide and metal hydroxide. This provides a negative electrode active material for a non-aqueous electrolyte secondary battery that is highly stable in aqueous slurry, having a high capacity, favorable cycle performance and first efficiency.

Owner:SHIN ETSU CHEM IND CO LTD

Negative electrode active material for non-aqueous electrolyte secondary battery, non-aqueous electrolyte secondary battery, method for producing negative electrode material for non-aqueous secondary battery, and method for producing non-aqueous electrolyte secondary battery

ActiveUS20180261833A1Good slurry stabilityIncrease capacitySecondary cellsNegative electrodesCarbon coatingSlurry

A negative electrode active material for non-aqueous electrolyte secondary batteries which has particles of negative electrode active material, the particles of negative electrode active material containing a silicon compound (SiOx: 0.5≤x≤1.6) that contains a Li compound, including a carbon coating on at least a part of a surface of the silicon compound and a salt coating containing one or more kinds of a metal silicate containing a metal element other than a lithium element and a metal salt containing a metal element other than the lithium element on a part of a surface of the silicon compound or a surface of the carbon coating or both of these. Thus, the negative electrode active material for non-aqueous electrolyte secondary batteries having high stability to an aqueous slurry, high capacity and excellent cycle characteristics and initial efficiency may be provided.

Owner:SHIN ETSU CHEM IND CO LTD

Negative electrode active material for non-aqueous electrolyte secondary battery, non-aqueous electrolyte secondary battery, and method for producing negative electrode material for non-aqueous electrolyte secondary battery

ActiveUS20190214637A1Good slurry stabilityAdvantageously producedPhosphatesElectrode thermal treatmentSurface layerSlurry

A negative electrode active material for a non-aqueous electrolyte secondary battery, wherein the negative electrode active material includes negative electrode active material particles, the negative electrode active material particles include a silicon compound particle which includes a silicon compound including oxygen, the silicon compound particle includes a Li compound, and the silicon compound particle is adhered with a phosphate salt in an outermost surface layer thereof. With this, the negative electrode active material which is high in the capacity and the stability to aqueous slurry as well as excellent in the cycle characteristic and the first efficiency can be provided.

Owner:SHIN ETSU CHEM IND CO LTD

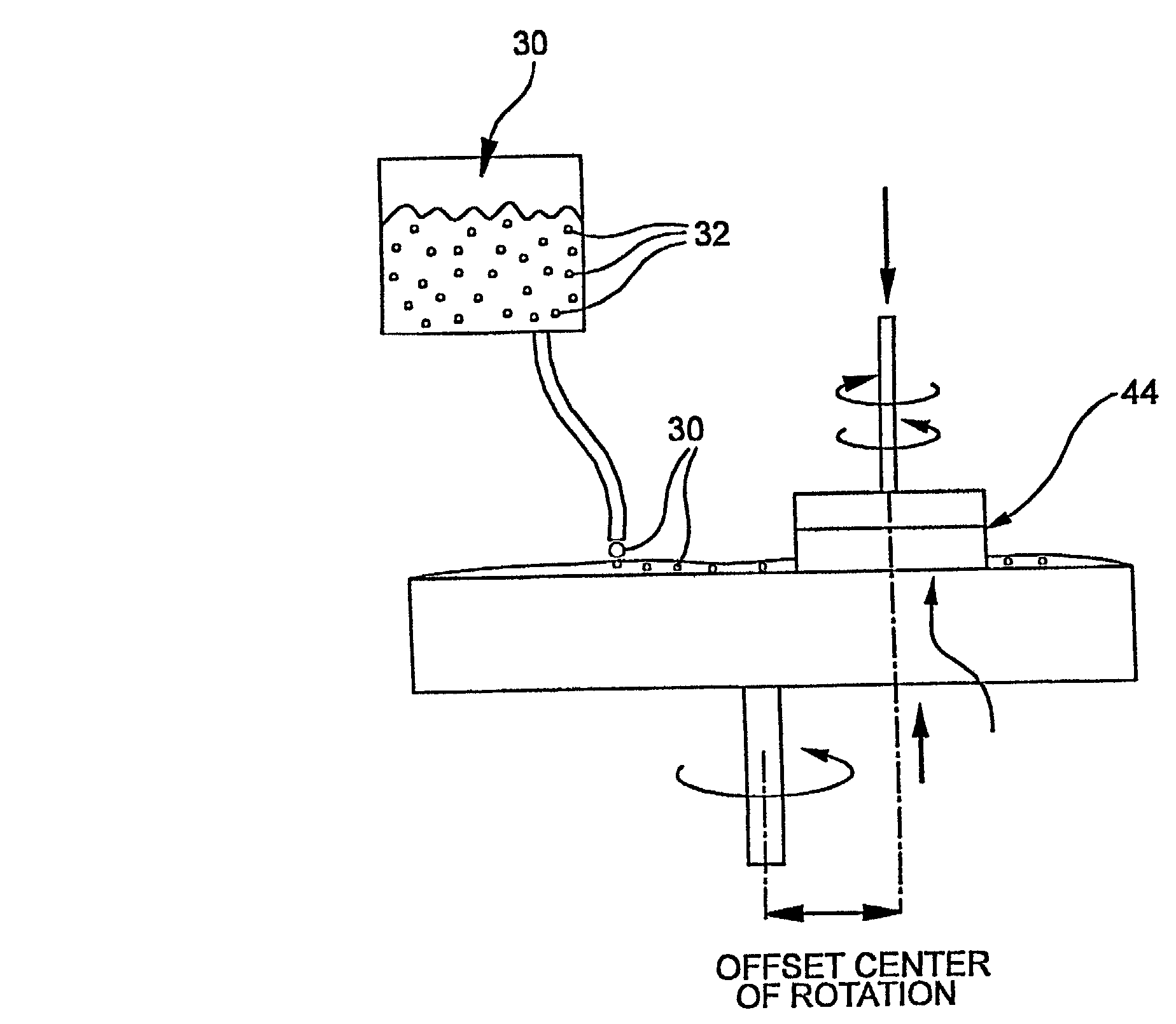

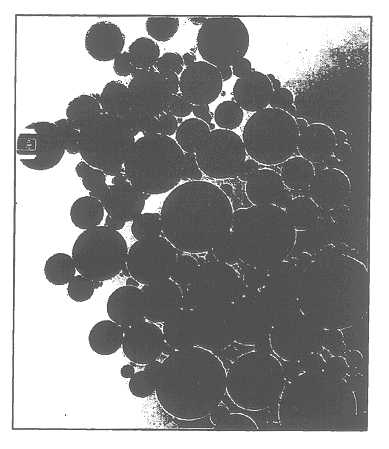

Method of making optical fluoride laser crystal components

InactiveUS20030148711A1Reduce flatness requirementsLittle to no scratchingPolycrystalline material growthAfter-treatment detailsColloidal silicaGas phase

The method of making optical fluoride crystal components provide optical components with beneficial final polished transmission surfaces for transmitting below 200 nm wavelengths of light, such as produced by excimer lasers and utilized in optical lithography. The invention utilizes colloidal silica soot in the polishing of optical fluoride crystal surfaces. This colloidal silica soot is a byproduct of chemical vapor deposition processing of fused silica or ultra low expansion glasses. The colloidal silica byproduct is referred to as "soot". Retaining the same physical properties as the parent glass and having a spherical morphology, the colloidal silica soot is an ideal for final polishing applications of optical fluoride crystals, and particularly for optical fluoride crystals such as calcium fluoride which have high transmission levels to below 300 nm light such as produced by excimer lasers. The soot has a large particle size and spherical shape when compared to conventional colloidal or fumed silica.

Owner:CORNING INC

Negative electrode active material for non-aqueous electrolyte secondary battery, non-aqueous electrolyte secondary battery, and method of producing negative electrode material for non-aqueous electrolyte secondary battery

ActiveUS10418627B2Good slurry stabilityIncrease capacityElectrode thermal treatmentSecondary cellsCarbon coatingSlurry

A negative electrode active material for a non-aqueous electrolyte secondary battery, includes: negative electrode active material particles that contain a silicon compound (SiOx: 0.5≤x≤1.6) containing a Li compound, wherein the silicon compound is at least partially coated with a carbon coating, and at least a part of a surface of the silicon compound, a surface of the carbon coating, or both of them are coated with a composite layer that contains a composite composed of amorphous metal oxide and metal hydroxide. This provides a negative electrode active material for a non-aqueous electrolyte secondary battery that is highly stable in aqueous slurry, having a high capacity, favorable cycle performance and first efficiency.

Owner:SHIN ETSU CHEM IND CO LTD

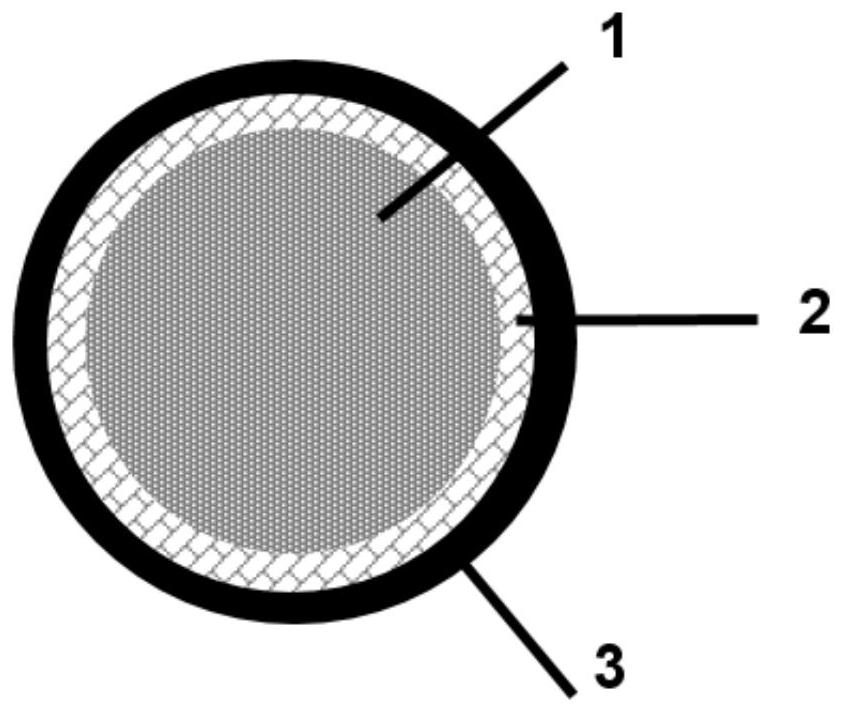

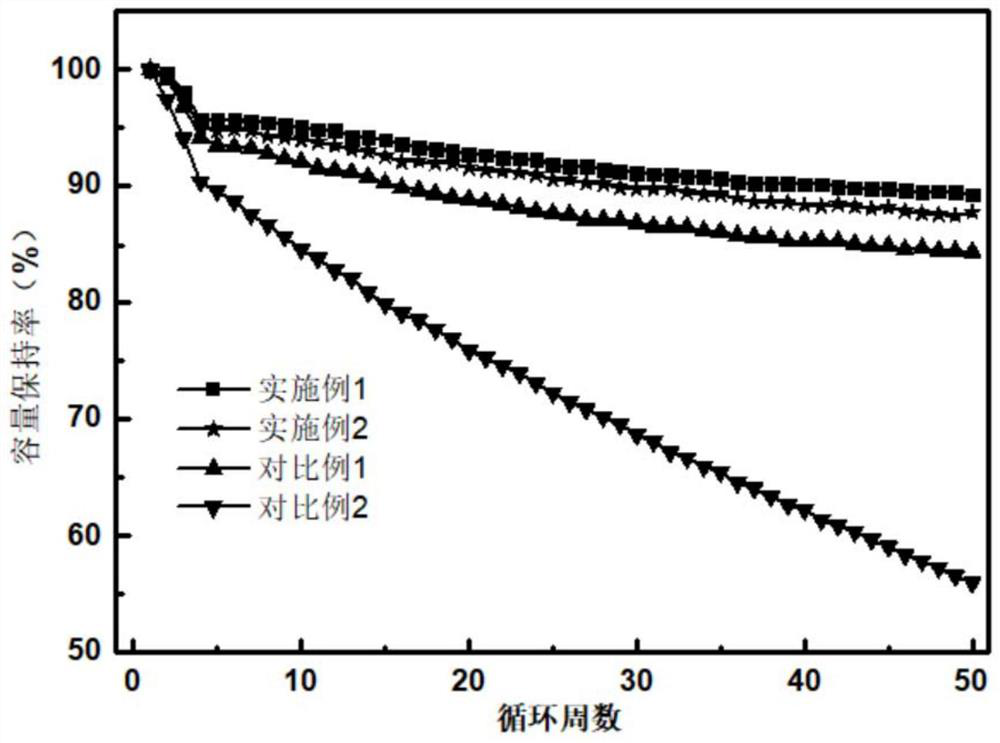

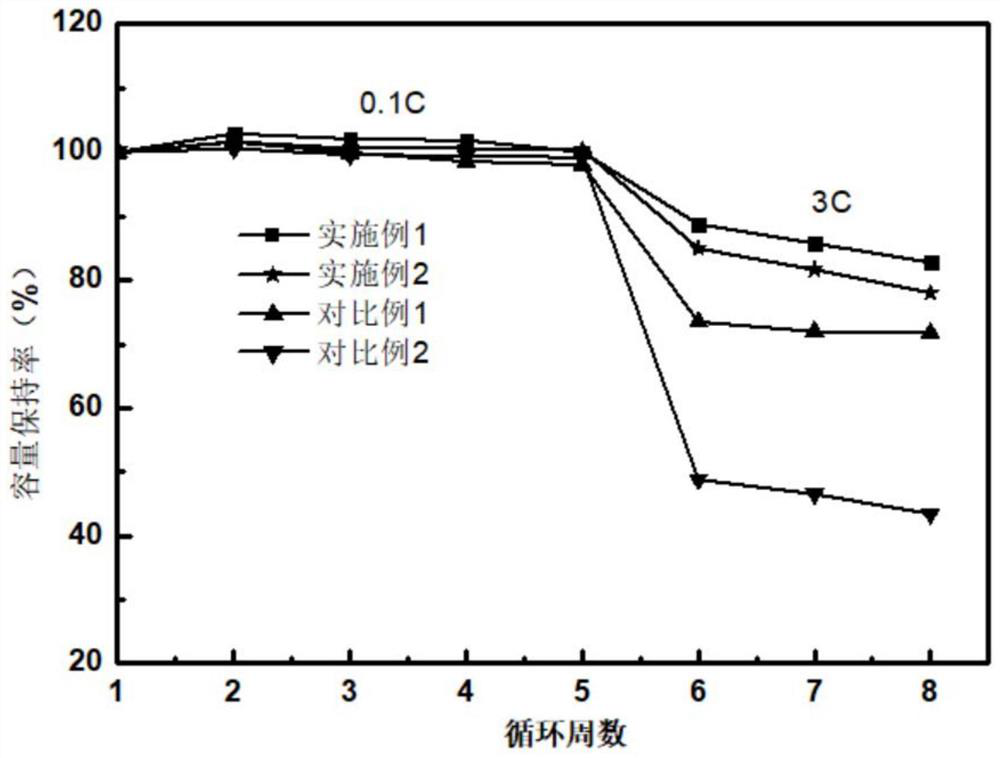

Composite material and preparation method thereof, negative electrode material, negative electrode plate and lithium ion battery

ActiveCN113130872AReduce bloatImprove electronic conductivityNegative electrodesSecondary cellsLithium compoundLithium-ion battery

The invention provides a composite material and a preparation method thereof, a negative electrode material, a negative electrode plate and a lithium ion battery. The composite material comprises an inner core comprising a silicon-oxygen-lithium compound, and a hydrophobic coating layer, wherein the core is partially or completely covered with the hydrophobic coating layer, the hydrophobic coating layer comprises a compound M with the chemical formula being LiaSiObXc and a compound N with the chemical formula being LidSiOeYf, a is larger than 0 and smaller than or equal to 5, b is larger than 0 and smaller than or equal to 5, c is larger than 0 and smaller than or equal to 5, d is larger than 0 and smaller than or equal to 5, e is larger than 0 and smaller than or equal to 5, f is larger than 0 and smaller than or equal to 5, X is a metal element, and Y is a non-metal element. The composite material provided by the invention has good electronic conductivity, high first coulombic efficiency, good cycle stability and high rate capability.

Owner:BTR NEW MATERIAL GRP CO LTD +1

Use of methylhydroxyethyl cellulose as cement additive

ActiveUS20120267108A1Prevent and reduce occurrenceMinimizes free fluidDrilling compositionSealing/packingCelluloseCement slurry

Methylhydroxyethyl cellulose may be used as an additive in cement slurries in the treatment of wells to prevent or reduce the occurrence of gas channeling. In addition to acting as a gas control additive, methylhydroxyethyl cellulose controls fluid loss, minimizes free fluid and stabilizes foam during cementing of the well.

Owner:BJ SERVICES LLC

Method of making optical fluoride laser crystal components

InactiveUS6669536B2Reduction in flatnessEasy to polishPolycrystalline material growthAfter-treatment detailsColloidal silicaGas phase

Owner:CORNING INC

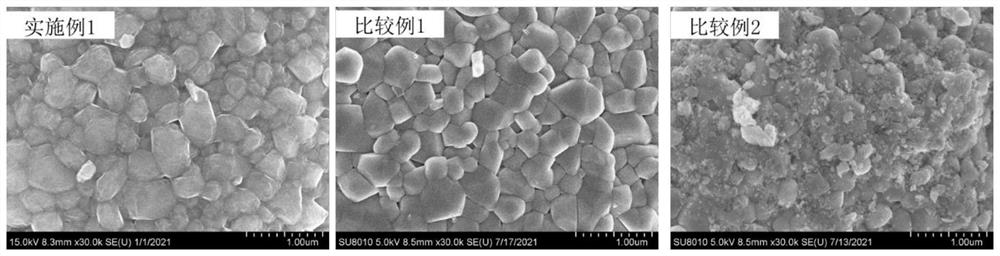

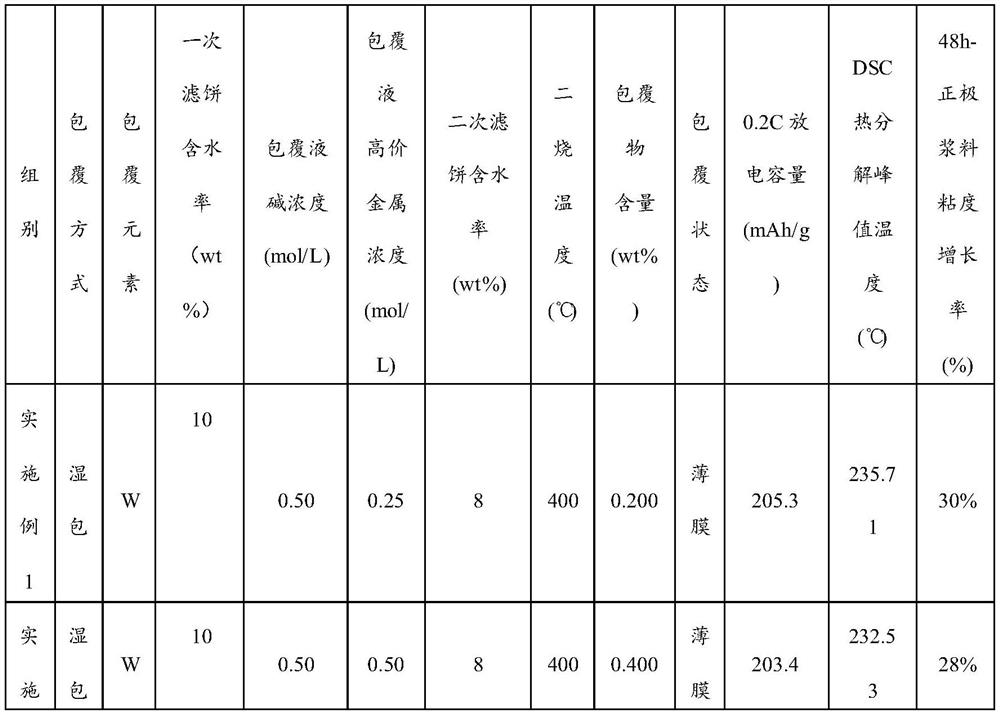

High-nickel multi-element positive electrode material as well as preparation method and application thereof

PendingCN114725338AImprove thermal stabilityGood slurry stabilityElectrode thermal treatmentSecondary cellsChemical physicsLithium metal

The invention provides a high-nickel multi-element positive electrode material which is composed of particles with a general formula of Li1 + kMe1-kO2 and a high-valence lithium metal oxide compound coated on the surfaces of the particles, and high-valence metal ions in the high-valence lithium metal oxide compound are positive ions which do not have electrons on the outermost d orbit and are not less than + 5 valence states. The invention further provides the high-nickel multi-element positive electrode material and application thereof. The high-nickel multi-element positive electrode material provided by the invention has high slurry stability, cycling stability and thermal safety performance, so that the electrochemical performance of the high-nickel multi-element positive electrode material serving as the positive electrode material of the lithium ion battery in various aspects is balanced.

Owner:NINGBO RONBAY LITHIUM BATTERY MATERIAL CO LTD

Negative electrode active material for non-aqueous electrolyte secondary battery, non-aqueous electrolyte secondary battery, method for producing negative electrode material for non-aqueous secondary battery, and method for producing non-aqueous electrolyte secondary battery

ActiveUS10707482B2Good slurry stabilityIncrease capacitySecondary cellsNegative electrodesCarbon coatingPhysical chemistry

A negative electrode active material for non-aqueous electrolyte secondary batteries which has particles of negative electrode active material, the particles of negative electrode active material containing a silicon compound (SiOx: 0.5≤x≤1.6) that contains a Li compound, including a carbon coating on at least a part of a surface of the silicon compound and a salt coating containing one or more kinds of a metal silicate containing a metal element other than a lithium element and a metal salt containing a metal element other than the lithium element on a part of a surface of the silicon compound or a surface of the carbon coating or both of these. Thus, the negative electrode active material for non-aqueous electrolyte secondary batteries having high stability to an aqueous slurry, high capacity and excellent cycle characteristics and initial efficiency may be provided.

Owner:SHIN ETSU CHEM CO LTD

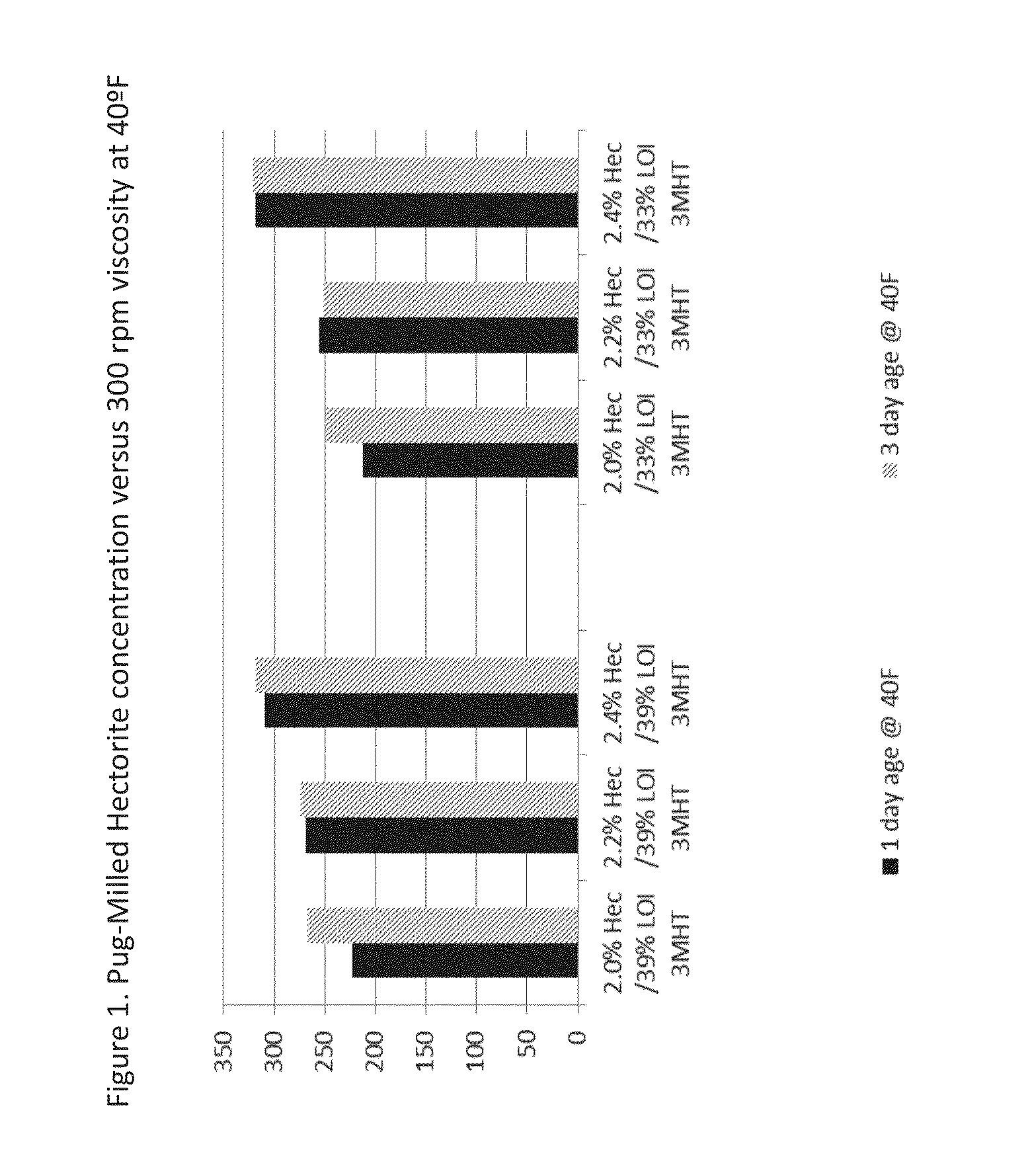

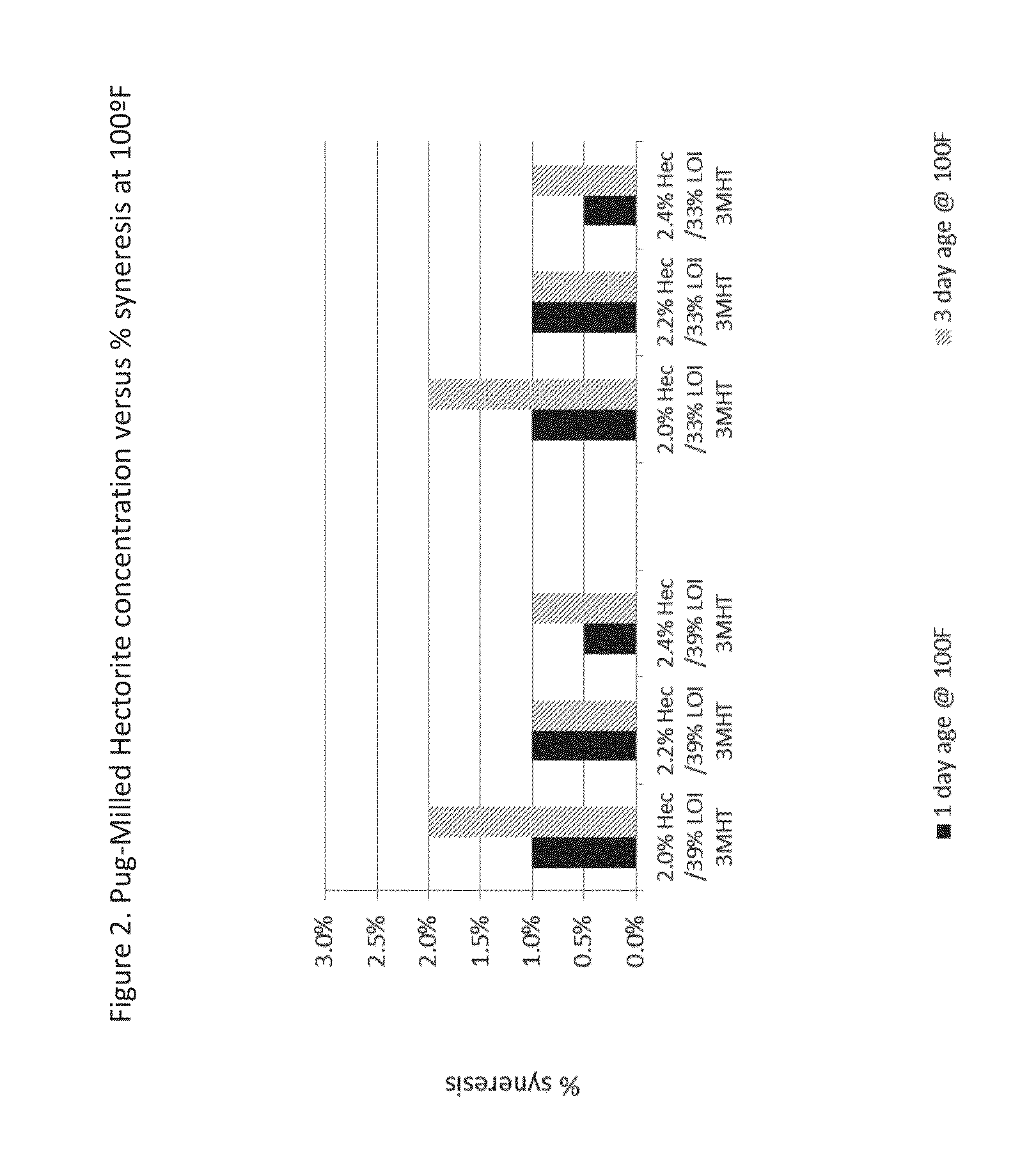

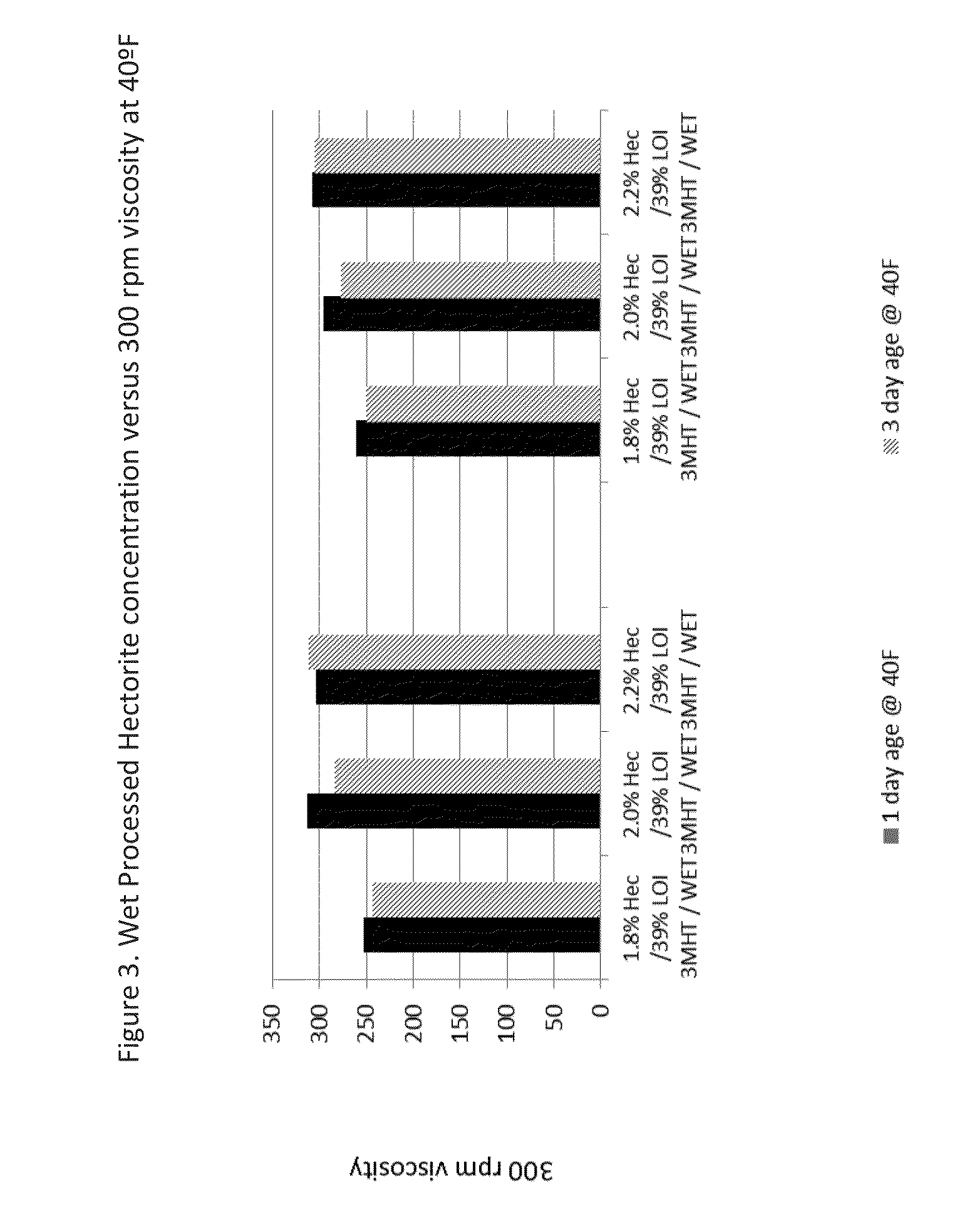

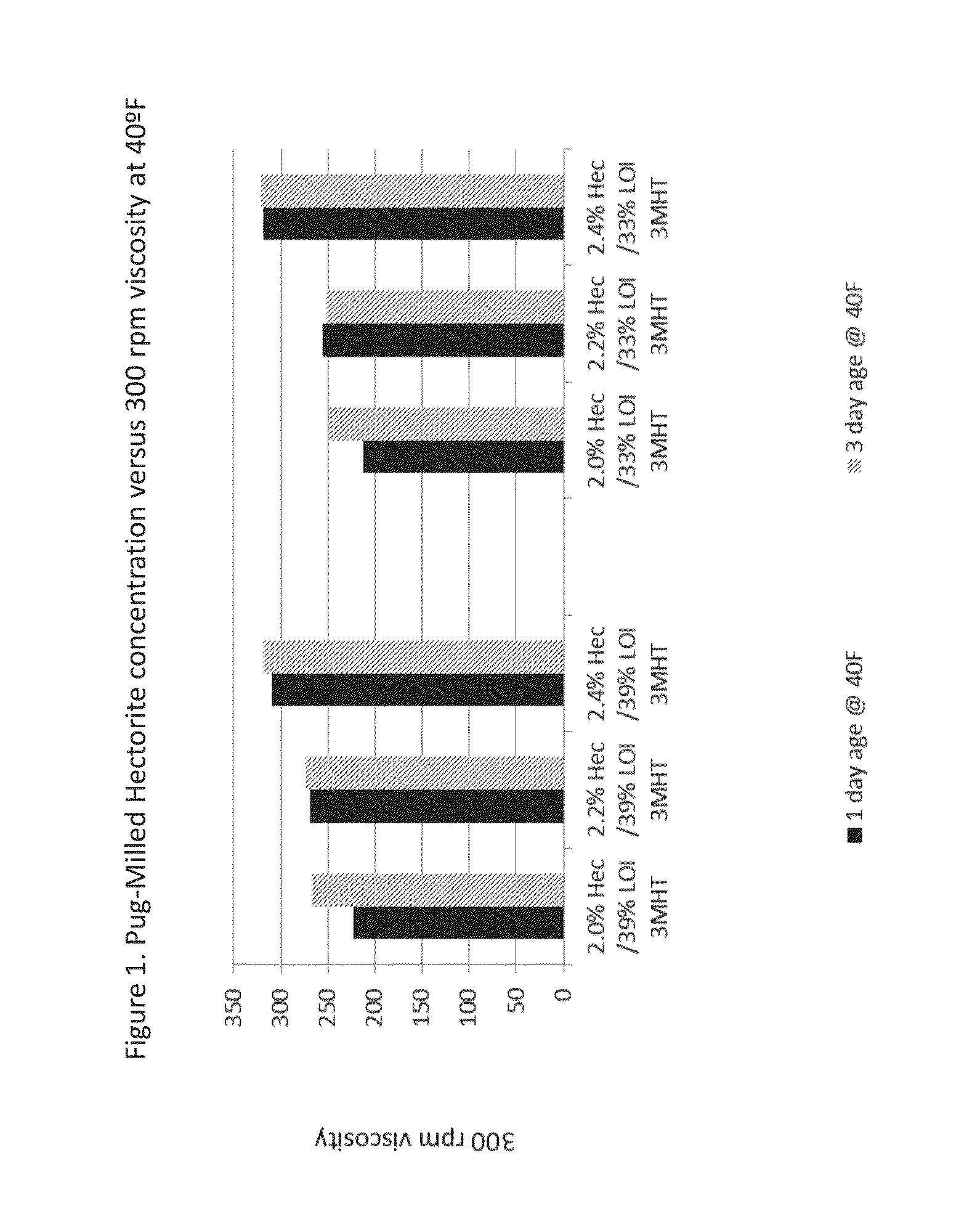

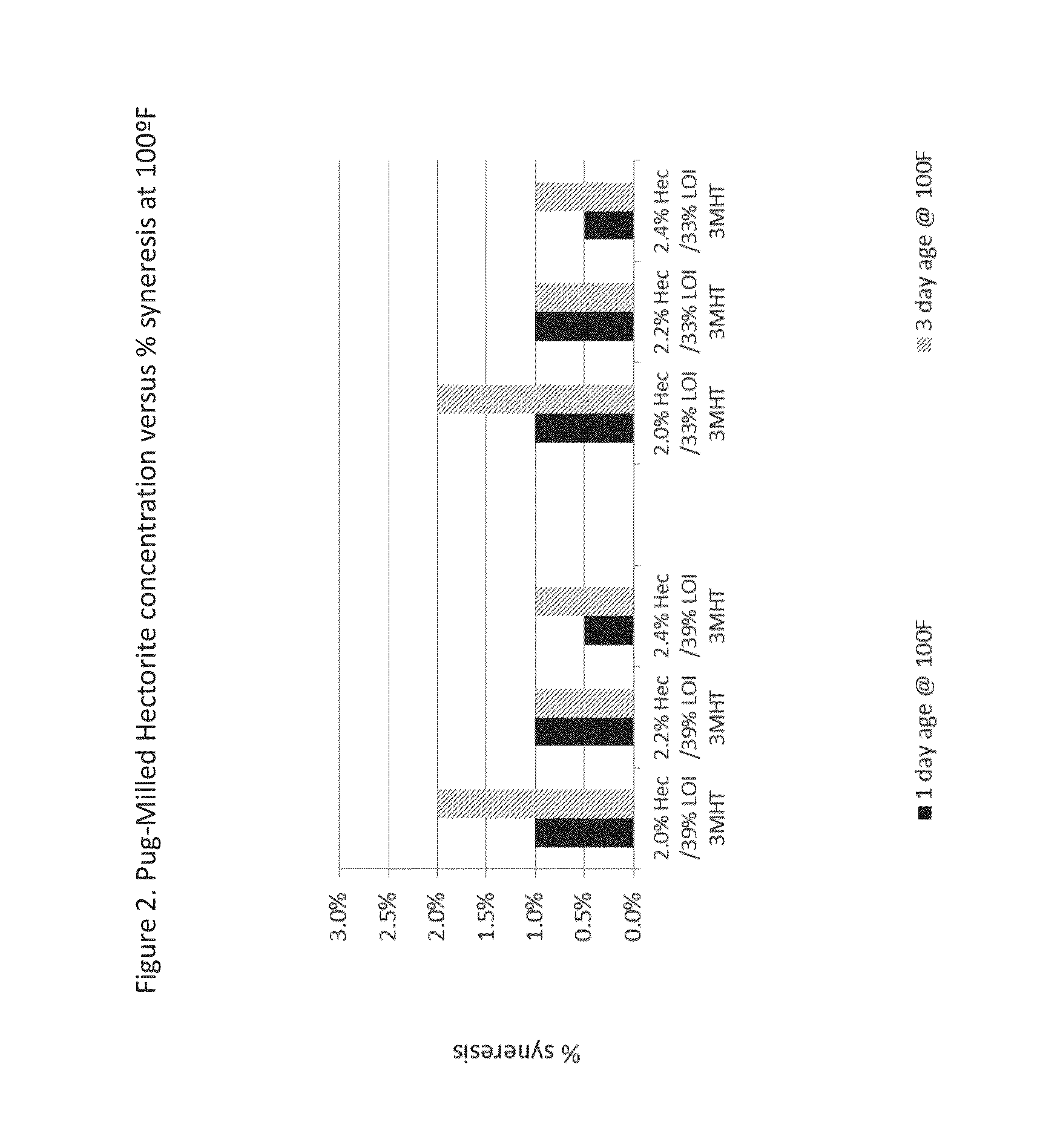

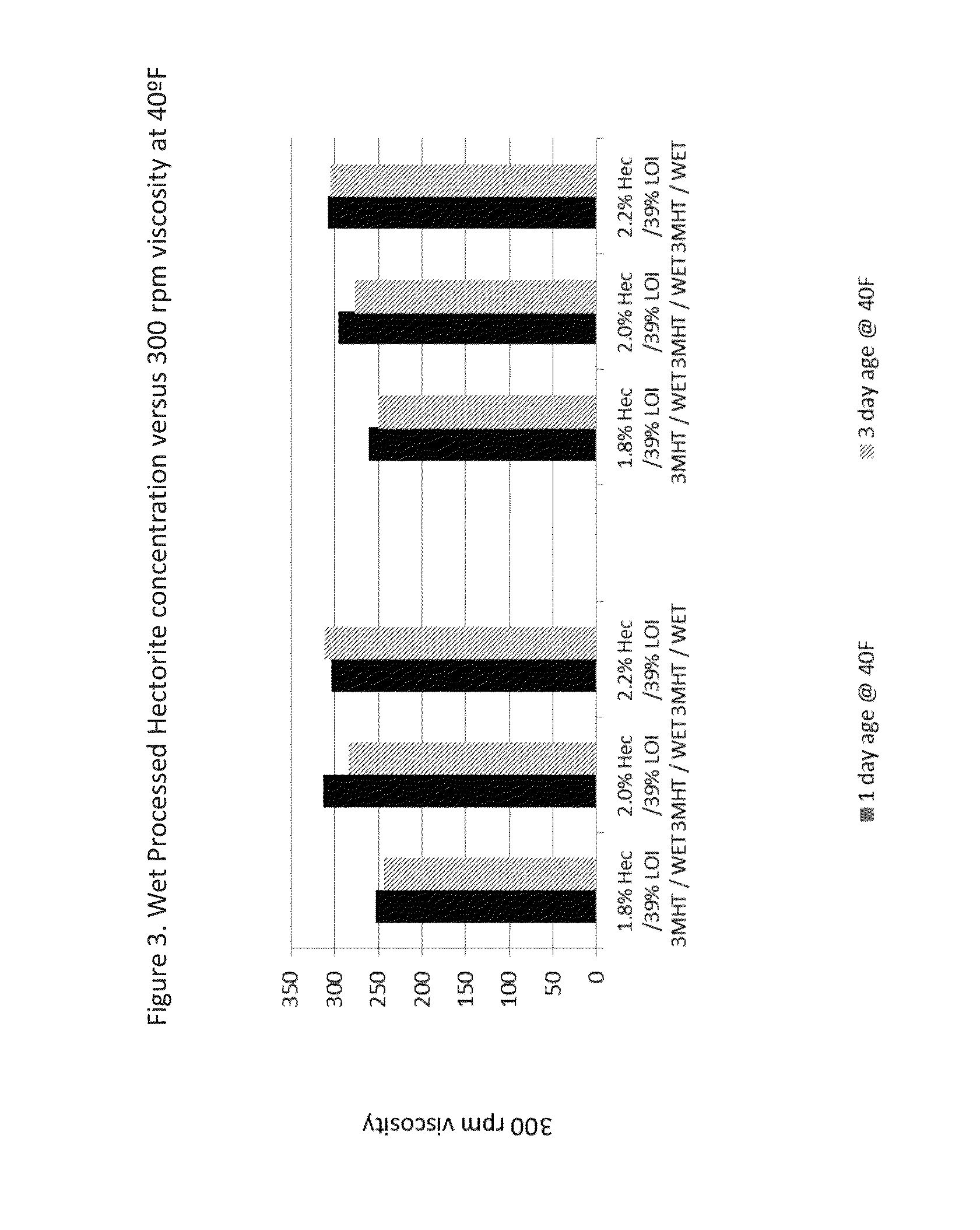

Slurry concentrate and associated methods of use

ActiveUS20150051121A1Good slurry stabilityViscosityFlushingDrilling compositionPolymer scienceSlurry

Owner:ELEMENTIS SPECIALTIES INC

Binder composition for secondary battery electrode, slurry for secondary battery electrode, and secondary battery electrode

ActiveUS8110306B2Low in capacity reductionImprove cycle performanceOrganic chemistryActive material electrodesPolymer scienceOrganic solvent

There is provided a binder composition for secondary battery electrode, containing(A) a sulfonic acid group-containing polymer, and(B) an organic solvent composed mainly of N-methylpyrrolidone,wherein the proportion of the sulfonic acid group in the polymer (A) is 0.005 to 1.0 mmol / g.

Owner:ENEOS MATERIALS CORP

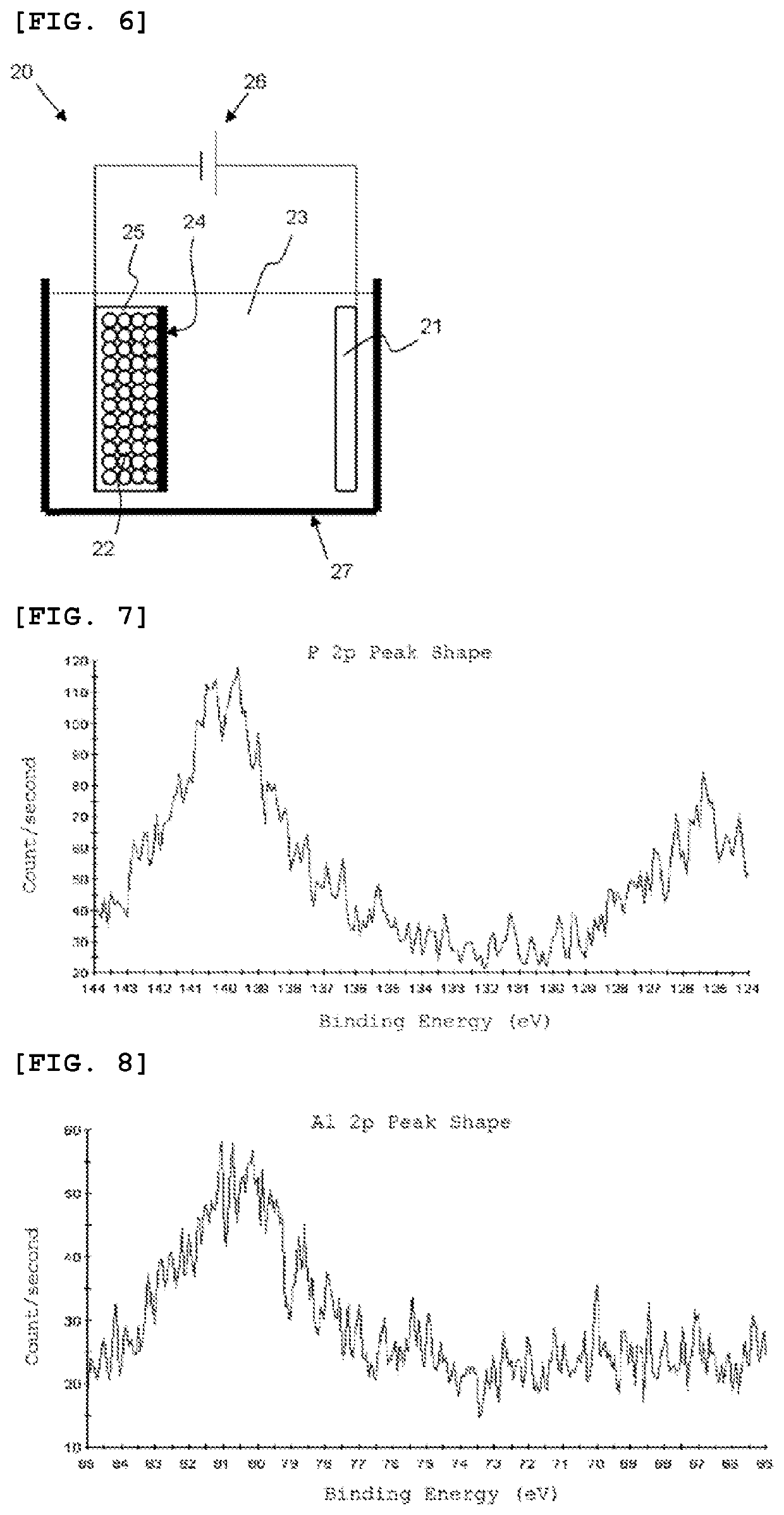

Negative electrode active material, mixed negative electrode active material, and method of producing negative electrode active material

ActiveUS11335905B2Large capacityGood slurry stabilityNegative electrodesAlkali metal silicatesPhysical chemistryComposite oxide

A negative electrode active material particle including: a silicon compound particle containing a silicon compound that contains oxygen, wherein the silicon compound particle contains a Li compound; and the negative electrode active material particle including aluminum phosphorous composite oxide attached to at least part of the surface, wherein the aluminum phosphorous composite oxide is a composite of P2O5 and Al2O3, and the P2O5 and the Al2O3 are in a mass ratio in a range of 1.2<mass of the P2O5 / mass of the Al2O3<3.0, wherein the negative electrode active material particle including aluminum phosphorous composite oxide has at least one peak in a region of a binding energy of more than 135 eV and 144 eV or less in a P 2p peak shape given in an X-ray photoelectron spectroscopy.

Owner:SHIN ETSU CHEM IND CO LTD

Modified premixing plant waste slurry slag and preparation method and application thereof in foam concrete

ActiveCN110615635AImprove insulation effectImprove insulation performanceCeramicwareFoam concreteFiber

The invention relates to modified waste slurry slag of a premixing plant as well as a preparation method and application of the modified waste slurry slag in foam concrete. The modified waste slurry slag of the premixing plant is composed of waste slurry slag of the premixing plant, modified shale pottery sand, a dispersing agent, fibers and water, and the modified shale pottery sand is obtained by infiltrating shale pottery sand in a tea saponin aqueous solution until the shale pottery sand absorbs water to be saturated. After modification treatment, the overall activity of the waste slurry residues is improved, slurry is more homogeneous, the waste slurry residues can be used as an admixture to be doped into a concrete material, and the utilization efficiency of the waste slurry residuessubjected to filter pressing in a premixing plant is remarkably improved. The modified pre-mixing plant waste slurry slag is used in the foam concrete, so that the slurry stability of the foam concrete can be improved, the properties of crack resistance, heat preservation, strength and the like are improved, and the problems of easiness in cracking, difficulty in maintenance and the like are solved. The preparation method of the modified waste slurry slag of the premixing plant is simple and can be connected with the whole foam concrete production process, modification and production are carried out synchronously, and a technological process and a production mode for efficient utilization of the waste slurry slag of the premixing plant are formed.

Owner:CHINA STATE CONSTR READY MIXED CONCRETE CO LTD +1

Cement and preparation method thereof

InactiveCN103102112AImprove performanceImprove waterproof performanceSodium phosphatesPhysical chemistry

The invention relates to cement, which comprises the following components by weight: 50-100g of 80# cement, 20-30g of silica sand powder, 5-10g of diatomite powder, 10-15g of barium sulfate powder, 3-8g of OP-10 emulsifier and 5-10g of sodium phosphate, wherein the granularities of 20-30g of silica sand powder and 5-10g of diatomite powder are respectively 100-300 micrometers. The preparation method of the cement comprises the following steps of: 1, taking the components by weight for later use; 2, uniformly mixing the 80# cement, the silica sand powder and the diatomite powder to obtain a mixture, and grinding the mixture to reach the granularity of 50-100 micrometers in an air-current mill; 3, adding the barium sulfate powder, the OP-10 emulsifier and the sodium phosphate into the ground material, and stirring for 10-20 minutes in a stirrer. The cement is excellent in waterproofness and can be used for improving the performance of cement paste with higher water content by using a material consisting of phosphate and mineral substances; the cement is especially suitable for being used during waterproof operation to small gaps; and the cement paste is good in paste stability and quick to harden.

Owner:杨益

Positive and negative electrode material and preparation method thereof

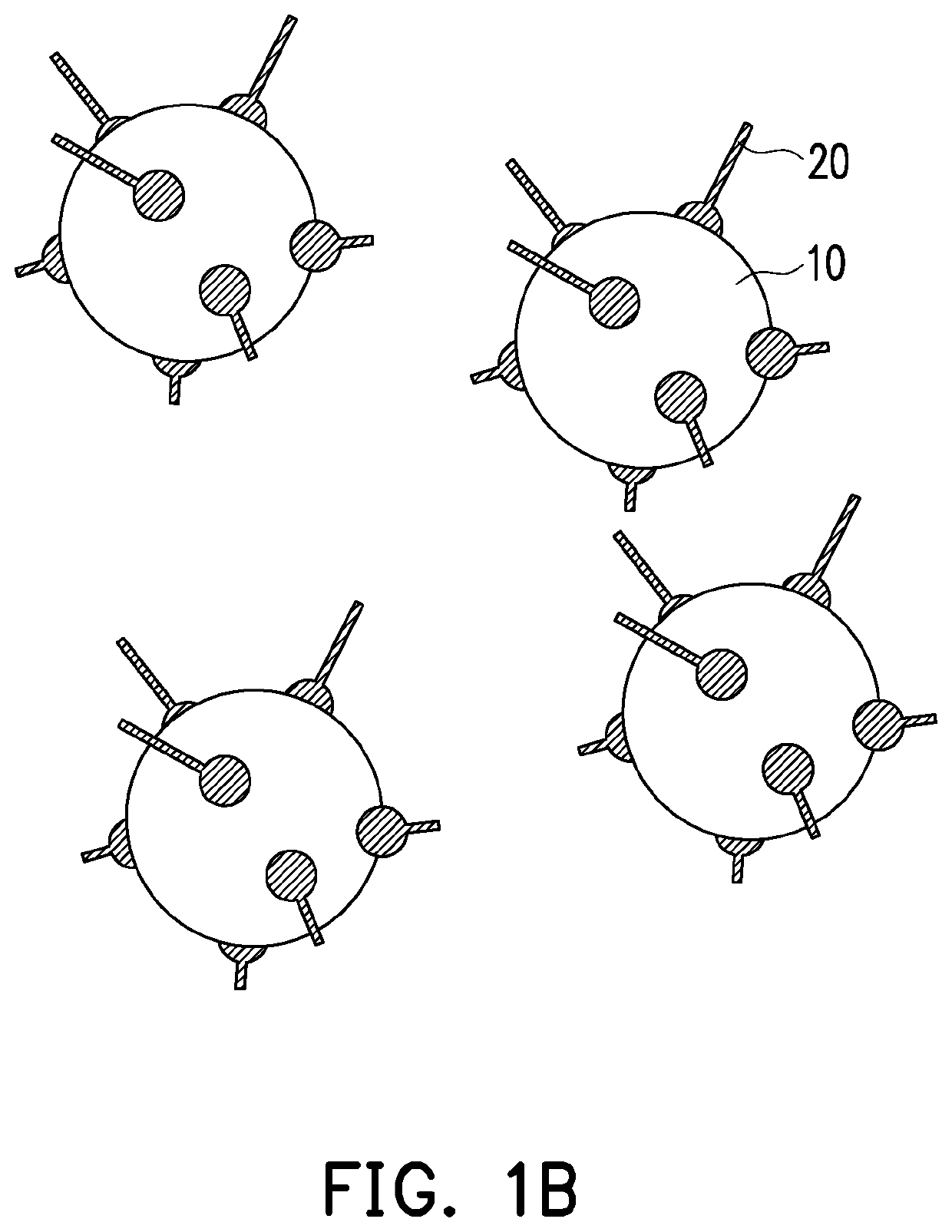

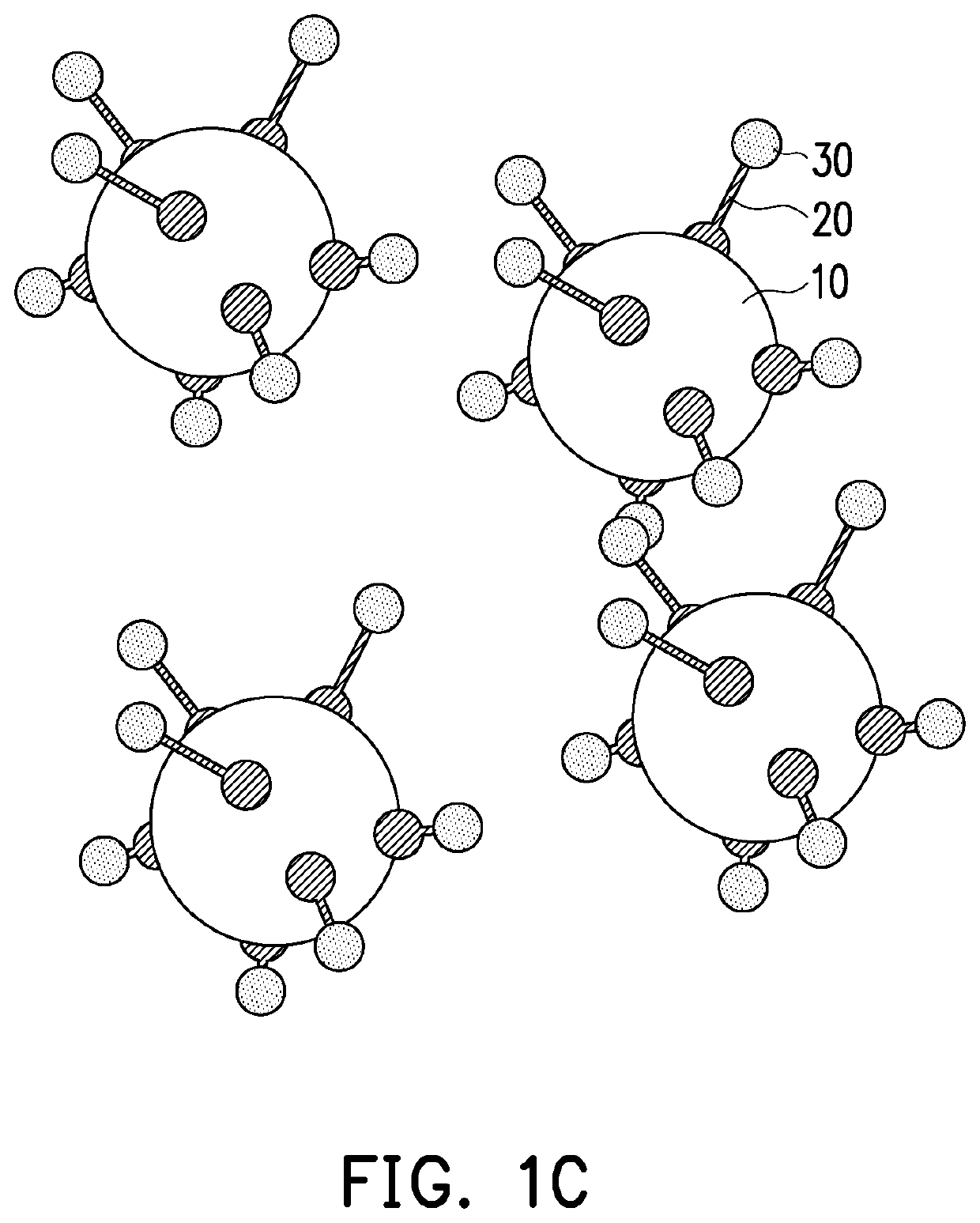

PendingUS20210020934A1Improve first cycle efficiencyImprove cycle lifeNegative electrodesSecondary cellsLithium iron phosphatePhysical chemistry

A positive and negative electrode material and a preparation method thereof are provided. The positive and negative electrode material includes a powder, a first seed growth layer and a second graft growth layer. A material of the powder includes graphite, silicon based material, lithium titanate, tin oxide, tin alloy, lithium nickel cobalt manganese oxide, lithium nickel cobalt aluminum oxide or lithium iron phosphate. The first seed growth layer is formed radially on a surface of the powder, and the second graft growth layer is radially connected to the first seed growth layer.

Owner:GIGA SOLAR MATERIALS

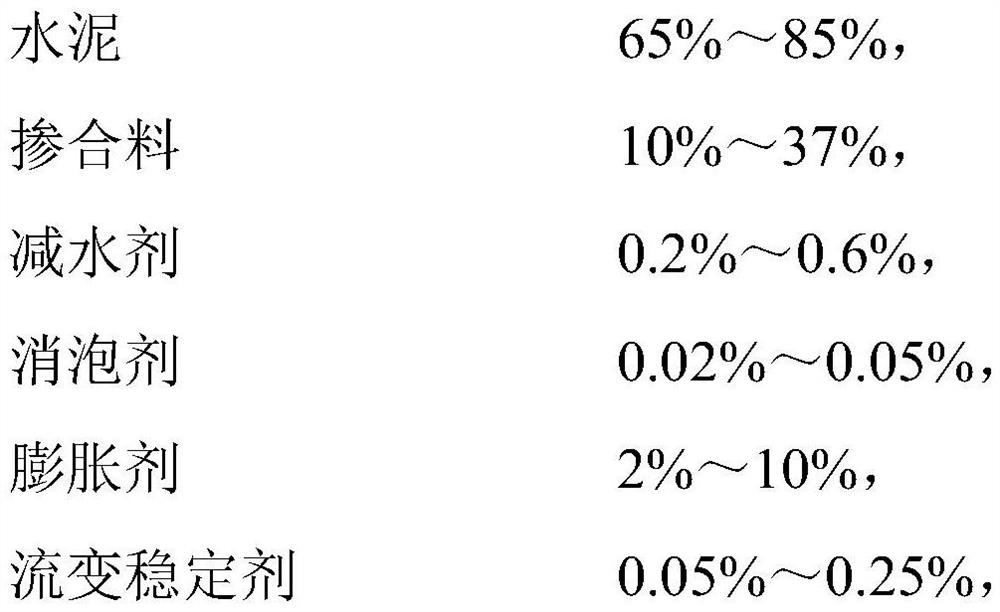

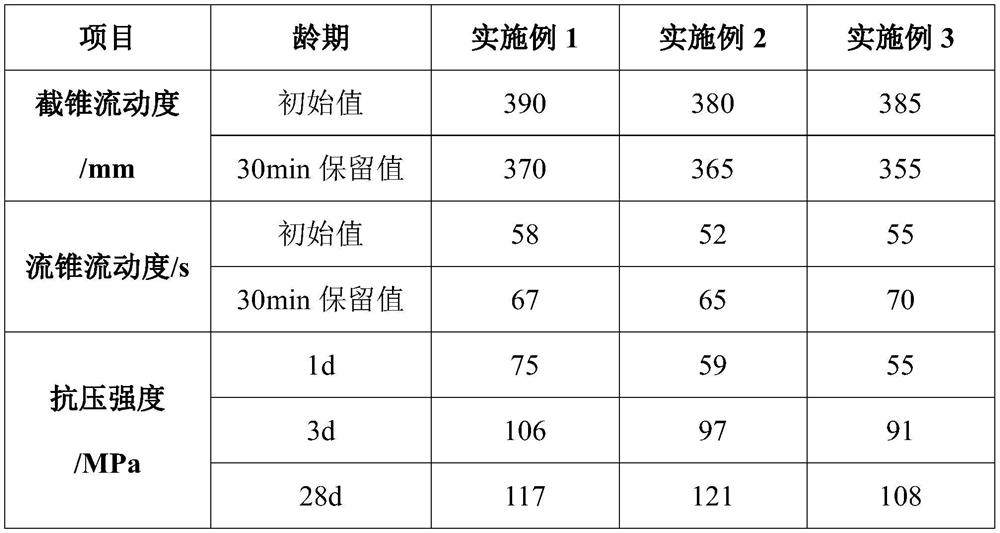

Cement-based grouting material for fan foundation reinforcement and preparation method thereof

The invention belongs to the field of building materials, and specifically discloses a cement-based grouting material for fan foundation reinforcement and a preparation method thereof. The raw material composition of the cement-based grouting material is as follows: 65% to 85% of cement, 10% to 37% of admixture, 0.2% to 0.6% of water reducing agent, 0.02% to 0.05% of defoamer, The expansion agent is 2% to 10%, the rheological stabilizer is 0.05% to 0.25%; the water is 18% to 25%, and water is removed, and the total weight of each component is 100%. The cement-based grouting material for fan foundation reinforcement provided by the invention has the advantages of high fluidity, high strength, micro-expansion, high durability and the like.

Owner:BEIJING NEW VISION BUILDING CONSTR TECH +2

Negative electrode active material for non-aqueous electrolyte secondary battery, non-aqueous electrolyte secondary battery, and method for producing negative electrode material for non-aqueous electrolyte secondary battery

ActiveUS11316152B2Good slurry stabilityIncrease capacityNegative electrodesAlkali metal silicatesElectrical batteryPhysical chemistry

Owner:SHIN ETSU CHEM IND CO LTD

Method for preparing oily sludge blended coal water slurry by using fluorine-containing polycarboxylic acid dispersing agent through ultrasonic dispersion

The invention discloses a method for preparing oily sludge blended coal water slurry by using a fluorine-containing polycarboxylic acid dispersing agent through ultrasonic dispersion. The method comprises the following steps: firstly, dispersing components of oily sludge through ultrasonically intensified mass transfer, so as to improve the stability and the uniformity of an oily sludge system, subsequently adding the fluorine-containing polycarboxylic acid dispersing agent in the process that the oily sludge is blended with the coal water slurry, so that oil, water and sludge form a uniform and stable system; dispersing the prepared coal water slurry by using the ultrasonic waves after the oily sludge is blended into the coal water slurry to prepare slurry, so that the stability and the uniformity of the coal water slurry are further improved and the prepared coal water slurry has relatively high coal slurry concentration, good flowability and good slurry forming stability. The needed equipment is simple, the oily sludge treatment efficiency is high, the oily sludge which is tempered by using the ultrasonic waves can be directly blended with coal to prepare the coal water slurry which can be gasified for use in a conventional coal water slurry preparation process, a guarantee is provided when the oily sludge resource is utilized to be blended into the coal water slurry, harmless treatment and resource utilization of the oily sludge are achieved, and relatively high industrial application values are achieved.

Owner:SHAANXI YANCHANG PETROLEUM GRP

Density-matched polymer slurries

ActiveUS7863362B2Readily transported and introducedGood slurry stabilityPaper coatingCoatingsParticulatesSlurry

Polymer slurries of ultrahigh molecular weight polyalpha-olefins are made stable toward settling, separation and agglomeration by surface treatment with a combination of wax and optional relatively high-density particulates. The selection of the surface coating acts not only as an anti-blocking agent, or partitioning aid to keep the tacky polymer particles separated, but also provides the suspended polymer particle with a density that matches the carrier. This prevents separation of the slurry components over time. Such materials, ultimately used as pipeline additives to reduce the fluid drag and increase the volumetric throughput, can be stored and shipped for extended periods of time without degradation of the slurry quality. Upon injection into the pipeline, the polymer particle dissolves quickly, unhindered by the coating.

Owner:BAKER HUGHES INC

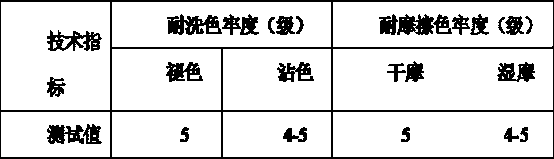

Printing gum for polyester fabrics and novel low-gum printing method

The invention relates to printing gum for polyester fabrics and a novel low-gum printing method. The novel low-gum printing method is realized by the aid of a combination synergia effect of a printing gum composition for the polyester fabrics. The printing gum composition is used for replacing high-concentration sodium alga acid gum for printing polyester fabrics, and problems that the conventional printing gum is difficult to clean, utilization quantity is high, wastewater COD (chemical oxygen demand) is high, disperse dye fixation degree is low, dyeing fastness is poor, color mixing is severe, efficient soaping process flow is long, and the like are resolved. By the aid of the printing gum composition for the polyester fabrics and the novel low-gum printing method, the process flow of a printing processing procedure of fabrics is reasonable, the quantity of wastewater is reduced, a production process is clean and environment-friendly, the quality of products is table, and dye color yield is high.

Owner:浙江嘉欣兴昌印染有限公司

Positive active material for rechargeable lithium battery, method of preparing the same, and rechargeable lithium battery including the same

PendingUS20200343550A1Improved power output characteristicsHigh voltage characteristicElectrode thermal treatmentPositive electrodesLithium metalPhysical chemistry

A positive active material for a rechargeable lithium battery includes a nickel-based lithium metal oxide having a layered crystal structure, and a coating layer including a lithium-metal oxide disposed selectively disposed on (003) crystalline plane of the nickel-based lithium metal oxide, wherein the positive active material includes at least one secondary particle including an agglomerate of two or more primary particles.

Owner:SAMSUNG SDI CO LTD +1

Post-tensioned pre-stressed concrete beam pipeline grouting agent

The invention provides a post-tensioned pre-stressed concrete beam pipeline grouting agent. The post-tensioned pre-stressed concrete beam pipeline grouting agent comprises the following components in parts by weight: 0.5-10 parts of a water reducing agent, 0.1-5 parts of a plastic expanding agent, 5-20 parts of a hardening swelling agent, 5-15 parts of a suspending agent, 0.001-0.05 part of a water-retaining agent, 0.01-0.5 part of an antifoaming agent, 0.1-4 parts of a thixotropic agent, 0.1-8 parts of a lubricating agent and 10-80 parts of a mineral admixture. The post-tensioned pre-stressed concrete beam pipeline grouting agent has the beneficial effects that the pipeline grouting agent has the characteristics of being quick in flow second, good in fluidity retaining, good in slurry stability, un-bleeding and the like, and therefore, the pipeline grouting agent can be used for effectively protecting steel strands, is suitable for post-tensioned pre-stressed concrete beams of road bridges and culverts, and also can be used for concrete structure pipeline grouting of general engineering.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +2

Slurry Composition for Electrode of Secondary Battery, Electrode of Secondary Battery, and Secondary Battery

PendingUS20210384512A1Good slurry stabilityAvoid layeringSecondary cellsNegative electrodesMeth-Electrical battery

A slurry composition for an electrode of a secondary battery, has a hydrophobically modified alkali-swellable emulsion (HASE), a poly(meth)acrylic acid and a conductive agent. The slurry composition is capable of realizing excellent electrode adhesion in high energy electrode. The electrode of a secondary battery prepared using the same, and a secondary battery are also provided.

Owner:LG CHEM LTD

Negative electrode active material for non-aqueous electrolyte secondary battery, non-aqueous electrolyte secondary battery, and method for producing negative electrode material for non-aqueous electrolyte secondary battery

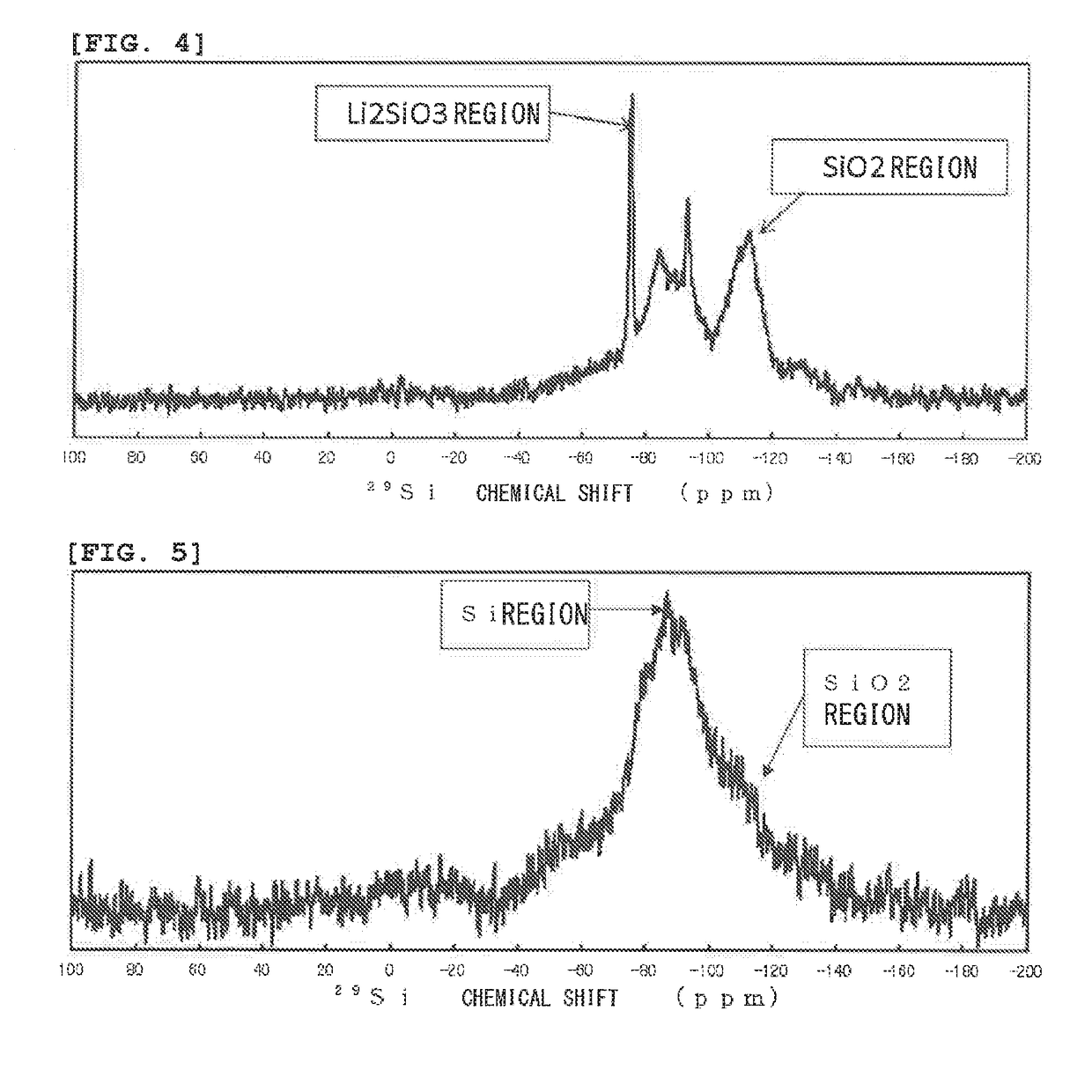

PendingUS20220069297A1Good slurry stabilityIncrease capacityNegative electrodesAlkali metal silicatesElectrical batteryAqueous electrolyte

A negative electrode active material for a non-aqueous electrolyte secondary battery contains negative electrode active material particles which include silicon compound (SiOx: 0.5≤x≤1.6) particles. The negative electrode active material particles are at least partially coated with a carbon material, contain one or more selected from Li2SiO3 and Li2Si2O5, and satisfy Ib / Ia≤4.8 and Ic / Ia≤6.0 in an X-ray diffraction measurement using a Cu-Kα line. Ia represents an intensity of a peak around 2θ=28.4° attributable to Si obtained by the X-ray diffraction. Ib represents a peak intensity of a peak attributable to Li2SiO3 obtained by the X-ray diffraction. Ic represents a peak intensity of a peak attributable to Li2Si2O5 obtained by the X-ray diffraction. Thus, a negative electrode active material for a non-aqueous electrolyte secondary battery, is stable over a long period even in an aqueous slurry and enables high capacity, favorable cycle characteristics and first-time efficiency.

Owner:SHIN ETSU CHEM IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com