Method for preparing oily sludge blended coal water slurry by using fluorine-containing polycarboxylic acid dispersing agent through ultrasonic dispersion

A fluorine-containing polycarboxylic acid and ultrasonic dispersion technology, which is applied in the field of coal-water slurry pulping, can solve problems such as the inability to meet the stability and slurry-forming requirements of coal-water slurry pulping, high sludge composition requirements, and increased process links. Achieve the effect of improving stability and uniformity, high coal slurry concentration, and improving dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

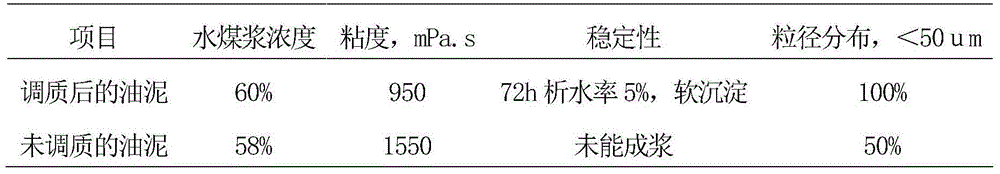

[0022] Taking the "three muds" produced in the sewage workshop of an oil refinery in northern Shaanxi and the oil sludge at the bottom of a crude oil settlement tank of an oil production plant combined station in northern Shaanxi mixed at a mass ratio of 1:6 as an example, the initial water content is 60%, and the oil content is 60%. 30% of similar substances and 10% of mud content. The specific pulping method is as follows:

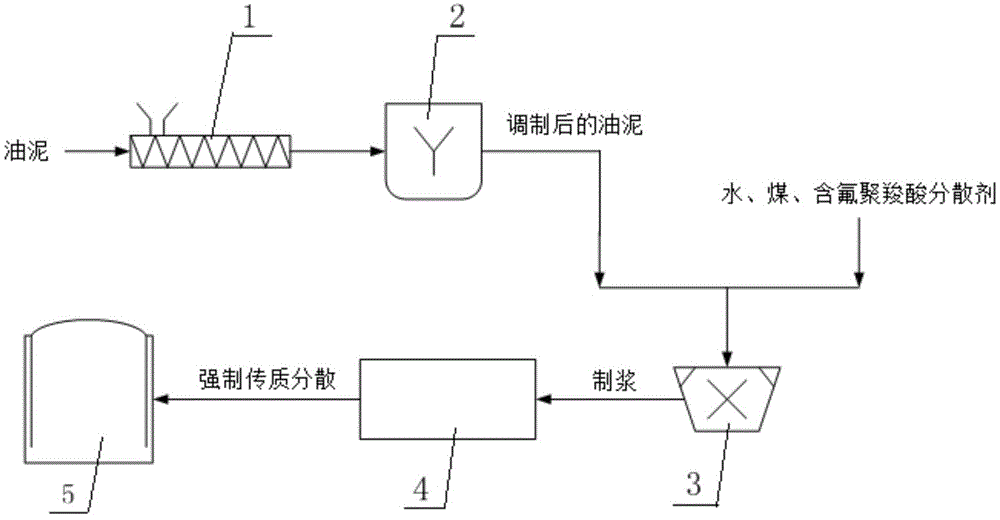

[0023] 1. Ultrasonic quenching and tempering treatment of oil sludge

[0024] Such as figure 1 As shown, the oil sludge is separated by flocculation and sedimentation with zwitterionic polyacrylamide with a weight-average molecular weight of 15,000 Daltons, and the amount added is 0.3% of the weight of the oil sludge. Separation, to obtain the oil sludge of reduction and separation treatment, which contains 40% water, 40% oil, and 20% mud. The oil sludge after reduction and separation treatment is transferred to the machine with mechanical stirring and ...

Embodiment 2

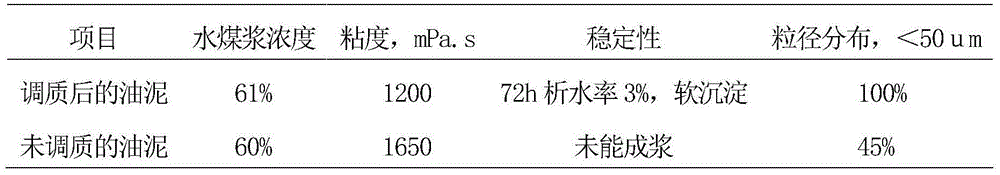

[0031] Taking the oil sludge at the bottom of a crude oil settlement tank of an oil production plant combined station in northern Shaanxi as an example, its initial water content is 35%, oily substance 40%, and mud content 25%. The specific pulping method is as follows:

[0032] 1. Ultrasonic quenching and tempering treatment of oil sludge

[0033] Such as figure 1 As shown, the oil sludge is separated by flocculation and sedimentation with zwitterionic polyacrylamide with a weight-average molecular weight of 12,000 Daltons, and the amount added is 0.3% of the mass of the oil sludge. Separation, to obtain the oil sludge of reduction and separation treatment, which contains 40% water, 30% oil, and 30% mud. The oil sludge after reduction and separation treatment is transferred to the machine with mechanical stirring and ultrasonic strengthening dispersing device by screw conveyor 1. In the sludge conditioning tank 2, the temperature of the sludge is raised to 50°C under stirrin...

Embodiment 3

[0040] 1. Ultrasonic quenching and tempering treatment of oil sludge

[0041] Such as figure 1 As shown, the oil sludge after the reduction and separation treatment is transferred to the oil sludge conditioning tank 2 with mechanical stirring and ultrasonic enhanced dispersion device with the screw conveyor 1, and the oil sludge is heated to 90°C under the stirring condition, and the power is 30kW 1. Ultrasonic waves with a frequency of 500 MHz pre-disperse the oil sludge in the oil sludge conditioning tank 2 for 1 second to obtain oil sludge after conditioning.

[0042] 2. Sludge mixed with coal water slurry to make pulp

[0043] The conditioned oil sludge, coal, water and fluorine-containing polycarboxylic acid dispersant are sent to the wet-process rod-shaped coal mill 3 for coal-water slurry slurrying, wherein the amount of oil sludge added is 10% of the total coal-water slurry mass, containing Fluoropolycarboxylic acid dispersant addition is 1.0% of total coal-water slu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com