Cement-based grouting material for fan foundation reinforcement and preparation method thereof

A technology of wind turbine foundation and grouting materials, which is applied in the field of wind power engineering materials, can solve the problems such as the need to improve the compressive strength, achieve the effects of improving the stability of the slurry, the preparation method is simple, and the compactness of the structure is improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

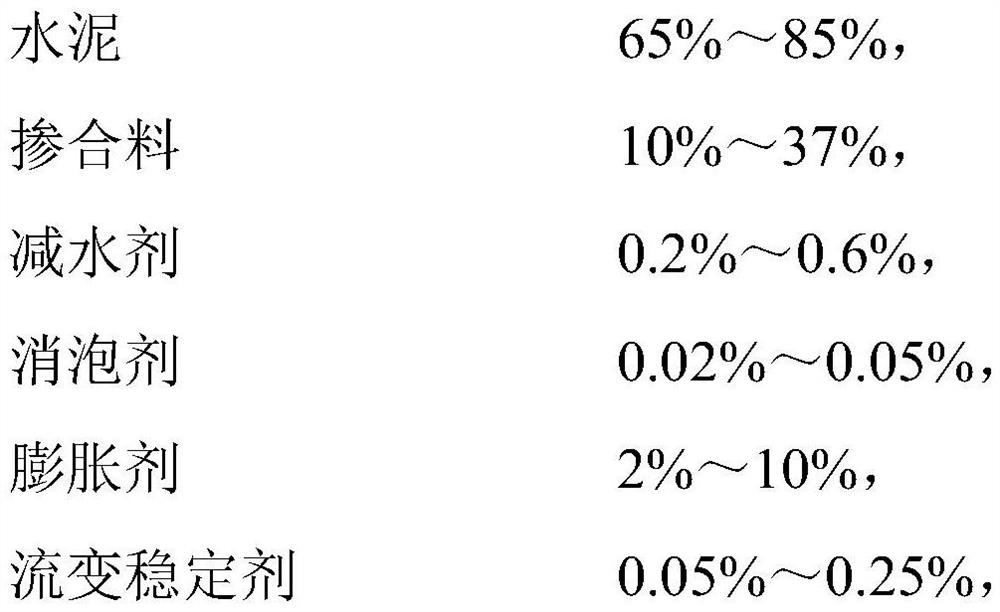

Method used

Image

Examples

Embodiment 1

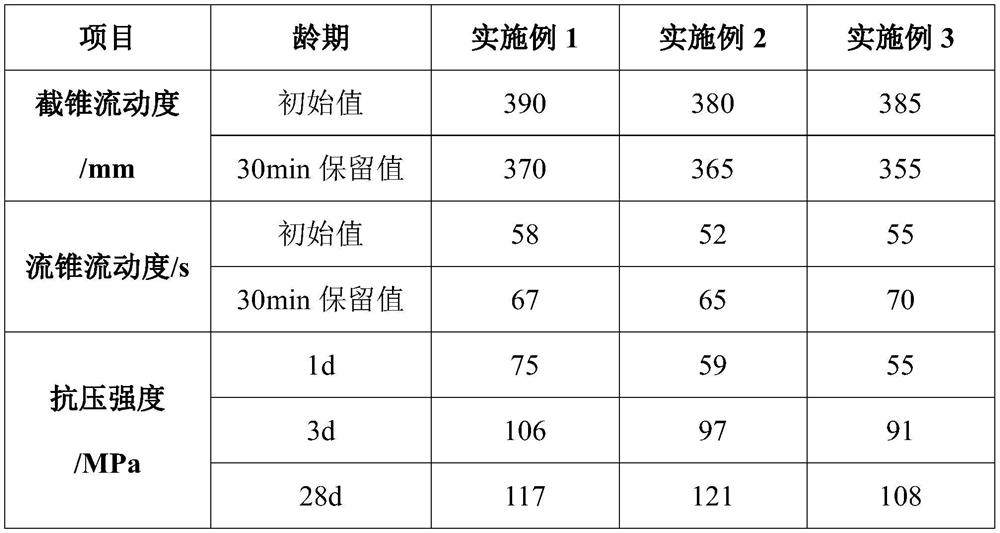

[0032] P·Ⅱ52.5 Portland cement 81%, finely ground slag powder 4.4%, microbeads 5.2%, silica fume 1.5%, polycarboxylate water reducer 0.4%, polyether defoamer 0.05%, magnesia expansion agent 7.2%, cellulose ether 0.03%, organic bentonite 0.22%. After mixing the above materials uniformly, add water with a total mass of 24%, stir uniformly, and let stand for 1 min to obtain the cement-based grouting material of the present invention. The physical properties of the grouting materials tested under standard conditions are shown in Table 1.

Embodiment 2

[0034] P·Ⅱ52.5 Portland cement 73%, finely ground slag powder 8.2%, microbeads 10.3%, silica fume 3.5%, polycarboxylate water reducer 0.2%, polyether defoamer 0.03%, sulfoaluminate Calcium swelling agent 4.6%, cellulose ether 0.02%, organic bentonite 0.15%. After mixing the above materials uniformly, add water with a total mass of 19%, stir uniformly, and let stand for 1 min to obtain the cement-based grouting material of the present invention. The physical properties of the grouting materials tested under standard conditions are shown in Table 1.

Embodiment 3

[0036] P·O52.5R grade ordinary Portland cement 75%, finely ground slag powder 5.2%, microbeads 8%, silica fume 2.4%, polycarboxylate water reducer 0.3%, silicone defoamer 0.04%, magnesium oxide Bulking agent 8.9%, cellulose ether 0.02%, organic bentonite 0.14%. After mixing the above materials uniformly, add water with a total mass of 21%, stir uniformly, and let stand for 1 min to obtain the cement-based grouting material of the present invention. The physical properties of the grouting materials tested under standard conditions are shown in Table 1.

[0037] Table 1 Physical properties of the grouting material of the embodiment (standard laboratory test environment)

[0038]

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com