High-nickel multi-element positive electrode material as well as preparation method and application thereof

A positive electrode material and multi-component technology, applied in the field of high-nickel multi-component positive electrode materials, can solve problems such as poor coating uniformity, lithium dissolution in material structure, battery capacity loss, etc., to avoid overwashing or uneven coating, and improve slurry stability performance, improve thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

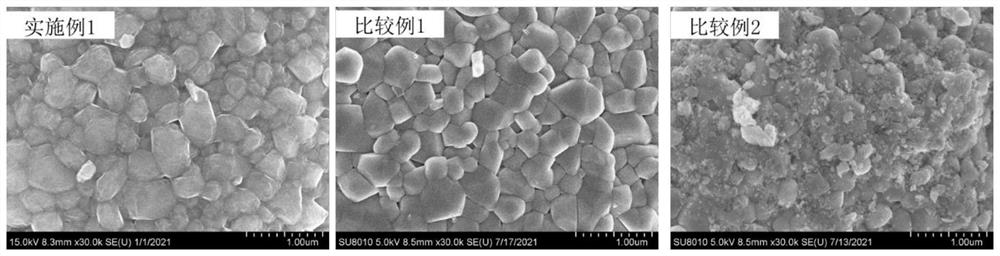

Image

Examples

preparation example Construction

[0042] The present application also provides the preparation method of the high nickel multi-element cathode material, comprising the following steps:

[0043] Mixing the initial positive electrode material with the general formula (I) with water, washing with water, and separating solid and liquid to obtain a primary filter cake;

[0044] The primary filter cake is poured and filtered with an alkaline solution containing high-valent metal ions, and solid-liquid separation is performed again to obtain a secondary filter cake;

[0045] The secondary filter cake is dried and then heat-treated to obtain a high-nickel multi-element positive electrode material;

[0046] Li 1+k Me 1-k O 2 (I);

[0047] Among them, -0.03≤k≤0.10, Me=Ni c Me' d Co e R f ;

[0048] 0.80≤c≤1, 0.00≤d≤0.20, 0.05≤e≤0.20, 0≤f≤0.05, Me' is selected from one or both of Mn and Al, R is selected from Mg, Ti, B, Ba, one or more of Sr, Zr, Y and Na;

[0049] The high-valence metal ion is a cation with ...

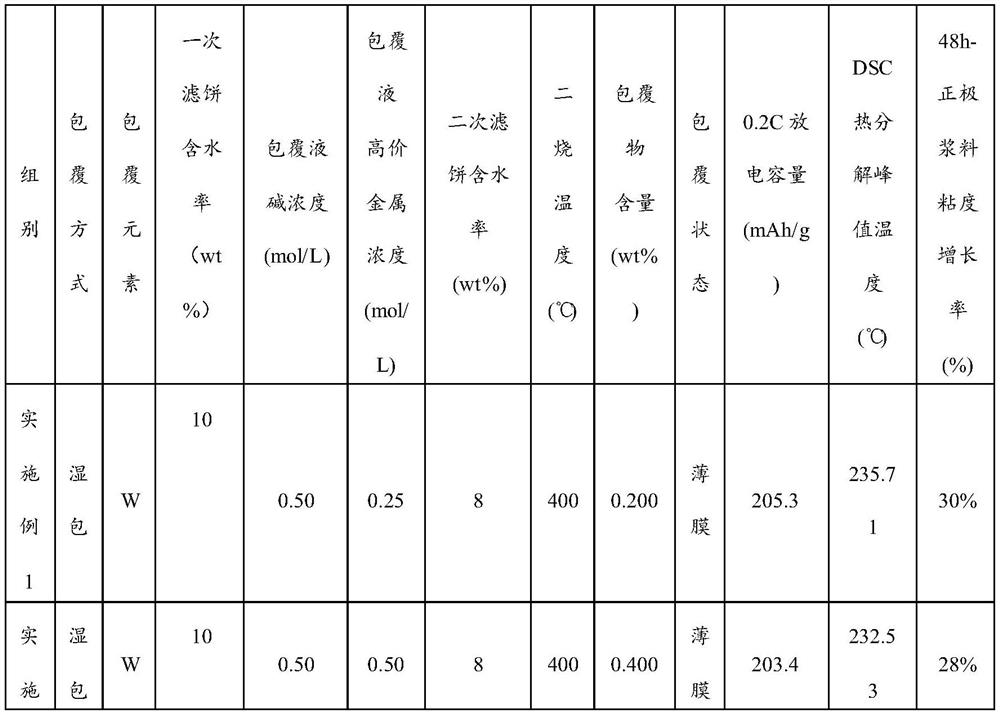

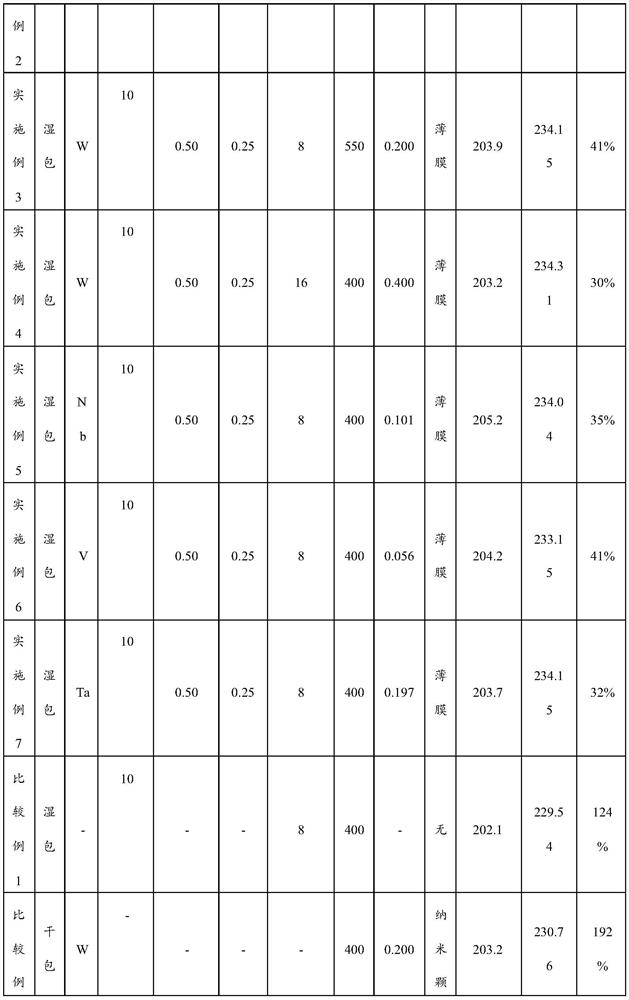

Embodiment 1

[0056] The primary sintered cathode material powder base material is obtained by mixing nickel composite hydroxide and lithium hydroxide and firing in an oxygen atmosphere, using Li 1.025 Ni 0.90 Co 0.06 Al 0.04 O 2 It shows that the average particle size of the high nickel cathode powder is 10.6 μm, and the specific surface area is 0.28 m 2 / g; 500g primary sintered positive electrode material and deionized water were washed for 10min at a weight ratio of 1:1, and the feed liquid was subjected to suction filtration and dehydration for 30min through a Buchner suction filter bottle to obtain a primary filter cake with a moisture content of 10wt%; 3.15 g of lithium hydroxide (LiOH H 2 O) 8.69 g of tungsten oxide (WO) was added to the aqueous solution obtained by dissolving it in 150 mL of pure water 3 ) and the tungsten concentration formed is the tungsten-containing alkali solution of 0.25mol / L; the alkaline solution is evenly poured and filtered on the primary filter cake...

Embodiment 2

[0058] 6.30 g of lithium hydroxide (LiOH·H 2 O) 17.38 g of tungsten oxide (WO) was added to the aqueous solution obtained by dissolving it in 150 mL of pure water 3 ) to form a tungsten-containing alkali solution with a tungsten concentration of 0.50 mol / L. Other than that, it carried out similarly to Example 1, and obtained the multi-element high nickel material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com