Exhaust device having deflection plates

a technology of exhaust device and deflection plate, which is applied in ventilation systems, heating types, stoves or ranges, etc., can solve the problems of affecting the efficiency of operation, so as to prevent the leakage of pollutants or soot, and effectively exhaust high-temperature pollutants or soot

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

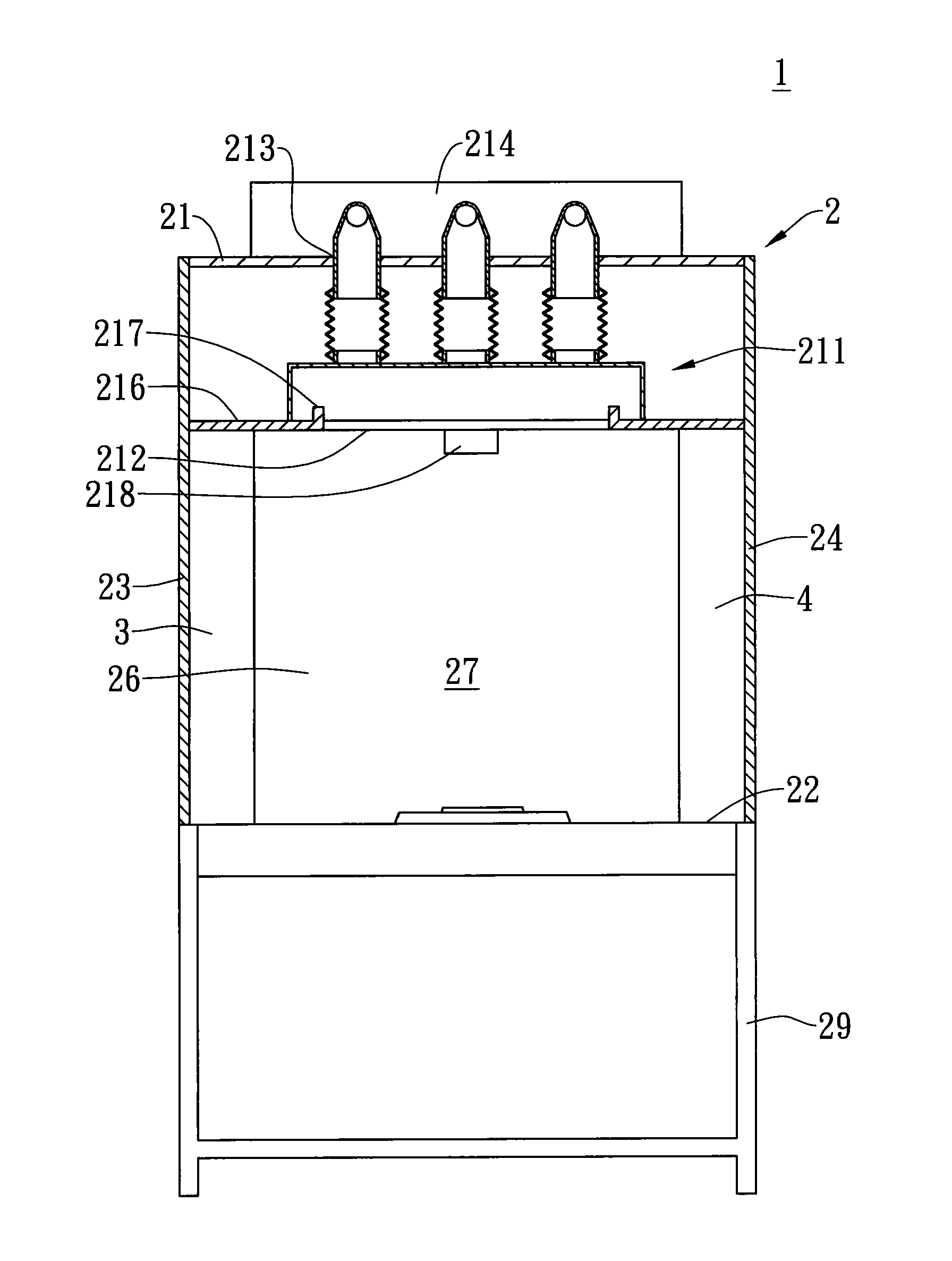

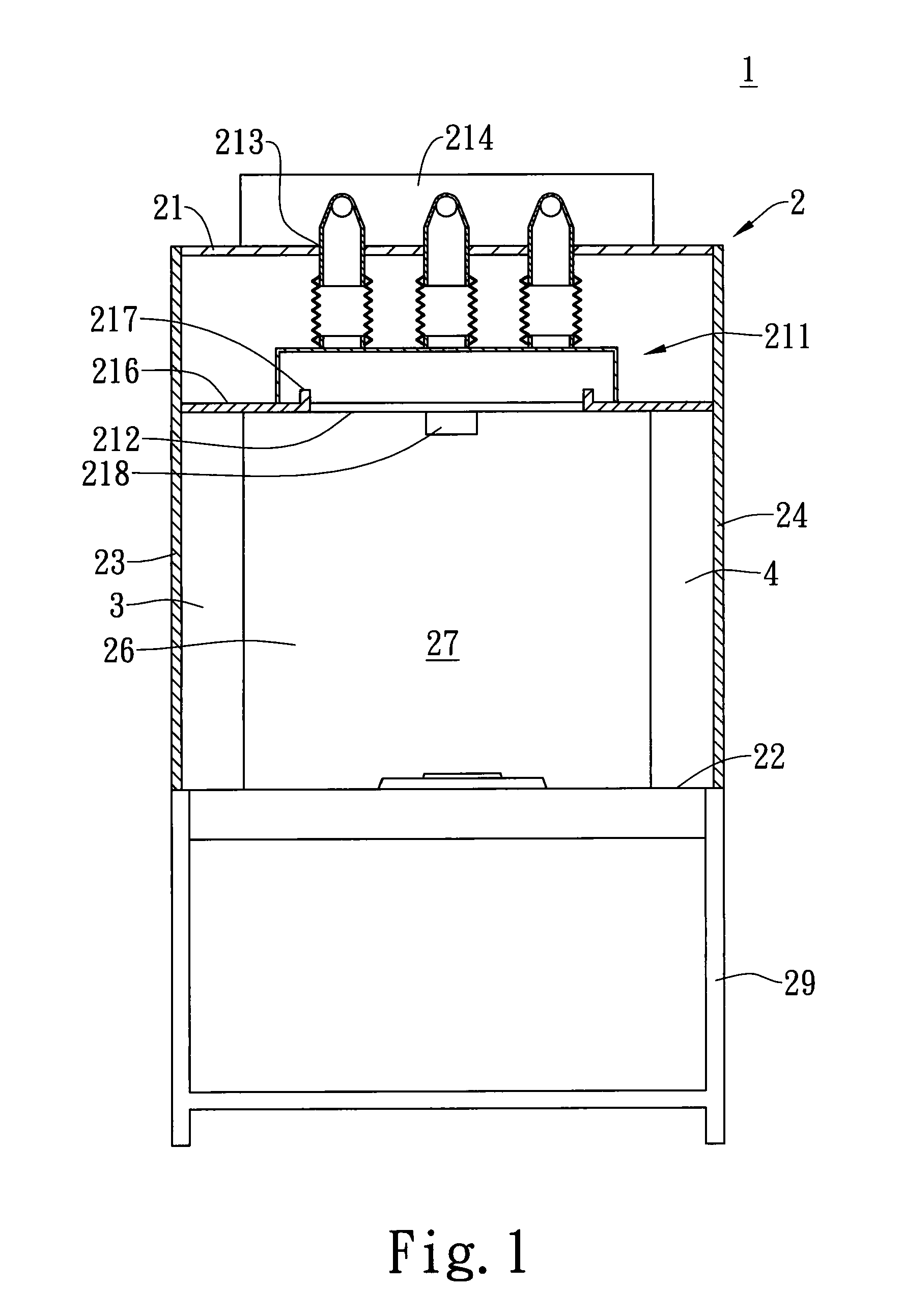

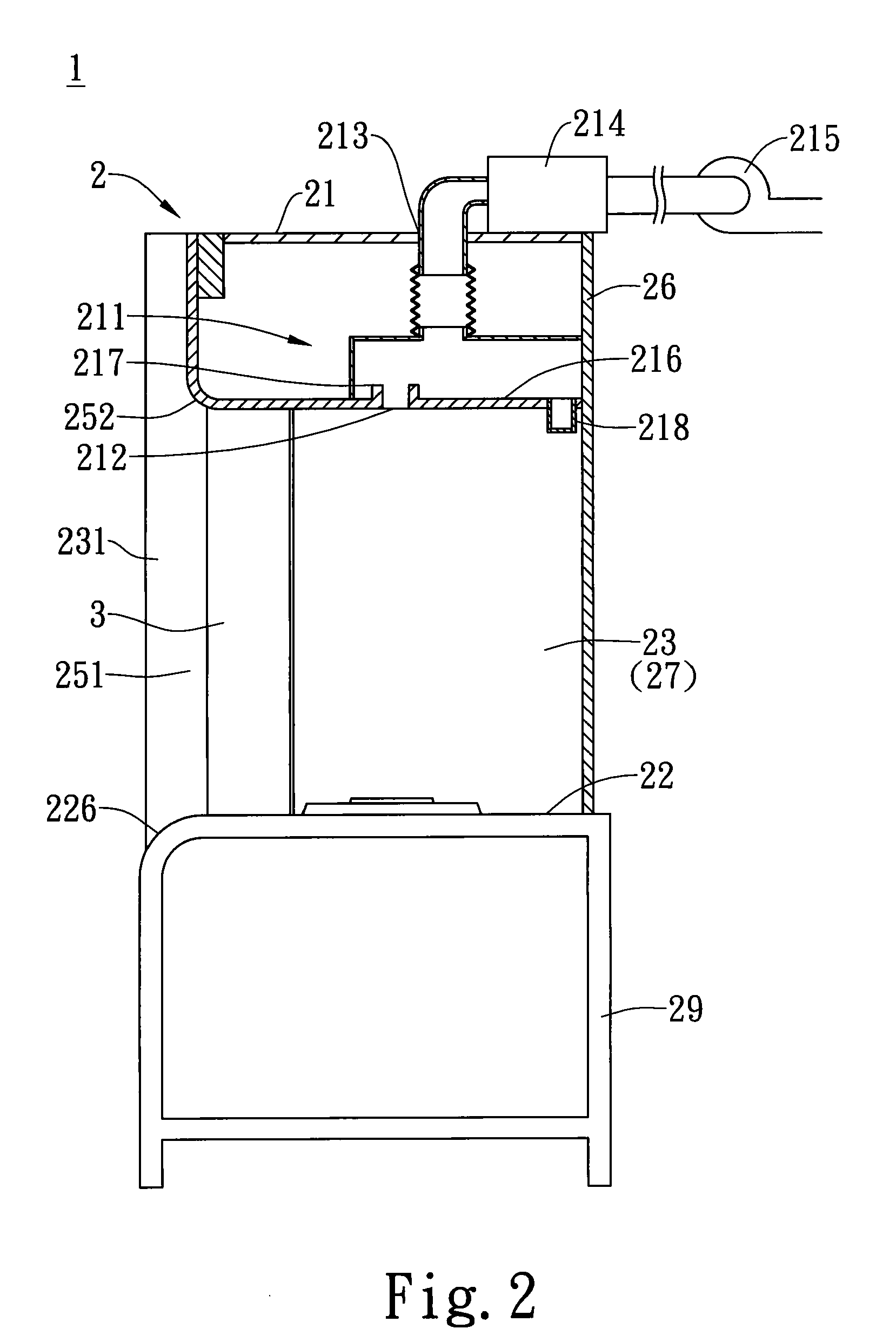

[0029]Please refer to FIGS. 1-3 showing an exhaust device having deflection plates 1, which comprises a cabinet 2, a left deflection plate 3, and a right deflection plate 4.

[0030]The cabinet 2 is in substantially rectangular or square shape. The lower part of the cabinet 2 is provided with a storage cabinet 29 for storage purpose. The storage cabinet 29 has legs and is able to support the cabinet 2. The cabinet 2 has an air-extraction hood 21, a bottom plate 22, a left lateral plate 23, a right lateral plate 24, and a rear plate 26. After being assembled together, above components define a space 27 within the cabinet 2. An opening 251 is provided below the front end of the air-extraction hood 21. Besides, a curved first guiding part 252 is provided at the bottom of the front end of the air-extraction hood 21, and a curved second guiding part 226 is provided at the top of the front end of the bottom plate 22. The front ends of the left lateral plate 23 and the right lateral plate 24 ...

third embodiment

[0037]Please refer to FIG. 11, in which is shown an exhaust device 1 having deflection plates. In this embodiment, a strip-shape air blow device 253 is provided at the bottom, either inside or outside the cabinet, of the front plate 25. The strip-shape air blow device 253 draws the fresh air outside the cabinet and blow the drawn air downward so as to enhance ability of preventing leakage of pollutants or high-temperature soot. In implementation, two air blow devices 253 can be provided respectively at two ends of the bottom of the front plate 25. Alternatively, as shown in FIG. 11A, when the lateral part of the front plate 25 is overlapped with a movable cabinet door 255, the air blow device 253 is provided at the bottom of the movable cabinet door 255.

fourth embodiment

[0038]Moreover, FIG. 12 shows an exhaust device 1 having deflection plates 31, 32, 41, and 42. In this embodiment, two openings 251, 253 are respectively provided in front of and in back of the cabinet 2. In other words, the two openings pass through the cabinet 2. In the space 27, a front and a rear left deflection plates 31, 32 are respectively provided in a manner of being relatively oblique to the left lateral plate 23, and a front and a rear right deflection plates 41, 42 are respectively provided in a manner of being relatively oblique to the right lateral plate 24. A first included angle θ1 is formed between the front and the rear left deflection plates 31, 32 and the left lateral plate 23. A second included angle θ2 is formed between the front and the rear right deflection plates 41, 42 and the right lateral plate 24. Besides, the front right deflection plate 41 is symmetrical to the front left deflection plate 31 while the rear right deflection plate 42 is symmetrical to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com