Thermal conductive sheet, insulating sheet, and heat dissipating member

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

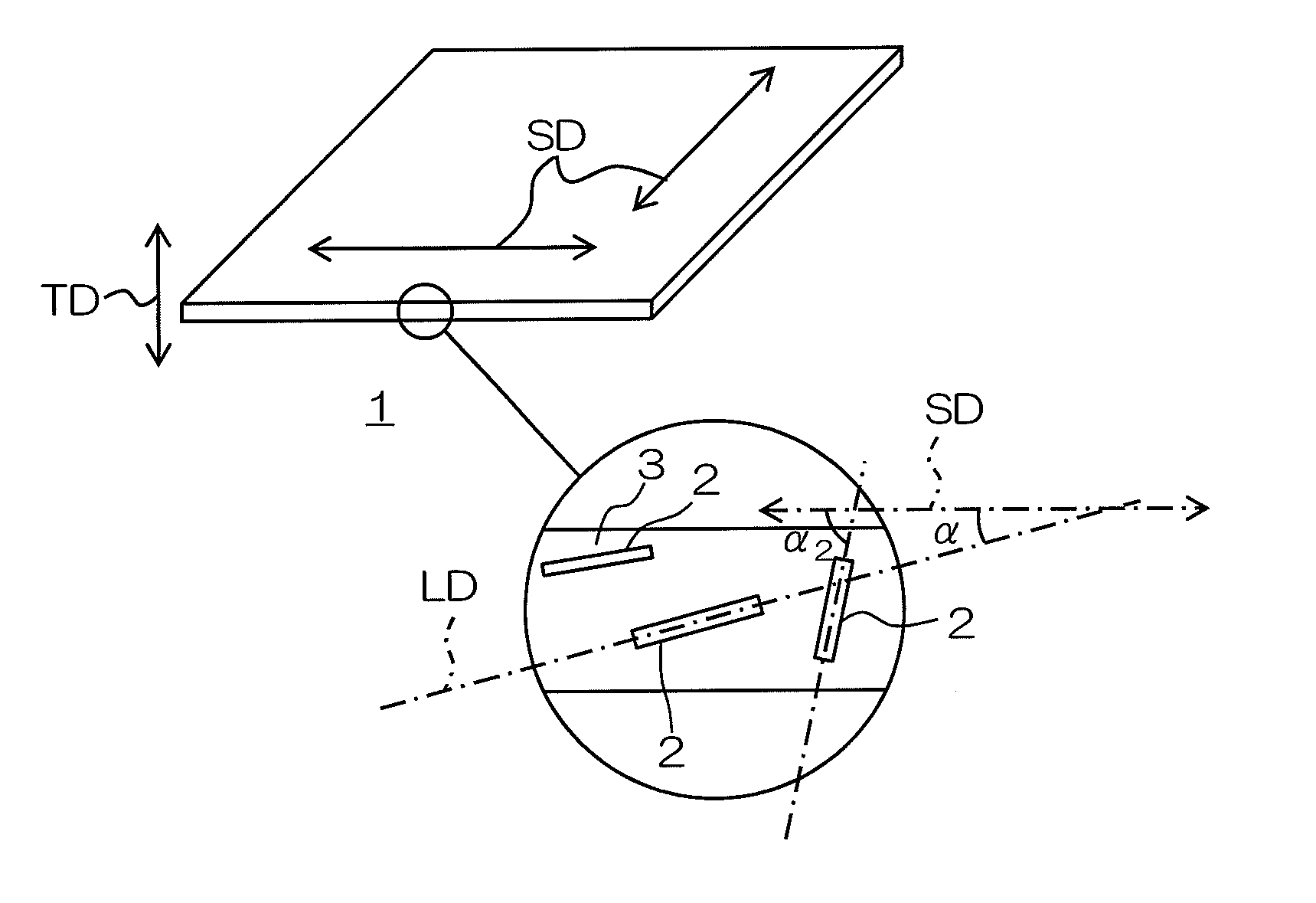

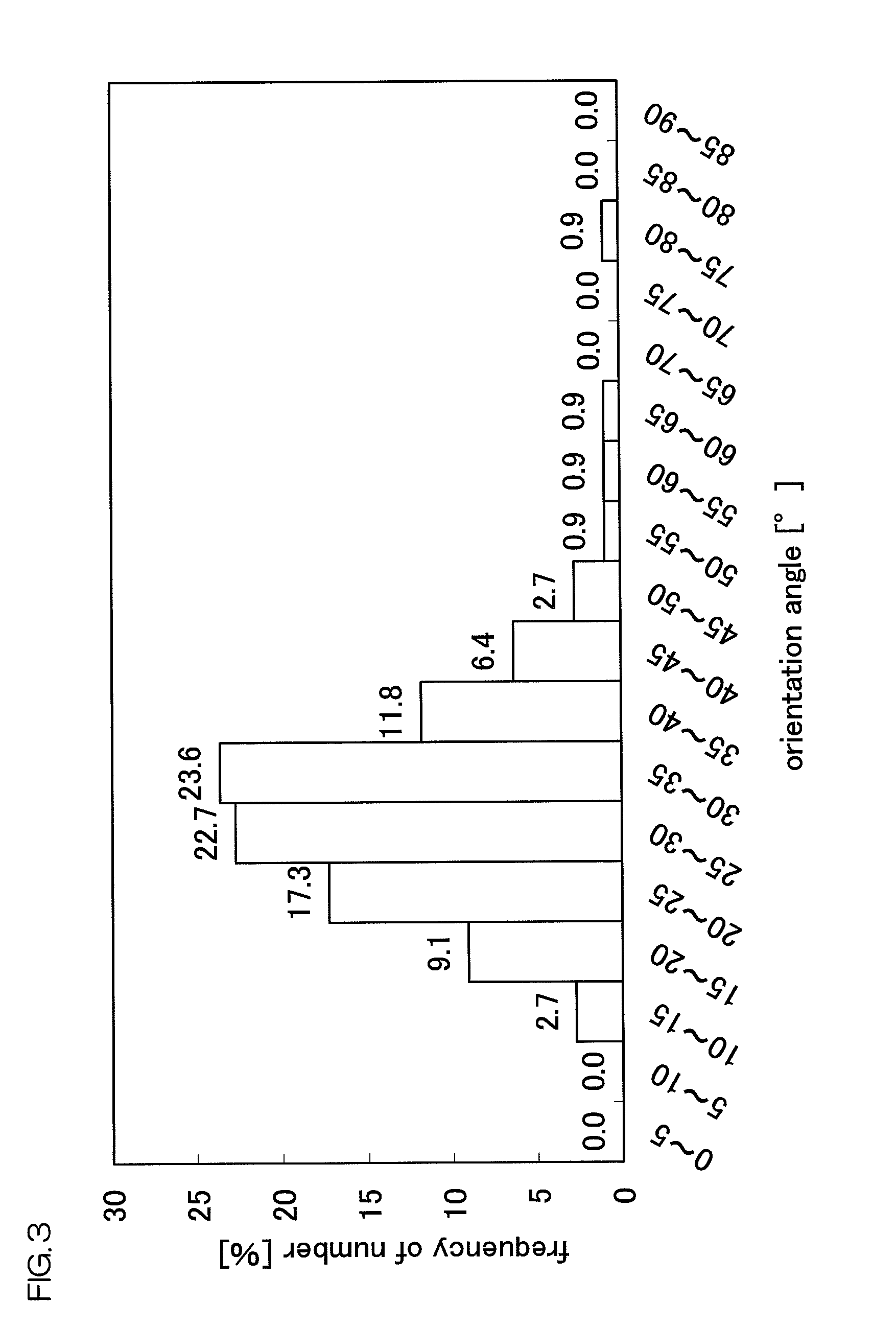

Method used

Image

Examples

example 1

[0128]6.71 g of PT-110 (trade name, plate-like boron nitride particles, average particle size (light scattering method) of 35 to 60 μm, manufactured by Momentive Performance Materials Inc.) was prepared.

[0129]1.2 g of EPPN-501HY (trade name, phenol novolak epoxy resin, solid, epoxy equivalent of 163 to 175 g / eqiv., softening temperature (ring and ball test) of 61° C., manufactured by Nippon Steel Chemical Co., Ltd.) and 0.3 g of YSLV-120TE (trade name, bisphenol epoxy resin, solid, average particle size (analysis of SEM image) of about 100 μm (classified with a sieve after pulverized), epoxy equivalent of 250 g / eqiv., softening temperature (ring and ball test) of 120° C., manufactured by Nippon Steel Chemical Co., Ltd.) were dissolved in 2 g of solvent (acetone). Next, after 0.05 g of imidazole curing catalyst (curing agent) (2P4 MHZ-PW, manufactured by Shikoku Chemicals Corporation) was added thereto, the above-described PT-110 was mixed and then dried at 60° C. for one hour to rem...

example 2

[0133]A thermal conductive sheet was obtained in the same manner as in Example 1, except that 1.2 g of jER1001 (trade name, bisphenol A epoxy resin, solid, epoxy equivalent of 450 to 500 g / eqiv., softening temperature (ring and ball test) of 64° C., manufactured by Mitsubishi Chemical Corporation) was used instead of EPPN-501HY.

example 3

[0134]A thermal conductive sheet was obtained in the same manner as in Example 1, except that 1.2 g of jER1002 (trade name, bisphenol A epoxy resin, solid, epoxy equivalent of 600 to 700 g / eqiv., softening temperature (ring and ball test) of 74° C., manufactured by Mitsubishi Chemical Corporation) was used instead of EPPN-501HY, and 0.5 g of YSLV-80XY (trade name, bisphenol epoxy resin, crystalline epoxy resin, solid, average particle size (analysis of SEM image) of about 100 μm (classified with a sieve after pulverized), epoxy equivalent of 200 g / eqiv., softening temperature (ring and ball test) of 140° C., manufactured by Nippon Steel Chemical Co., Ltd.) was used instead of YSLV-120TE.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com