Absorption Cycle System Having Dual Absorption Circuits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

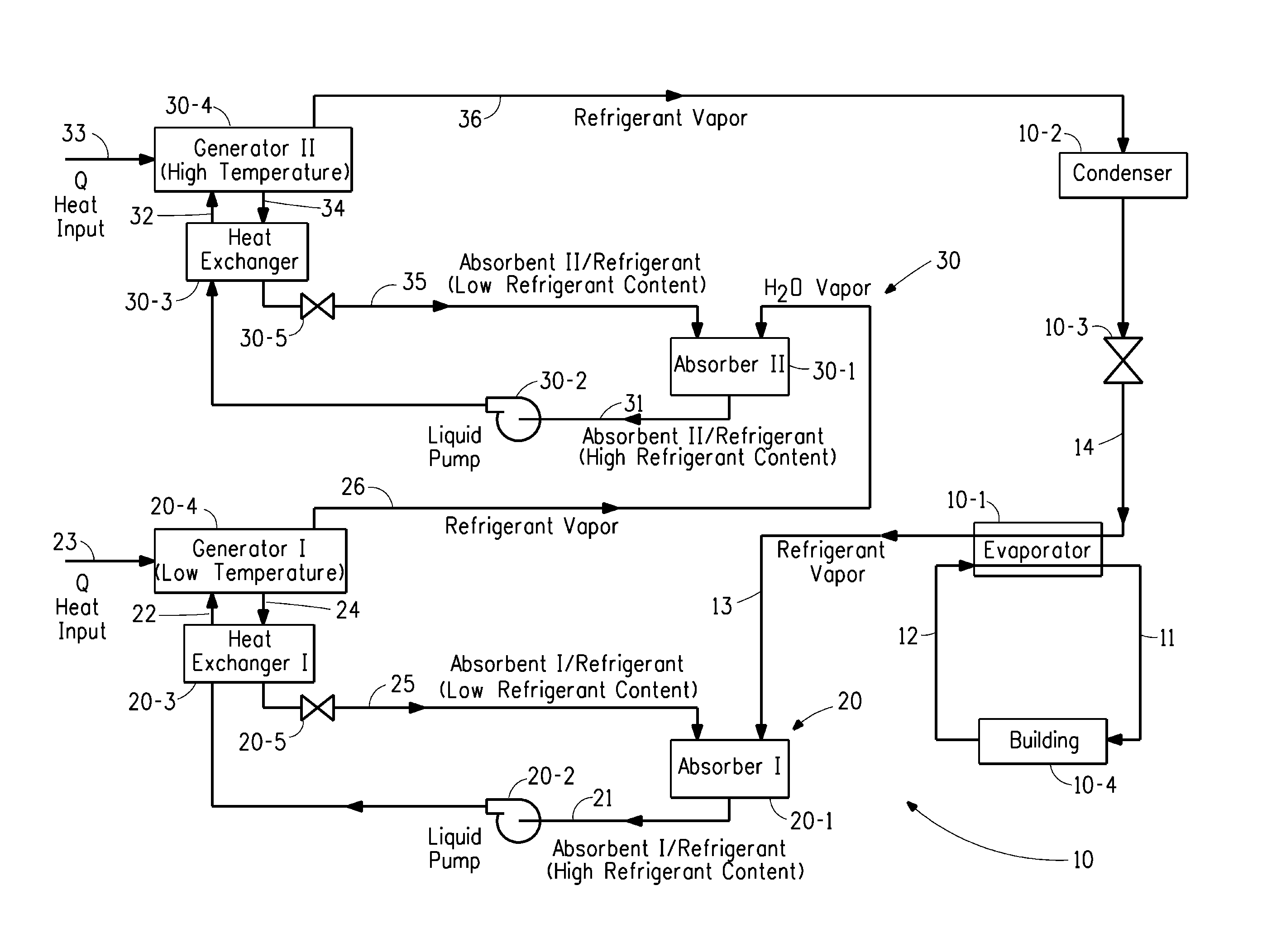

Image

Examples

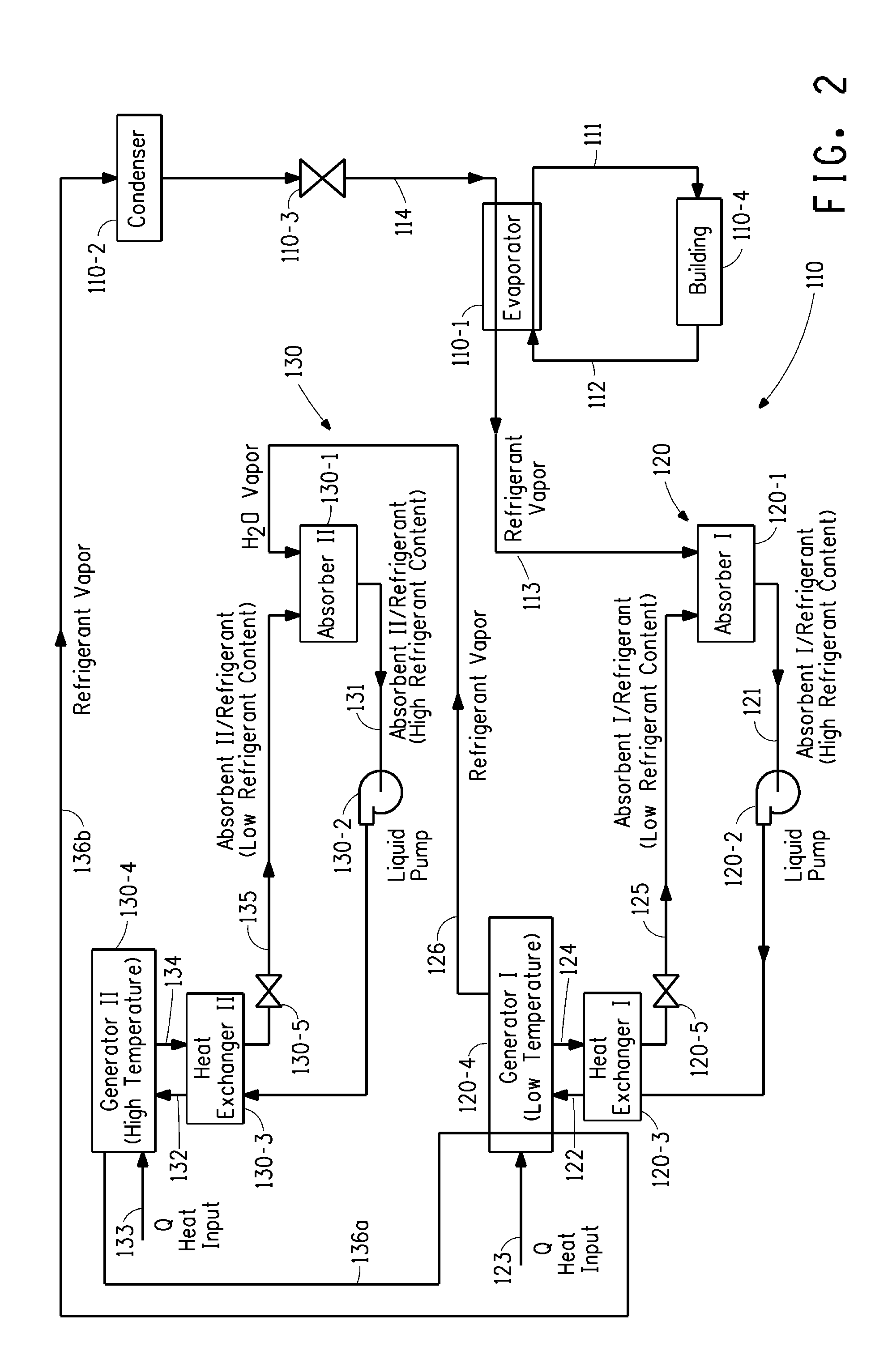

second embodiment

[0026]FIG. 2 shows an absorption cooling system of the present invention. Such a system is generally shown at 110. The system includes an evaporator 110-1 disposed in fluid communication with a first absorption circuit, shown generally at 120 in FIG. 2, a second absorption circuit, shown generally at 130 in FIG. 2, disposed in fluid communication with the first absorption circuit, and a condenser 110-2 disposed in fluid communication with the second absorption circuit and the evaporator.

[0027]The evaporator of the system of the present invention includes an inlet line 114 for delivering a refrigerant to the evaporator. Again, the refrigerant in the system of the second embodiment of the present invention is water, it being understood that other refrigerants may be used in this system. The evaporator of the second embodiment operates in the same way that the evaporator of FIG. 1 does. Thus, refrigerant is partially evaporated liquid when it enters the evaporator. The evaporator also ...

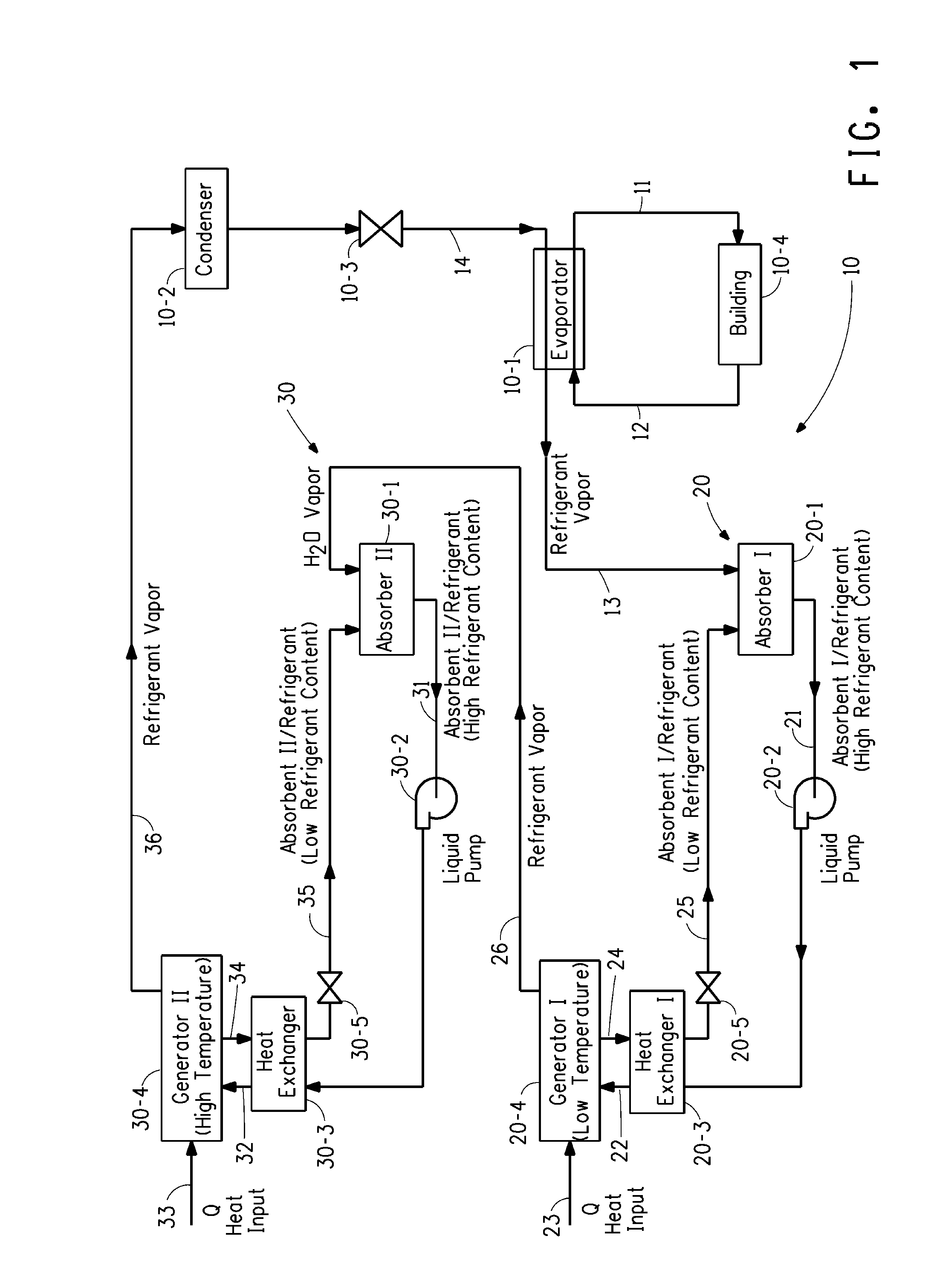

first embodiment

[0033]Second pump 130-2 pumps the high refrigerant-content second-absorbent / refrigerant mixture via a line 131 to the second heat exchanger 130-3, which, like the first heat exchanger, may be a shell and tube type heat exchanger. The second heat exchanger pre-heats the said mixture before it enters the second generator 130-4 via a line 132. The second generator is supplied with high-temperature heat from any suitable external source. In one embodiment, within the second generator is a bundle of tubes (not shown) which carry combustion gases, steam, or hot water which are supplied to the generator via a line 133. The combustion gases, steam or hot water transfer heat into the high refrigerant-content second-absorbent / refrigerant mixture. The heat causes the mixture to release refrigerant vapor, which exits from the second generator through a heat recovery line 136a, leaving a low refrigerant-content mixture behind in the second generator. The refrigerant is now a high pressure vapor,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com