Tape attaching apparatus and tape attaching method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035]Next, modes for carrying out the invention will be described in detail with reference to the drawings. Herein, an example is described in which a tape attaching apparatus according to the present invention is applied to attachment of a dicing tape to a semiconductor wafer.

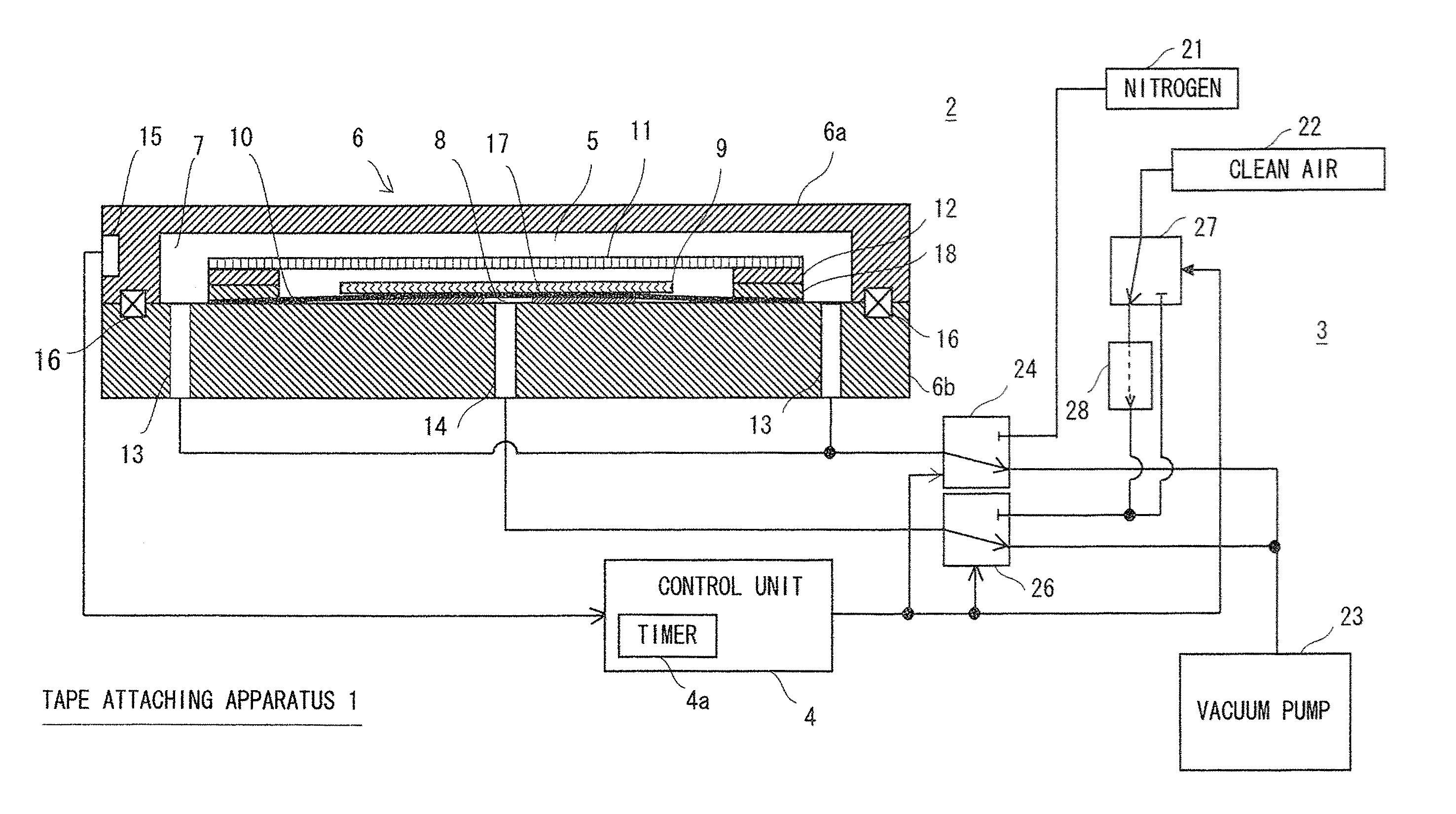

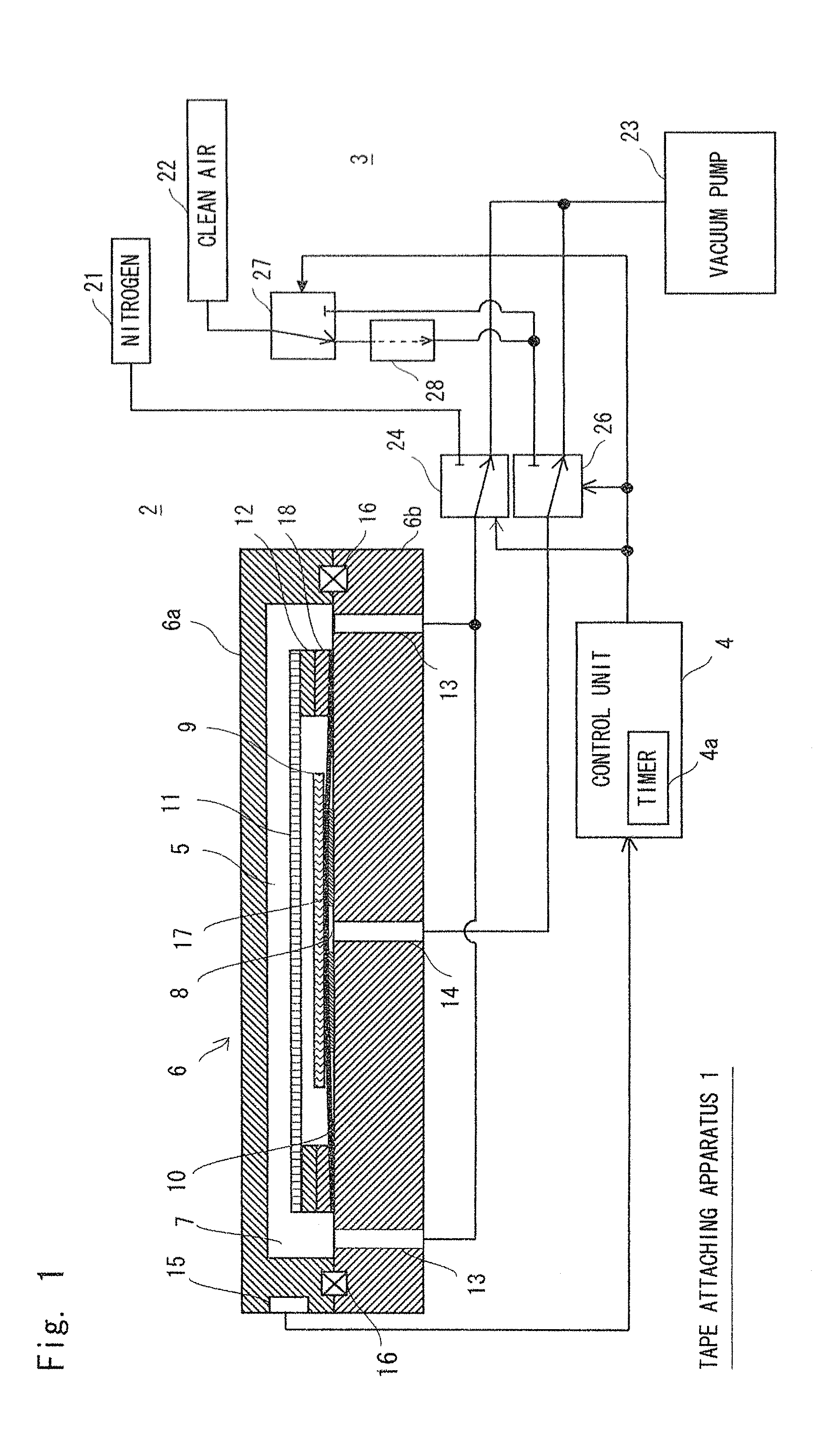

[0036]FIG. 1 shows an exemplary embodiment of the tape attaching apparatus according to the present invention. This tape attaching apparatus 1 is broadly divided into an apparatus main body 2, a supply / exhaust mechanism 3 which supplies air (clean air) and nitrogen to the apparatus main body 2 and sucks air or the like from the apparatus main body 2, and a control unit 4 which controls timings for supplying / discharging air or the like.

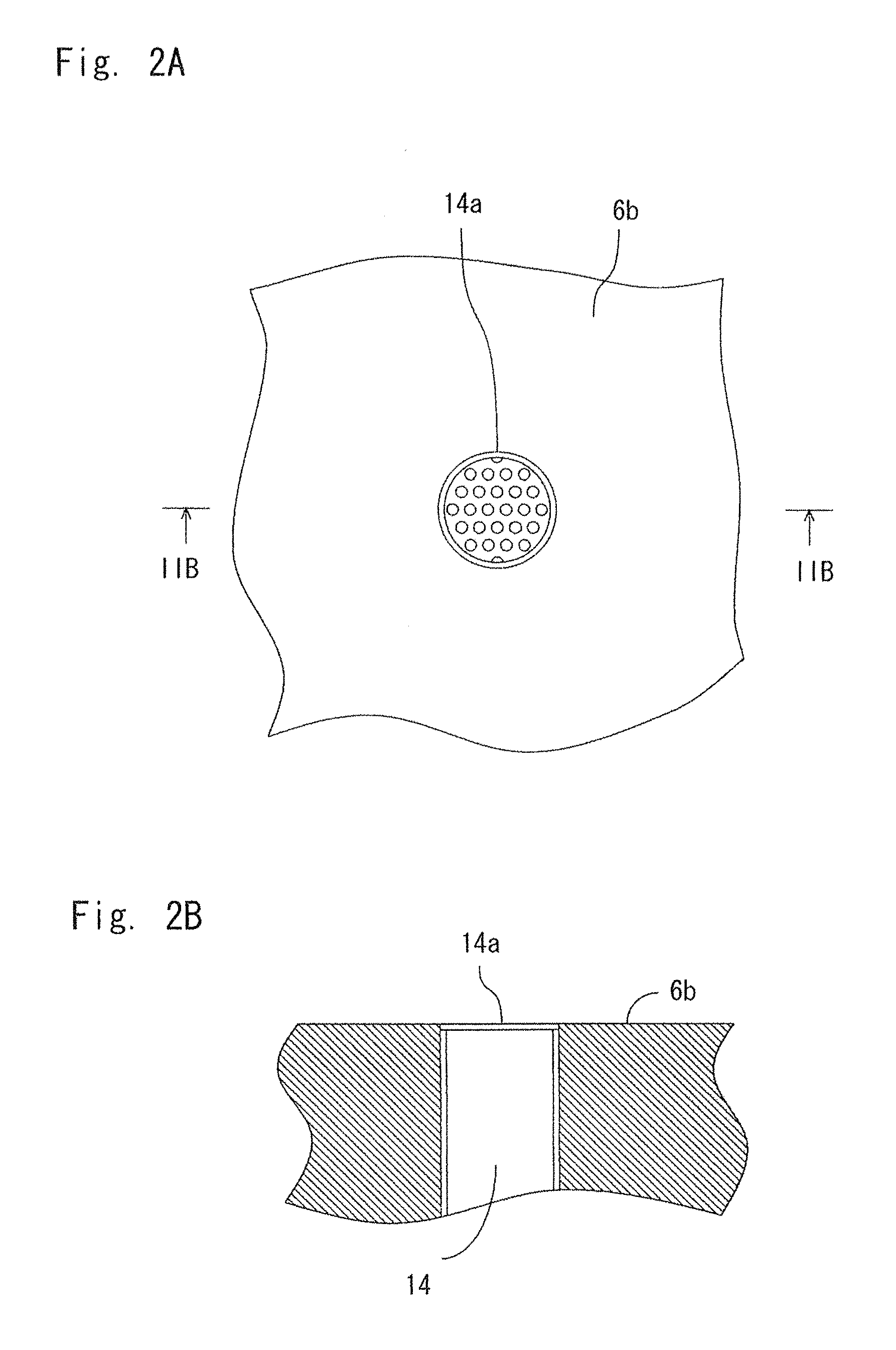

[0037]The apparatus main body 2 is an apparatus for performing an attachment operation. The apparatus main body 2 is formed in a cylindrical shape. This apparatus main body 2 includes a chamber (container) 6 having an airtight space 5 formed therein; a rubber sheet 10 which part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Speed | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com