Oxidation process

a technology of oxidation and process, applied in the field of wastewater processing, can solve the problems of increasing the contamination of wells with pathogens, affecting the quality of waste water, and not being suitable for general disposal back into the atmosphere,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

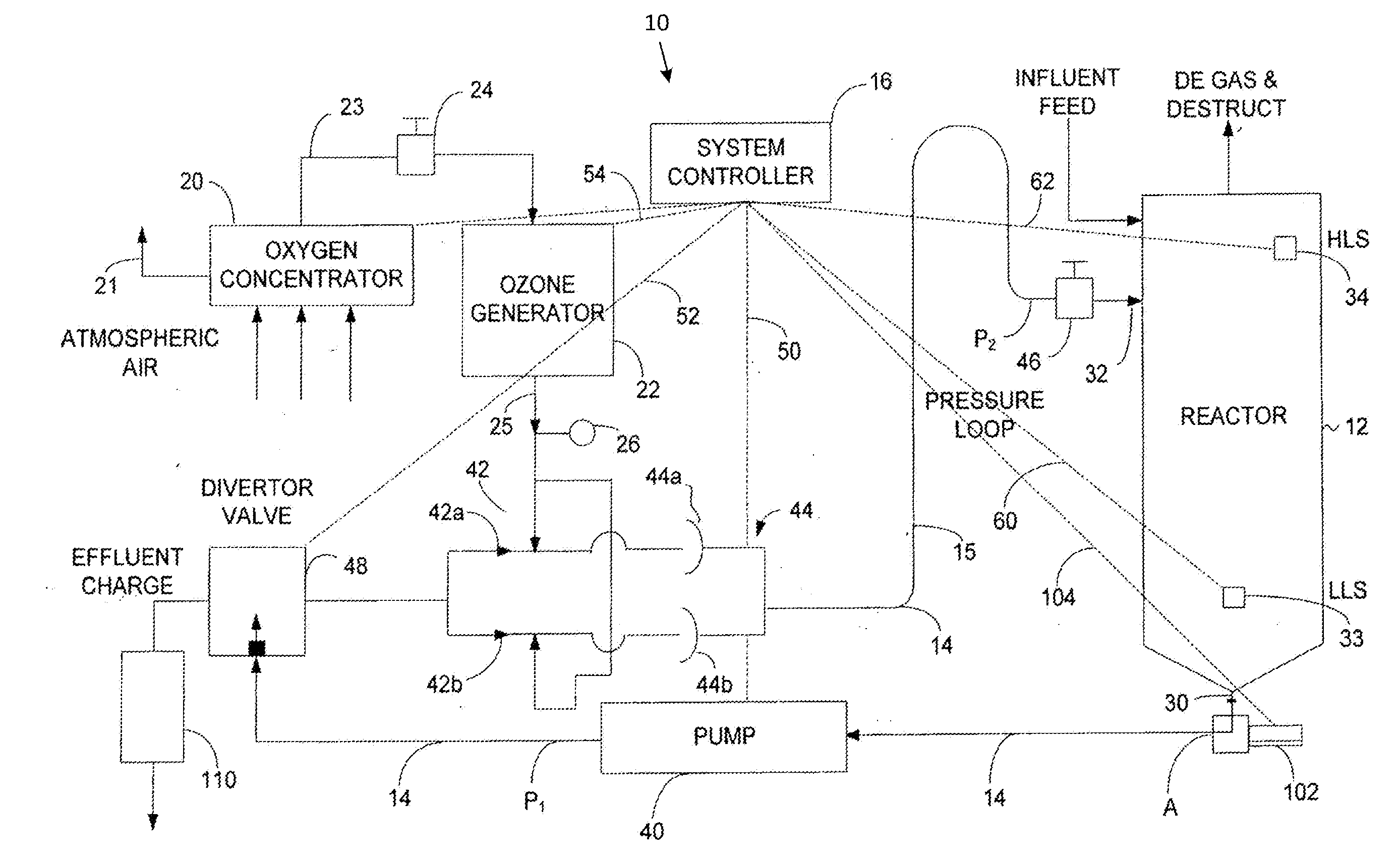

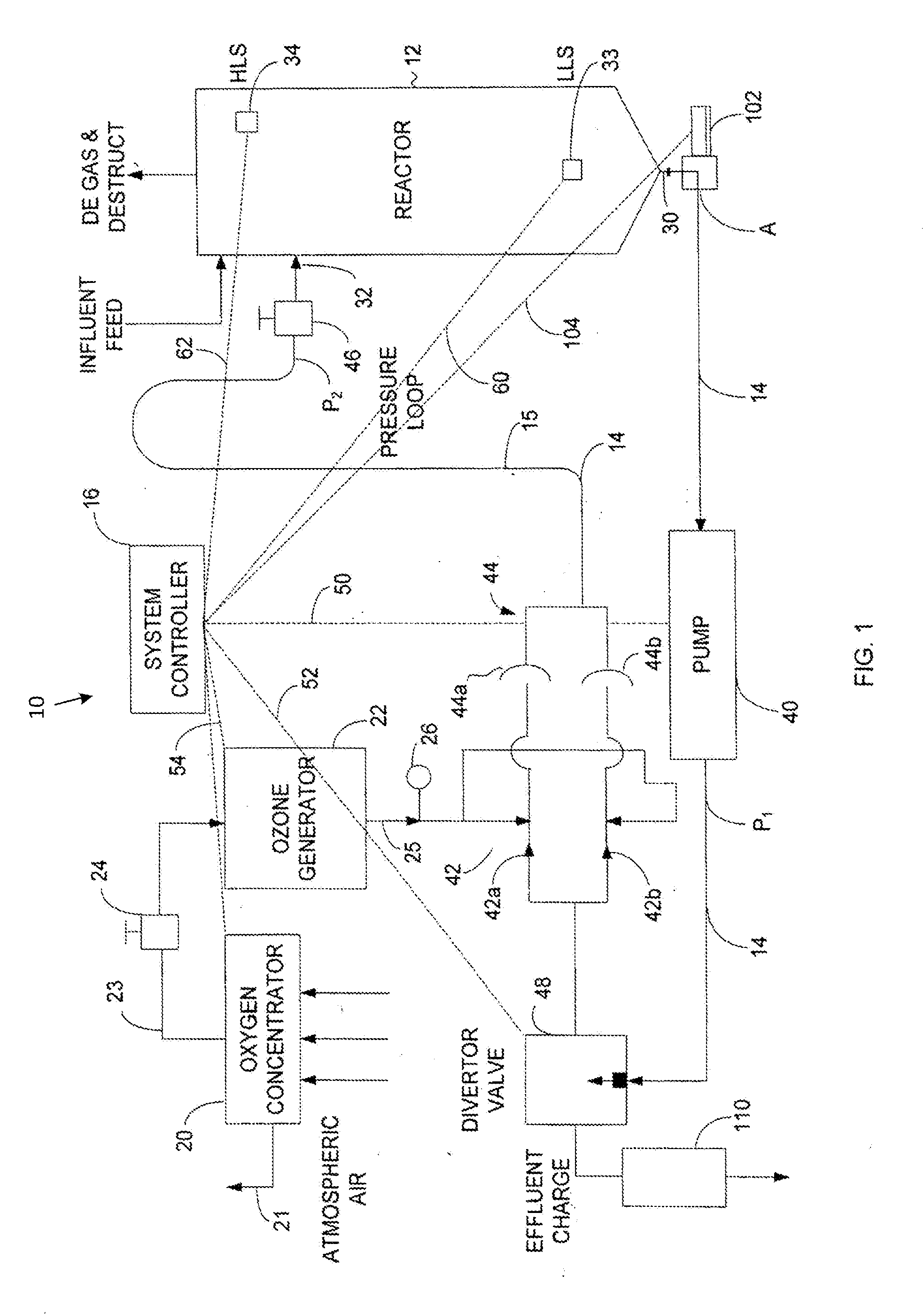

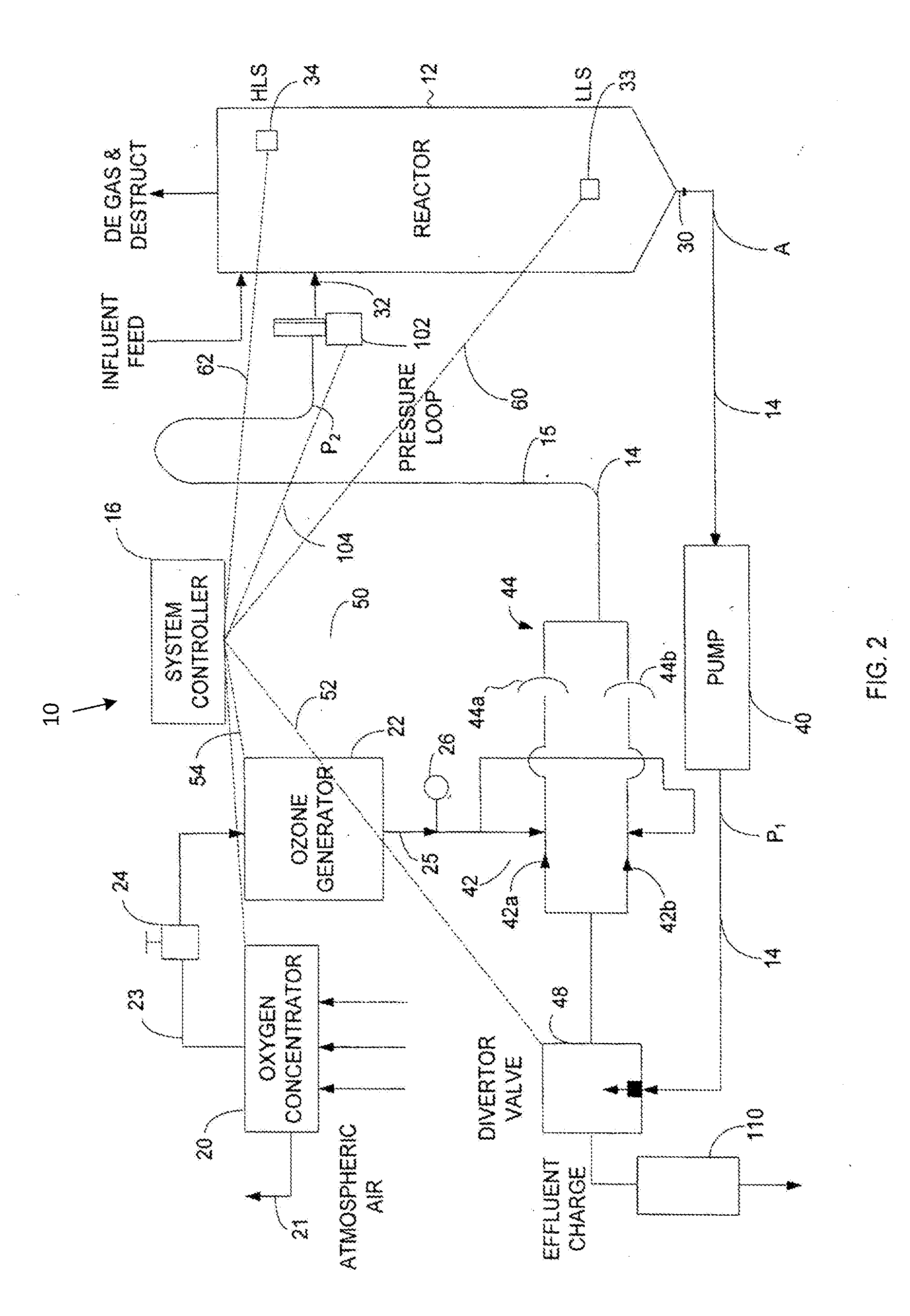

[0044]The description that follows, and the embodiments described therein, are provided by way of illustration of an example, or examples of particular embodiments of the principles of the present invention. These examples are provided for the purposes of explanation, and not of limitation, of those principles and of the invention. In the description, like parts are marked throughout the specification and the drawings with the same respective reference numerals. To the extent that the illustrations herein include piping symbols, those piping symbols are thought to be conventional in the art, and, unless otherwise indicated, are intended to have the meanings of those symbols as conventional in the art. The presence of an arrow on piping indicates the intended direction of flow, whether a check valve is shown or not. Check valves are shown as triangles within a circle, with the point of the triangle indicating the direction of flow. Positionable valves movable between open and closed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com