Inverted Dome to Supply Dose

a technology of inverted domes and doses, applied in the field of containers, can solve the problems of increasing the operational force of limited opening ports, affecting the use of end users, and affecting the safety of ingredients, so as to and prevent inadvertent activation and dispensing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

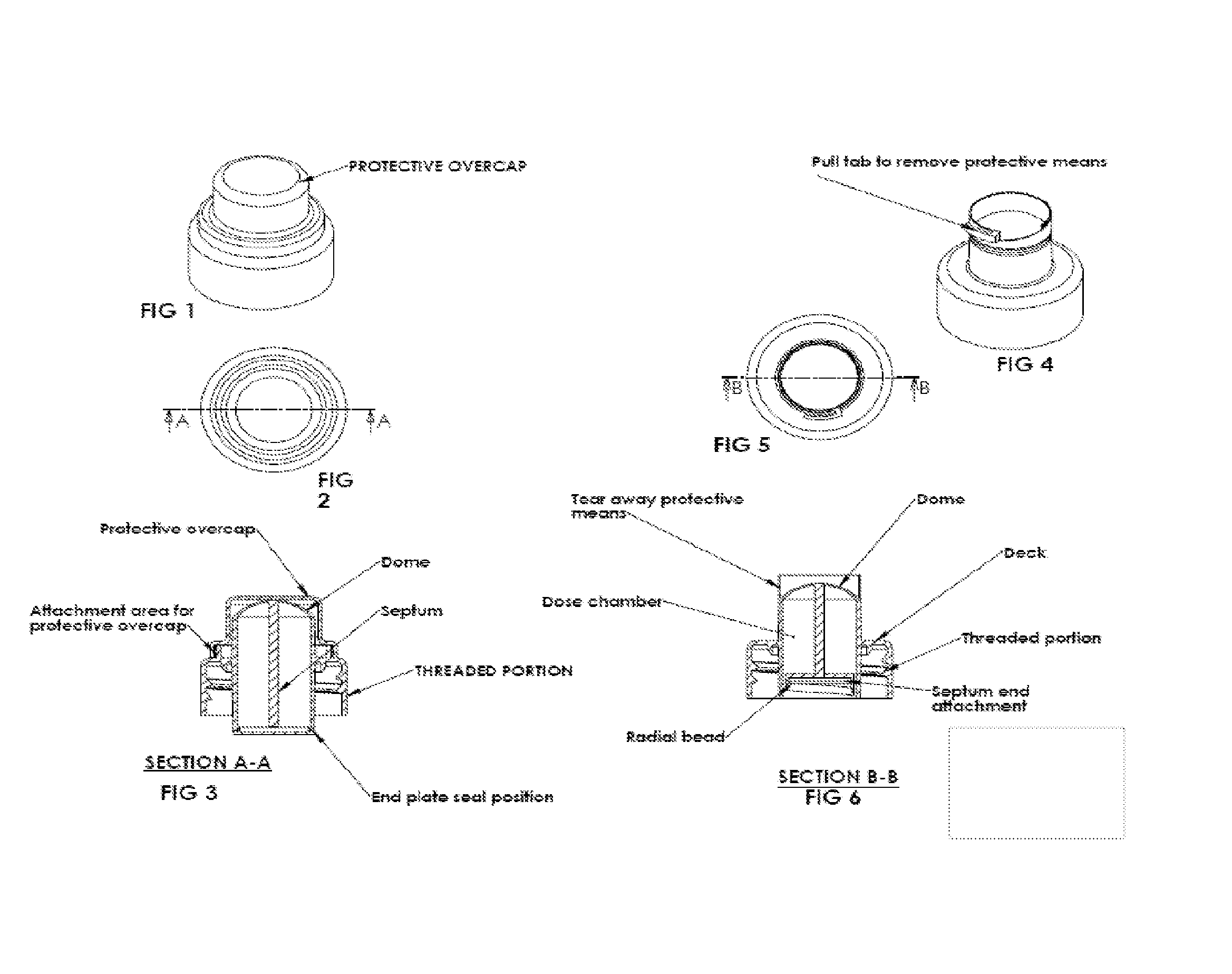

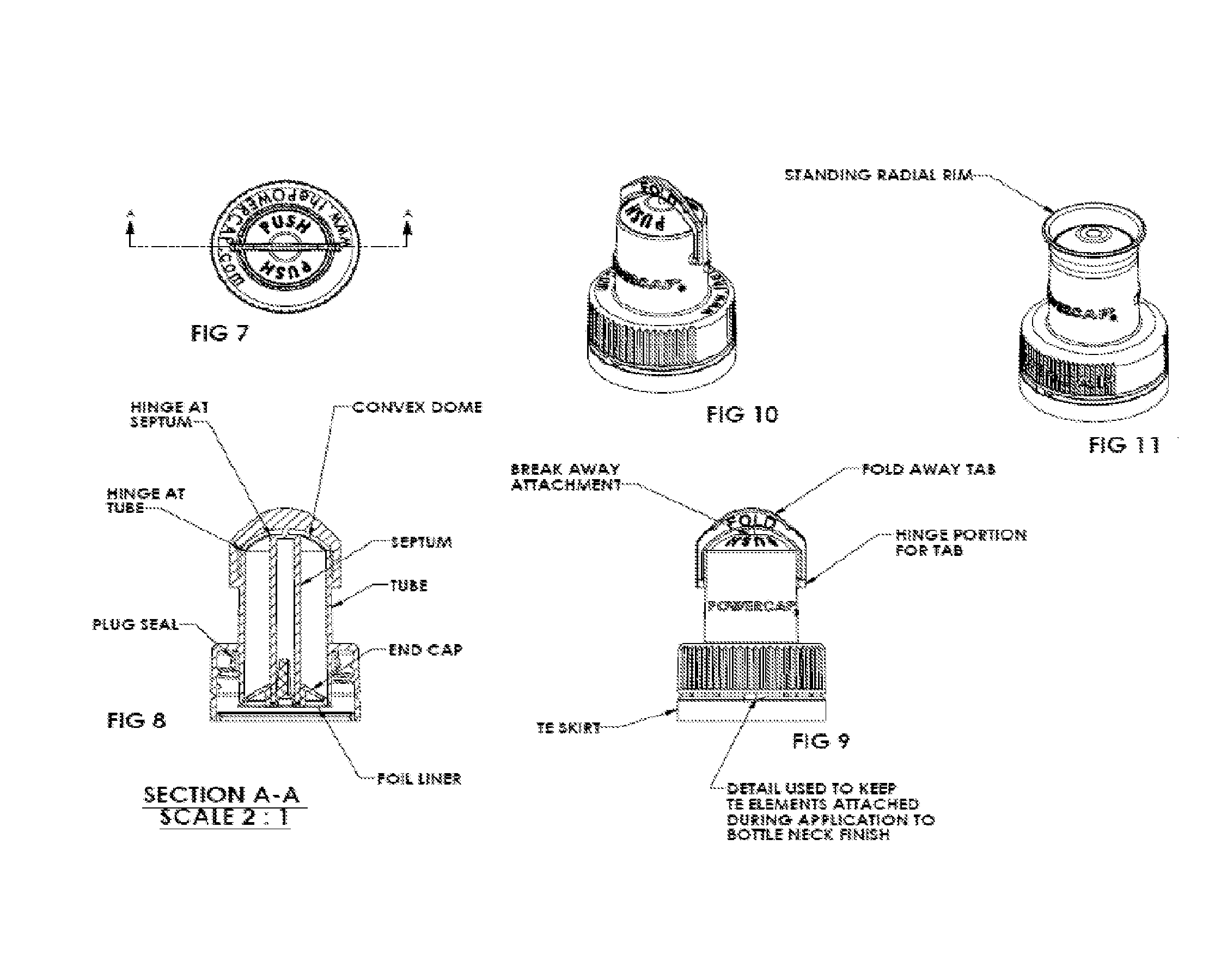

[0087]The POWERCAP® in one form comprises: a housing and a closure radial skirt; the housing comprising a dose chamber and a user-actuated means for dispensing one or more product and an end plate seal; the user-actuated means comprising a convex dome, septum and end cap; the convex dome further comprising a standing radial rim; the closure radial skirt further comprising a tamper evident skirt.

example 2

[0088]Many nutrients and vitamins that can be used to create functional beverages are sensitive to the conditions most often utilized to manufacture and store such products (i.e. heat, light, water). The POWERCAP® dosing closure is a beverage technology that can protect ingredients in an enclosed chamber with a friction fit seal that can be engaged to dispense stored materials into liquid to create a functional beverage at the time of use. This experiment investigated the ability of the POWERCAP® dosing closure to retain the chemical integrity of vitamin C (ascorbic acid) and caffeine as compared to subjecting those nutrients to the conditions typical of hot fill beverage manufacturing. A standard formulation, containing known quantities of both vitamin C and caffeine, was distributed among four experimental conditions: 1) within the POWERCAP® chamber and stored without attachment to a bottle; 2) within the POWERCAP® chamber and stored fully threaded onto a standard form threaded bo...

example 3

[0089]The dispensing closure of the present invention is useful for the creation of alternative form or variants of existing brand beverages. Such variants include by non-limiting examples convenience forms, travel forms, dehydrated forms requiring only the addition of water, variants with an extended shelf-life, sugar-free forms, and variants with attributes of freshness, efficacy, potency, stability and consistency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com