Consumer oriented system for delivery of product including single-serving package for preservative-free fruit pieces

a technology of preservative-free fruit and a delivery system, applied in the direction of transportation and packaging, synthetic resin layered products, containers preventing decay, etc., can solve the problems of insufficient availability of knives or special equipment, inability to meet the dietary guidelines of most people in the u.s. and other developed nations, and the processing of most fruits is considerable. , to achieve the effect of reducing contamination and spoilage, enhancing convenience of use and consumption, and reducing the risk of accidental

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

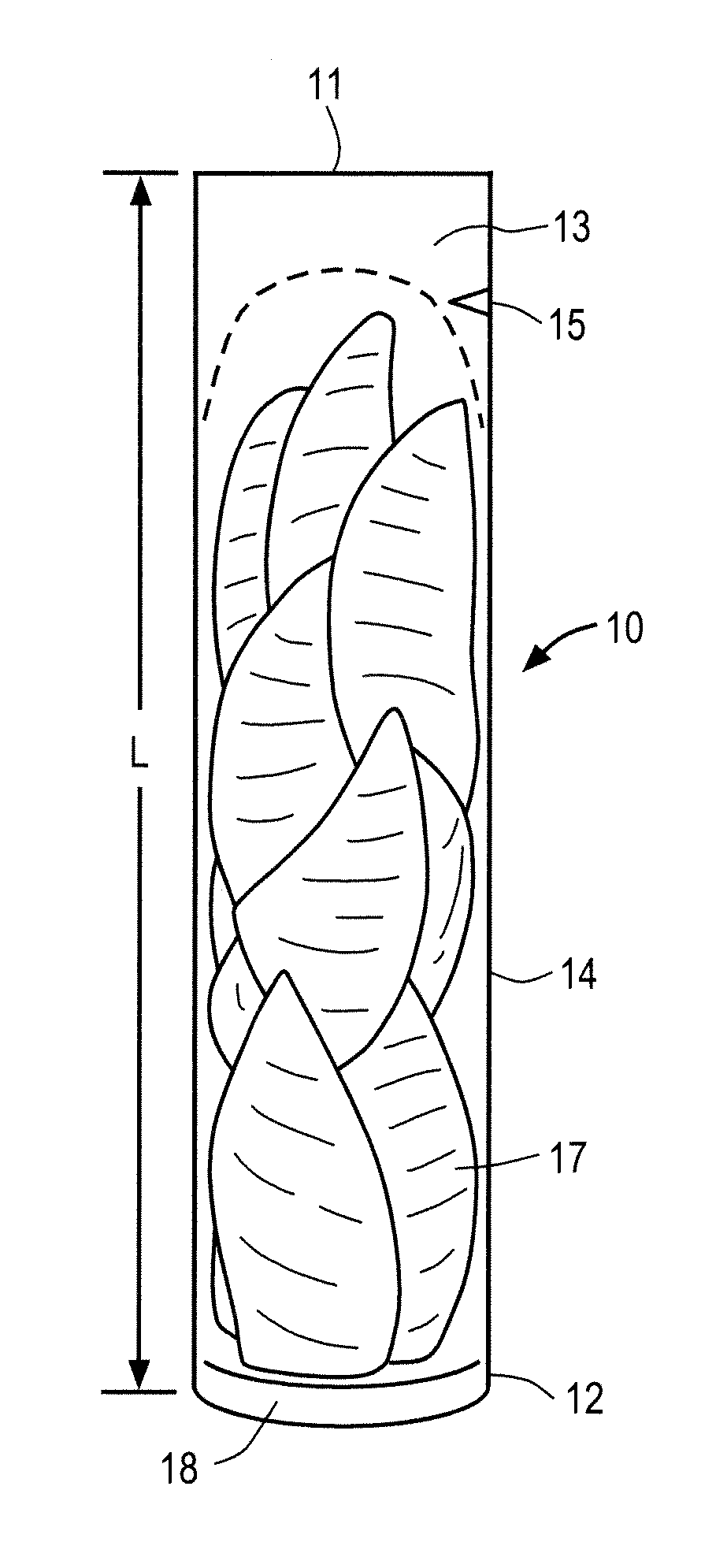

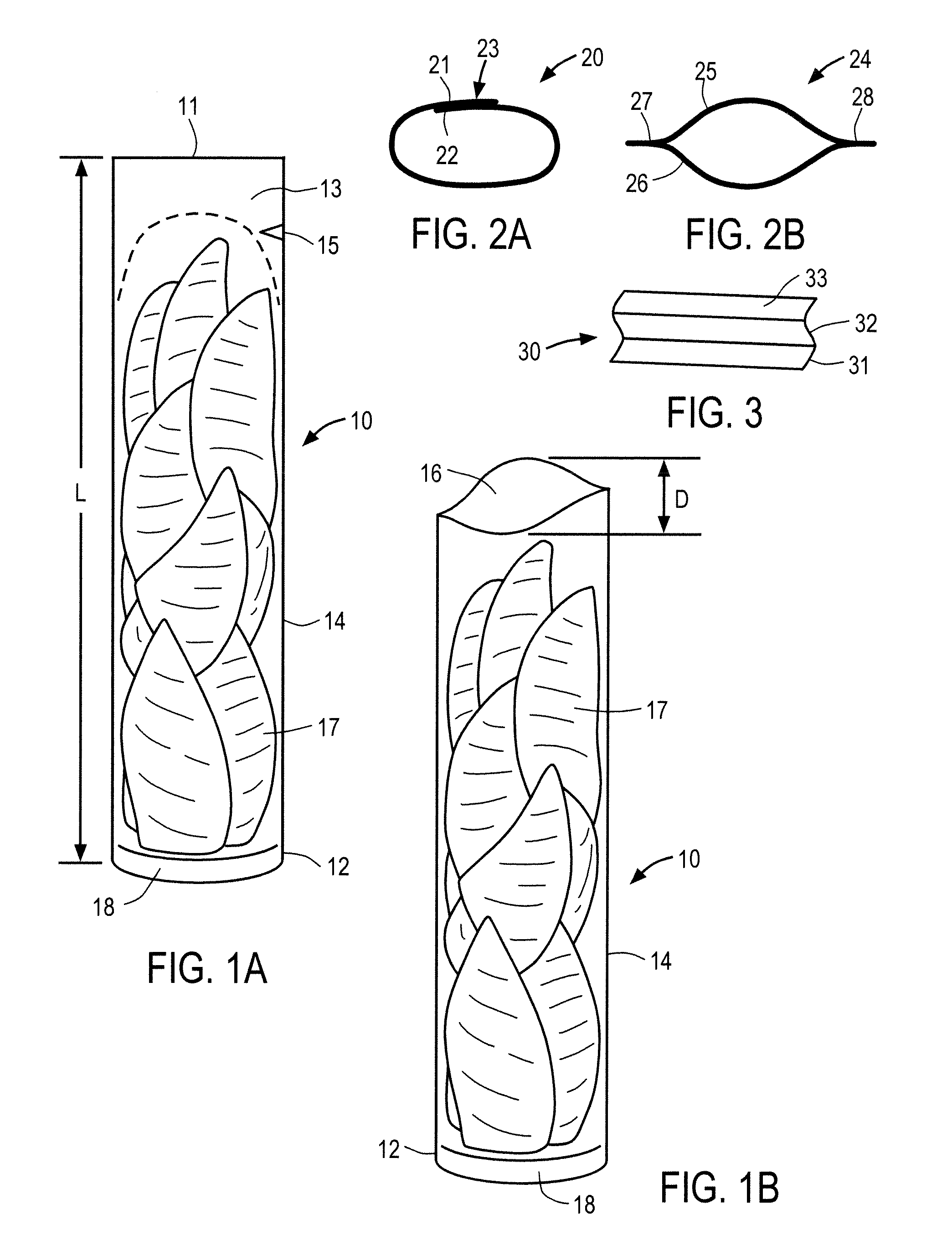

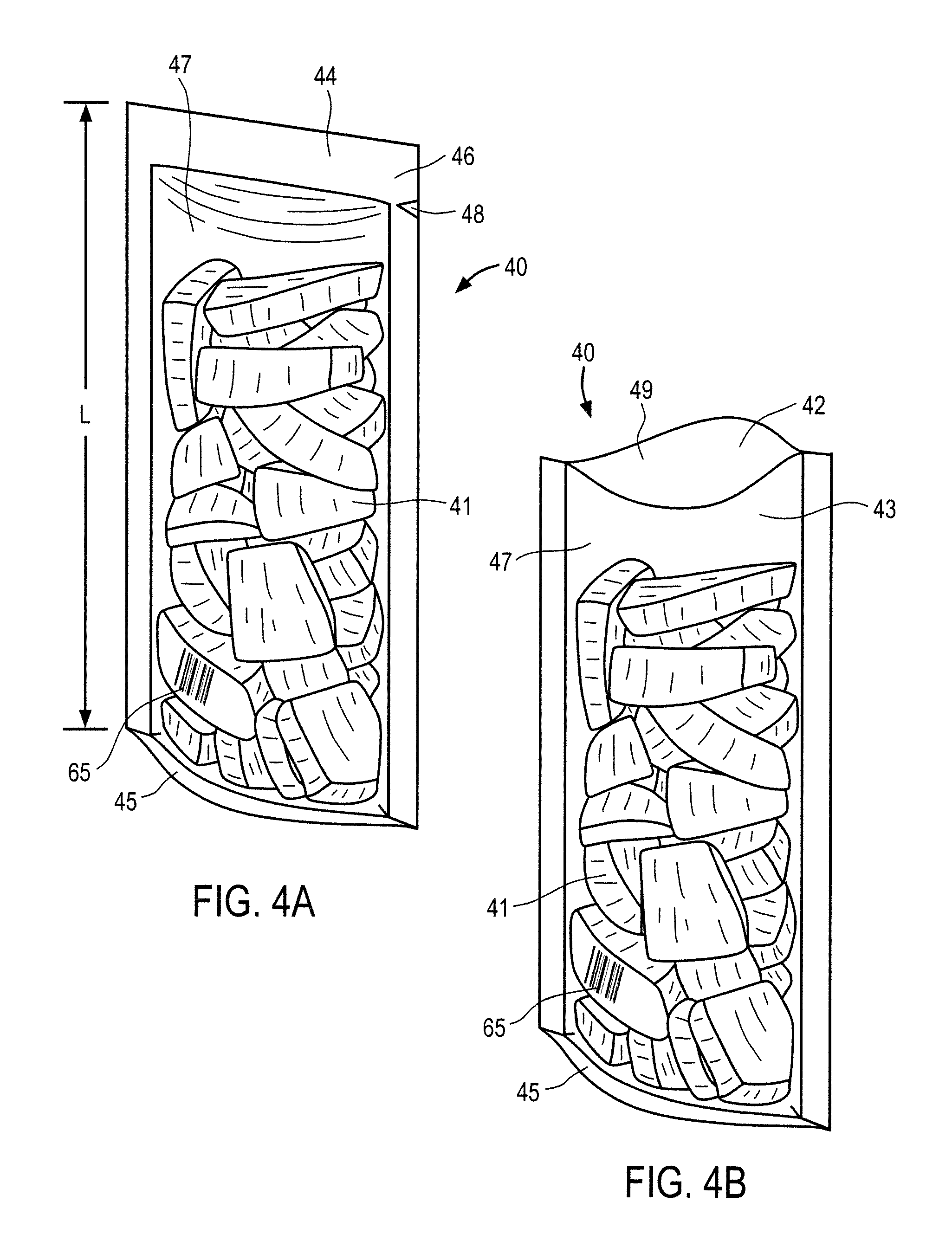

[0025]According to one embodiment of the present invention, a unique consumer-oriented system for the delivery of produce, especially fruit pieces, including improved methods of safety and packaging is provided for the purpose of reducing or eliminating pathogens, increasing shelf life, and for reducing spoilage.

[0026]In certain embodiments, the term “produce” shall hereinafter refer to all fruit, vegetables, or other foods, which may be adaptable for use with the various embodiments described herein.

[0027]In certain embodiments, the term “produce” shall refer to fruit.

[0028]In certain embodiments, the term “produce” shall refer to vegetables.

[0029]Even though embodiments described below in the specification are primarily directed towards fruits, produce other than fruits may be included.

[0030]For the purpose of the present invention, the term “fruit” shall hereinafter refer to all fruit, which are adaptable for use with the processes described herein. Given the rigorous nature of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| weight | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com