Microchannel heat exchanger fin

a technology of heat exchanger and microchannel, which is applied in the field of microchannel heat exchanger fin and tube configuration, can solve the problems of retaining large quantities of moisture, water or condensate within the fin and tube structure, and reducing the thermo-hydraulic performance or effectiveness of the heat exchanger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

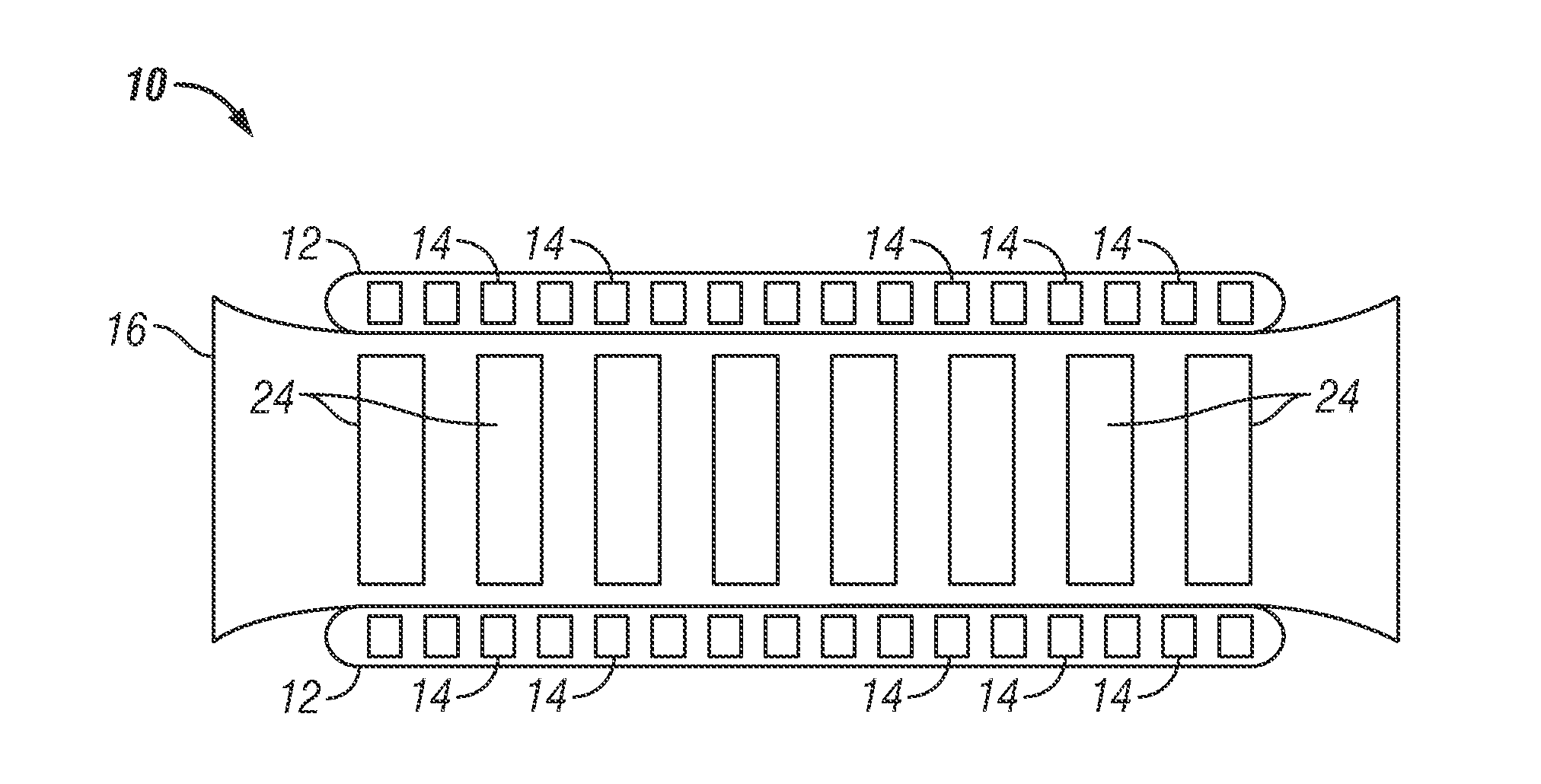

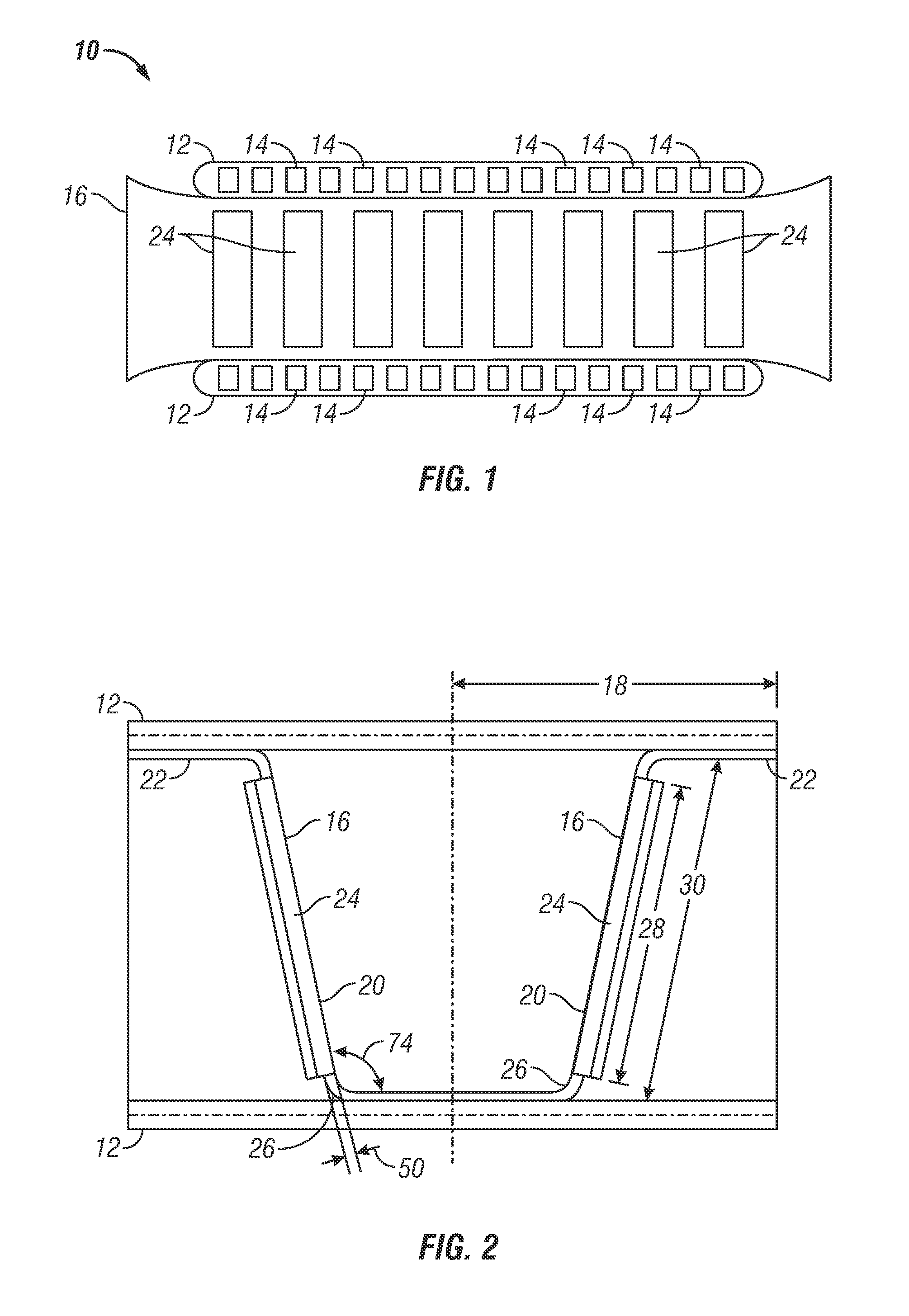

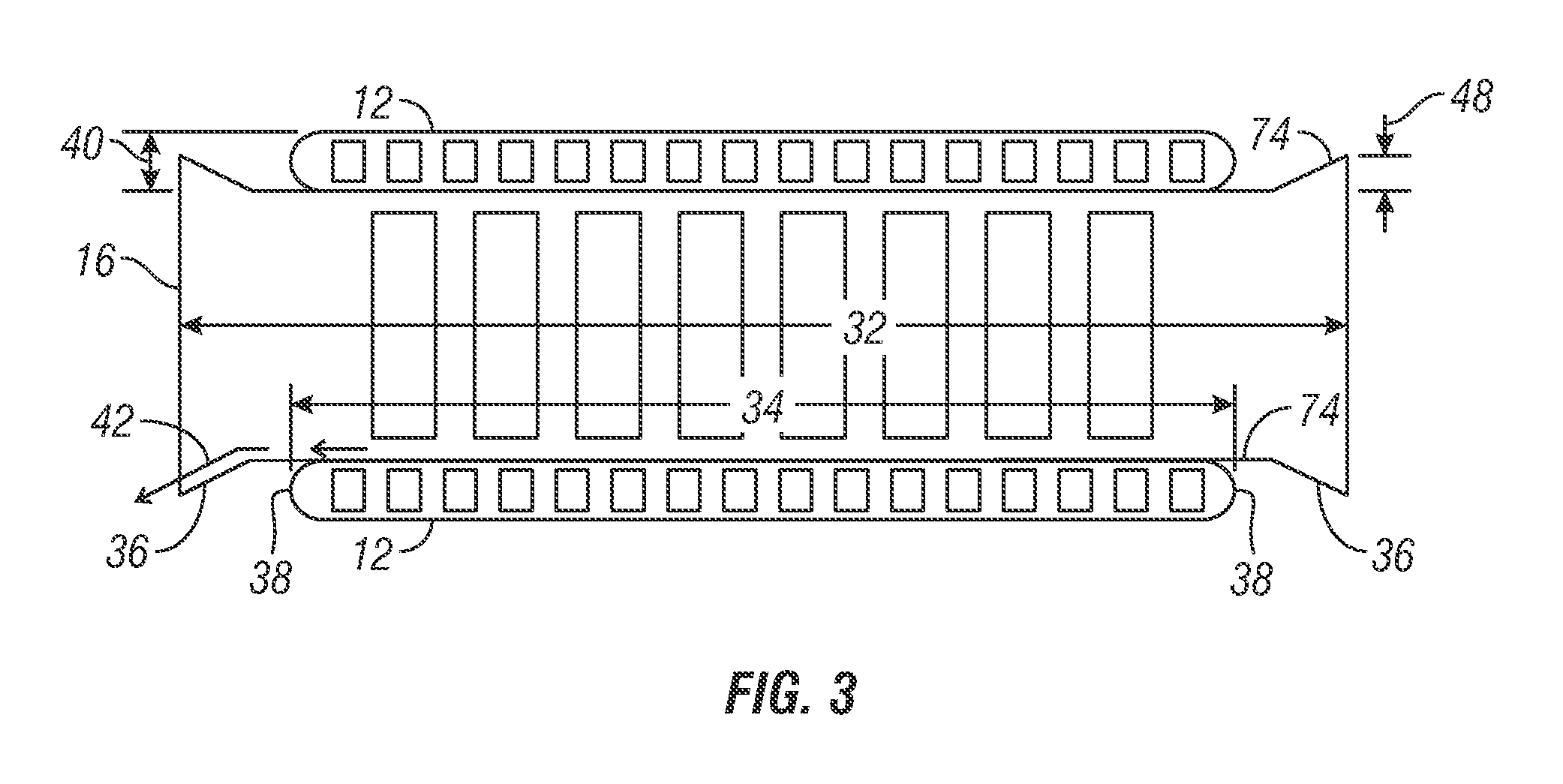

[0016]Shown in FIG. 1 is an embodiment of a tube and fin arrangement of a heat exchanger 10. The heat exchanger 10 includes a plurality of tubes 12. Each tube 12 in the embodiment shown includes multiple channels 14 through which cooling fluid is circulated. In the embodiment of FIG. 1, each tube includes sixteen channels 14, but it is to be appreciated that any number of channels 14 may be utilized. A plurality of fins 16 extend between the tubes 12 to aid in increasing heat transfer between the tubes 12 and the surrounding air. In some embodiments, the fins 16 are secured to the tubes 12 by, for example, brazing, or other suitable means such as for instance soldering or gluing, and in some embodiments, the fins 16 may have a fin thickness (FTH) of between about 50 and about 100 microns. It is to be appreciated that the fin thickness is merely exemplary, and other fin thicknesses outside of the described range may be utilized within the scope of the present disclosure. The heat exc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com