Plow Blade Assembly

a technology of plow blades and assembly parts, which is applied in the direction of snow cleaning, way cleaning, construction, etc., can solve the problems of affecting the operation of equipment, affecting the service life of equipment, so as to improve the cleaning and/or removal action, improve the conformance to the substrate, and improve the effect of movability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

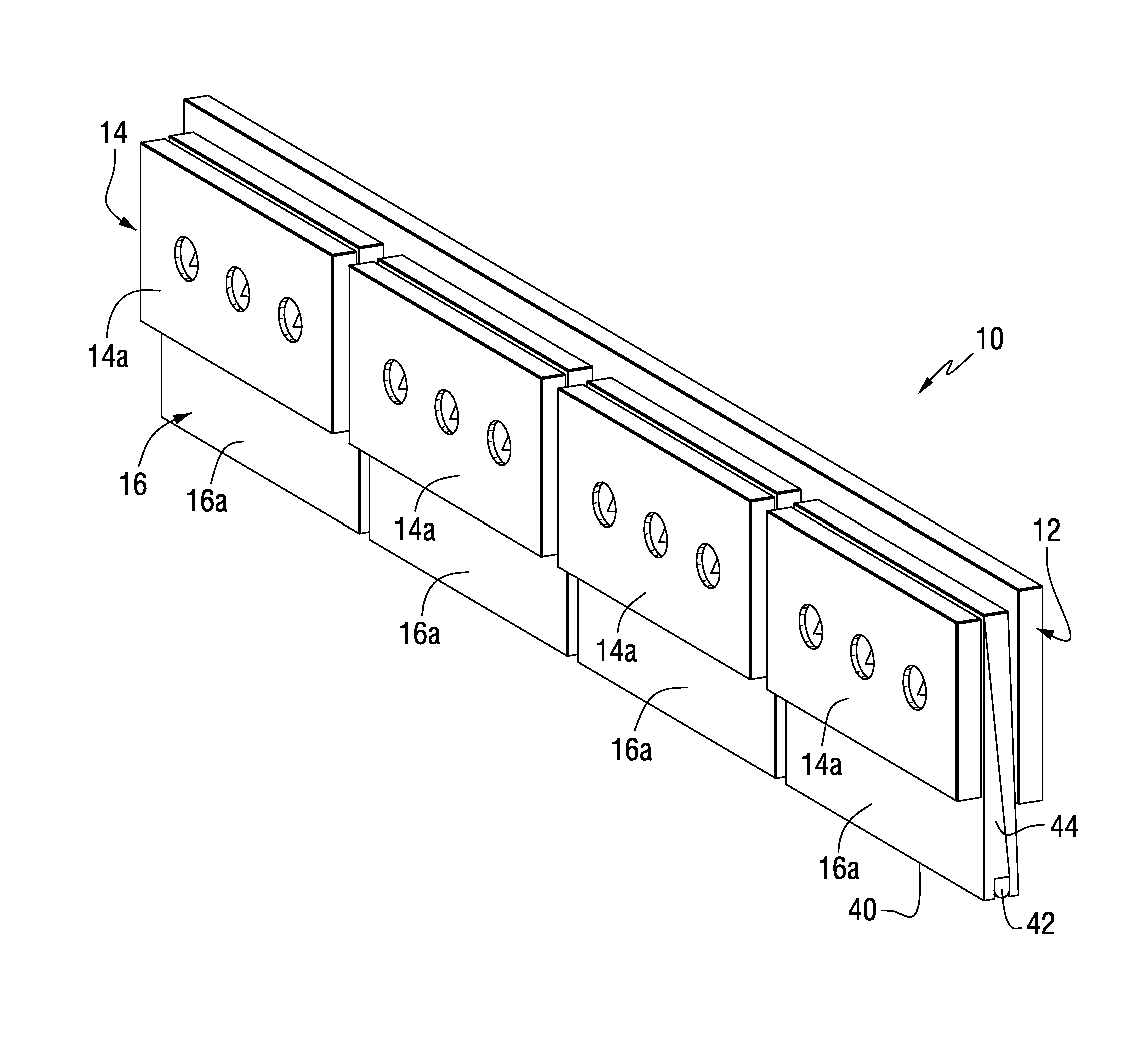

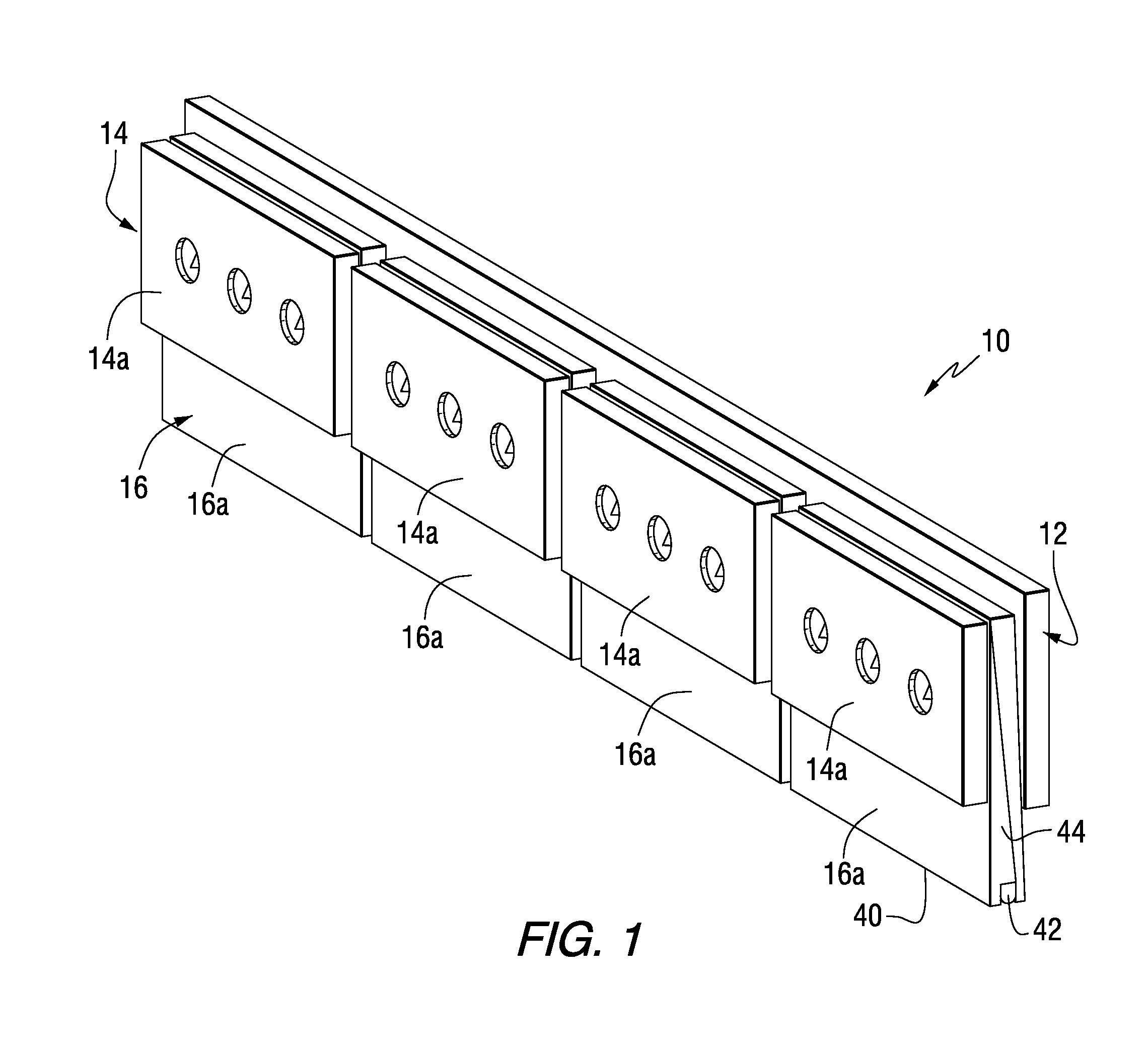

[0018]Referring to FIGS. 1 and 2, there is illustrated a plow blade assembly 10 in accordance with an aspect of the invention. The plow blade assembly 10 may be mounted on or used in association with a vehicle (not shown) for plowing or grading a surface, such as, for example, a road surface or earth strata.

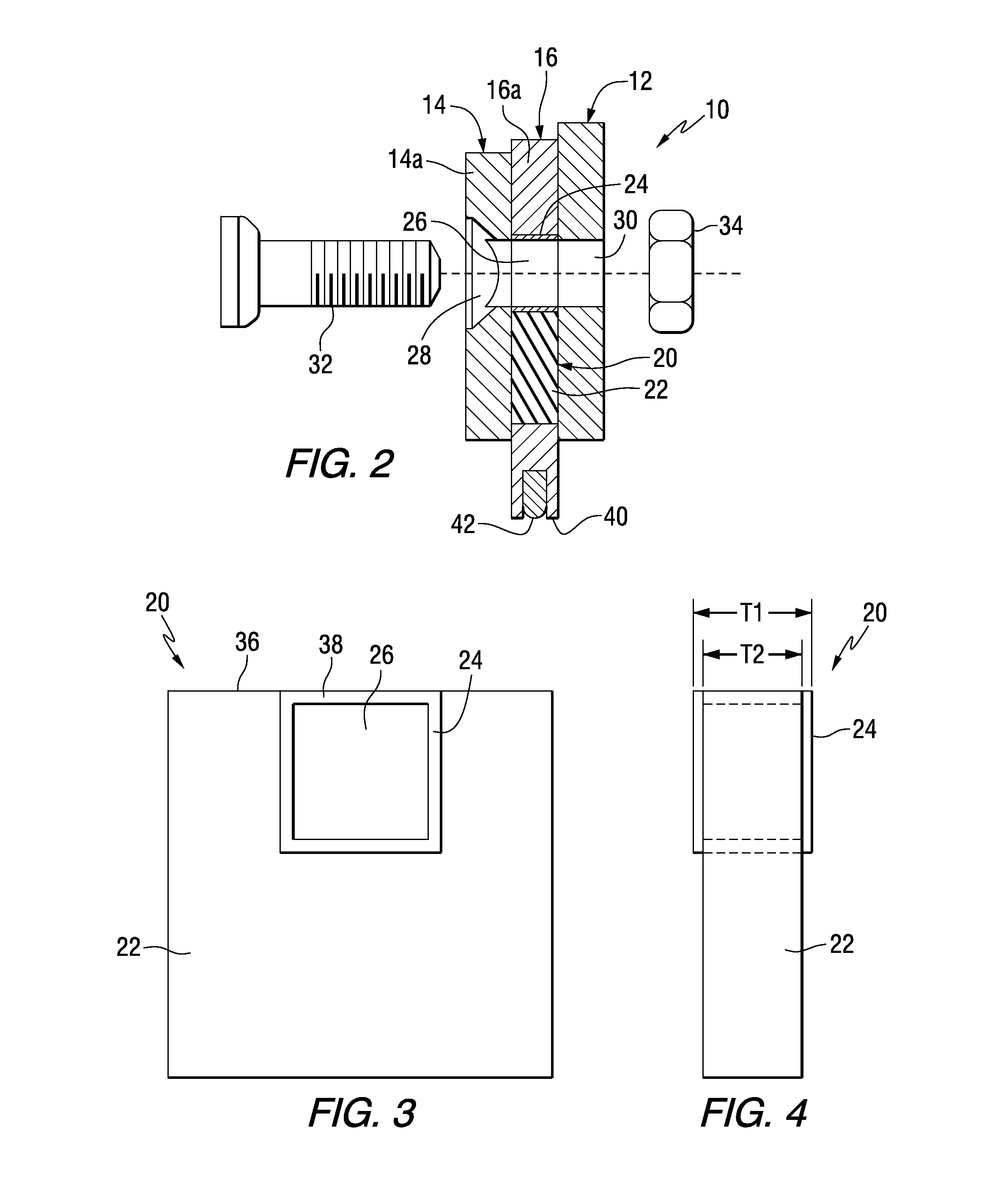

[0019]Still referring to FIGS. 1 and 2, the plow blade assembly 10 includes a moldboard adapter plate 12, a cover plate 14, and a flexible or articulating blade 16 mounted between the moldboard adapter plate 12 and the cover plate 14. As best illustrated in FIG. 1, the moldboard adapter plate 12 may be a continuous member. The cover plate 14 may include multiple cover plate members 14a corresponding to multiple articulating blade segments 16a of the articulating blade 16. Thus, it will be appreciated that the components of the plow blade assembly 10, i.e., the moldboard adapter plate 12, the cover plate 14, and the articulating blade 16, may be provided in various configurations ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com