Design of Integrated Heat Exchanger into Solar Absorber for Affordable Small-scale Concentrated Solar Power Generation (SCU)

a solar absorber and heat exchanger technology, applied in the field of solar energy devices, can solve the problems of large area to achieve sufficient conversion efficiency for the cost of the system, limited conversion efficiency, and inability to meet the economic needs of small-scale concentrated solar power generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

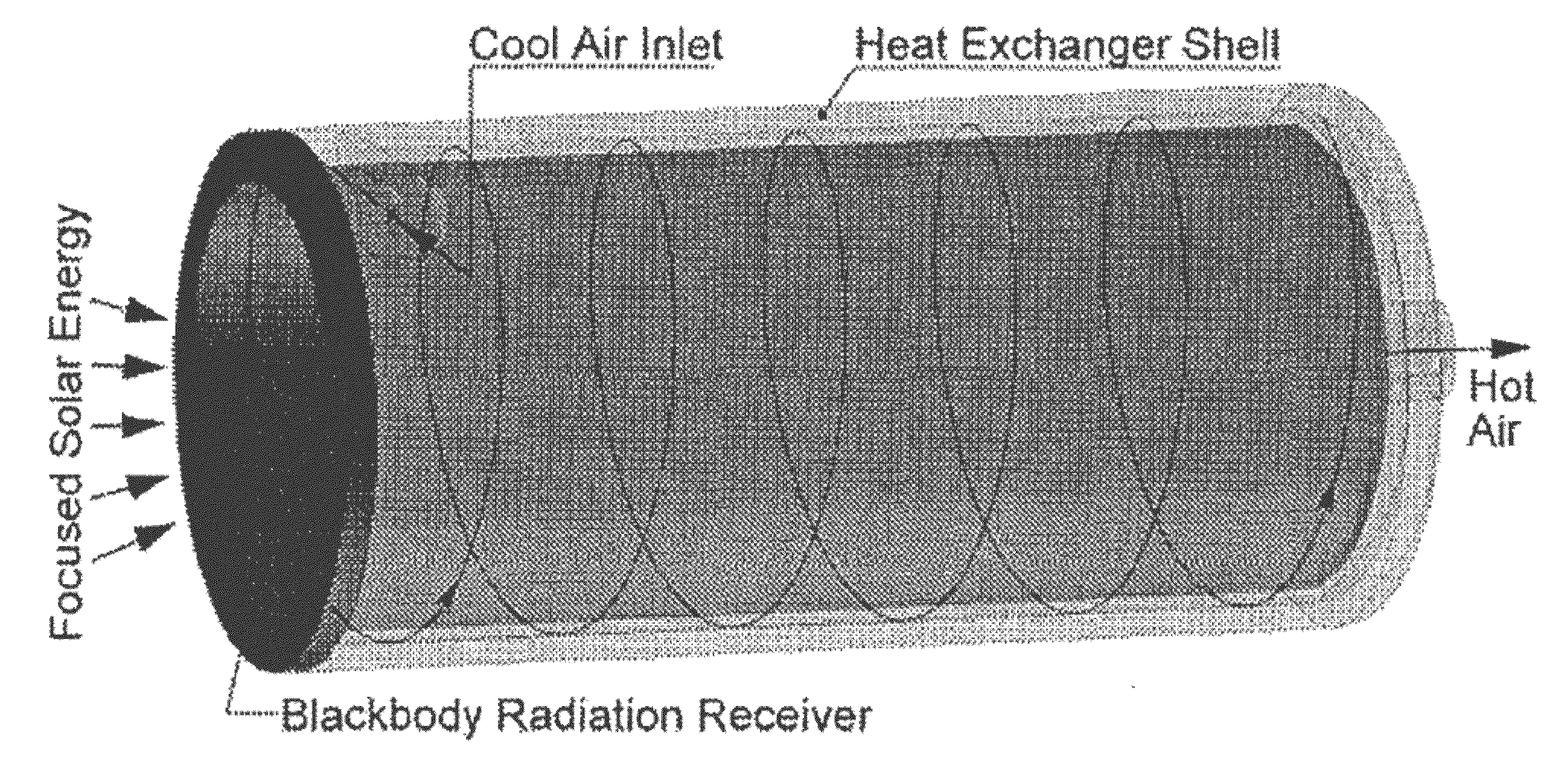

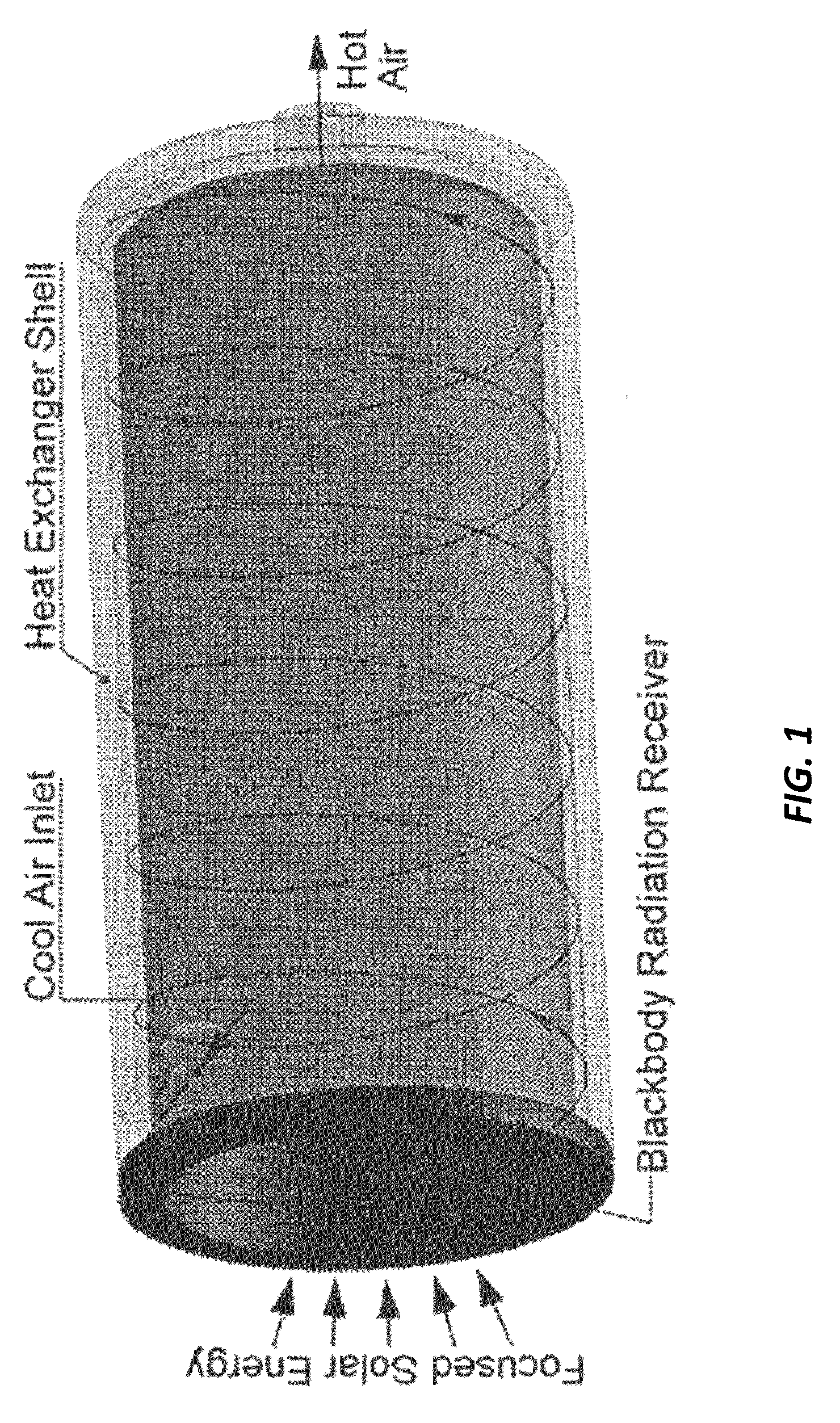

[0011]In one aspect, a scalable and modular concentrated solar thermal dish-Brayton system is provided in response to growing demand for renewable energy and distributed power generation. One embodiment of the current invention reduces production costs and creates a viable small-scale solar power system for home or neighborhood use by achieving better conversion efficiency.

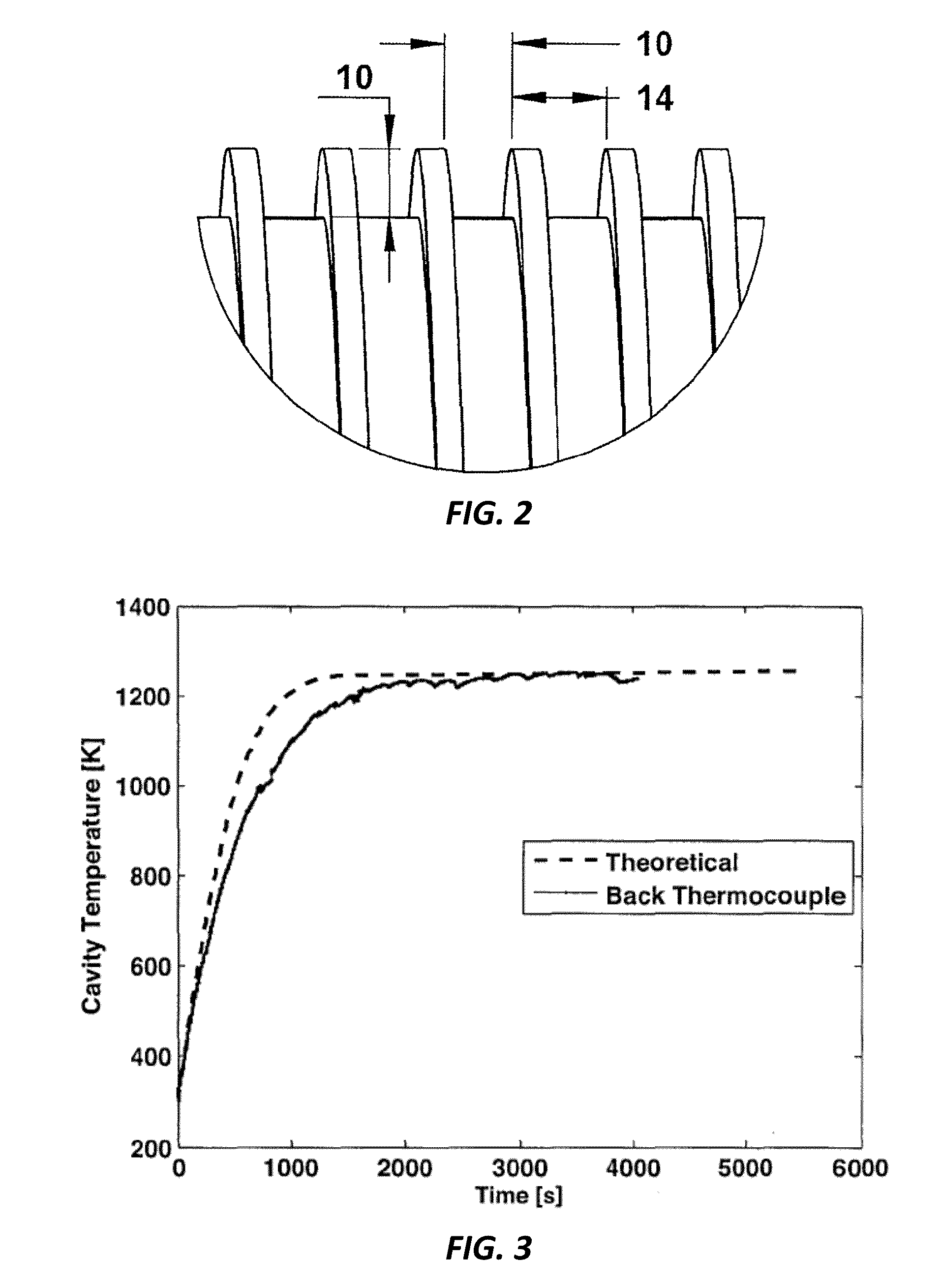

[0012]One embodiment of the invention includes a low cost, high efficiency solar receiver with the capability to achieve much higher operating temperatures than current receivers. The current embodiment of the invention uses a cylindrical shaped blackbody cavity to absorb solar radiation at a temperature of about 1700 K, much higher than existing receivers at 1250 K. This is made possible by using silicon carbide to manufacture the cavity. The fabricated cylindrical part boasts high absorption and thermal conductivity at a low fabrication cost. The advantage of the high absorption allows for the cylindrical design...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com