Solar Absorber for Concentrated Solar Power Generation

a solar energy and absorber technology, applied in the field of solar energy devices, can solve the problems of inefficiency and expense, add complexity, and cost to the design, and the conversion efficiency achieved with such systems is limited by the materials and manufacturing processes used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015]In one embodiment, a scalable, modular, low cost, high efficiency solar absorber is provided for a concentrated solar power system such as a thermal dish-Brayton system or heliostat field system. It has reduced production costs and creates a viable small-scale solar power system for home or neighborhood use by achieving better conversion efficiency through its capability to achieve much higher operating temperatures than current receivers.

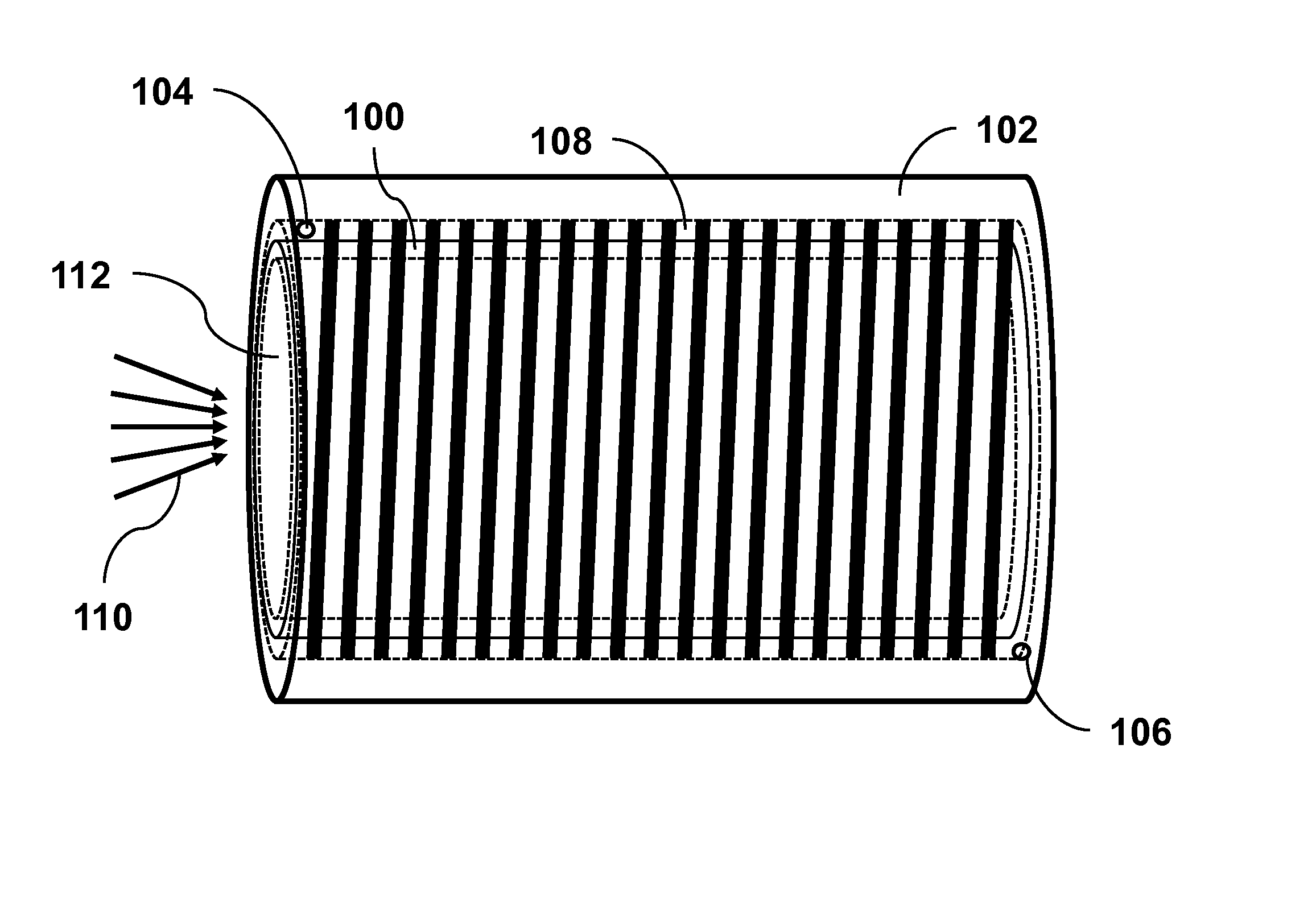

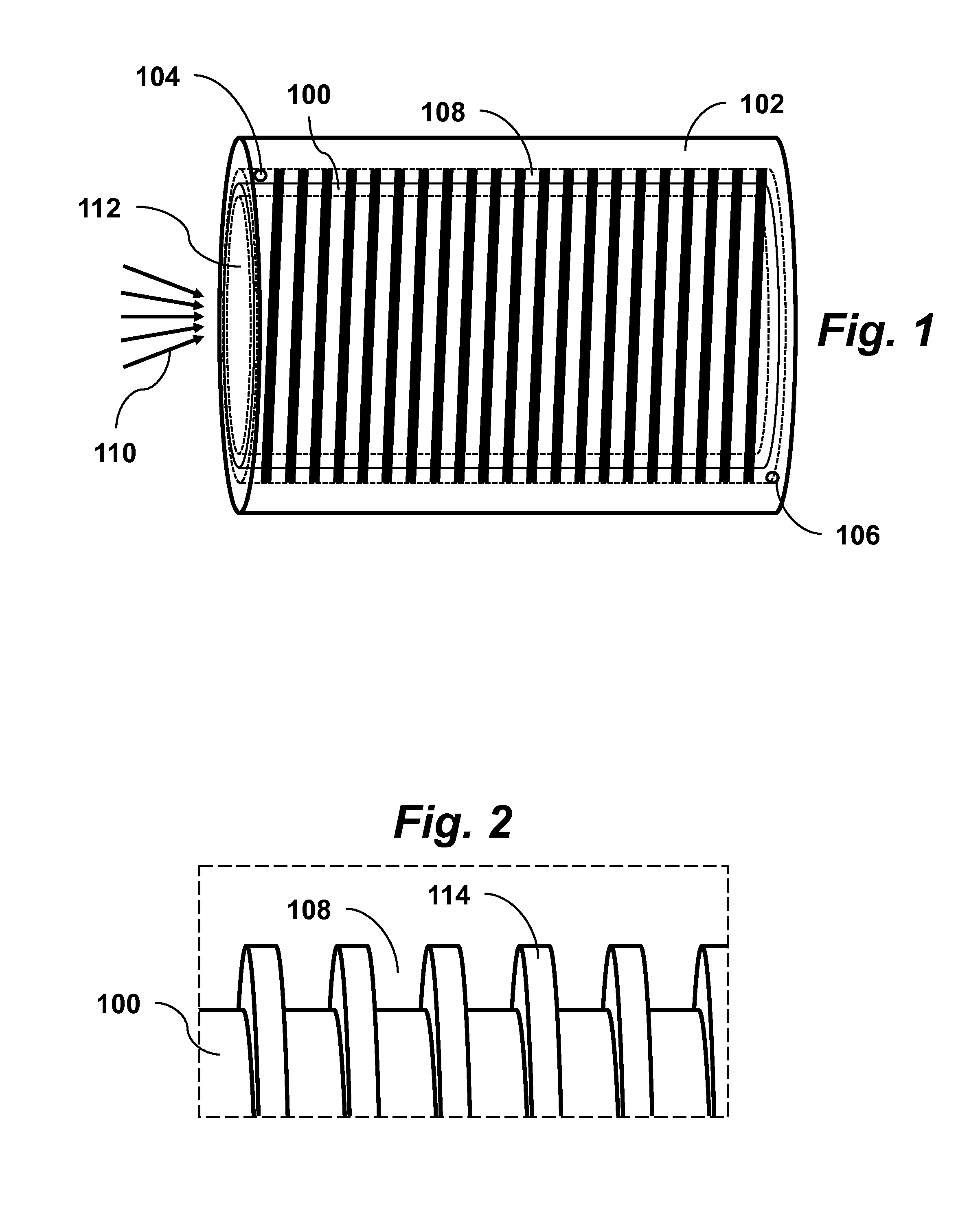

[0016]FIG. 1 shows a schematic drawing of a solar absorber according to an embodiment of the invention. The absorber includes a blackbody radiation receiver 100 and heat exchanger shell 102. An air passage entrance 104 through the shell serves as a cool air inlet and air passage exit 106 serves as hot air outlet. Also shown is the helical air passage duct 108 around the solar cavity receiver 100. This embodiment of the invention uses a cylindrical shaped blackbody cavity 112 of the receiver 100 to absorb incident solar radiation 110 at a temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com