Sapphire temperature sensor and manufacturing method thereof and temperature measuring system

A production method, sapphire technology, applied in thermometers, measuring devices, measuring heat, etc., to achieve the effect of strong anti-electromagnetic interference, high precision, and controllable spraying parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

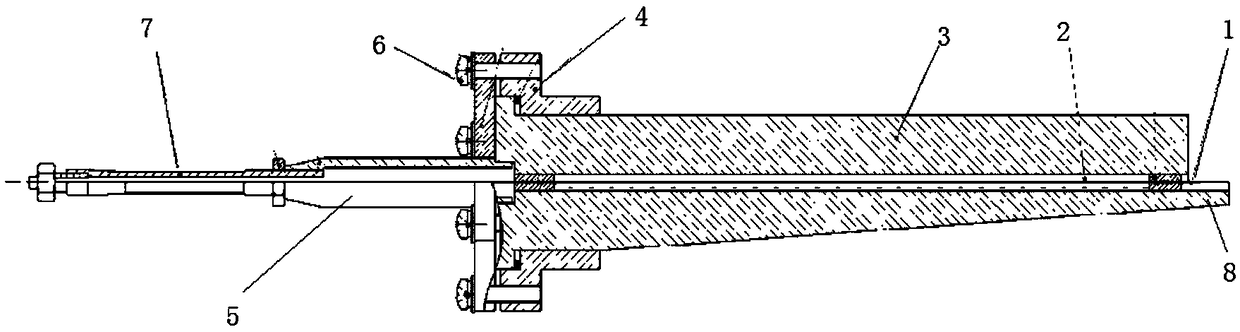

[0076] figure 1 A schematic structural diagram of a sapphire fiber optic temperature sensor according to an embodiment of the present invention is shown.

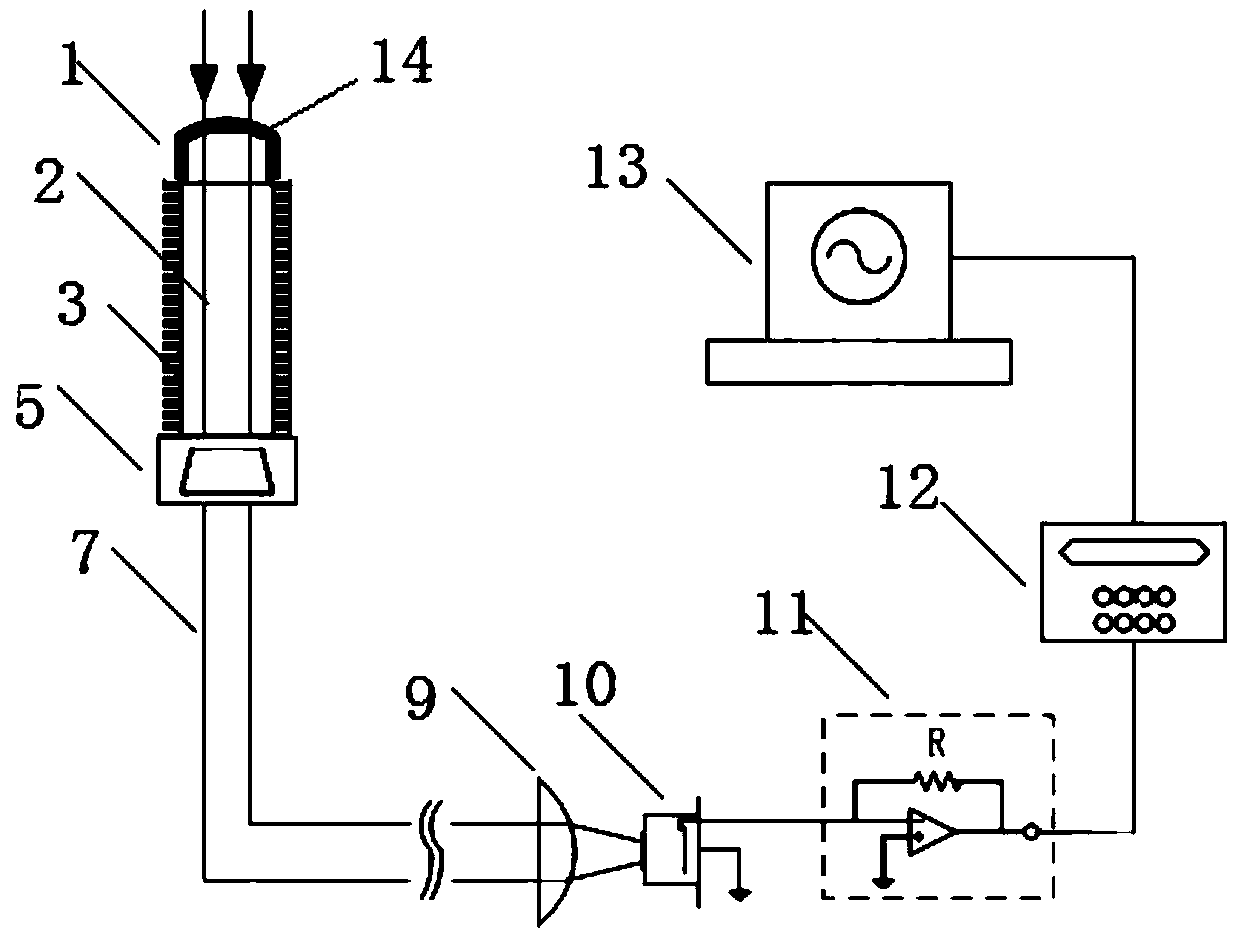

[0077] Such as figure 1 Shown, a kind of sapphire optical fiber temperature sensor of the present invention comprises thermal protection device, sapphire optical fiber probe, optical fiber coupler 5; One end of sapphire optical fiber 2 probe is sensing head 1, and the other end is connected with optical fiber coupler 5; The heat protection device surrounds the outside of the sapphire fiber 2; the sensor head 1 is placed at one end of the heat protection device, and the other end of the protection device is connected to the fiber coupler 5; the sensor head 1 is covered by a black body cavity 14 on one end of the sapphire fiber 2 The black body cavity 14 is formed by various temperature-sensitive material particles heated to a molten state by a plasma arc and uniformly sprayed on the outer surface of one end of the sapphire ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com