High-precision blackbody cavity and manufacturing method thereof

A blackbody cavity and high-precision technology, which is applied in the field of optical radiation measurement, can solve the problems that the degree of extinction is difficult to achieve the ideal effect, reduce the number of times the cavity coating absorbs light, etc., so as to avoid the decline of emissivity and ensure uniformity and consistency , Improve the effect of absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

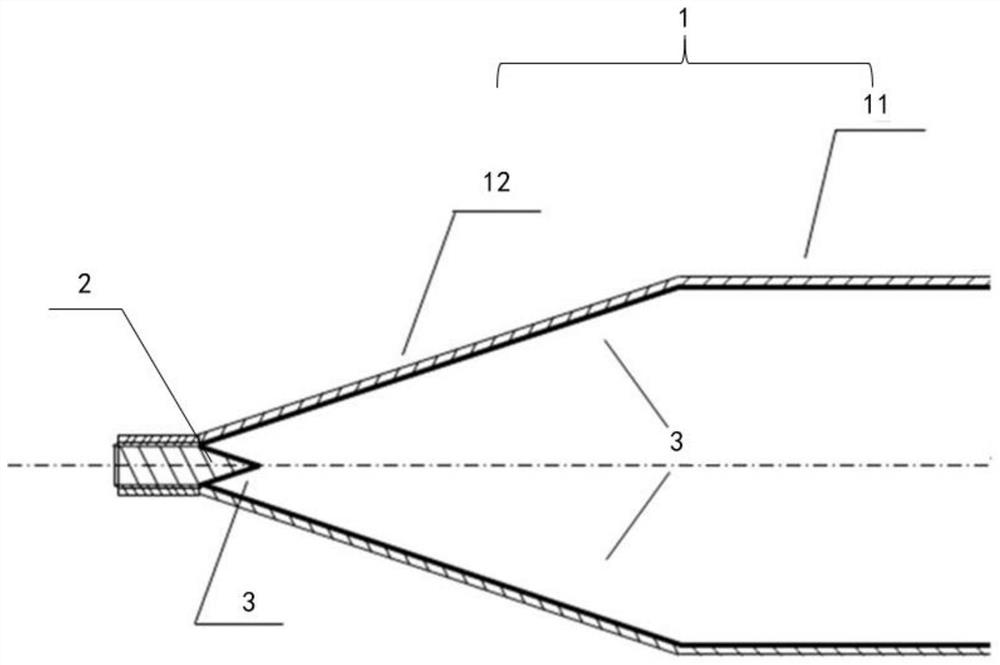

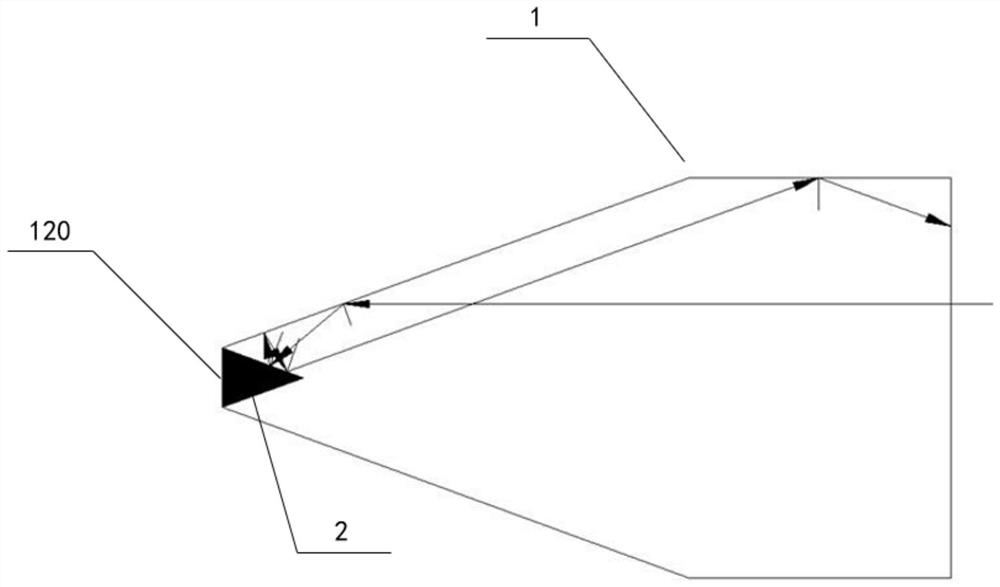

[0036] Such as Figure 2-3 As shown, the application of the present invention provides a high-precision black body cavity, including a first cavity 1 and a second cone 2, the first cavity 1 is an open cavity structure, mainly including a cylindrical section 11 and a cone The cylindrical section 11 is a cylindrical open barrel structure, and the conical section 12 is a notch 120 formed by cutting the top of the cone through the wire cutting process to form a flat opening, that is, the conical section 12 is a boss structure, and the column The shape section 11 and the tapered section 12 are preferably integrally formed to form the first cavity 1. The first cavity 1 is a cavity structure with both ends open, that is, the opening on the cylindrical section 11 and the tapered section The notches 120 of 12 are respectively located at both ends of the first cavity 1 , the opening on the cylindrical section 11 serves as the entrance of incident rays, and the notch 120 serves as the co...

Embodiment 2

[0041] Such as Figure 2-3 As shown, this embodiment 2 is formed on the basis of embodiment 1, mainly through the structural coordination and optimization of the second cone and the first cavity, the number of reflections of the blackbody cavity is increased, and the absorption of the blackbody cavity is improved. rate, specifically:

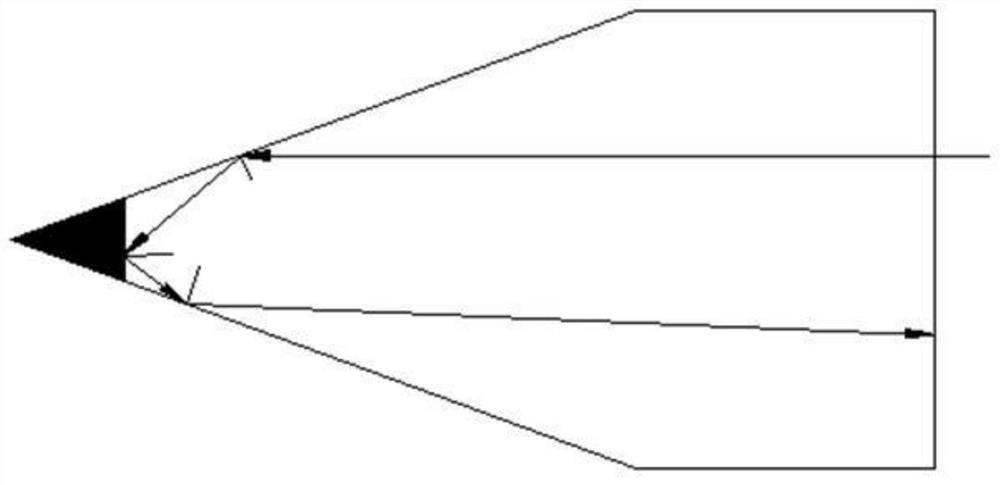

[0042] The taper angle of the tapered section 12 of the first cavity 1 is 35 °~37 °, preferably, the taper angle of its tapered section 12 is selected as 36 °, meanwhile, the taper angle of the second cone 2 is the same as that of the tapered section 12 have the same taper angle, that is, the taper angle of the tapered segment 12 is the same as the taper angle of the second cone 2 . The conical section 12 in the first cavity 1 and the cone angle of the second cone 2 can be found to have the effect of increasing the number of reflections through the Monte Carlo ray tracing method. figure 2 It can be seen intuitively that the number of reflecti...

Embodiment 3

[0047] Such as Figure 2-3 As shown, this embodiment 3 is a method for manufacturing a high-precision black body cavity formed on the basis of embodiment 1 or embodiment 2, including the following steps,

[0048] S1: Fabricate the first cavity 1 by mechanical processing, and obtain an open cavity structure including two parts: a cylindrical section 11 and a conical section 12;

[0049] S2: Cutting off the apex of the conical section 12 to form a notch 120 by wire cutting process, and processing the connection structure at the notch 120;

[0050] S3, using mechanical processing technology to manufacture the second cone 2 with the same cone angle as the cone section 12, and processing the connection structure at the tail of the second cone 2;

[0051] S4: Grinding the inner surface of the first cavity 1 produced in step S2, and spraying an infrared high-emission coating 3;

[0052] S5: Grinding the outer surface of the second cone 2 produced in step S3, and spraying an infrare...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com