Golf club shaft and golf club

a golf club and shaft technology, applied in the field of golf club shafts, can solve the problems of deformation of the shaft, less power for players to swing golf clubs with such shafts, etc., and achieve the effect of low elastic modulus, easy deformation, and easy deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034]Hereinbelow, an embodiment of a golf club shaft and a golf club according to the present invention will be described.

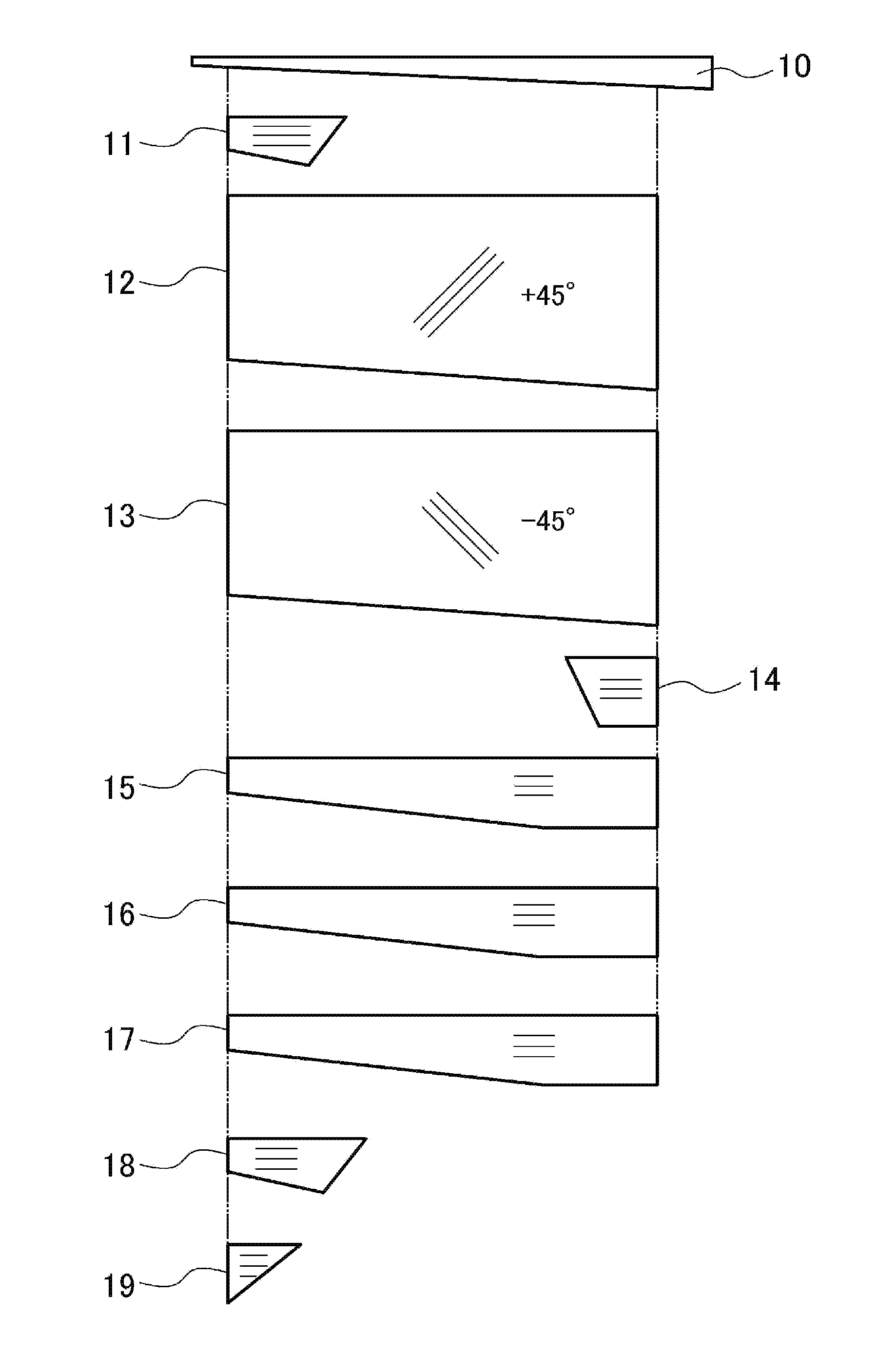

[0035]FIG. 1 is a development illustrating various types of prepregs for manufacturing an embodiment of the golf club shaft according to the present invention. In this manufacturing method, a mandrel 10 and prepregs 11 to 19 are used. The axial line of the mandrel 10 is a straight line. The shape of the cross section perpendicular to the shaft axial center line of the mandrel 10 is circular. The mandrel 10 includes a taper such that the tip side (head side) is narrow and the butt side (grip side) is thick. However, the mandrel 10 may include a portion having a regular diameter, which has a partially constant diameter.

[0036]Preferably, after applying a mold release agent on a surface of the mandrel 10, sheet-like prepregs 11 to 19 are serially wound.

[0037]The prepregs 11 to 19 include carbon fibers and a matrix resin. The carbon fiber for the prepreg 11 is a pitc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com