Electrospray atomization electrode, nozzle, apparatus, methods and applications

a technology of atomization electrodes and nozzles, applied in the field of electrochemical atomization electrodes, nozzles, apparatus and methods, can solve the problems of general limited silicon wafer availability, and achieve the effects of low cost, simple and rapid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

1. GENERAL CONSIDERATIONS

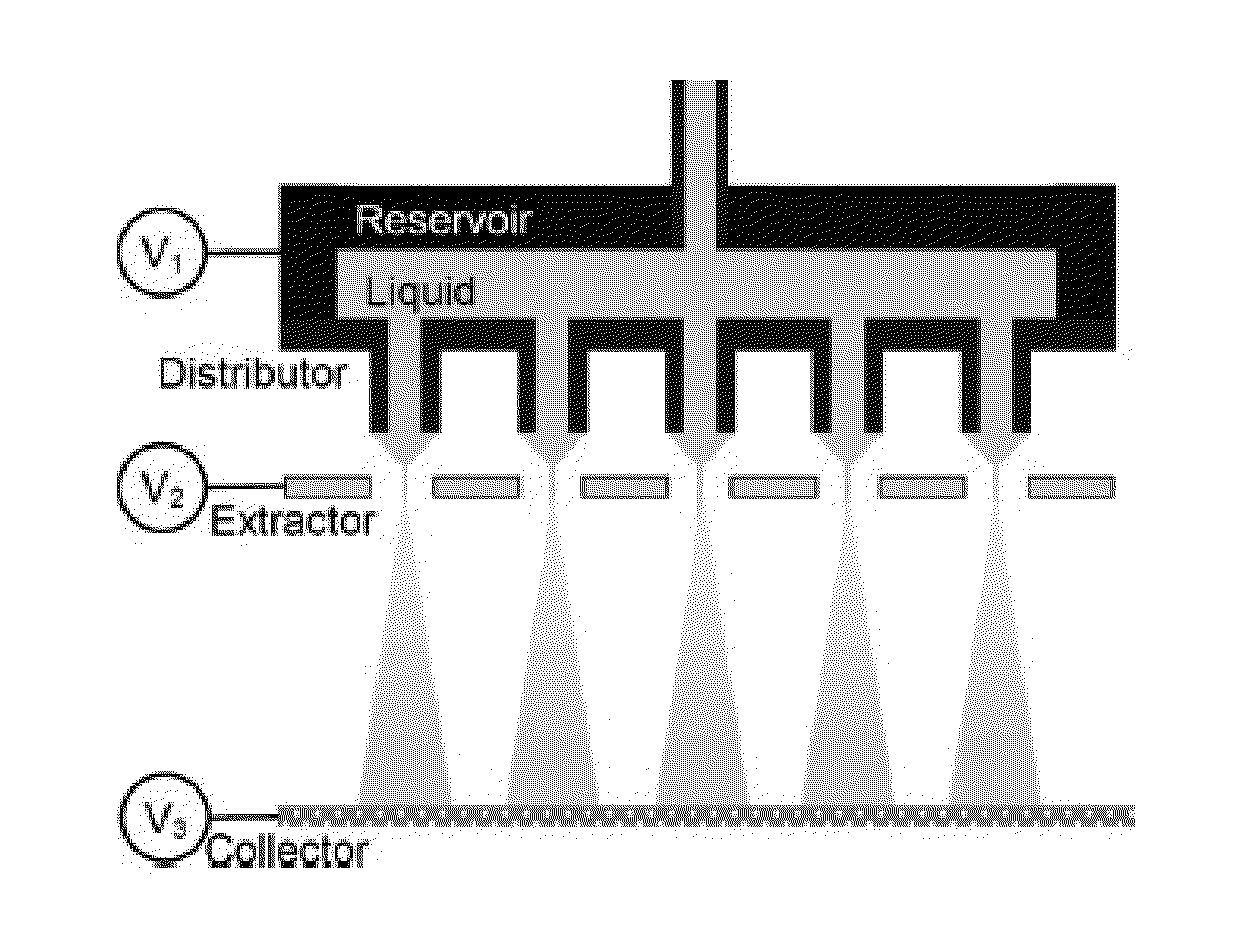

[0027]Embodiments provide a multiplexed electrospray nozzle for use within a multiplexed electrospray apparatus where the multiplexed electrospray nozzle may include a stepped slotted extractor electrode with respect to a plurality of distributor electrode emitter sources. Use of such a stepped slotted extractor electrode with respect to the plurality of distributor electrode emitter sources provides the multiplexed electrospray nozzle and the multiplexed electrospray apparatus with enhanced performance, and in particular increased resistance to clogging of the stepped slotted extractor electrode. The stepped aspects of the stepped slotted extractor electrode (which is thinner nearer and surrounding the slot and thicker further from the slot) allow for optimization of electric field (due to thinness nearer and surrounding the slot) within the context of mechanical stability (due to thickness further from the slot).

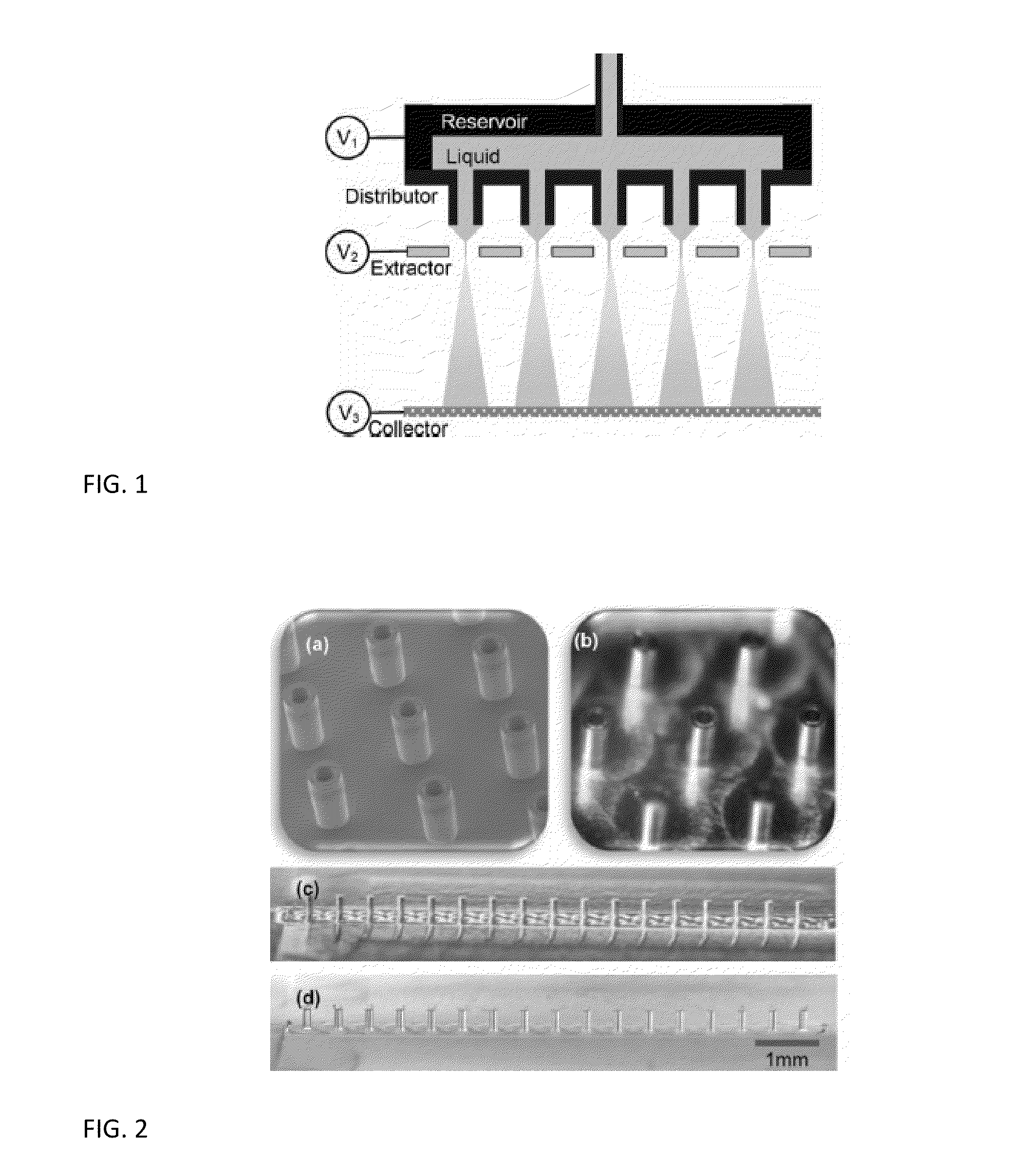

[0028]For example, FIG. 8A shows an image of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com